There’s an old military pilot saying that goes, “Never fly the A model of anything!” While test pilots will argue the idea, the typical squadron pilot wants an airplane that does what it is supposed to do and does it without breaking down—that’s understandable. But for those of us flying “experimental” aircraft, it can be hard to salute the concept—except by choosing a kit from a company with thousands of examples flying. After all, if they’ve got that many in the air, the significant problems have probably been ironed out—and in general, they have!

There’s an old military pilot saying that goes, “Never fly the A model of anything!” While test pilots will argue the idea, the typical squadron pilot wants an airplane that does what it is supposed to do and does it without breaking down—that’s understandable. But for those of us flying “experimental” aircraft, it can be hard to salute the concept—except by choosing a kit from a company with thousands of examples flying. After all, if they’ve got that many in the air, the significant problems have probably been ironed out—and in general, they have!

If you buy a kit from one of the top-producing companies, you are likely to get a well-thought-out airplane that gives you few troubles—so long as you build it the way the factory designed it and wants you to build it. Deviate from the plans, and you’re on your own! (Of course, if you are buying one of their kits with a single-digit serial number, expect a few inconveniences and service bulletins.)

But of course, every aircraft design has a prototype, and then it has its early kits (the “A” models, so to speak)—and it is not uncommon for those early kits built by early adopters to have some issues. It’s usually not a safety or handling issue—those get worked out before a design is unleashed on the general public, or the producing company is going to be short-lived. But problems with wear, cracks, vibration, or things like delamination, cracking Plexiglas—those can only be found by putting time on the machines. Make no mistake about it: If you have a low serial number, you are a beta tester for the company. And that’s OK—so long as you know and acknowledge it going in.

In our case, we have several pretty low-numbered aircraft. The first is RV-6 kit Number 4—yes, that is a single-digit serial number. Fortunately, the prototype was wrung out pretty thoroughly, and my wife didn’t buy this particular airplane until it had a couple of thousand hours and had gone through several owners. It was also built by someone closely associated with the factory, so it was solid to begin with.

My little jet SubSonex is serial number 21, and we have had no structural issues, nor have any significant service bulletins been issued—unless you consider a 50-hour visual inspection of the turbine wheel significant. (It takes about 45 minutes to conduct with a borescope and is done by the owner—so that’s not significant in my book.)

And then there is our Dream Tundra—the genesis for this article. Developed in the early 2000s in Canada, our example was the first to be purchased as part of the factory-assist program and was probably in the first five serial numbered kits to be delivered. And with that introduction, our story begins.

Growing Pains: Dream or Nightmare?

The Dream Tundra is a four-place, all-metal high-wing utility plane designed and marketed for backcountry pilots. The prototype was built as a floatplane, with the taildragger main gear implemented on later aircraft. Dream was based in Canada, with the principals, including the designers, drawing on the desire for a plane that could carry reasonably large loads in and out of rough locations reachable by water or backcountry strips. Aiming at the Cessna 170/180 crowd, the airplane received positive reviews in various publications, including KITPLANES® (in the March 2004 issue). Indeed, it flew well and performed as promised when it came to range and carrying capability.

But like all new designs, it had growing pains. Our particular copy was the first to be produced using the factory-assist program. The original builder (later our partner) traveled to Quebec to work with the shop personnel to build the airframe. The aluminum structure was then containerized and shipped to Nevada, where he began working on systems and firewall-forward projects. Time passed (eight years) in which not a lot of progress was made, but eventually, Dream sold in the neighborhood of 36 kits. To the best of our knowledge, approximately 15 to 18 had flown by the time ours first took to the air. We have not heard of any other completions.

So what about those growing pains? Well, the Phase I testing actually went very well. We used the EAA Flight Test Manual in its draft form (we were trying it out to give comments back to the team), and it took about 35 hours to complete the test program. The only real problems we ran into were a strong tendency for the tailwheel to shimmy, which we found was due to the geometry of the tailwheel spring and the resulting angle of the pivot shaft. We also discovered a need for vortex generators on the bottom of the horizontal stabilizer—along with a ballast box in the baggage area—because we did not have enough tail power to flare in landing configuration near the forward half of the CG envelope. That’s where we mostly flew.

But as we were changing the oil at the end of the Phase I program, we noticed some odd wrinkles in the belly skin between the firewall and the landing gearbox. Uh-oh…wrinkles are never good! We communicated with the factory and determined that we probably needed to double the thickness of the skin. As a matter of fact, we probably wanted to do that all the way back to the aft door post, plus add a doubler under the pilot’s seat. Getting the factory to make the appropriate parts (compound curves involved) and shipping them from Canada took several months. In the meantime, we had to drill out about 300 rivets and purchase a pile of expensive CherryMax pulled rivets for reinstallation. Cleaning everything up, upsizing holes and reinstalling the skins took several months when you account for manufacturing and shipping. The cost was in the neighborhood of a thousand dollars when it was all done.

