Nearly every aircraft utilizes metal cables to operate control surfaces like elevators, rudders and ailerons. As a builder, you may be required to fabricate these cables by attaching fittings to each end. The sleeve is the component that is responsible for a secure, permanent connection when properly swaged onto the cable. When reviewing kit aircraft, have you noticed these sleeves come in two colors? Are there any differences between these, and does it matter?

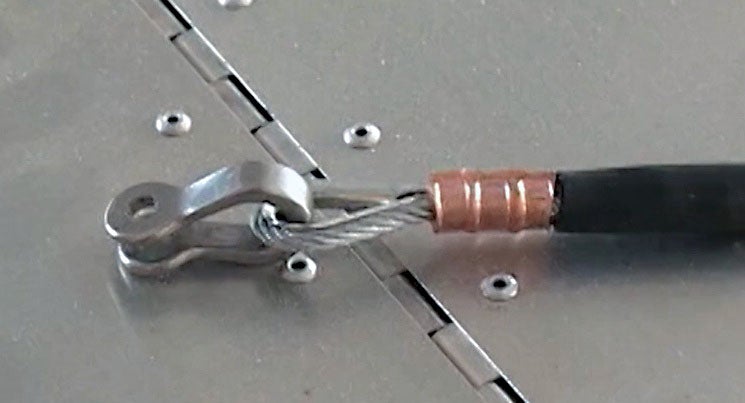

There are silver- and copper-colored sleeves that are used when forming the critical ends of aircraft control cables. These are the sleeves that get swaged (crimped) onto the stainless steel or galvanized steel cables that transfer movement to flight control surfaces. The choice of sleeves for making these cable ends is critical as any slippage of these parts can lead to loss of control. The question is simple: How do you choose the right sleeve for your cable? At first glance it appears you have two choices: the copper- or silver-colored sleeve.

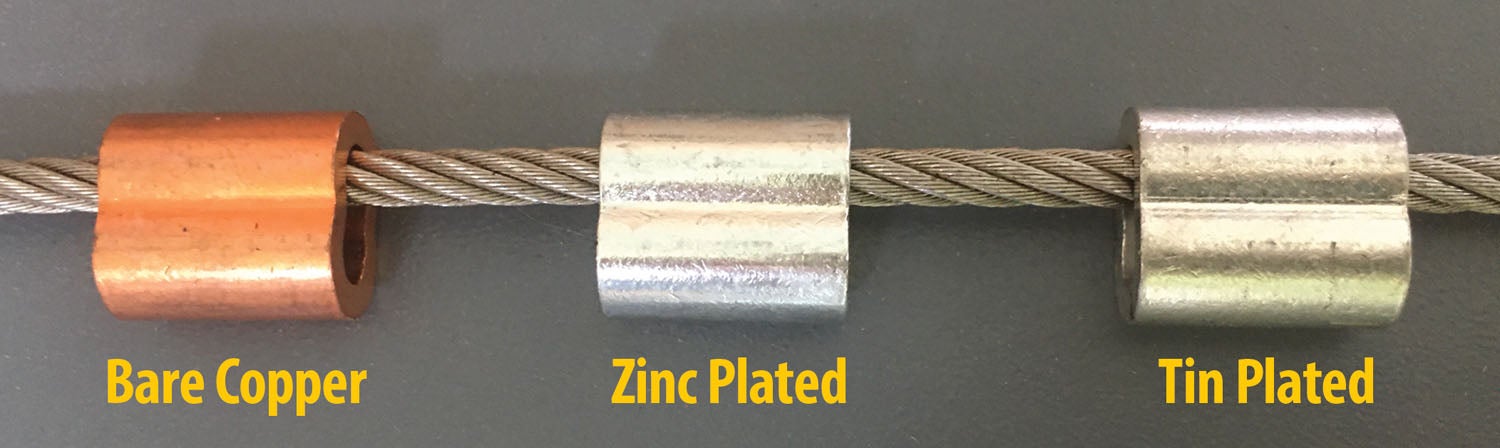

Looking at the photos, we see that there are actually three types of sleeves available at your local aircraft supply house. Do not confuse these with similar looking components found at hardware stores, industrial supply houses or Amazon as those are used for all sorts of applications other than aircraft! In fact, we are going to limit our discussion here to Nicopress brand products—a brand that we are familiar with. The company has documents on their website, www.nicopress.com, that direct the selection and use of their products.

The three Nicopress choices include bare copper, zinc plated and tin plated. (Note that you cannot tell the zinc from the tin very easily!) The first interesting fact is that all three are made of copper alloys. The tin and zinc get their color from the plating applied. The second important detail is that you need to know whether your cable is made from galvanized steel or stainless steel. This will determine which sleeves are to be used.

For galvanized cable there are two choices of sleeves: bare copper and zinc plated. Both are equally suitable for the job. The difference between the two? Cosmetic! Zinc may mask copper discoloration from outdoor elements—but that’s about it. Remember, the copper alloy that the sleeves are made from is the same in both types. There is no difference in holding strength or durability.

For stainless steel cable there is essentially one choice of sleeve: tin plated. This sleeve has a slightly different formulation of copper alloy and is covered with a tin coating. (There is a stainless steel sleeve that can be used with stainless steel cable, but that sleeve requires a special swaging tool, so we will not consider it in this discussion.) Note that it is difficult to tell tin and zinc sleeves apart, so keep them separated and labeled if stocking both.

These are the only choices for sleeves from Nicopress for your aircraft. If you visit their website, you’ll find data sheets that support these details along with other installation information. When you visit the online catalogs of legitimate aircraft parts suppliers, you will find the descriptions of these sleeves listed as bare copper, zinc plated and tin plated. With this basic knowledge you can rest assured that your cables are using the proper components for a secure hold on all things that need to be controlled. Plane and Simple!