So about welding…

I have spent 50 years working on airplanes of all types and materials—from tube and rag to metal plus a bit of composite. I have learned all sorts of fabrication and assembly skills. But one thing I have missed out on (probably because I took calculus instead of shop in high school) is welding. I have always admired those who could weld and love to see fine weld work. As a senior engineer in complex space programs, we talked about devices and components that had been welded, and evaluated their readiness for flight—but I had never really done it myself. With a bit of slack time between major airplane projects, I figured it was finally time to give it a try. (The fact that my wonderful wife gave me a welding helmet for Christmas probably gave me a clue that it was OK to explore a new skill as well.)

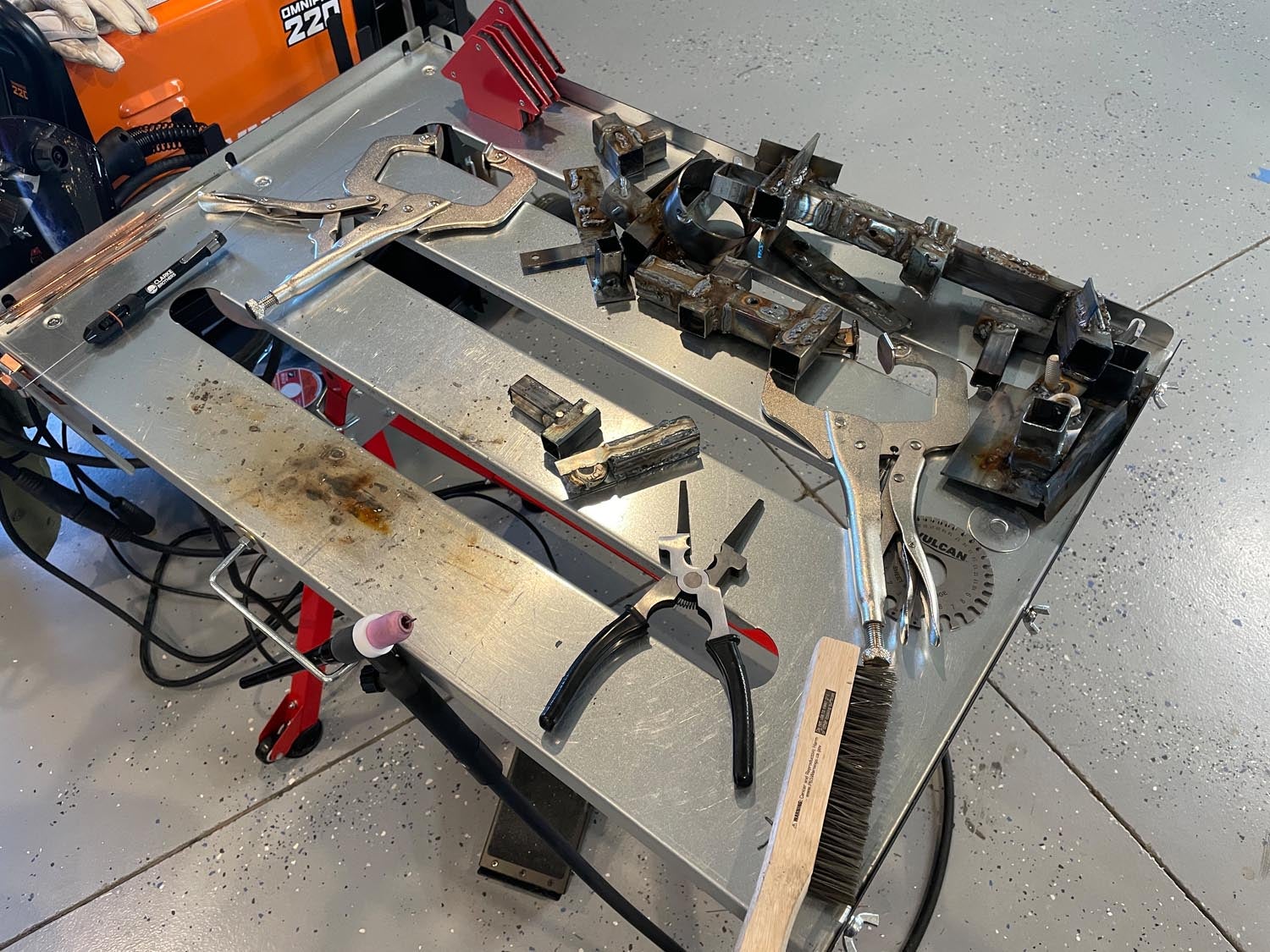

There are lots of different types of welding and the truth is that this is more of a sampler endeavor for me than something I am going to use in my routine airplane work. If I build a ragwing, I’ll most likely have someone else weld up the fuselage. Aluminum airplanes require precious little welding—and what there is (exhaust systems for instance) requires considerably more skill than I am probably going to develop. But there are reasons to weld around the shop—making tools, brackets, storage and fixtures, for instance. Owning my own hangar has me looking around at things that I could make, such as tie-down fixtures and workbenches. So forget the gas welding—I bought a multi-purpose unit that does stick, TIG and MIG.

Finding welding classes in a world where there are shortages of skilled welders is problematic—all the classes are full of folks wanting to get a job, so dilettantes aren’t welcome. But many of my neighbors are skilled at welding and they were happy to show me the basics, then turn me loose on scrap piles of steel to see what I could do. So far, I have pasted together a lot of scraps, cut them apart, and tacked them back together again.

So far, TIG seems to be winning out over MIG for the kind of work I need to do—mostly building small tools—but it’s nice to know I can stick bigger pieces together (like shelves or machine bases) when I need to.

So, no, welding isn’t an essential skill for the homebuilder. But it sure can come in handy—and if you’ve got slack time in the shop, it’s worth the time for “education and recreation.”