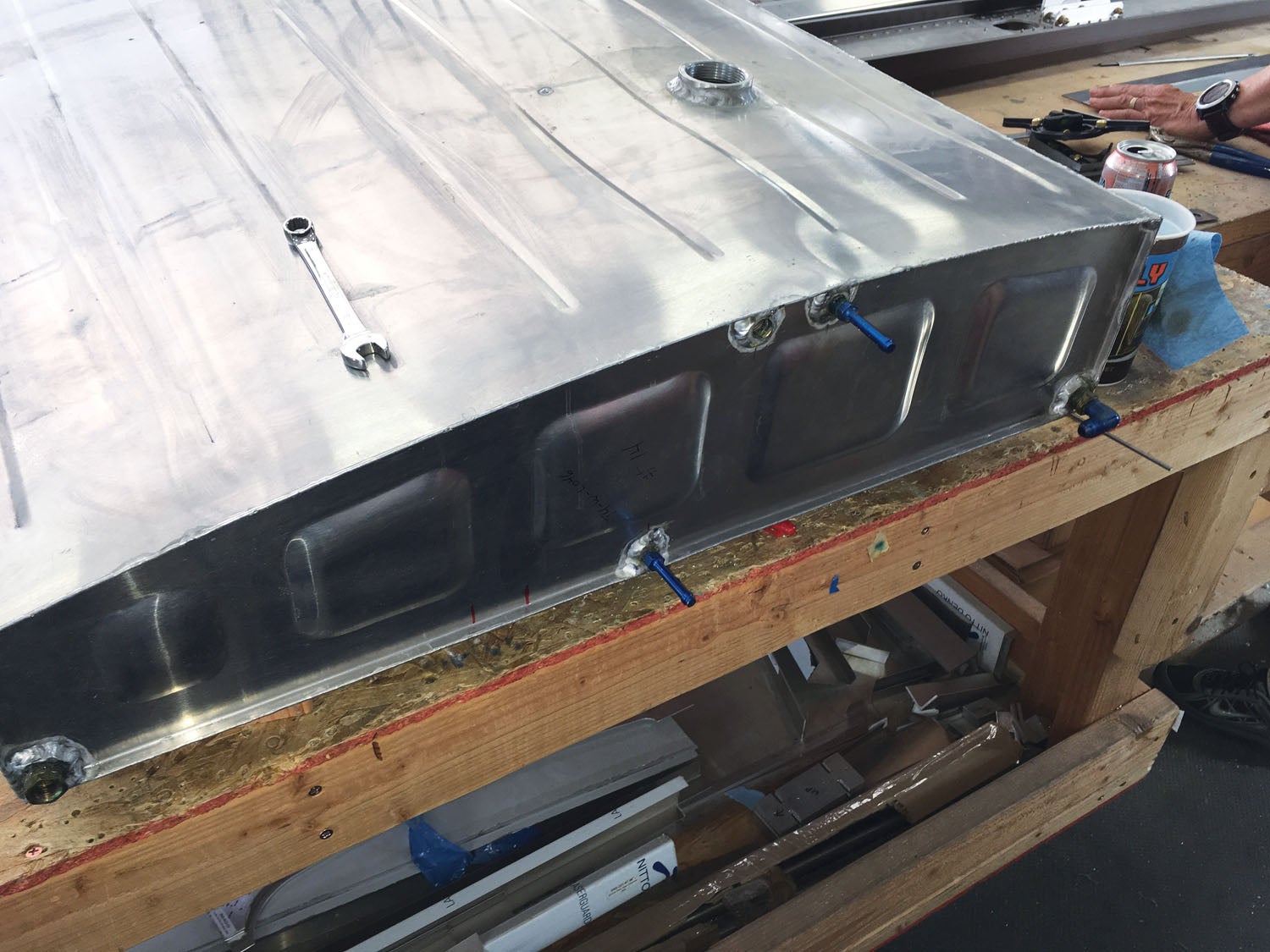

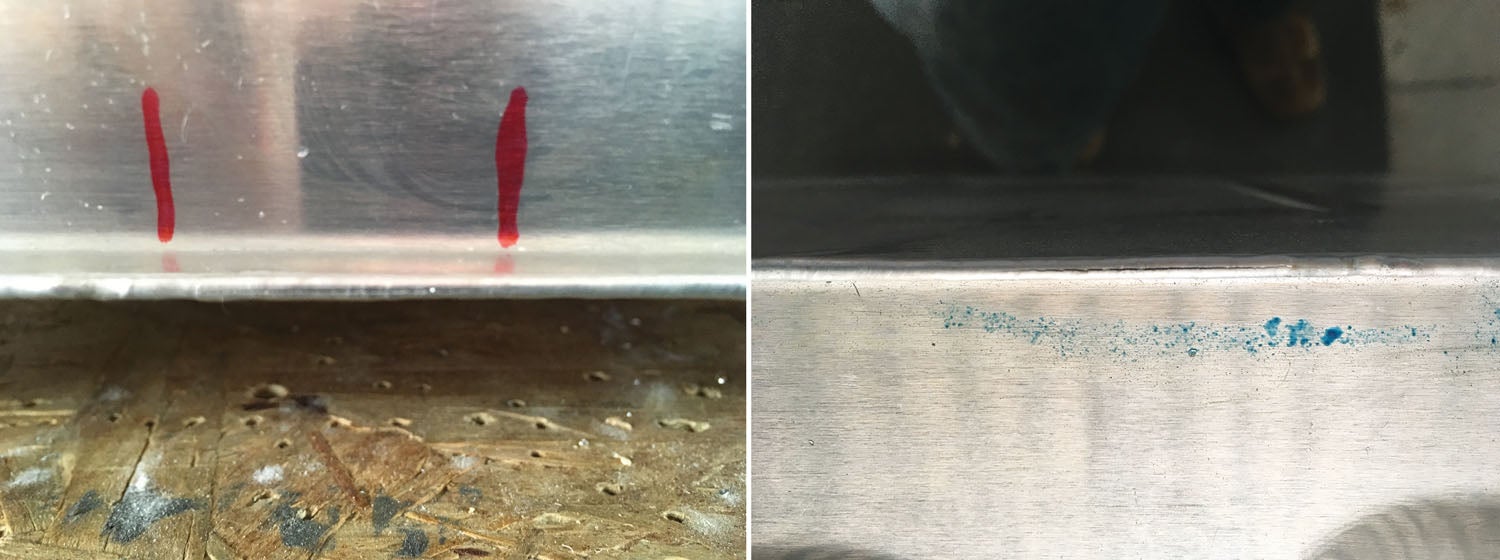

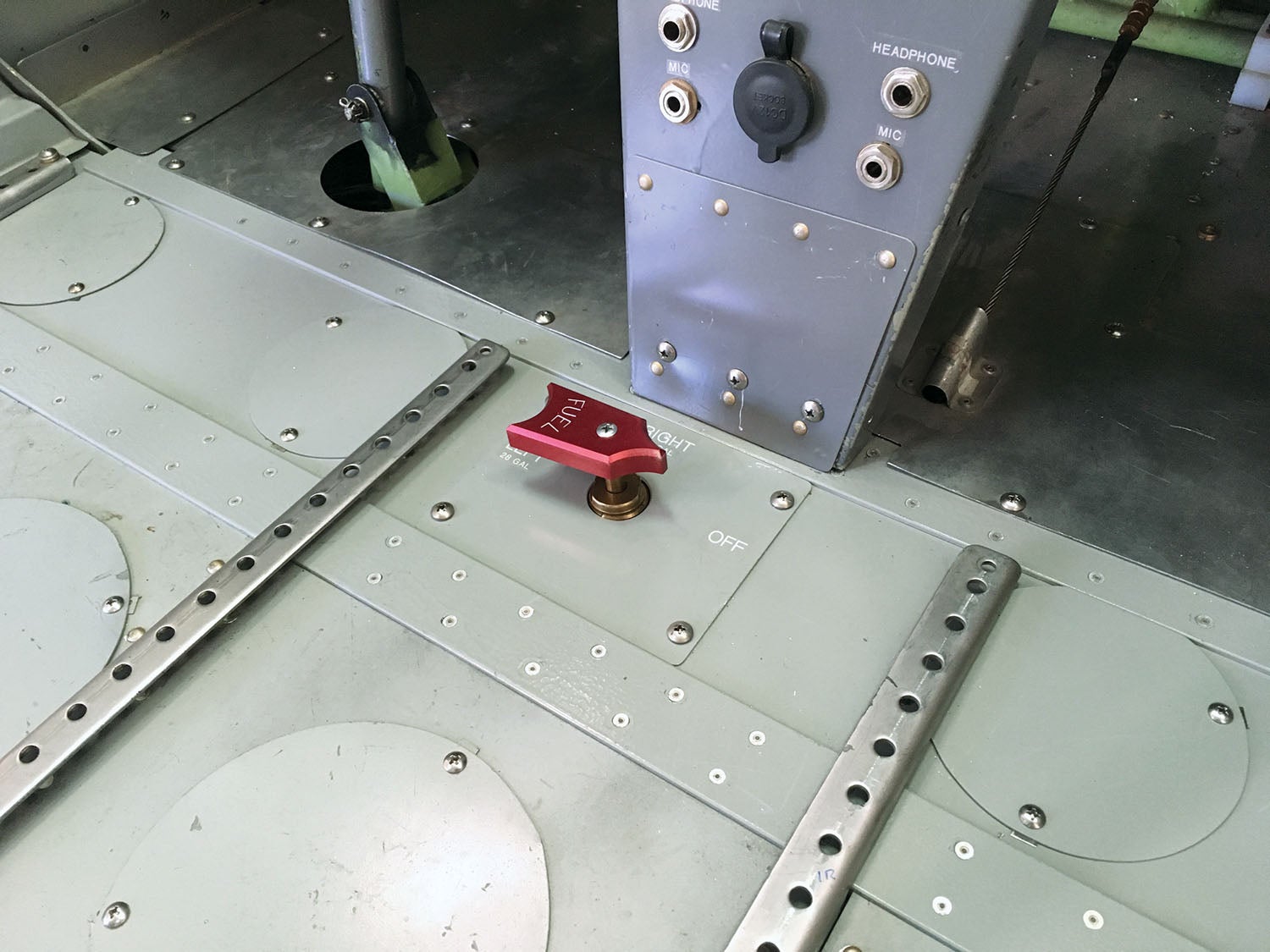

With the new belly, we dashed off into Phase II, hoping to get the airplane out in the backcountry. In fact, that was where we were—a short rough wooded strip in Idaho—when we noticed a strong fuel smell and blue fluid dripping off the trailing edge of the left wing. We quickly realized that the left fuel tank had cracked, and while one person dashed off to a fire crew lounging at their camp nearby for some jugs to catch the 100LL, the other started removing screws to access the tank. We couldn’t see the source of the leak but determined the other tank was fine—so we filled it up and headed home, making more fuel stops on the way to Nevada because we only had half the capacity.

It turned out that the fuel tanks were built in a very odd manner and of material that was thin enough that they broke the edge welds that held the fuel in when they