Van’s Aircraft at 50 is a remarkable company with an incredible history and a full product line—of low-wing aircraft. Whether you want a single-seater that is a nimble high performer or you want to carry four adults at 170 knots for 800 miles, you can find the airplane of your dreams from Van’s—as long as it is a low-wing machine. Basic math says that Van’s has come out with a new model every 3.57 years (50 years, 14 models if you count tricycle-gear variations separately), and it has been a few since something entirely new has come out of Aurora.

Speculation was heavy as AirVenture approached last year—after a hiatus of two years—so it was with great celebration that Van’s announced that, yes indeed, there would be an RV-15! And there was significant discussion when they added “…and it will be a high-wing, backcountry-capable aircraft with sticks.” And that was all the detail they would offer at AirVenture and, amazingly, little more has leaked out since then. Sure, there were online memes and forum speculation, including a few snapshots of Maules and things with “RV-15” badly Photoshopped on the tail, but the actual airplane kept a very low profile through much of 2022.

Now we have the real thing. Sort of. (We’ll explain.) We have been gifted early access to the RV-15 in the weeks before its AirVenture debut, including long debriefs with the engineering staff, many offside discussions about the airplane and where it might fit in the Experimental world and many other things besides. What you see on these pages is, indeed, the RV-15. The real deal. But we can’t see into the future. As this is written, the RV-15 has completed its early flights without incident and was on track to clear hurdles to be flown to AirVenture. But this issue goes to the press before they leave for the show and, as they say in flight test, anything can happen.

Another open question: Is the RV-15 on these pages the airplane whose kit you may be able to buy sometime soon? That’s a very good question, one we can’t answer now and that Van’s may not be able to answer for some time. That’s because the RV-15 is somewhere between a test article and a prototype. (Confused? See “What’s a Test Article?” below.) This may be a distinction without importance if what Van’s eventually sells is a lot like the RV-15 you see here. Then it can be considered a prototype and the basis for the production engineering that has to go on before kits are sold. But it could also require substantial changes, making this a test article and the modified airplane something more like a prototype we’re familiar with.

Bottom line, then: What will be kitted may be much like the test vehicle, it might have some minor changes that don’t really change its performance or mission profiles or it might have such significant differences that this view of the RV-15 is akin to seeing a child’s drawing of one as opposed to sneaking a peek at the CAD drawings. It’s been reinforced in our meetings with Van’s that many aspects of the design remain to be proven. Assume things will change. How long will it take? They won’t know until flight testing is much further along.

The Metal We Have

Now, back to the RV-15 itself. It is indeed a high-wing, two-seat backcountry airplane with a large cargo allowance that can be lifted by its IO-390 engine. It is a hefty airplane—not six-seat hefty, but easily the size and weight of a Cessna 170, which is large by homebuilt standards. Compared to other two-seat high-wings on the market, it is different—so how did Van’s come to this configuration? Well they didn’t just pull it out of the employee suggestion box. Van’s has been asking their customers for several years now what they would like in the next model, and they have been listening—as hard as that can be when you ask a large group of pilots what they want. The noise in the virtual room has been tremendous, with lots of great ideas tossed about.

Rian Johnson, president and chief technology officer, understands that you have to pull all of the information together and look for consensus—you can’t give everyone what they want because many ideas are diametrically opposed. When we have looked at the market ourselves, looking for a niche that hasn’t been filled, we have come to the conclusion that Van’s has hit an open spot with the RV-15—it’s larger than LSA-capable machines, smaller than a Moose—and right where the burgeoning backcountry market is looking to expand. It’s a load hauler that can get you from the flats to the mountains in reasonable time, with enough camping gear to keep you there in style. The market spoke, Van’s listened, and they gave the most they could to the largest number of potential builders.

Aircraft designs are sized by first picking a powerplant. If you are looking at an airplane initially designed for a Rotax, it is going to be LSA-capable (in most cases). If you are planning on bolting up a Lycoming 360 or larger—you’re talking about something bigger. If you want to go fast enough to make a trip from the center of the U.S. to the backcountry of the West practical, then you need horsepower to make that happen (as well as good aerodynamics).

Van’s sense of the market was that there were plenty of capable LSA-sized backcountry airplanes already out there and, on top of that, the Cub-a-likes are all growing in gross weight and horsepower. So they figured it was time to shoot for the larger end of the spectrum right off the bat. If you want to carry two full-sized adults and their camping gear—and maybe bring back a deer or an elk—this is the size airplane you end up with. And a very useful size it is.

