I am hoping to catch some readers who are just now narrowing down their final choice for a first-time aircraft kit purchase. This is a big decision that will become a major focus of time and money for months to come. You have probably been doing lots of research to select the best kit that fits your needs. If you feel a little apprehensive, that is a good sign that you are taking this venture seriously! Having once been in this situation myself, let me shed some light on some critical issues that you might not have considered. I don’t want you to fall into an uncomfortable trap that might not be obvious at this stage of your building journey.

A common problem occurs when a kit builder finds they have encountered a construction task that is either confusing or appears too challenging to complete. Or worse, there is doubt as to whether the task was completed correctly and safely. The great news here is that popular kit manufacturers have nearly eliminated this issue over time with better documentation, tech support and building techniques geared toward first-time builders. We all have different talents and abilities when it comes to building. Most kit vendors have designed their products to ensure success for most first-time builders.

What Can Go Wrong?

It is easy to overlook that the kit manufacturer you have chosen does not make the engine you need to install. But because an engine is required for flying, they can steer you toward those engines that might be a good fit for your airframe—those having proper weight, power, etc. They might even sell you the engine for a one-stop shopping experience. You may get an economic advantage with this type of purchase, and at least you’ll know you are buying a recommended powerplant for your kit. Nevertheless, there are some things to be aware of.

That great documentation you used while building the airframe probably does not exist for engine installation tasks (also called firewall forward installation). Ask your kit manufacturer and find out if this is true. I cannot think of a more challenging effort than installing, plumbing, wiring and testing an aircraft engine. You need more and better documentation and tech support rather than less. Sadly, it rarely exists. This is a big bump in the road for many first-time builders.

What Tasks Are Involved?

