In the next issue, I will continue discussing common in-flight failures. This month, I want to share a personal experience. I’ve previously mentioned how things can slowly degrade with regards to aircraft performance until something fails, sometimes going completely unnoticed by the owner. In this case it was my own RV-10.

During the month of July, we completed trips to Alaska and AirVenture, along with some out-of-state prebuy inspections and DAR activities that amounted to almost 80 hours of flying time. That’s a lot of flying condensed into a short time span, and except for most of the Alaska trip, the time was spent in cruise with the autopilot engaged.

During these boring periods, I spend some time thinking about “what if” scenarios. Truth be told, my mind spent a lot of time on the “what-if” scenarios during a good part of the Alaska trip, as we are in the food chain if we go down, and we are not at the top of the food chain.

During these past 80 hours, I noticed what I thought was lower airspeed than normal. During climb-out I thought the deck angle appeared lower than normal for the same airspeed I was used to seeing. During cruise, it appeared to be about 10 or more knots slower. On final approach, I thought the visual cues looked like a higher groundspeed than I was used to seeing. Of course, probably not unlike anyone else, I managed to convince myself that there were mitigating factors involved and everything was perfectly normal.

About 90% of the time, I fly the RV-10 by myself, and it is certainly a sporty machine at those light weights. We were definitely heavier on these trips, with two people on board and packed full of luggage and two weeks’ worth of survival gear. Plus, it was hot outside, so the density altitude was much higher. That could certainly explain the different visual cues on final and the lower overall performance of the aircraft.

I found myself continually checking the power settings, and I even started to wonder if the 1200-hour engine was getting tired. The power settings showed the steady fuel flow, temps and pressures that I was used to seeing. I had done a lot of preventive and preemptive maintenance on the engine prior to leaving for Alaska, so I couldn’t help but wonder if I had done something to cause this.

By the time we were on our last leg flying home from AirVenture, I decided that everything with regards to the engine was normal and it was an indication problem. I came to that conclusion by carefully paying attention to the winds and groundspeed displays. They did not seem right to me, and knowing the winds are just a computation of the interaction between airspeed, heading and groundspeed, I just needed to figure out which one was the problem.

Flying in parts of the Midwest makes it very easy to check your heading indicator along the section lines that run east/west. The heading indicator was dead on. That left airspeed, and since the headings of both ADAHRS for the Advanced Flight Systems EFIS agreed with each other and the Garmin G5, I decided it was an airspeed indication error, and I surmised the only thing it could be was a pitot leak. I couldn’t wait to get home and check it.

