If we could magically transport a modern homebuilder back to the 1960s, they would probably be amazed at just how far we have come. In the early days of the homebuilt aircraft movement, most machines were designed to be built from wood or steel tube construction and covered with fabric. All-metal airplanes were almost nonexistent in the pantheon, and there were few sporting engines that claimed more than 100 horsepower. Continental ruled the roost with the small C-65 series—unless you were going all-in on the homebuilding thing and using an old Ford Model A engine to power your contraption. Needless to say, nothing went very fast!

If we could magically transport a modern homebuilder back to the 1960s, they would probably be amazed at just how far we have come. In the early days of the homebuilt aircraft movement, most machines were designed to be built from wood or steel tube construction and covered with fabric. All-metal airplanes were almost nonexistent in the pantheon, and there were few sporting engines that claimed more than 100 horsepower. Continental ruled the roost with the small C-65 series—unless you were going all-in on the homebuilding thing and using an old Ford Model A engine to power your contraption. Needless to say, nothing went very fast!

A Little History

One of the reasons dope and fabric over wood or steel tube was so popular was that everything had to be measured from plans, and the methodology of laying things out was not that much different from the model airplanes that most homebuilders had grown up with; stick and paper construction translated directly into tube and fabric. The technology of the modeler grew up into full-sized man-carrying aircraft—emphasis on the singular because many of them held only the pilot. These were truly built for “education and recreation” because you learned a lot by getting them to fly, and you couldn’t use them for much else other than flying around locally.

But technology always advances. Just as commercially built (or government designed and commercially built) aircraft went from tube and fabric to metal construction in the 1930s for the purposes of commerce and war-fighting, homebuilding followed suit with metal airplanes beginning to show up in significant numbers by the 1970s. These were still plans-built airplanes, built from sheets of aluminum you could buy flat and mold to your purposes. All holes had to be marked out and drilled by the builder—there were no shortcuts and no one to do the work for you.

Most parts in these airplanes were built with single curves; you formed conic sections and didn’t have to deal with compound curves, which was good, because not many homebuilders had experience with English wheels to form the more complex parts. For those designs that did require such metal work, designers started to supply preformed parts to match their drawings, and the kit industry began.

