In 1850, British physicist Joseph Swan began experimenting with paper coated with carbon in a glass tube that was partially evacuated from air. His paper glowed rather dimly, and the poor vacuum pumps of the day let enough oxygen into the glass tube to set the paper on fire when the electrified carbon got hot enough to give out a dull red glow.

Returning to the problem nearly 30 years later, after vacuum pumps had much improved, he began coating linen thread with carbon and achieved the first practical light bulb. It had enough of a life and gave off enough light to be commercially viable, and he was granted a British patent in 1879.

In a parallel effort, Edison began working on his light bulb using bamboo instead of thread but with the same carbon element, and he was awarded an identical USA patent in the same year, 1879.

Fast forward to 1901 when a fellow by the name of Hewitt put a drop of mercury into a glass tube, pulled a vacuum on the tube, and made an arc light out of the mercury vapor (very much like the mercury vapor lamps used today in large parking lots). But the light was greenish-blue and really didn’t have much practical use until 30 years later when engineers at GE coated a tube with a phosphor that had all three light colors—red, green, and blue—and very much simulated daylight. Then the catfight between GE, Sylvania, et al. ensued as to who really invented the fluorescent light. However, that all sorted itself out, and a few years later, the fluorescent tube became a popular way of lighting stores and workshops.

As I said in the May 2019 issue, General Electric tossed a little aluminum into a gallium arsenide diode in 1962 and got a brilliant red light, and the Light Emitting Diode (LED) chase was on.

Would you please now fast forward to where your chair is sitting. Let’s think about what is right and what is wrong with fluorescent tubes when used as shop or hangar lights. On the right side, they are relatively inexpensive ($25 or so with bulbs at your local handyman store for a 4-foot fixture), they last a reasonably long time, they come in three shades of white (cool, warm, sunlight), and they are fairly simple to install.

What is wrong with fluorescent lighting? You get 360-degree light no matter whether you want it or not. If you want floor light, you also get wall light. If you want floor and wall light, you also get ceiling light, and if the “white” of the fixture isn’t matched to the “white” of the light, that light does not get reflected. Fluorescent lighting is also relatively inefficient (25% of the power is converted into light; 75% is wasted in the ballast and in converting mercury vapor into visible light), the ballast is rather life-limited, the burned-out tubes are a hazardous waste because they all contain mercury, and they require 110 VAC power to operate. Worse, if a stray rivet or scrap of metal squirts loose and hits them, you have hazmat all over your floor.

Yes, I know you can now buy LED replacement lights for fluorescent tubes, but they still give you 360-degree light and require 110 VAC to operate. And, as of right now, they are somewhat expensive.

LED strips, on the other hand, can be made conformal into most any shape you want. You want light strictly on the bench and not on the ceiling? No problem. You want light on the wall shelves and not on the floor or the ceiling? No problem. You want cool white, warm white, yellow, green, red, blue and most any color of the rainbow (plus IR and UV)? No problem.

And for those of us poor souls that have to drag out the portable generator to light up the shop or the hangar, the little rascals run on +12 volts DC, just like our airplane batteries. Now solar lighting is starting to make sense.

Best of all, current LEDs are approximately double the efficiency of fluorescents in converting energy to visible light and have a lifetime approaching 50,000 hours (that’s 8 hours a day, 365 days a year for a bit more than 17 years). Another plus is that it costs about $10 to build replacements for the $25 fluorescent fixtures, and they’re a lot easier to paint to match the surroundings. They also don’t break and hazmat up your floor.

Given all these advantages, I thought you might be interested in some work I’ve done testing whether or not all those claims are true. Strangely enough, I found most of them to be true.

To test my theory, I bought two 5-meter (16 feet, 5 inches) strings of cool white LED strip lights from Amazon. Since I was going to test the light by replacing a current fluorescent fixture, I got a couple of 12-volt, 2-amp “wall wart” power supplies and mating connectors from Jameco, as the specifications for the lights said that they would require a quarter-amp per foot, and I was going to be running two 2-foot strips per 4-foot length of fixture.

