There is so much to learn by simply observing the handiwork of others. Some builders are just plain creative when it comes to organizing the myriad parts and pieces we need to install in the engine compartment: wires, hoses, cables, sensors to name a few. We will look at the creative use of Adel clamps by a fellow builder that were used to organize components forward of the firewall.

Adel clamps—more properly called MS21919 aircraft clamps—are commonly used to support bundles of cables and other components. You may also hear them referred to as “cushion clamps” due to the soft material that surrounds the inner metallic strap. This soft surrounding material may be made of a rubber or silicone material. The inner band may be made of steel or aluminum.

The specific materials used in an Adel clamp can be determined by the suffix to the MS21919 number. Your favorite aircraft supply catalog will describe these details for the clamps they offer. Purchasing from a generic vendor like Amazon will probably lack this specific material information. This may become an issue if you are trying to choose a clamp with a high heat resistance for using near the engine.

Available clamp sizes range from about 1/4 inch to several inches in diameter. Although not adjustable, they can be obtained in 1/16-inch-diameter increments. The size is the last number at the end of the MS number expressed in 1/16-inch increments. A single nut and short screw is all that is needed to secure the clamp. Clamps with the letter “W” following the MS number indicates that the cushioning material used will possess a small “wedge,” which helps seal the enclosure so small wires cannot escape. This feature has become quite common with most clamps.