flexed. It took several tries and probably four months to finally come up with a fix involving a lot of Pro-Seal and doublers for the tank flanges. The tanks probably went in and out four or fives times in the process. It was either that or have entirely new tanks manufactured to a custom set of drawings out of thicker material. We even considered fiberglass tanks to drop in place of the stock metal units but put that off as a future project if the leaks reoccurred.

Out in the Wild

Once again airworthy, the airplane made its first long trip to Oshkosh—16 hours each way. Typical cross-country events occurred with windy landings and stops for storm avoidance. With the airplane and occupants back home, on inspection, we noticed a bulge in the floor just ahead of the pilot seats. Removing some access panels showed the truth—the structural beams that join the two landing gears (the “gearbox structure”) were buckling. Again—not a good thing in a bush plane!

Frustrated was hardly an adequate description of our mood at this point, and I closed the airplane door and walked away for a few days. But our life is airplane projects, and it was either work on the Tundra or straighten ribs—46 of them—for our motorglider, so I started engineering a repair for the Tundra’s structural heart. The factory was unresponsive by this time—they had provided little to no help on the fuel tank issue and now didn’t answer emails or calls.

It took some careful hydraulic work to straighten the beam flanges, then some engineered and fabricated doublers for the flanges of the built-up I-beam structure, followed by steel cap strips to finish the job. I figured that this structure is hung in the middle of the build space when the airplane is begun and everything else is built around it—so a replacement was really not in the cards. Repair was possible, so with a handy dog-eared copy of AC 43.13, we spent a couple more months getting the airplane flying again.