What We Know So Far

The RV-15, as promised, will debut as a taildragger—albeit with a new kind of gear arrangement for Van’s—and eventually be developed into a trike as well. It’s not expected that the two will be “reconfigurable” as the CubCrafters NX Cub or Glasair Aviation Sportsman are. The test article/prototype RV-15 is powered by a Lycoming IO-390 driving an 80-inch Hartzell Trailblazer two-blade, constant-speed prop. Van’s plans to make the parallel-valve O-360 engines an option down the road, but it’s starting off with the heavier/more powerful engine for now.

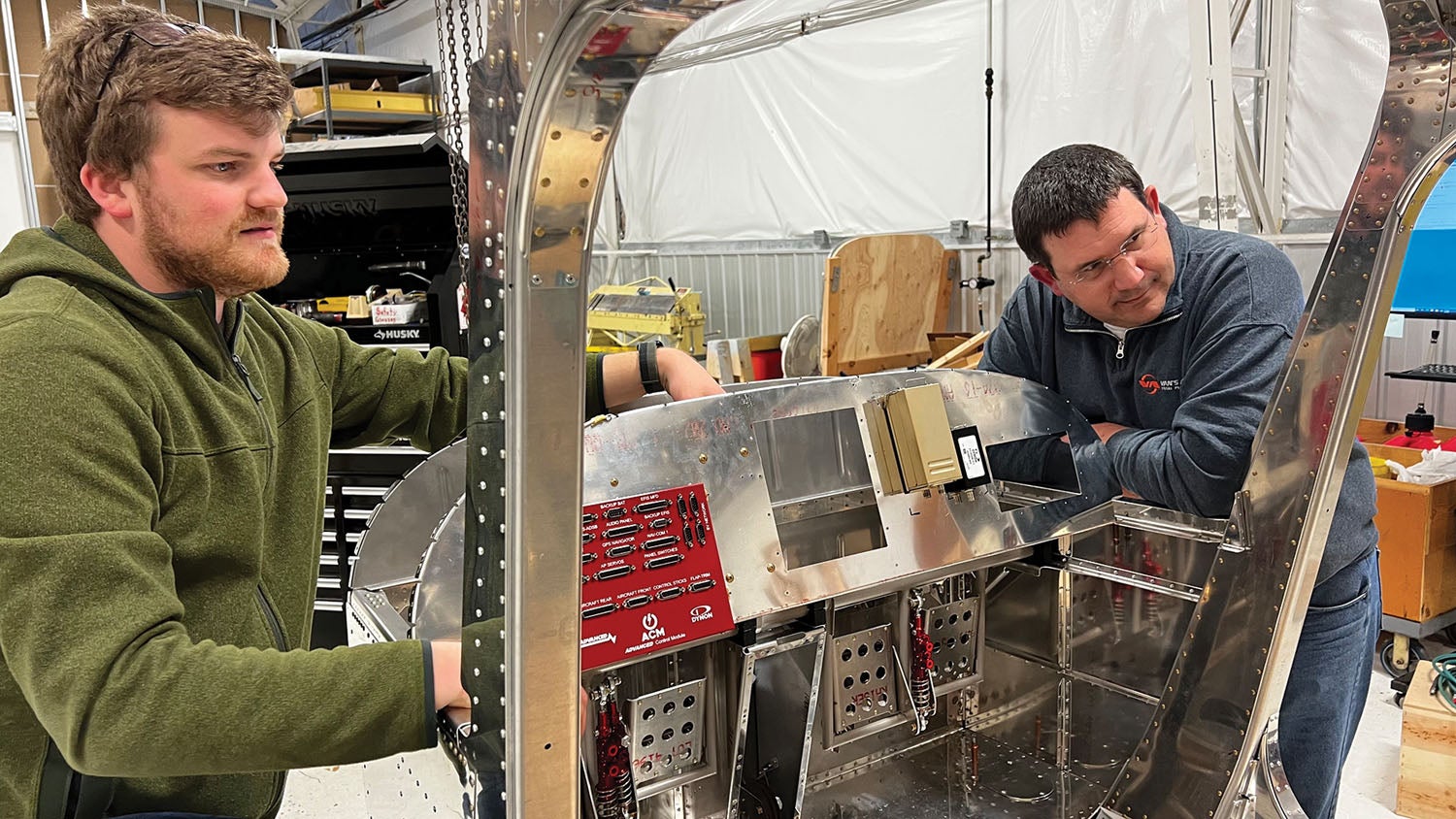

We can tell you that the engineering behind the RV-15 is extensive and first-rate, and benefits from a top-notch team. Besides longtime Van’s engineer (and current president) Rian Johnson, there’s Rob Heap, formerly with Scaled Composites and Cessna. Brian Hickman recently engineered for Glasair Aviation. Another recent addition is Axel Alvarez, a graduate of the U.S. Navy Test Pilot School (as a civilian) and highly experienced test pilot and engineer. These professionals join many Van’s stalwarts to help make up an impressive 12-person engineering and prototype-shop team—and Van himself is only a phone call away for a carefully expressed opinion.