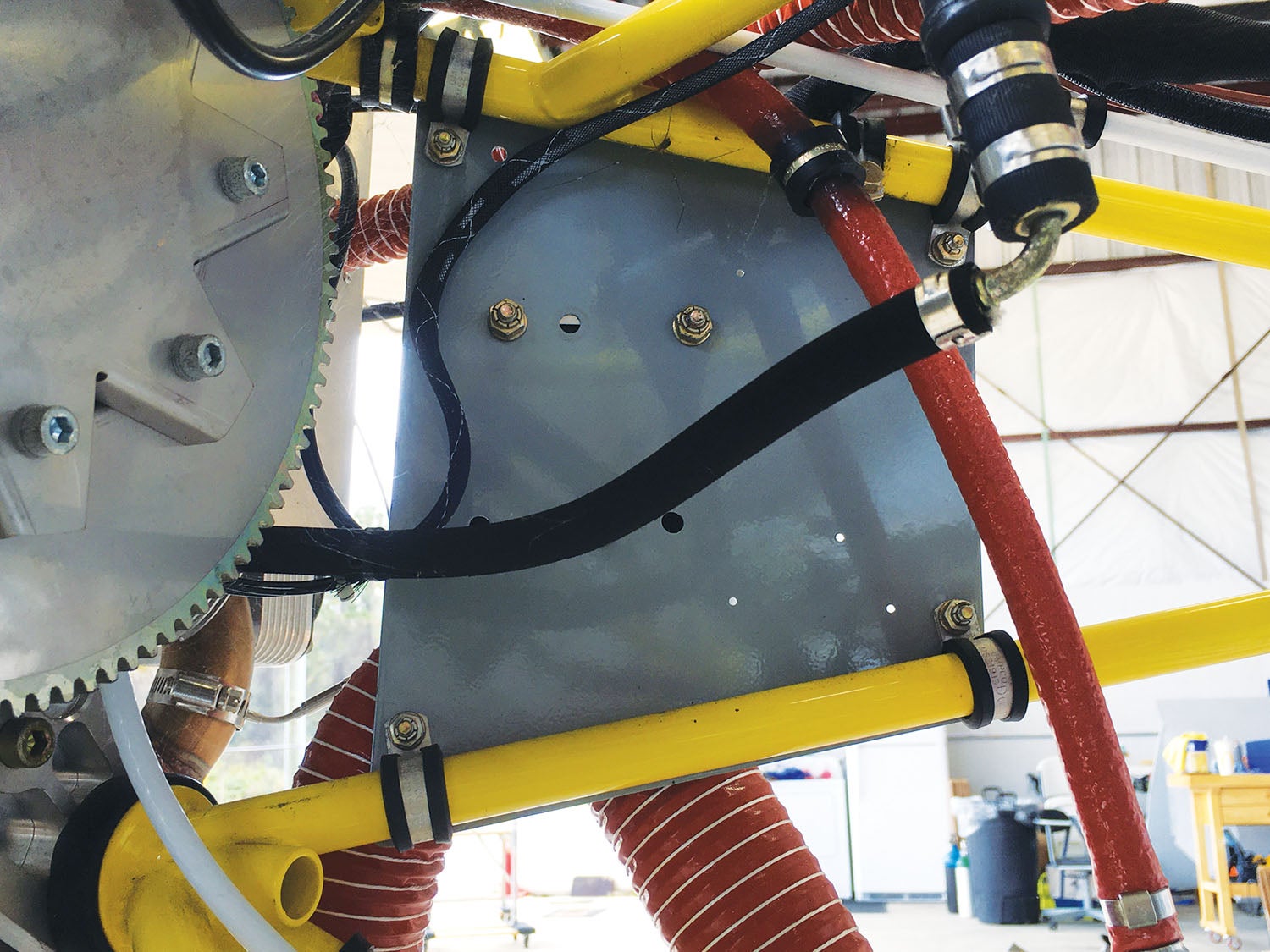

The photos shown here provide some ideas on how these clamps can secure many of the wires and cables in your engine compartment. Unlike cable ties, Adel clamps can be disassembled to allow for repairs, upgrades, and maintenance in the future. A larger or smaller clamp can be substituted as needed to accommodate future changes. Their robust construction means they are as permanent as the airframe. They will not need future replacement like plastic cable ties, which will eventually fail.

Note the technique of “doubling up” a pair of clamps, connecting end to end to produce a flexible standoff device. One clamp is sized to fit an engine mount tube, for example. The other clamp, sharing the same securing nut and screw, is sized and used to hold the wire bundle (or hose or cable). This technique can be used to robustly support the most difficult to mount items such as fuel filters, oil pressure sensors and other electronic sensors. Since the aircraft’s engine mount is generally built from rigid metal tubes, the Adel clamp is naturally suited to making a strong attachment at any location and offering a flexible mounting point for accessories.

Supporting electrical wires, fuel lines, and other cables at multiple locations not only makes for a nice, professional-looking engine compartment, it also provides reliability for those systems in the form of strain relief. It is a small investment for a good return on added mechanical reliability. Plane and simple!

Having worked on aircraft for over 40 years I would disagree with the statement “Their robust construction means they are as permanent as the airframe”. The rubber on Adel clamps, especially in the engine compartment are subject to deterioration with exposure to fuel, oil and other solvents. The rubber or cushion will swell, turn gummy or crack and crumble. Adel clamps need to be inspected routinely for their condition, even if they are not in the engine compartment.

How about a “how to” article with tips on how to put these into service. I have a hard time because I was born with two hands and three seem to be required.

To install adel clamps, especially doubles, you need the safety wire trick. Put an awl through the holes and pull the clamp tight. There are special vise grip tools the make this easier. Then put a little loop of safety wire around the legs of the clamp to hold it tight while you remove the awl and vise grip tool. This way you can get the hardware started through it (them) and get a nut started. Pull the safety wire and tighten the hardware. This trick will safe hours of grief.

Ed Holyoke

SS clamps with hi-temp silicone cushions are also available. From Aircraft Spruce they cost just a little more than the standard clamps we all know and love under part number MS21919 WCH. I use them forward of the firewall near exhaust pipes. But also, they’re much easier to close than the aluminum/black version, so I use them in places where the aluminum clamps just keep springing open when trying to bolt them on; we’ve all had that problem before. I keep about an equal stock of both types these days.

I use self fusing tape between clamps and engine mount tubing.

I’ve pictures of debris getting under the clamps and taking off the finish.

Maybe that’s just poor installation?