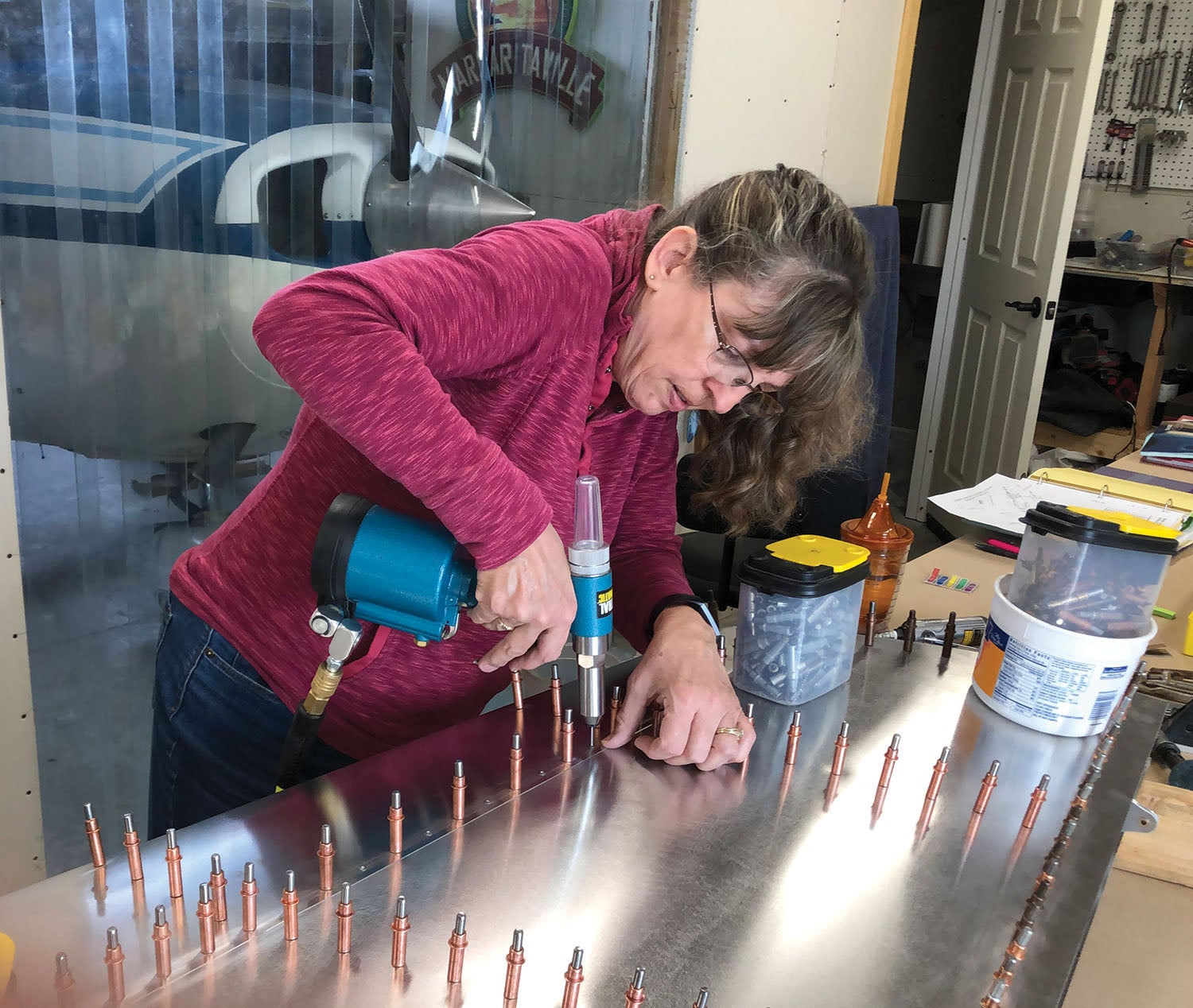

Metal airplane kits have gone from a stack of uncut sheet metal and a bunch of drawings to carefully packaged finished parts that simply need to be Clecoed together and riveted. Along the way, we went from no holes, to some (pilot) holes being prepunched in flat sheet parts, to adding holes in parts such as ribs, to the point where virtually all holes were prepunched as pilot holes. The next step came just a few years ago when those prepunched, matched holes started being delivered as final sized holes—no drilling required. Just Cleco the parts together and start pulling Clecoes to be replaced directly with rivets.

This revolution has come about due, of course, to the advent of computer design and manufacturing. Computer design tools have reached the point where individuals have the capability to design complex parts in three dimensions and locate holes in every single part that match every other part. Just to bring you up to speed on terminology, “prepunched” means that the holes exist in the right locations, probably as pilot holes for silver Clecoes. You’ll have to use those holes to drill holes in the matching parts, like drilling skins to ribs. “Matched hole” means that all the holes are punched precisely in the correct spots in parts that join—so you can Cleco the ribs directly to the skins as they come out of the box. “Final sized matched hole” means that you put in final sized Clecoes to hold the parts together.

As we said, all of this is possible because the designer laid out the parts and holes on the computer, and then that information was transferred directly to the big machines that cut and punch holes in the sheet metal to final sizes. If you have ever fabricated parts from flat sheet and bent them to final shape, you are probably aware that it doesn’t take much error in a bend radius to make the holes end up slightly off from where you thought they’d be. This is all taken care of in the design programs of today. Frankly, to anyone that has built an early kit—it’s the next closest thing to magic.

So where does it go from here? How much easier can the kits be made for the assembler (a term that is more and more being used instead of “builder” although it is somewhat derogatory)? Well, in the latest kits I have built, there is still some fabrication work to be done by the builder of record when it comes to brackets and clips: making parts out of aluminum angle, cutting them to length and shape, and match drilling holes to the sheet metal. More and more of these parts are coming roughly shaped—or in final shape—with pilot holes drilled by laser. I expect that the age of getting a long piece of aluminum angle that is to be made into many short pieces in a kit is rapidly going away.

But how about going further? Quickbuild fuselages and wings have paved the way for kit companies delivering largely finished structures—can’t they do more? Well, technically of course, they could just sell you an airplane ready for fuel. What’s stopping them from going that course isn’t technology—it’s the rules.

The Rules

The drive to make kits more complete will always run into the FAA’s 51% rule, which requires that the major portion of fabrication and assembly of an E/A-B registered aircraft must be performed for the “education and recreation” of the builder. As actually administrated, this has been broken down into a list of approximately 180 tasks that go into building an airplane—things like installing wing skins or fabricating ribs. A kit is evaluated task by task, and each task is assigned either to the builder or to the factory. The builder’s side of the ledger must come out greater than the factory side in order to merit Amateur-Built certification. Otherwise, the airplane will have to be licensed with more restrictions in the Exhibition category.

So as kit companies try to make their kits more complete, they continually run into this 51% barrier. There have been some very creative interpretations of this rule in recent years by some manufacturers, particularly when it comes to builder assistance. The traditional way of making a building assistance center work is to have the builder come in to install one wing rib, with the assistance (assistance is always allowed) of an expert, and then the assist center does all the rest. All of the ribs are fabricated in advance, but the builder gets credit for rib installation.

Another manufacturer turned this on its head by having the builder come in to the factory to “fabricate” almost all the parts for their kit. The parts all go into a storage bin, and the “builder” goes home while the manufacturer’s people assemble the parts into an airplane. The builder comes back to hang the wings and do a few additional tasks to fill out their 51%. The kicker is that many of the parts that they fabricate are actually CNC machined, so the builder is really just kicking off automated processes. It’s legal and it gets a person an airplane that meets E/A-B requirements…albeit for an increased price tag!

What Do We Really Want?

The Experimental/Amateur-Built category grew out of people’s desire to create their own flying machines. In my experience, there are two major reasons for this desire: One is the simple challenge of making, with your own two hands, a machine that flies. The other is to save money. Certified aircraft are expensive to buy and maintain, and rolling your own has always been the cheap way to go.