Built using CAD-designed parts and match-hole technology, the prototype was put together with parts produced from punch presses and CNC machines directly from design drawings. This was not cut and pasted by hand, as past prototypes have been—theoretically, production parts for kits can be produced from the same files that made the test article. But a lot of testing will go into the machine before the first customer receives any kit parts and Van’s is happy with the design.

For now, the maximum gross weight is 2050 pounds. Again, this is the test article. Van’s hasn’t said if that’s the final weight goal or not, but our guess is that it isn’t. There’s a lot of wing on this airplane—easily 170 square feet or more—which would support higher gross weights while maintaining a low stall speed for good backcountry airfield performance. Then again, it’s not out of the realm of possibility that this is more wing than Van’s finds optimal. So much could change.

The Basic Airframe

The basic airframe is conventional for an aluminum machine. About the size of a Cessna 170, it features a strut-braced wing (there’s a single streamlined lift strut on each side) with large Fowler-style flaps that take up a significant portion of the trailing edge. There are no leading-edge slats (fixed or movable, nor does the leading edge seem drooped, like Cessna did for some of its later designs)—a design goal for simplicity. But the flaps extend to a whopping 50°.

The airfoil is, in Van’s tradition, constant chord but it’s not an RV-10 wing with different dimensions. In fact, it’s a custom airfoil co-designed by Steve Smith (who did the RV-10 wing) and Van’s. The goal was to find a compromise between high lift and forgiving stall characteristics. Constructed without built-in camber, the wing has a low pitching moment that Van’s says helps with tail authority.

Counteracting all this wing is a horizontal tail consisting of a stabilator. The current stabilator has a removable leading edge for easy replacement should it become dinged up in the backcountry—or if Van’s decides they want to try something else. A stabilator was chosen instead of a conventional horizontal stabilizer and elevator to provide a wide range of pitch control for the large flaps. An added bonus is that the stabilator will hopefully prove to be lighter, as it gives more power for less area, which means less weight. The test article’s stabilator uses two different tabs—one is the trim tab and the other is an anti-servo tab. Stabilators in other designs—think Piper Cherokee—move the anti-servo tab for pitch trim.

Overall, the control system is conventional in that cables connect from the pedals to the rudder and the control sticks activate the stabilator through a pushrod—these are concepts Van’s is well familiar with. For other Van’s models, roll control is also via pushrod, and one might wonder how that works with a high wing. (With a low wing, pushrod-activated ailerons are almost trivial from a design standpoint.)

Here’s where you might end up confused. The test airplane you see here—and might have crawled through at AirVenture—does not represent the likely final form. This airplane carries a series of pushrods and bellcranks to translate stick motion up through the aft door frame (the B pillar), with a short torque tube and then a long pushrod that’s actually just ahead of the aft spar. From there, a bellcrank and short pushrod connect to the aileron.

In early flight testing, this seemingly complicated system did result in good roll feedback but, we’re told, the balance and rates weren’t what Van’s wants. Plus, the aileron pushrod goes through the space where you’d want a fuel tank. So, the plan is to rework the aileron-control system to have pushrods going up the forward door post (the A pillar) and connect to a long pushrod in the leading-edge D section, then back to the ailerons. This change will displace the pushrod running in the D section that you can see on this airplane; it controls the flaps. The flaps, in turn, will likely change to cable operation, keeping the overhead manual flap handle. Phew. See what we meant by early test articles and the nature of changes?

The fuselage is all aluminum and has forward and rear wing spar carry-through structure as part of the cabin ceiling. There are large entry doors on each side of the cabin, with steel-tube-framed plexiglass doors covering the openings. The doors are hinged on their front edge but have quick-release pins on the two hinges so they can be removed in about 10 seconds to allow open-door flying. Although the doors may look bulged out, they actually follow the contour of the fuselage. The cabin feels and looks roomy. The engineering team is not certain that the doors will be rugged enough as-is, so they might be iterating on the design with a beefier armrest or other structure.

