Wiring a panel? How about upgrading to the ultimate avionics work surface? What might that be? Well glad you asked – because it’s really simple.

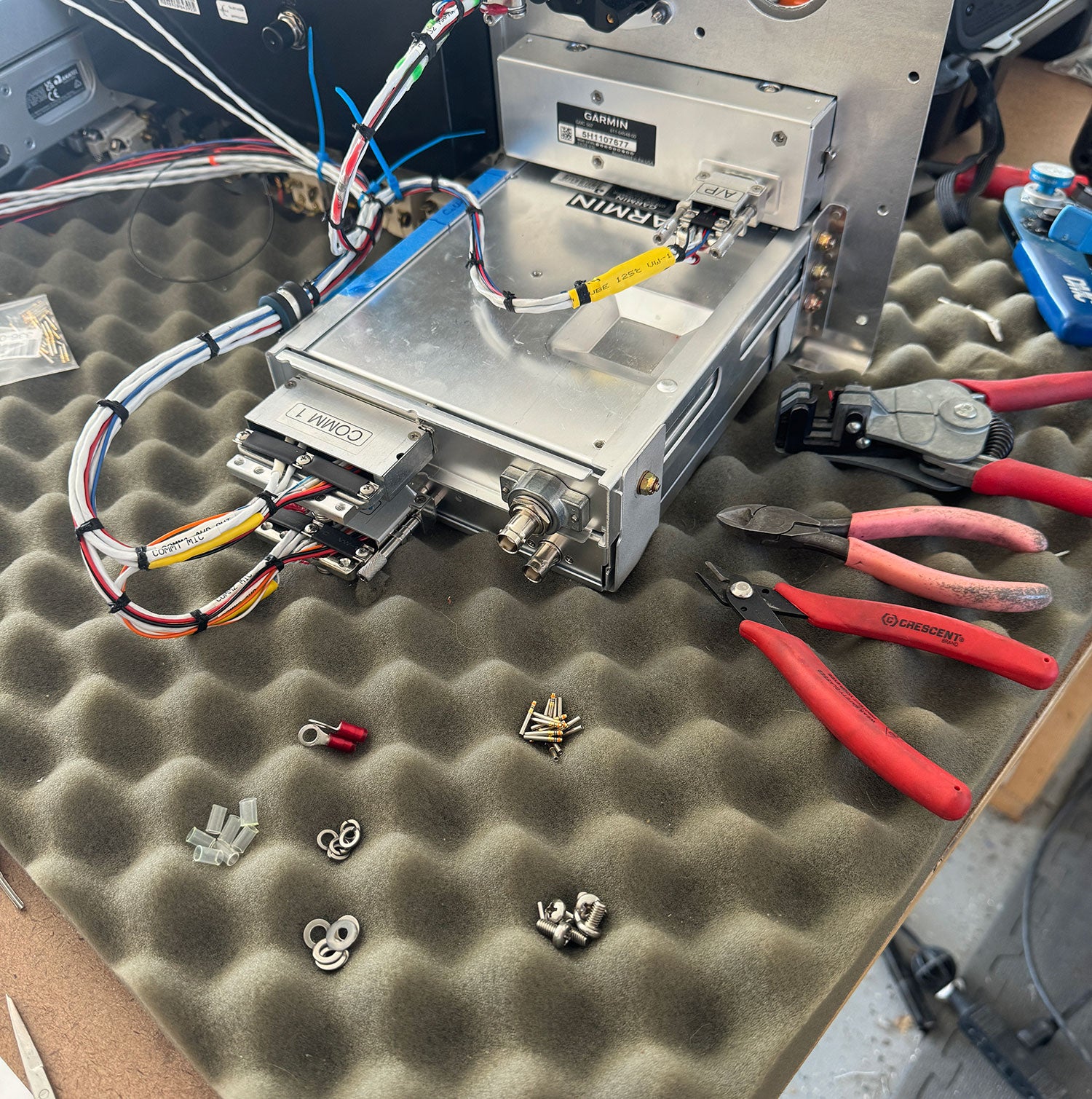

I have no idea where this “egg crate” foam came from—I have several sheets of it about 24” by 36”—must have come as packing material for something delicate, perhaps my little jet engine! But it is perfect for working on instrument panels. Not only is it soft, protecting the painted surfaces no matter if you have to tip it on to the front face or let it sit upright – but the depressions are perfect for keeping all of the little pins, screws, and washers that are part of any panel build. Try that with a flat workbench and you’ll have $0.62 (each) D-Sub pins and sockets getting swept off the bench and onto the floor by random bits of wire (been there, done that).

Watch out for ESD. Generic foam can hold a lot of charge. The anti-static foam is usually pink.

As an engineer, I have a bunch of ESD foam of different types I save for this exact purpose, both at work and at home. I have different sizes and types of foam depending upon what I’m working on. I also recommend people do this as much as possible. A lot of ESD safe packaging foam gets recycled where I work, so it’s easy to acquire plenty of it.