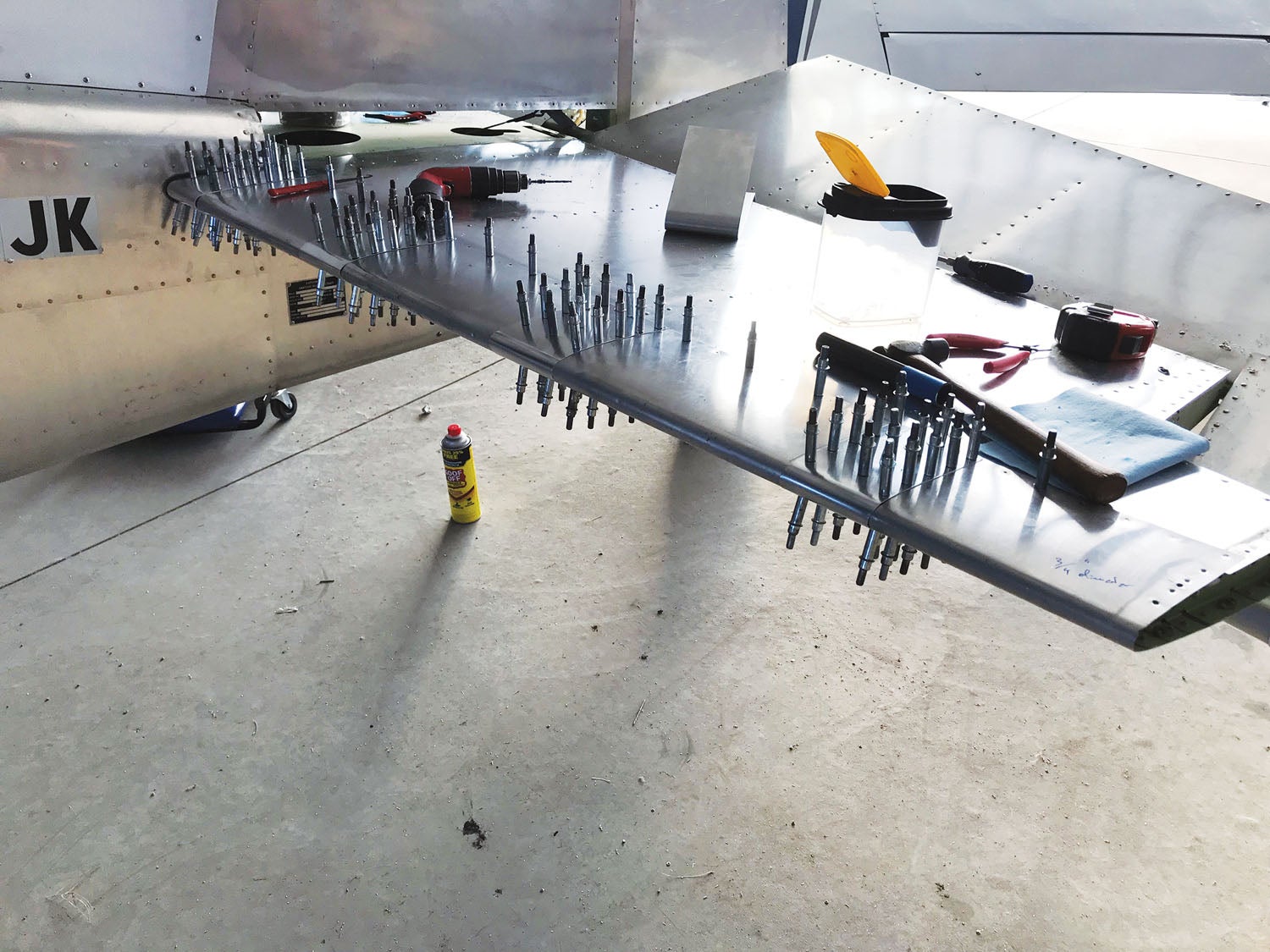

July rolls around every summer, and once again, we had a reason to take the Tundra to Wisconsin—this time to support the little jet we were taking to the show. The jet has room for a pilot, fuel and a toothbrush—everything else went in the Tundra. Once again, it took two days each way and once again, the Tundra came home to roost on the ramp, the Superior IO-360 panting in the setting sun. And as I pushed the airplane back into the hangar, I noticed little spidery lines emanating from the AD3 rivet heads on the leading edge of the horizontal stabilizer. Yup—there were cracks in the skin at almost every rivet on almost every nose rib!

Ribbed!

Again by this time, there was no point in contacting the factory for parts. In fact, I had received a phone call (in my capacity as a journalist) from someone representing the owner of Dream asking if I had any idea of someone who might want to buy the entire program—the rights to the design, the intellectual property, remaining parts, the prototype and several complete kits. So I knew that we were again on our own. Since the leading edges were tapered in two directions, replacing them was not going to be an easy sheetmetal job. When I de-riveted them, I also found problems with double-drilled holes for the skin rivets—meaning I was going to be making nose ribs. So once again, I pulled out my very worn copy of AC 43.13 plus my sheetmetal mechanic’s handbook and went to work on doublers that would patch the skin at each nose rib. Lots of drilling and fitting followed, with extensive trimming to make everything fit nicely. Hundreds of tiny rivets later, the tail was once again airworthy.

But with all of these issues, how could we ever trust taking the airplane out into the true backcountry? What happens if you discover a major structural problem when you are at an airstrip unreachable by roads? What does it cost to bring in a heavy-lift helicopter to retrieve a wounded bird?

