It is common practice for builders to cut openings in aluminum aircraft structures. Popular examples include creating inspection or access panels in the wings and fuselage or adding openings in the instrument panel to make way for another instrument. Whether these cutout openings are included in the original kit design or are added by the builder to improve accessibility or customization, it is important to understand the proper methods required for making cuts into the aircraft.

The aluminum that holds your aircraft together is naturally under some degree of mechanical stress. The thickness of an aluminum skin, for example, is chosen by the designer to ensure there is enough strength to keep things together. Although we cannot see them, the internal stresses on that skin span in many directions as lines of force. They may be pulling, pushing or twisting. The aluminum holds together as long as these stresses are within the design limits. So, what happens to these stresses when we cut an opening in that skin?

An opening cut for an inspection panel is often rectangular in shape. This means that there will be corners where the edges of the opening meet. It is these corners that are the focus of concern! The lines of force we mentioned previously get sharply concentrated (magnified) at these corners. Think of the force lines as being interrupted by the corners as they flow through the material. In addition to inside corners, other irregularities like a groove, notch, nick or scratch can potentially concentrate these forces. In this discussion we are concerned about the effect of introducing corners into the aluminum material.

This concentration of forces, also known as a stress riser, is what we want to avoid adding to our aircraft’s structure. If the forces become too great, the metal can fail. The most common form of failure for a corner stress riser is a crack developing at that corner. The crack may then grow with resulting disaster. Repeated flexing of metal (fatigue) caused by the vibrations from the engine, for example, can result in mechanical failure at a stress riser location. Brittle materials (aluminum) are more prone to this failure than ductile ones (steel, generally speaking).

So, if we want to eliminate stress concentrations, do we need to eliminate the use of corners? The answer is that it is a matter of degree—a sharp corner is the most powerful stress riser. As the corner is rounded (radiused), the level of stress at that location goes down. The larger the radius, the less concentration of stress. The simple solution is to avoid sharp corners—always. This is really an easy task when it comes to creating your opening. Here are some examples.

If you have a sharp-cornered opening already in place, take a small round file to it. By rounding out and eliminating those sharp corners, the stress concentration is drastically reduced. The larger the radius you can make, the better.

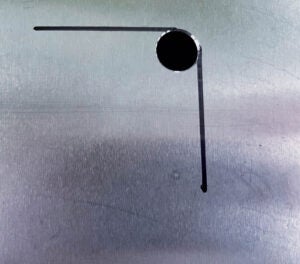

The best situation is to plan the round corners in advance. With this method, the resulting cut will look better too. Simply drill large-diameter holes first so that the intersecting edges you cut next will blend in. This also allows a saw blade to easily cut from one hole to the next. Make those holes as large as you can stand!

By designing your access openings with large radiused corners in advance, you will maintain nearly the original strength of your structure for its life. Take note of every opening you see on an aircraft and notice the lack of sharp corners. By remembering that stress risers are caused by inside corners, notches, nicks and other irregularities, you can keep ahead of potentially dangerous situations in your aircraft building. Plane and simple!