The baggage area is built large—large enough for a couple of small bicycles, a full set of camping gear, a couple of dogs—or maybe an elk, if hunting is your thing. There was no baggage door when we visited the factory in June, but the frame for a large baggage door was sitting on a worktable, ready to be installed when they have the time. How large? Big enough for a cooler—or for a medium-sized person to crawl through without extensive cave exploring training! And the design goal is to have the bottom edge of the door flush with the baggage area floor, so that you don’t have to lift items in and out—they can slide through the door easily.

Landing Gear

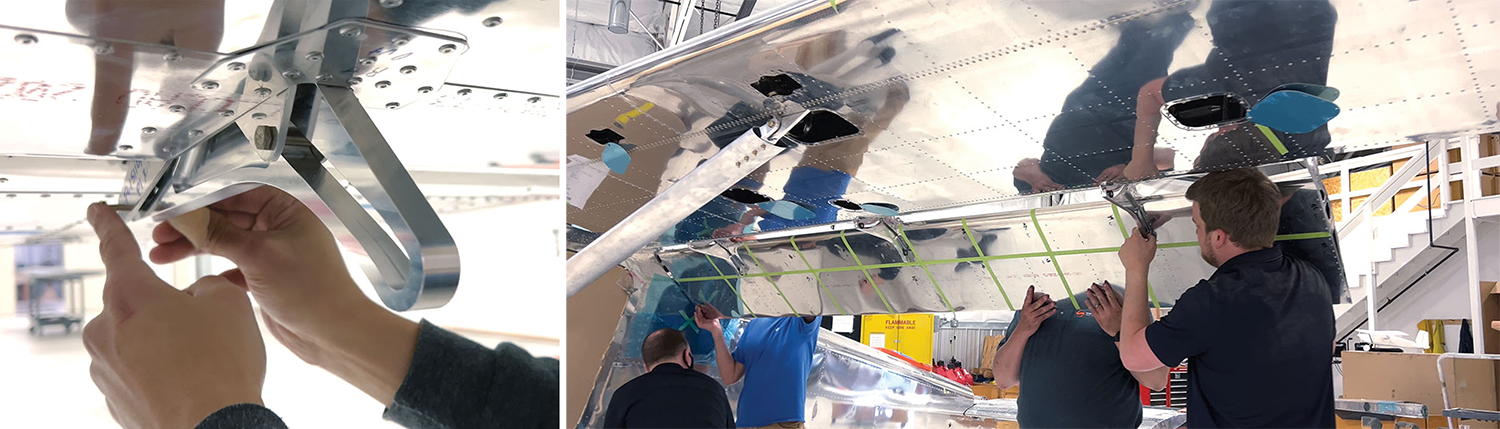

Let’s talk about the gear. Both the main gear and tailwheel are using TK 1 Shock Monster shocks for their action—a proven brand out of Lincoln, California, that is equipping a large number of bush aircraft. The main gear is unlike anything Van’s has designed before, with two separate aluminum legs hinged at the lower corners of the fuselage. Part of the leg extends upward, above the hinge point, and is connected to the large shock absorbers that are oriented across the fuselage laterally and are sandwiched between the belly skin and the floorboards.

The shock absorbers will provide both spring and damper functions so that landing loads are absorbed without the plane being rebounded back into the air. The tailwheel is similarly sprung, with a vertically oriented shock absorber connected to a custom-CNC-machined pivot block that is mounted to an arm hinged to a point on the fuselage about 10 inches in front of the shock. The result is a long-travel gear that should be able to take quite a pounding, plus the linkage allows the tailwheel pivot to have constant camber even with a significant amount of travel.

The shock absorbers will provide both spring and damper functions so that landing loads are absorbed without the plane being rebounded back into the air. The tailwheel is similarly sprung, with a vertically oriented shock absorber connected to a custom-CNC-machined pivot block that is mounted to an arm hinged to a point on the fuselage about 10 inches in front of the shock. The result is a long-travel gear that should be able to take quite a pounding, plus the linkage allows the tailwheel pivot to have constant camber even with a significant amount of travel.

Main gear is currently sporting 6.00×6 tires on Berringer wheels (and brakes). Current plans are to fly it on those, but they have a set of 26-inch bush wheels sitting in the shop for use on the plane—that is their default size for “bush wheels.” They have incorporated provisions for an easily installable jack point on the gear, inside of the axle, to make jacking easier.