All of these questions kept the Tundra flying close to home for the last year. We liked to go out to the dry lakes within 100 miles of home, but we knew that most of those lakes could be reached by jeep if we needed recovery. It just didn’t seem prudent to depend on the airplane away from civilization.

Losing faith in an airplane is tough—you have invested a lot of time and money into the thing, and quite honestly, the thought of abandoning that investment is hard to swallow. And of course, how could you think of selling such a bird to anyone—even if you disclosed all of the problems to that point, it would be hard to let something with your name on it out into the world when it had already demonstrated a propensity for creative and unusual failures. No, this was an airplane which we would have to live with until we came up with a solution that didn’t involve a chain saw.

The Final Straw

I put airplane problems into a couple of primary categories—those that annoy and frustrate me, cost me money and take the airplane out of service. And those where the airplane is dangerous and trying to kill me. Everything that I have mentioned up until now fell into that first category.

Finally, the thing tried to kill me!

I have never really liked the long all-thread trim-tab pushrod. Van’s uses a similar link between the servo and the tab, but it is short and straight. This one was long and bent. But it was allegedly factory-approved as a way to add electric trim (the original design was manual), and it was a slow-speed airplane. The fact that it is a slow airplane probably saved my bacon this day, as I was descending over the Pine Nut mountains into our home field. The speed was up about 120 KIAS when all of a sudden I got a huge pulsing in the stick, the airplane started pitching down and the airframe started vibrating.

In about three milliseconds, I looked both ways to see if I had lost a wingtip, aileron or flap, thought about if I might have hit a bird and even considered if a gear leg had fallen off. After realizing that the engine was still running smoothly, I determined that the problem had to be back in the tail. At the same time, I eased power off and pitched up to bleed off airspeed. So long as you have control, slowing down is rarely the wrong thing to do—and if slowing down makes control worse, you can generally speed back up again. The vibration got less violent, and I figured either I had lost a major tail fairing, or the trim tab was fluttering. As I got down below 80 knots, the vibration got tolerable, and it went away at about 65. Of course, I realized I had no trim about this time, confirming my suspicions.

This is not an easy airplane to flare for landing without full nose-up trim at forward CG, and flaps only increase the problem. But I wanted to land as slow as possible, so I compromised with one notch of flaps and aimed for the end of the runway. I saw a NORDO aircraft using the opposite end of the runway that I had used when I took off 45 minutes before, but our wind often changes direction about that time in the morning, so I aimed in that direction and made a blind call that I was having control problems and was landing as soon as I could.

It turned out that the other plane had shot a straight-in from a long way out and hadn’t checked the winds, then departed straight out, which, of course, set me up for a downwind landing. But I wanted to get on the ground while I still had control and didn’t want to maneuver any more than necessary, so I pulled all the power and took the float until I touched down when the plane ran out of energy. That is what 5000 feet of runway is for, and I only used half of it. I’m not into kissing the ground after I get back to Earth after an emergency, but I was happy to be able to taxi back to the ramp.

I was not the least bit surprised to find the linkage broken when I hopped out on my ramp, and also not surprised to see cracks in the tab skin near the root end and a crease extending about 4 inches beyond the end of the crack. It was probably doing some real flapping at some point. There was no apparent damage to the elevator itself, and the piano-hinge eyes that hold the trim tab in place showed no deformation, so the loads transmitted to the rest of the tail probably weren’t excessive. And with an airplane this slow, it seems intuitively hard to believe that the elevator could be seriously damaged by the relatively small mass of the trim tab. But ultralights have been lost due to flutter at very low speeds—so you just never know.

And the Future Is

So now that the airplane has truly tried to kill me—as opposed to just pissing me off—I have to make some hard decisions. Of course, it is repairable, although parts aren’t available, so it would be a scratch build of the trim tab. But the real question is: What is going to break next time? Are we just flying on borrowed time? I can be pretty forgiving of annoying problems in airplanes as long as I know how to fix them, and there don’t appear to be ongoing issues. One-time deals in low-serial-number airplanes are expected. But have we used up our bucket of luck?

Are there control-cable attach points deep inside with potential fatigue problems? And what do we know about the structure itself? It appears that the kit manufacturer had under-designed the belly skins, fuel tanks and the horizontal stab nose skin. What is going to give way next? And more importantly, will it give significant warning before it fails? Or will it go all at once? These and other questions create trouble for me as both a pilot and an owner.

