On a hot Saturday night Charlie Taylor stopped by to gas with the boys down at the bicycle shop. It was June 1901, Dayton, Ohio and, as they came to be known to Charlie, the boys were Orville and Wilbur Wright.

The automobile had started its ascendancy and bicycle prices were falling; a custom-made bike was down to about $20. But a good repairman/machinist was needed for the shop, so an offer of employment was made and accepted. The Wrights had been increasingly involved in the attempt to fly and needed someone to mind the store when they were at Kitty Hawk. Thirty cents per hour for a 60-hour week was a nickel raise, which doesn’t sound like much, but 20% is substantial by most anyones measure.

They trusted me to handle not only their customers but their money, Charlie said.

The Wright brothers were just realizing that the wing design data published by Otto Lilienthal was wrong, and they had embarked on the design and construction of their third glider using a wind tunnel of their own design.

Engine Origins

The engine had a different genesis. In the December 1913 issue of Flying, Orville related that he had written to several manufacturers with the requirement of 8 horsepower from an engine not exceeding 200 pounds.

That they would establish such a low requirement is amazing, because the leading lights of the day were aiming a bit higher: Samuel Langleys machine, powered by 52 hp, dropped like a handful of mortar into the Potomac River, and Hiram Maxims machine got nowhere with two steam engines trying to lift its 4 tons off the rails.

Most of the companies answered that they were too busy…but one company replied that they had motors rated at 8 horsepower, according to the French system of rating, which weighed only 135 pounds… Charlie explained.

After investigating this sole entry they concluded that with 8 hp as the rock-bottom minimum, the engine just had no margin. It was, as Charlie put it, a one-lunger, and the company’s claim was probably exaggerated anyway. As it turned out, they needed substantially more.

The only choice left was to design an engine. It was to have four cylinders with a bore of 4 inches, a stroke of 4 inches and be horizontal, that is, the pistons moved sideways, not up and down.

As is often the case, the configuration of the engine was controlled by factors including weight, power and drag. While it can be argued that without a change in the frontal area, the difference in drag of an upright engine versus horizontal is minimal, especially given the total drag of all those wires and struts, the difference between success and failure is frequently separated by such small improvements.

Using their bicycle experiments as a basis, they calculated that a pilot in the prone position would cut drag by 50%. So if the pilot is prone, making the engine the same would be one less variable in the equation.

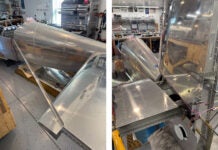

However, a look into their shop reveals another part of the equation: They had only a drill press and a lathe to build the entire engine. Micrometers and dial-indicating calipers were in the future; simple dividers and a good scale were all Charlie had at hand.

Home Machining at its Best

The lack of a milling machine meant that theyd have to figure out how to bore out the bore, so to speak, with a machine thats designed to spin the material, not the tooling. Lets consider that a little more carefully. Their lathe, as most lathes, was designed to have the material clamped to the head stock and spun while a rigidly mounted tool is moved by miniscule amounts into the material. So it seemed that the potential for machining this large block of aluminum was in the realm of getting chickens to fly. However, this was a farming community, and any farmer will tell you of the time he found the chickens roosting on a tree limb.

While there are lathes designed specifically for this style of cutting, they are usually about the size of a Winnebago and cost a bit more than the $250.85 they spent for a 14-inch Putnam. Of course, they also got a three-jaw and a four-jaw chuck and a set of riser blocks for that price.

The solution was to be found in the horizontal configuration of the engine. Those four widely spaced feet supporting the finished engine were ideal mounting points for the machining operations. A couple of steel bars were employed to span the distance between the feet and provide positions for bolting it all to the lathe cross-slide. That meant the cutting tool could now be spun by the head stock, so Charlie fabricated a long steel bar to accept not one, but two tool bits. The bit closest to the head stock would cut the bore to accept the cast-iron cylinder sleeve, and the farther bit would cut the combustion chamber. Depth was a simple matter of moving the entire block left-to-right as needed, but diameter of the bore was tougher. Charlie had to position the bits within their mounting bar without the aid of the fine control afforded by the crank on the cross-slide.