The trike is likely to use an RV-10/14-style nose gear and a more common aluminum leaf gear with a less complex fuselage structure; the thinking is that the trike is less likely to be taken far into the backcountry and therefore doesn’t need the weight or complexity. I was told flat out that they would not try going head to head with the NX Cub.

The Cockpit

The roomy cockpit is designed with two seats, which are mounted on rails for easy adjustment as well as easy ingress and egress. The seats in the test article are actually from another (unnamed) airplane and are being used to “get it flying.” Cockpit controls feature a standard control stick that has been shaped with a large curve to avoid contacting the seat or the pilot’s legs. In fact, we were shown a couple of different sticks that will be tried, to see which the test pilots prefer. Rudder pedals likewise featured two different designs, one for the pilot, one for the copilot. Test pilots will use both and decide which gets the nod for incorporation into the kit. The pedals feature toe brakes, as is typical on Van’s aircraft. Engine controls are conventional push-pull knobs mounted under the center of the instrument panel.

Seat adjustment is done by raising a lever on the right front of the seat, then sliding the seat forward or aft while holding on to some structure on the door post. Designers are still trying to decide where to put handholds in the cockpit, since they designed a structure that doesn’t require steel tubes above the glare shield and behind the windshield, as are typical with high-wing airplanes. Strategically placed handholds will be an excellent alternative, and a good trade for the clear visibility of the unobstructed window. There is currently no boarding step, something that most average-height humans will want to help get in and out of the -15. But such amenities aren’t required for a test airplane, and the design team has some ideas about how to add them without compromising on drag.

Visibility from the cockpit on the ground appears to be excellent. Comparing it to similar taildragging high-wings, I’d have to say that it is superior to most. The upright seating allows you to easily move your head forward to see around the forward door post if required to see what’s coming up in a turn. And the view over the top cowl was excellent for taxiing. The design eye height is fairly high in the cockpit, and an extra cushion (on top of the temporary seats) was required to get my average height up to that level—but once I did, it sort of felt like I was sitting in an Air Tractor, casually surveying a large domain. I liked it!

Without flying the airplane, it is hard to tell what the control motions will be like, but we were able to move the stick in a wide circle since the ailerons were disconnected while we were there. The designers have a couple of stick designs in mind should it be necessary to help give wider travel between the legs, especially in the back half of the pitch range. The grip height was just above the legs, allowing pilots to rest their forearm on the thigh for precise and steady flying.

The flap handle is a large affair hanging from the ceiling between the two occupants, and it is beefy, as befits the large barn-door flaps. Flaps are deployed by pulling straight down—no trigger pull is required, and there are currently three notches of flap available. Retracting flaps requires pushing forward on a latch with your thumb—ergonomically, this felt just fine. It will be interesting to see how much force is required to pull full flaps—but getting the first two notches out will slow the airplane automatically, making the last notch easier. It appeared to me that the flap/aileron split was about 60/40 for span, with the ailerons having more chord. It’ll be interesting to see how they gear this system to get that “RV” handling from the system.

And before we leave the cockpit, let’s answer the obvious question I know is out there—can you add a back seat? We talked about it with the design team, and they are well aware that someone is going to add one or two. The current design doesn’t preclude it, but it also isn’t specifically designed with anchor points or extra structure. Nevertheless, the current thinking is that the RV-15 is a two-seat airplane with a generous baggage capacity.

Firewall Forward

The cowling was covering up the IO-390 during our visit, so there isn’t much to say except that the smooth lower cowl hides a snorkel connecting the horizontal induction to the air cleaner in the left cooling inlet for induction air. The firewall-forward installation was borrowed almost intact from the RV-14, making prototyping easy. We were told that the airplane has been conceived to be built with either the angle-valve or parallel valve motors from 180 to 225 hp and that different engine mounts will likely be available, along with a cowling that can be cut to appropriate length. Rian Johnson noted that the current cowl is pretty much a copy of the RV-14’s, and that he wants to explore different inlet shapes and sizes as the design is refined.

What about fuel? The first article has 40-plus gallons of fuel in a handmade tank fitted where a passenger would go. This is for several reasons. First is to ensure that the first flights would have a conservative CG loading. Second is that Van’s hasn’t decided if the fuel, to be carried inboard in the wings, will be in separate tanks fitted into the wings, or if the wings will be “wet” like most RVs are. (Remember the aileron pushrods go through the wing D section, so, if this is the configuration used in the kits, fuel can’t go there.) Final fuel capacity is also still being discussed—but the engineering team wants to provide maximum flexibility in loading and range for the pilot, so our expectation is for bigger rather than smaller. Let’s call it in the ballpark of 50 gallons.