(We know of one other Tundra owner who bought his airplane from the builder, and during an annual condition inspection, the A&P noticed that as he pushed up and down on the wingtip, he got a repeatable clicking and creaking noise from somewhere in the structure. There also appeared to be motion in the wing root area, as if the structure was deforming. After exhaustive poking and probing, the owner still couldn’t find what was wrong to a level that he was willing to accept and reported the issue to his insurance company, which scrapped the airplane and wrote a check.)

You see, this isn’t the kind of stuff I would want to punt down the road to a new owner. Yes, I would obviously detail every single problem we have had and how it was repaired if I were to sell the aircraft—but I have been a buyer and know how enticing a good deal might be—and how easy it is to reduce the significance of problems in your mind. You want something bad enough that you can ignore warning signs that you should be taking very seriously.

It is one thing to decide that you don’t want the personal liability of selling an airplane like an RV with thousands of flying examples. There are those who render their homebuilts unairworthy by cutting the spar or drilling holes in other primary structure and then donating them to museums. There is an infamous video on the internet of a wealthy person crushing his RV-8 rather than accept a presumed liability trail by selling it. (Even though there has never been a successful lawsuit against a builder of an E/A-B aircraft.) But it is another thing entirely to sell an airplane with a known history of problems to someone who intends to fly it.

So can we salvage the airplane and salvage the airplane’s reputation to our satisfaction? How many chances do we give it? One way to restore some level of faith in the machine is to do a top-down, thorough safety review of the entire design. We probably can’t do an actual stress analysis of the structure, but we can go over it all for things that might be bent or fasteners that are popped. We can do a pulley-by-pulley and cable-by-cable analysis of the control system, calculating loads on all components from aerodynamic and pilot inputs. We can check every attachment point for wear or fatigue to ensure that the control system is intact. We can go over the fuel system (once again) to look for leaks or deformation that might show a tank beginning to leak.

All of this starts with an outline for the safety review—coming up with a plan that lists every component that we want to inspect and verify. It is a daunting task, with lots of details to consider.

In industry, there would be a large team of people working on a review like this. For an individual, it is important to enlist one other qualified and inquisitive person to look at and challenge the process and results. But it is certainly a feasible task and one that can help to decide if we can regain confidence in the airplane.

Is it worth it? Well, certainly the airplane does much of what we want it to do, and a bird in the hand is certainly worth a great deal when you consider that kit prices today are higher than they were when we built this. On the other hand, we have an engine, prop and avionics that could be transplanted to another airplane. But we’ve got other airplanes to fly and a busy schedule—so we’ll take our time to decide.

After all, it’s far better to be on the ground, wishing you were up there than being in the air, wishing you were on the ground.

My first question would be, “where did the sheet product come from and the other metal materials? Sounding like the Canadian designer may have found a “cut rate” materials supplier and bought in………just surmising. Good story and eye opener. The overall design seems to be solid and appealing……..sorry to hear about your run of luck with this aircraft.

Actually, I found no defects in materials themselves – the company was certainly well-meaning and had a significant background in aerospace fabrication. The design just never reached numerical critical mass to solve the growing pains that are part of every aircraft design effort.

Great article. I shudder to think of someone without your level of capabilities droning along with a leaky creaky mess until either it took itself out of rotation or with the aid of bandaids and lipstick, got passed on to someone totally unsuspecting.

Sadly few have your levels of ability, patience and integrity.

Might be cathartic to truck it to the playa with some long sticks and marshmallows.

Excellent article very well written and very much enjoyed. I remember 3 of us that totally fell in live with the plane back at EAA the first time it was there. The workmanship was way far ahead of any kit on the market at that time. We tried to get a special EAA price on 3 kits that year but they would not negotiate. After being an EAA member for most of my life and being involved in sport aviation I have learned many things that a novice would not consider. I picked the Zenith 750 for a lot of reasons from what I learned. There are a lot of them flying, the company is the best in the business, repair parts are shipped the same day, and help is on the phone for any problem immediately. If you like the Tundra, consider the Zenith Super 750, or the 801 or super 801.

Great article! I have been interested in this aircraft and inquired about it without a response. Now I know why!

Thanks!

I have to agree with Myron, above. I can’t imagine someone without Paul’s obviously good eye and very experienced engineering mind having a cascade of this kind of problems to deal with. Many people would have just ignored the warning signs, or patched everything over without really fixing it. Or worse yet, as he discussed, dumped it without qualms on some other unsuspecting buyer who might go out and kill him/herself in it.

I also appreciate his sharing the thought process that goes into making this kind of decision, as well as the ones that preceded the final one.

This is why I read Kitplanes. And Paul’s articles are right at the top of the list when I recommend it to others.