Once the bore for a cylinder had been cut, its bit was removed and a threading tool was inserted. This allowed the cylinder with its threaded base to be screwed into the block.

With the tooling removed, the cross-slide crank allowed the block to be moved to the next cylinder. Put the tooling back into the head stock, and they’re back in business. And, having mounted the block on the cross-slide, each cylinder stayed in a straight line.

Theory Versus Practice

This was a 14-inch lathe, meaning that it was 7 inches from the lathe bed to the center of rotation of the head and tail stocks. But the engine block was more than 7 inches from the feet to the center of the bore and, once mounted on those steel bars and placed on the cross-slide, the cylinders were well above the required line of the cutting tool.

The solution came about in a way that we cant do with todays lathes. Both the head and tail stocks were unbolted from the ways and placed on riser blocks. Long bolts were then used to clamp the stocks to the ways with the risers sandwiched in between. Shimming completed the height adjustment.

Before all this, though, there was one minor problem to be overcome. The Wrights lived on the wrong side of the river in Dayton where there was no electricity. Some years before, Wilbur and Orville had designed and built a one-cylinder engine that ran on natural gas. This engine spun a large flywheel with a leather belt that went up to a system of pulleys and shafts in the ceiling rafters, across the shop, and then down with more leather belts and pulleys to send power to the lathe and the drill press.

The good news is that the flexibility of those belts made it a simple project to power the lathe with the head stock no longer in its original position. It was up on the risers, remember? Once again, the attitude was, Don’t tell me I cant do it. Just hand me that wrench, will you?

Having thought through that problem, and while waiting for the casting, Charlie turned his attention to the easy part, the crankshaft, the first component to be built. He started with a 100-pound billet of tool steel 6x31x15/8 inches. He later recalled, I traced the outline on the slab, then drilled through with the drill press until I could knock out the surplus pieces with a hammer and a chisel. Then I put it in the lathe and turned it down to size and smoothness. It weighed 19 pounds, and she balanced up perfectly, too.

Turning those off-center crank-throws is where the four-jaw chuck comes into play. With a three-jaw chuck holding the end of the crank, the connection-rod journals will move just as they would in the engine. But in a four-jaw chuck, Charlie was able to move the end of the crank off center enough that the connection-rod journals spun on the centerline. Now those bearing surfaces could be cut while the crank ends moved in a circular path.

The pistons, along with the cylinder sleeves, were cast from iron in one of the foundries in the Dayton area. They were well made and, unlike the crankshaft, required comparatively little finishing work, which was done on the lathe.

The engines design, though, was an ongoing process. Orville, Wilbur and Charlie would toss around ideas, sketch something on a scrap of paper and then spike it on Charlies workbench. Unfortunately, none of the sketches survive. In fact, it was not until 1928 that the Kensington Museum in England produced a set of drawings of the 1903 engine.

When all the boring was done Charlie had four holes in the crankcase opposite the cylinders. Those were tapped and plugged with 15/16-inch pipe plugs and the excess was filed off.

The trio started by building what they called a skeleton model to ascertain that all the parts fit and didn’t interfere when in motion. Once they were sure that the sequences and distances were acceptable, they went on to build a fully assembled engine to run, using real gasoline-76 proof.

It was not completely successful. Fuel dripped onto the bar that controlled the exhaust cams, removing the lubrication, and the engine seized. How this came about might be a source of wonder to those of us who now take fuel injection for granted.

They used what is accurately named surface-carburetion. Gravity fed the fuel to a small valve stolen from a gas light. The valve then metered the fuel onto a hot plate where it vaporized and mixed with air. The intake valve was what we now call a poppet valve in that it had no cam mechanism to open it. It operated purely by the pressure differential caused by the descending piston. With this carburetor next to the intake valve it was only a short distance to get the charge into the cylinder.

By April of 1903 they received the new crankcase casting and started building the engine that would fly. This casting was the real departure from standard procedure-it was aluminum. It was not appreciated at the time, but it was later recognized as the first aluminum-block engine ever built.