Number, Numbers, Who’s Got the Numbers?

Trying to extract numbers for weight or performance is a bit of crystal-ball gazing. Obviously, the design weights are close to what Van’s is shooting for. They told us that this aircraft will sport a gross weight of 2050 pounds, and at the time of our writing, the empty weight was not yet finalized. But as is true of most airplanes (the RV line included), gross weights frequently rise as the design is tested and refined. My family’s personal RV-6, serial number 4, has a gross weight of only 1600 pounds, but the design’s max-gross eventually grew by 50 pounds. Will the RV-15 go heavier than 2050? Our expectation is yes, and we won’t be a bit surprised if it is closer to the mid-2200s. Why? Because that’s where a lot of airplanes that size end up. And, as mentioned before, there’s plenty of wing to support more weight—plus you know that Van’s has tested key structure to a weight well above what it is using with the first RV-15.

Of course, the other question is speed: How fast will it go? When we asked the engineering staff at Van’s this question, they smiled, shrugged their shoulders, and said “Well, I guess we’ll find out!” and as much as I (and every one of you, I suspect) want to know the answer to that question, we all just have to wait until they get the test article in the air and see what it does. Funny enough, it is far easier to predict slow speed numbers than it is high speed—unless you have access to wind tunnels and some pretty fancy modeling. If I were to guess, based on similar sized airplanes with motors we know—and the fact that the IO-390 has more horsepower than most of them—it will be competitive on cruise speed. Yes, there’s a lot of wing, but it’s not a Cub-style wing that strongly favors low-speed performance over cruise speed.

Where to From Here?

Let’s wrap up by talking about expectations. The RV-15 likely to be unveiled at AirVenture is a huge achievement for Van’s Aircraft—it represents years of market surveys, design and fabrication work using everything they have learned over 50 years of innovation and production. As we write this, no one has flown it except the Van’s test team—although we hope to get a crack at it soon. And realistically speaking, we expect that there are going to be design changes to make “it works” go to “we really like it!” With such a radical departure from previous Van’s designs, we have to expect that control harmony will be improved and tweaked until Van is happy to put his name on it.

When will it be ready? I’m sure that the standard homebuilder response of “Tuesday” is probably accurate. With the first flight just a month before the AirVenture debut, it is far behind the test curve of, for example, the RV-14. That airplane was introduced by surprise at AirVenture 2012, but it had been flying for a month before its debut. Tail kits weren’t being delivered for quite a while after that, and fuselage and wing kits followed. And while there were tweaks, the first customer airplanes were very much like what was seen at AirVenture that July.

The RV-15 will prove its place in the sky—and in the marketplace—within time, and we look forward to seeing them in numbers all over the backcountry. We’re not sure when that will be, but we are certain that Van’s success over a half century will continue, and another “total performance” machine will swell the ranks of E/A-B aircraft everywhere.

The RV-15 is still not to the prototype stage, and although it was built from CAD models that can be replicated by the push of a button, we expect that significant tweaking could happen before any kits are shipped. It is possible that the tail might change, or that the ailerons might need more or less area. If the ailerons have to change, that means the wing changes—and no one is going to want to “un-build” their kit to change things drastically. Manuals have to be prepared, and the factory tooled up to produce the new kit. So when will the kits be available? We expect it will be a while—but the wait will be worth it.

Photos: Bernardo Malfitano, Paul Dye, Marc Cook, courtesy of Van’s Aircraft.

Still a lot of design changes to be considered particularly the flying controls..the torque tube system is certainly the best but can be more complex and heavier than cables.

The protruding roof mounted ‘Johnson Bar’ is a hazard in turbulence (approach and landing) should shoulder straps allow lateral movement of the upper torso..

For me ,an RV owner not as exciting as the RV14 release…

EXCELLENT article PD. Well done on getting the scoop of Air Venture ‘22- including you MC! Really liking all the Vans thinking around the mains in the taildragger.

No way to open a window in flight, that’d be my first mod, a inflight flip “upable” window within the door. Says the guy who just flew a couple hours with his elbow hanging out in the breeze.

Looks like a Murphy Elite to me

Excellent article! Very good and detailed info and comparisons. Likely I will build it one day when jump to dark side (bush planes)