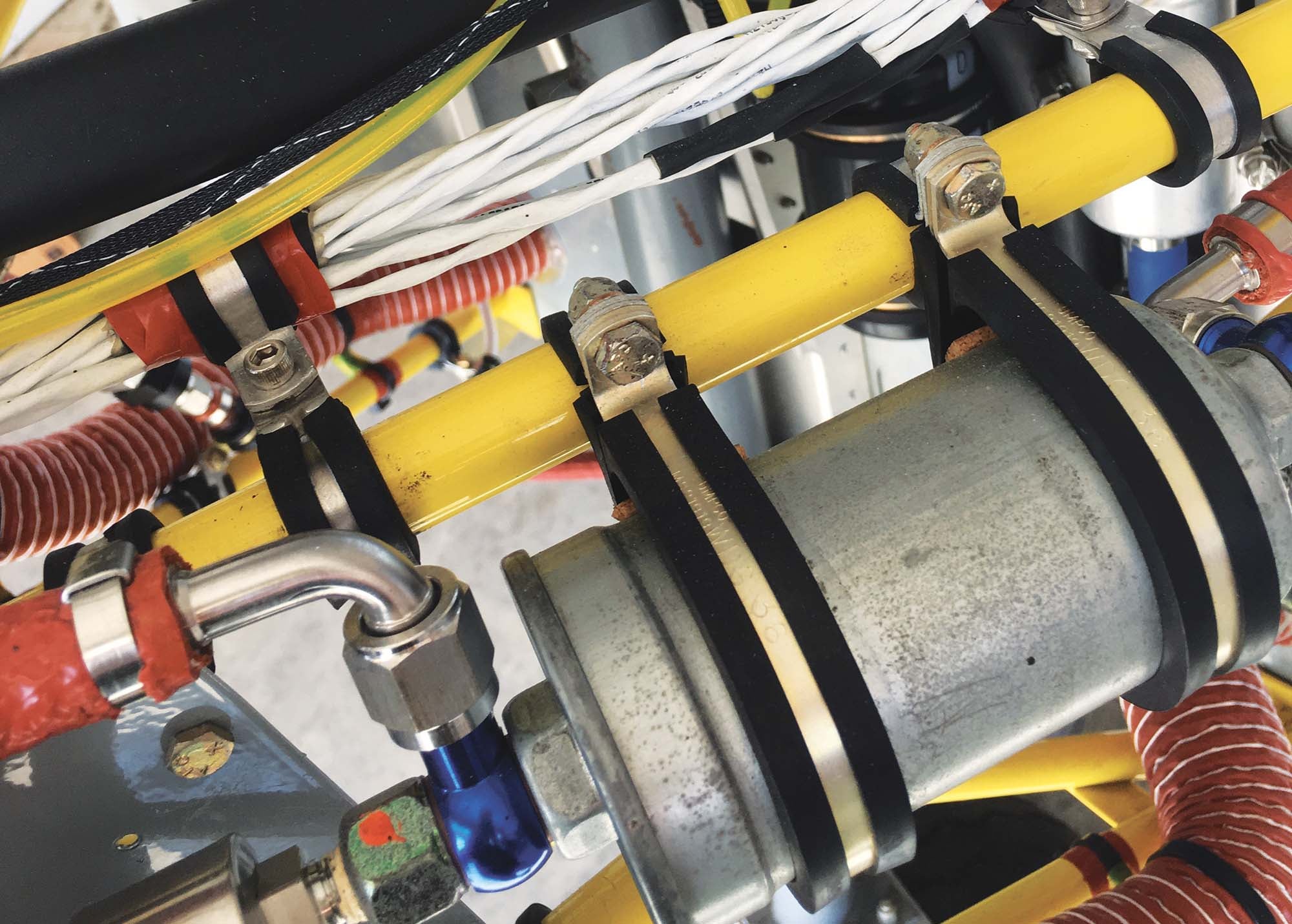

Engine installation is one of the most complex and fascinating areas of the entire project. Once the large, metal block of an engine is physically mounted, you move on to attaching fuel lines, pumps, hoses, throttle cables, air ducts, ignition cables, batteries—the list goes on and on. If you are not familiar with the skills required for this step (and who is the very first time around?), then daunting is a good word to describe the entire task of engine installation.

Why does it have to be this way? The companies that make the airframe kits don’t usually know what engine you will install—and the engine manufacturers don’t know what airframe is being used. This arena becomes even more challenging when you consider that an engine mount is a custom item that needs to match a specific airframe to a specific engine. Who should design and create instructions for the first-time kit builder on how to install these?

If this is not your first airplane kit, then a lot of these issues are less challenging. But for the first-time builder it can easily be a showstopper when it comes to finishing the aircraft. Even if a company packages and sells all the parts needed for an engine installation, I’ll bet the step-by-step, easy-to-follow instructions on how to assemble it all won’t be included!

My advice to any first-time builder researching aircraft kits is to always find out what instructional help will be available when it comes time to install the engine. Even if the engine choice is not made at the time of airframe building, that issue does not go away.

What Are Your Options?

At the top of the list of kits that simplify engine installation is Van’s RV-12/RV-12iS. Step-by-step instructions detail every nut, bolt, wire and hose used in the airframe kit as well as firewall forward. This kit all but guarantees that the first-time builder will succeed! I am not aware of another kit model sold today that can match its all-encompassing documentation.

While this might look like the perfect first-time builder kit, remember that all things in life are a compromise. Examine this kit’s price tag, single engine choice and low-wing design. If these are not an issue, then you have a great option for a kit choice.

Next on the list of aircraft vendors that do a reasonable job of supporting firewall forward installation are those that strongly recommend a specific engine model. As an example, Sonex Aircraft has traditionally urged builders to use the engine they supply (the AeroVee) in their Sonex aircraft kit. If you go this route, you receive good instructions on how to not only assemble that engine (the engine is a kit!) but also very specific instructions for installation. Again, the drawback is that you are limited to using just this engine if you want this very high degree of firewall forward instructions.

The next and largest category of kit manufacturers is those that recommend a limited choice of engines that they will “support” in their airframe kit. What this usually means is that the kit manufacturer has assembled and sells a package of firewall forward components that are needed for a specific engine. With this package you have everything you need to complete your engine installation—and hopefully the package includes some documentation. Ask to preview this documentation before you buy. Is there enough detail for you to complete the installation? I can almost guarantee it will not be in the form of step-by-step details like the airframe instructions may have been. Hopefully, the kit manufacturer will provide support if you need it. By using their engine components, they should be able to help you if you get stuck.

Compare this to purchasing an engine model that has no prepackaged firewall forward components, even if the airframe kit vendor agrees it can work. You are then on your own to find the right parts. This is a common path toward failure for many first-time builders.

Another category of engine installation support comes from custom engine manufacturers that have tried to make it easy for you to install their powerplants. This effort includes firewall forward component packages, documentation the engine manufacturer produces and videos showing typical installations. In some cases, a great engine may not be that great if you struggle to get it installed correctly or don’t understand how to wire and plumb it.

Ask to preview the documentation so you will know in advance what you are getting into. Do not rely solely on promises from the vendor as to how easy it is to get it installed. Also do a bit of research, online and by talking to other builders, to be sure you will get the support you need.

Be nice to yourself by making it easy to succeed as a first-time builder. Choose your engine wisely. Plane and Simple!

I found the firewall forward part easy. Hopefully the kit maker can provide some engine baffles. Those would be a pain to have to make from paper templates. The rest is pretty straight forward. That is for those of us who grew up around and working on planes. For those not so fortunate, taking pictures of similar planes with the cowling off is a good guide. Lots of pictures.