The Value of Aluminum

Although aluminum is the third most common element on earth, its affinity for oxygen prevents it from occurring in a pure form. It was not until 1845 that enough was refined to be able to test its qualities. Its first practical use was expensive at $500/pound. Thats in 1850 dollars when $500 would buy a house. It was originally specified for the capstone of the Washington Monument, and Queen Victoria had a bar of it with the crown jewels of England. By 1852, the process was improved and the price dropped to $5/pound. By 1916 it was down to 14 cents. Still, in 1903 it was an exotic material with not nearly the properties we enjoy today. A great deal of the metallurgical practice bore more of a resemblance to alchemy than chemistry.

Nowadays we feel smug in thinking we’ve gotten the process of going from an idea to a working model down pat. Its called rapid prototyping and involves computer modeling, computer-driven machines, enormous budgets and highly trained engineers. Yet Wilbur, Orville and Charlie, with only a high school education, acquitted themselves admirably by anyones standard. The design of the engine commenced in late December 1902, and they had it finished and tested by the following June.

Fabrication of the finished flying engine was even faster. Charlie stated frequently that once the basic design was completed and the materials were in hand, it took only six weeks to build and bench-test the first engine. Final cost of the engine: $300. The entire 1903 Flyer: less than $1000. But thats 1903 dollars.

At What Cost?

Adjusting that based on Charlies first weekly paycheck of $16.50 gives a number to which todays builder can relate: $15,000 for the engine and $45,000 for the flying machine. It is amusing to consider that this ratio is not greatly off from today: one-third for the engine, two-thirds for the airframe. The panel was really the only place where they built on the cheap. Wilbur and Orvilles ears and eyes were the whole thing.

Like many of us today, they didn’t have room to assemble the entire airplane at the shop; that would have to wait until they got to the airport some 700 miles away at Kitty Hawk, North Carolina. They were, however, able to bench-run the engine. Charlie said they rigged up a resistance fan with blades an inch and a half wide and five feet two inches long. The boys figured out the horsepower by counting the revolutions per minute. For the first few seconds after starting, the engine ran at a calculated 1200 rpm giving 16 hp. Continuous power dropped to 1025 rpm and 12 hp.

On June 7, 1903, Orville wrote, Our motor on completion turned out to be a very pleasant surprise. Instead of the 8 horsepower, for which we had hoped but hardly expected, it has given us 13 horsepower on the brake, with a weight of only 150 pounds in the motor.

Given the method of calculation and the fact that these numbers are reminiscences of many years later, the slight disparity of 12 or 13 horsepower is understandable. Nonetheless, it was sufficient to allow them to add up to 150 pounds of strengthening to the airframe if needed. Sounding thoroughly modern, that extra horsepower was needed when they found that the takeoff weight, including the pilot, had ballooned to 750 pounds.

Charlie didn’t go with them to Kitty Hawk; he stayed in Dayton to run the bicycle shop. It turned out to be fortuitous to have him available to fabricate and ship new propeller shafts per the telegrams sent from the field.

After several weeks of field experiments they achieved that first success we know so well. But its vital to note that without the power of the engine that Charlie built, 1903 would have been another year of glider experiments.

Charlie went on to other firsts along with becoming the first airport manager. The boys started selling rides, and it was Charlies job to sell tickets, pick the direction of takeoff, and keep the runway clear. He was also chief mechanic for the first U.S. transcontinental flight of the Vin Fiz. Cal Rodgers, the pilot, made a good choice if for no other reason than his airplane was a Wright Flyer. But thats another story.

Thanks to Dr. Tom Crouch, Curator of the Wright exhibit at the Smithsonian Museum for his aid in researching this article; Richard Dilbeck, my FAA DE, for suggesting it and supplying most of the source material; and Charlie Taylor III, (Charlies great-grandson) for his time and family stories. Greg Cone and Ken Hyde of The Wright Experience (http://www.wrightexperience.com/), builders of the aircraft used in the centennial re-creation of the first flight, were a great help with engine issues and welcome visits if you’re near Washington, D.C. Most of all thanks to Howard DuFour for spending years researching Charlie Taylor. His biography, Charles E. Taylor-The Wright Brothers Mechanician, is out of print. If you can find a copy, you’ll be treated to a most engaging story of the birth of flight.