But as technology makes things more and more complete, these two driving forces are directly affected. In the first case, the challenge of growing your own Sitka Spruce from a seed in order to create the lumber for your wooden spar is diminished when all you have to do is take the wrapper off a finished spar. And as the kit companies do more and more of the work for you, they have to raise the amount that they charge for the kit, so the affordability of homebuilt aircraft goes down. Anecdotally, when I started my first RV-8 kit, the anticipated cost of completion for most RV builders was in the $50,000–$70,000 range. Today, 15 years later, that expected number has almost doubled. So much for building on the cheap.

We have to admit that today we have a new breed of builder—someone accustomed to what technology has done to make life easier. They didn’t grow up as farm kids, used to building what they needed out of scrap materials. They want convenience and are willing to pay for it. In the old days, a certified airplane would outperform and have more capabilities than anything a homebuilder could craft. Today, we see just the opposite—there are homebuilts with better performance and far more capability when it comes to avionics than you’ll find in any certified airplane.

The RV-8 can carry two people at 175 knots for 800 miles and can be equipped easily with redundant avionics for excellent IFR capability. And it can fly a nice aerobatic routine when the weather clears. Find a certified airplane that can do that for the same cost. On the other end of the spectrum, most of the airplanes that are used in STOL competitions would spin heads in the certified world, their configurations being extreme in many respects. The bottom line is that if you want cutting-edge performance today, you pretty much have to go E/A-B.

The Techno Bottom Line

There is no reason technologically that manufacturers can’t deliver far more finished kits and do so at a cost-efficient price—if the rules allowed more to be done for the builder. And there are rumors of working groups within the FAA that are looking at revised rules for new aircraft categories that could allow more custom building of aircraft by manufacturers. Many modern builders don’t actually care that much if they build or not; they really want the capabilities of a modern homebuilt and are happy to let someone else supply the labor.

But that all depends on the politics of the day and is outside the scope of what is simply technologically possible. And while I have been referring mostly to metal aircraft here, it is important to acknowledge that technology has advanced in the areas of composites—and the fabrication of composite parts—as well. Composite homebuilts used to start with a pile of foam, some spools of cloth, and a few cans of chemicals. Now you are more likely to take delivery of what looks like a completed fuselage and a set of apparently finished wings—sort of like a giant plastic model airplane kit of old. Don’t be fooled; there’s still a lot of work to be done!

The ability to make parts more precisely makes things fit together better—even if it is simply that the manufacturer makes some scribe lines and a few prepunched pilot holes to better locate adjoining parts. The more repeatable the parts are, the easier it is to build, and the more people will be tempted into the building arena. The task of shaping a piece of Plexiglas into a finished canopy is considerably easier when the factory has interchangeable parts and scribes cut lines that guarantee a good fit every time—far better than the cut, fit, cut, fit of old days.

So long as manufacturers can be clever and stay within the rules, making things more repeatable will save assembly time, and that will attract people with more going on in their lives—like most people in today’s fast paced world. Old timers might look down their noses at someone who can “build” their airplane in less than half the time it used to take, but anything that gets more people into the air to enjoy the freedom of flight is, in my opinion, a good thing.

Photos: Larry Larson, Louise Hose, Paul Dye, Mike Starkey.

Great article, Paul. I always enjoy reading them here, as well as your contributions to Vansairforce, which brings me to my comment. One aspect left out that I think already plays a big role, but will play an even greater role in the future, is the online community and body of knowledge that surrounds today’s builder. I don’t have the detailed history, but my sense is that we’ve gone from the capable builder with existing “shop skills”, supplemented with perhaps a nearby EAA chapter and fellow builder to call, to the now amazing world of online forums and content. It’s hard to build an RV today and ask a build related question on Vansairforce that hasn’t already been thoroughly answered and documented on that site.

And now we’re seeing the next evolution using platforms like Youtube, where manufacturers like TAF Sling are showing section by section how to build a Sling TSi. When you combine digital plans, video tutorials, online forums/communities, video streaming, etc. with what you described (completeness of today’s kits, appeal of their performance), this provides a tremendous amount of interest and confidence for the future first-time builder like me.

The old adage still applies.. “90% done, 90% to go”

I think ‘m down to 89%

What a great learning experience!

Paul,

Regarding the cost of building – you’ve noted that one could expect to pay about double what it cost about 15 years ago. While I empathize with the feeling, the fact is that virtually everything has doubled in price over the last 15 years – including wages. So, in terms of relative ‘cost’ its all about the same. That aside, I am pleased with the higher level of refinement of the kits for the money – and, that the sheer number of kits being completed has lead to a collective knowledge base that makes it easier on the builder to find guidance and inspiration. After having built an Avid Flyer and Challenger, and owning an RV7 for many years, I just recently finished an RV14. The level of refinement on the kit was amazing, and the final product equally impressive in its functionality and performance. I think the bang for the buck in experimentals has never been better.

Thanks for the great articles you write – I always enjoy reading them.