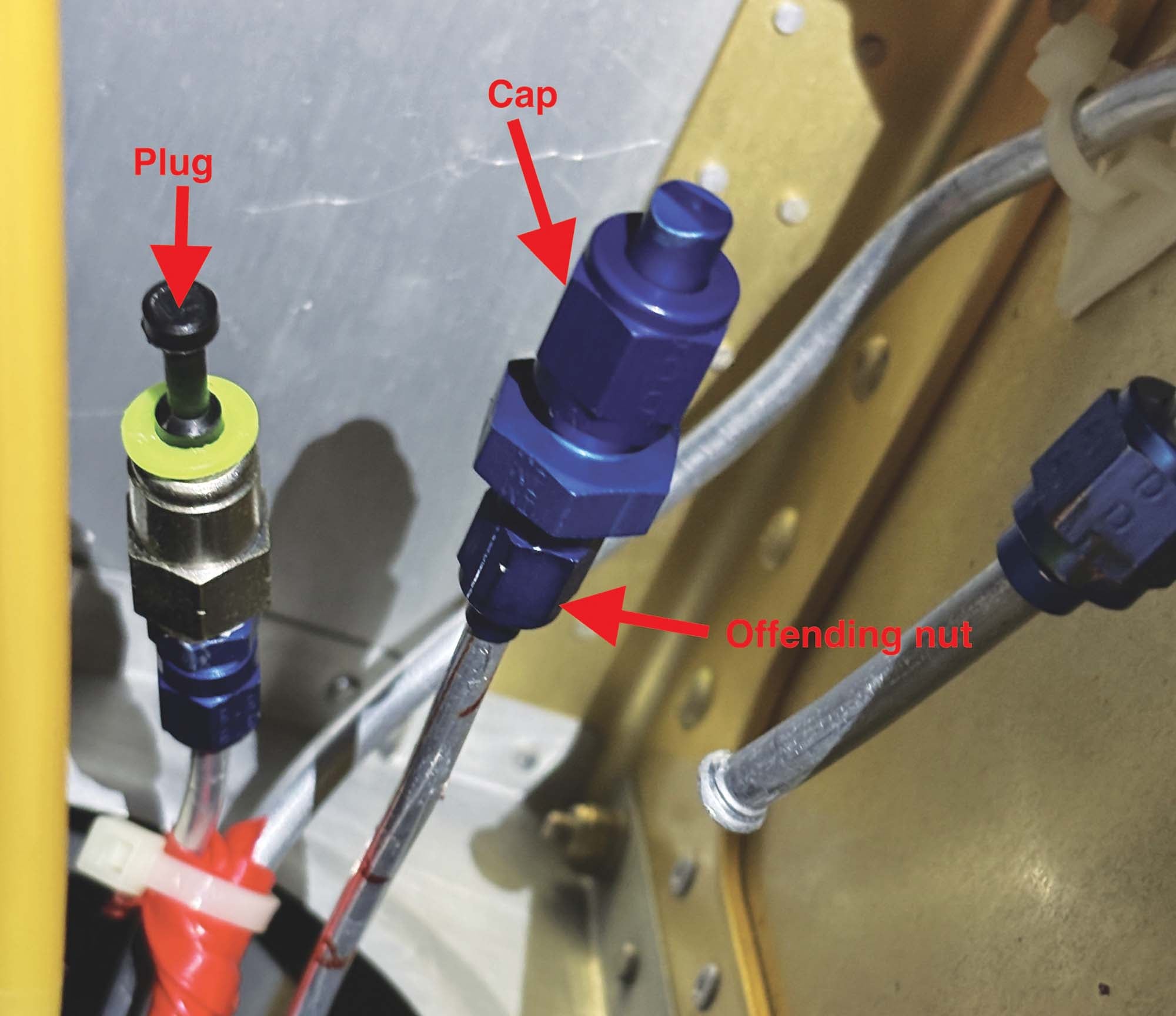

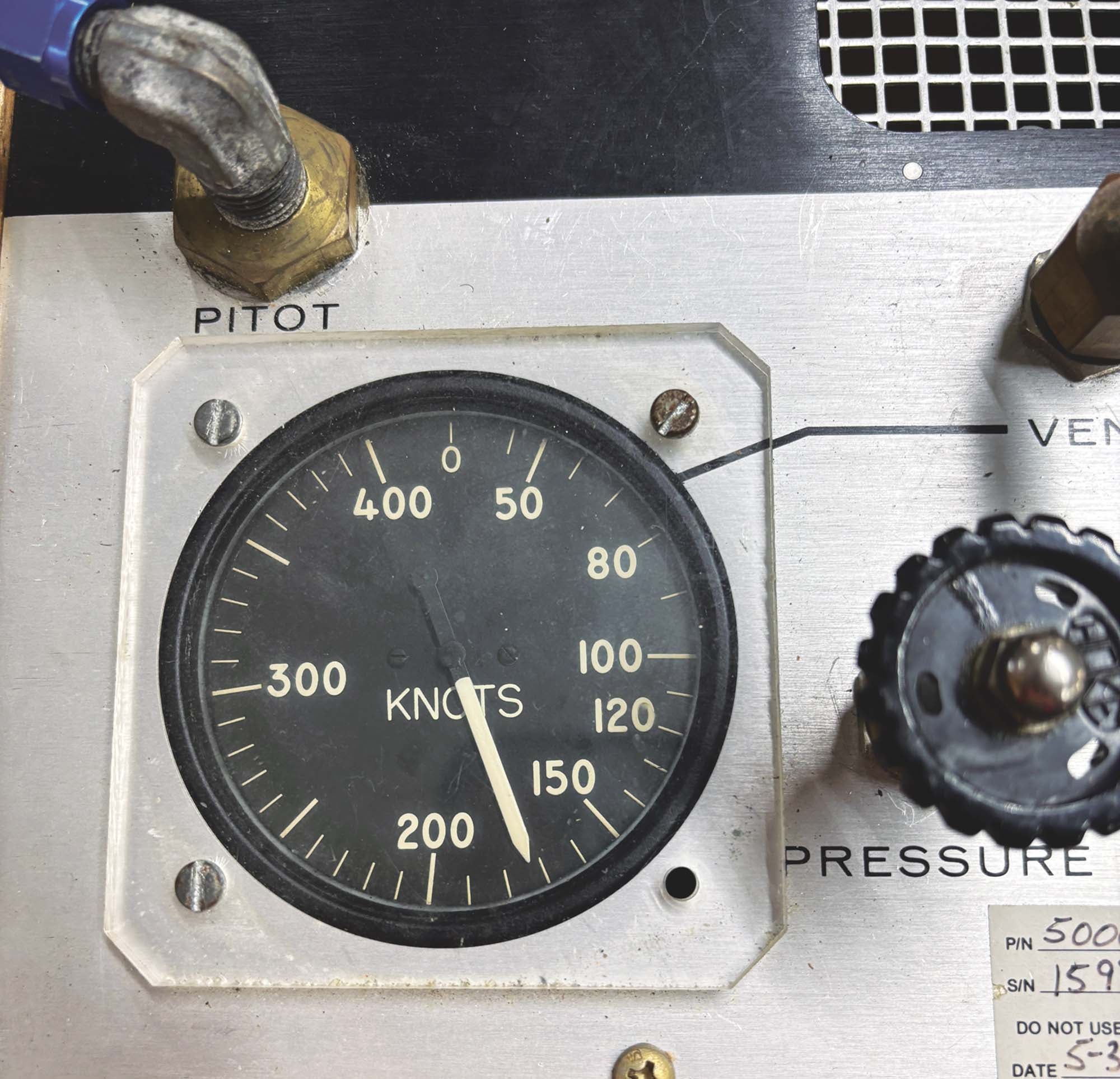

Sure enough, when I attached the pitot-static tester to the pitot tube and pressurized the pitot system, it showed a massive leak that was not there earlier in the year when we did the pitot-static leak check. Since I built the aircraft, I know where all the connection points are located, and the easiest thing to do is to split the system in half, as the system is split at the wing root allowing both pitot and static sources to go to both the front and rear of the aircraft. Unfortunately, both the front and rear of the aircraft still showed a massive leak, even when I capped off the tubing prior to it being teed to multiple instruments and the dual ADAHRS.

Finally, I remembered there were unions at the pitot tube itself, and upon removing the underwing inspection panel, I disconnected the tubing there and capped off the unions. It still leaked! Hmm.

About the time I was thinking I might have a bad pitot tube (I’ve only ever seen one other bad one), I put a wrench to the 3/16-inch fitting on the back side of the union. It turned a little, and I thought that couldn’t possibly be the problem. But upon repressurising that little section, the leak was now gone. Now it was time to reconnect everything back up and run the test again. Voilà, it worked! No leaks. The airspeed indication held steady for a good 5 minutes.

Unfortunately, the weather is horrible today, so I can’t flight test it, but I have the highest confidence that I am going to see higher airspeeds again. Not that I will get there any faster, as that is all about groundspeed. This was just an indication problem.

As a side note, I was careful to not crack open the static system, as that would require another certification check.

So, the lesson learned is if you start to see your airplane performance begin to degrade, check the pitot system. On the flip side, if you start to see performance increase, you probably need to check the static system, as a leak there will cause higher indicated airspeed readings.

Is there a way to check the pitot system without a pitot-static tester like the one in the article? Is it ok the pressurize just the line (no airspeed indicator attached) to a certain psi and use the soapy water method to check for leaks at connections? Thank you.