I agree with Ron C’s comments above and want to congratulate Paul on a very well written article and the professional way he attacked and resolved these major issues. Having just finished a Rans S-21 I sure would be disappointed and even angry if I had encountered problems of this magnitude, after investing a lot of time and money. And with an early serial number (0012) kit I understand the meaning of being a “beta tester”.

Excellent article Paul! This is the perfect illustration of why those letters “EXPERIMENTAL” are required and a good reminder of why Certified Airplanes are so expensive. The certification process seeks to solve issues before the airplane is certified. The homebuilder is placing faith and hope in the designer that there will not be an issue. It’s a matter of testing, time, and money thus a risk/reward balance. A prudent homebuilder may find it worthwhile to spend a few hours with 14CFR Part 23 Regs and the AC23-8 Flight Test guide (or Part 25 and AC25-7) to ask if their design will stand up to the scrutiny contained there-in. Depending on how they answer that question should help to establish the level of trust and risk envelope they are willing to take with their homebuilt.

My condolences on your experiences with the Tundra. It gave me flash backs to my experiences with my first plane. A Cessna 150C. The issues I dealt with were due to many years of weather, poor maintenance, corrosion, fatigue and the early 2000’s continental cylinder fiasco, not poor design. But I experienced the same loss of confidence (and cash) in the plane after repeated major repairs. I eventually sold it to an A&P when I was facing a $15,000 annual.

Your suggestion that a complete safety analysis could restore confidence could backfire. After spending all that time and effort you may just confirm that it’s not worth saving. If it were me, I’d go for the second option, put that great engine and avionics package in a deserving airframe, and take the Tundra to the aluminum recycle center. Lesson learned.

Aircraft development is hard. Fuel tanks are especially hard. Here is an article by Alfred Scott about what he went through while anglicizing Stelio Frati’s F.8 Falco fuel tanks: http://www.seqair.com/skunkworks/FuelSystem/Problems/Problems.html

A few years ago while I was at Air Adventure I sought out a few owners of Tundra’s. Being an A&P and seasoned flight test engineer I asked a lot of questions about the aircraft because I was interested in how it was really designed. It had everything I wanted in an aircraft. Everybuilder explained to me in detail all the modifications to the aircraft they felt where necessary to do while they assembled the aircraft. I realized from those conversations that it was more of a project than I wanted to take on. I just walked away from the Tundra.

Hi I have kit number 36 here in Australia and we have 170Hrs on it now and have had no problems with the plane ours came with the updated belly skin and different tail wheel mount and doubler skin on the fuse where the tail wheel attaches.

The only thing I find is the heaviness of the controls at cruise speed compared to our C180 but when you slow down to approach speed it is not to heavy on the controls.

Cheers Rob

Hi Rob – great to hear that you and the airplane are still doing well! So long as you really look in detail at all aspects of the airplane at every inspection, you should be able to catch and repair any problems as they arise. The most frustrating will probably be fuel tank leaks – they are just a real pain to work with, and you spend lots of time removing/replacing them in each iteration. This is just a design that needs some maturing, and the only way that happens is for it to accumulate flight time, and folks find problems along the way.

Paul

Aluminum monocoque aircraft have many more stressed areas that can be under engineered particularly at the really hard points such as landing gear and engine mount attach points. Without advanced computer modelling. It is more of a trial and error method of proving it adequate. Tubular airframes are much more forgiving in this area of design and I personally prefer them for that and crash worthy reasons. Recall the C-182 firewall deformation issue from hard landings where the nose wheel makes harsh contact with the ground after an inadequate flare due to forward CG catching the un aware pilot off guard. To produce an experimental all aluminum airframe for harsh duty takes a hefty dose of engineering expertise to get right the first time unless it is just over built. It will be interesting to see how many refinements the RV-15 will rack up. I think not too many as Vans is a well sorted aluminum aircraft manufacturer with decades of experience.

We, the experimental aviation community are very lucky to have someone with your level of knowledge and the ability to convey your experience to us.

Learn from others. You will not live long enough to learn it all yourself.

Thank you.

It’s nice to see Kitplanes address this. Problems aren’t always in the design. I had one of the earliest metal wing kits for the RANS S-20 (off the S-21). Here, it was strictly a manufacturing problem and lack of QC. I ended up selling the kit to a machinist who had the tools to fix the mess. I knew of “Never fly the A model of anything” but failed to heed it–never again.

Paul, totally can relate with your frustration having helped the owners of a one off kit that didn’t pan out. I also flew the A model F16 which did have growing pains but ended up being a great airplane and it’s lessons led to the C model which is still in service around the world.

My friend decided to donate his airplane to a Vo-Tech college with the stipulation it never flies again ever. Maybe you could explore this option…:)

Smokey