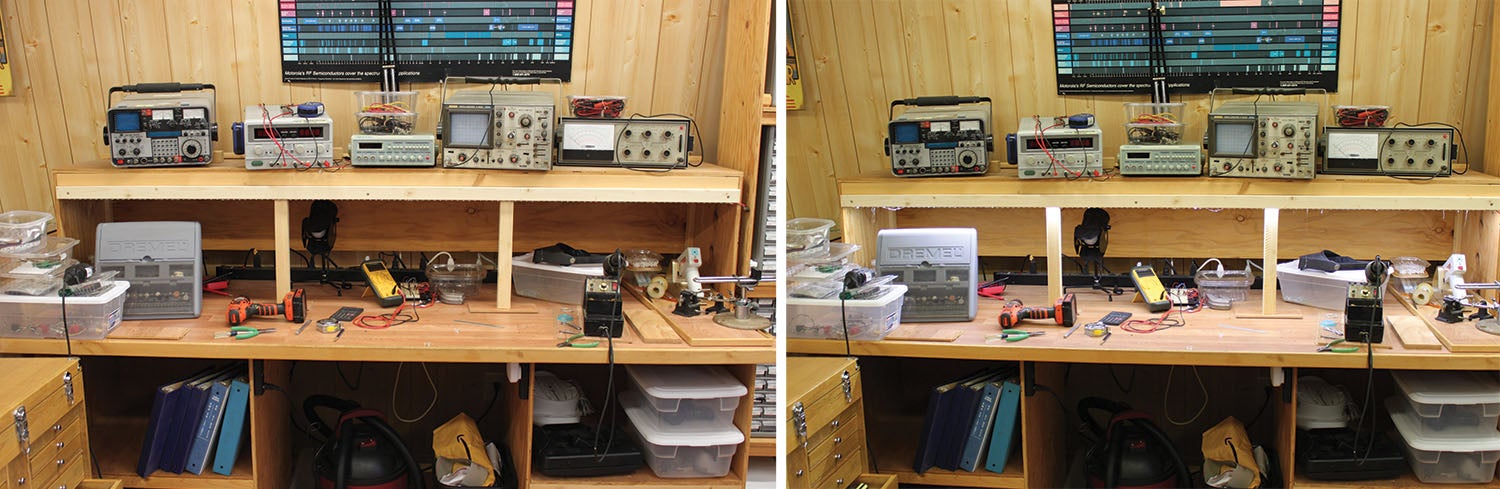

I considered pretty carefully what sort of “fixture” to use and decided that good old PVC water pipe of 1½-inch size would do the trick. I knew that I needed to light up the parts cabinets and the shipping bench on the sides, but the floor and the ceiling did not need light. Being able to position the strips exactly where I needed light was important, and the round pipe gave me the option of putting the LED tape exactly where I wanted it.

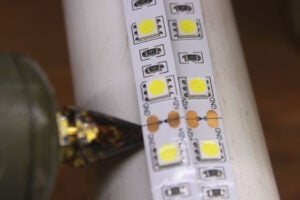

After my success in lighting the parts cabinets and shipping bench, I had a spare roll of strip lights and decided that the back part of my bench was very poorly lit and that it might just be necessary to light it up. This is where the versatility of strip lighting connections comes into play. Strip lights can be cut at 2-inch intervals, and the remaining part of the strip is usable because copper pads are placed every 2 inches. Cut in half, they are very solderable. The workbench now has very adequate lighting.

(Photo: Victor Korniyenko [CC BY-SA 3.0,https://creativecommons.org/licenses/by-sa/3.0])

Now let’s turn our attention to a power source for these strips. Certainly the little wall warts I used are available, but for a whole shop/hangar you might want to consider the little enclosed regulated supplies.

Something else to consider are these little laptop computer power supplies that are a dime a dozen on the used “surplus” market. You might also want to consider finding a 12-volt junked desktop computer supply and modifying it like this:

These strip lights have a glue backing, but the glue is horrible—no stick whatsoever to either PVC or wood. Get out the hot glue gun and glue them down every couple of inches.

That’s about it for the wonderful world of strip lights, but I’ll make you a deal. I’ve got a used Concorde aircraft battery that has been doubling as a doorstop in the lab for a couple of years, and I’ve always wanted no-generator lights in the hangar. In a month or so I’ll come up with a way of charging that battery using a small solar charger and rewiring the hangar to use battery power for lighting. Until then… Stay tuned…