A few years ago, the S-20 Raven made its debut with fabric wings and a Rotax 912 ULS engine (see KITPLANES July 2014 issue), setting a new standard for performance, handling, and ease of construction for RANS. Not content with leaving things well enough alone, RANS now offers the S-20 with metal wings and the option of a factory-supported 180-hp engine.

The airplane I flew for this review was an S-20LSM, a factory-built Special Light Sport Aircraft. The kit version of the same plane is called an S-20 with metal wings or an S-20 with 141 wings. (Wing area is 141 square feet for metal wings versus 153 square feet for fabric wings.) The plane was equipped with the optional 180-hp Titan (Continental) IO-340 engine. I also flew the new S-21 Outbound, but that article will not appear for a few more months.

The changes to the S-20 are not dramatic, but they are significant. Perhaps the most noticeable impact to builders will be the shortened build time made possible by RANS’ new metal wings. Randy Schlitter, owner of RANS Designs, says that his shop technician built his first set of new metal wings in 50 hours. That is for both wings, in case the word “set” slipped by you. With the original fabric-covered wings, a builder could easily spend that much time just covering the wings, without counting any time for assembling the internal structure.

RANS has put a functional and inexpensive panel in their factory S-20 with 141 wings. The choice of avionics is up to the customer and can greatly affect the price. This panel shows that you don’t need to spend a fortune to get around, at least VFR.

How Does It Fly?

As I alluded to in the review of the original S-20, there isn’t much point in building an airplane if it doesn’t fly well. Certainly, the S-20 with fabric wings flies well, and let me assure you those good flying qualities can also be found in the metal-winged version. There are minor differences to be sure. With the reduced wing area (153 vs. 141 square feet) you will see slightly higher stall speeds, both clean and with full flaps, but they are still on the low side. Less wing area and more weight simply means longer takeoff and landing rolls, and higher stall speeds. There just isn’t any way to beat the physics involved. The larger engine option erases half the difference in takeoff roll, but it can’t do much about the landing distance, which is again a factor of weight and wing loading. However, let’s keep in mind that the new numbers are still pretty impressive.

Flying over Kansas farmland was the perfect place to test the S-20 with metal wings. Clear skies, plenty of places to land, and no traffic was a welcome change from the congestion I’m used to in Southern California.

It is also worth noting that the Titan-engined S-20LSM as tested had been fitted with a Catto cruise prop (76×60). Less pitch certainly would improve takeoff and climb performance, but admittedly at the expense of cruise speed. A ground-adjustable prop might provide a good option for the owner who wants good cruise performance to the backcountry and then could switch to maximum takeoff performance once there. In most cases, builders will be satisfied with the metal-wing S-20’s short-field performance and will not be anxious to give away the 126-knot cruise speed. Honestly, takeoff and landing rolls of less than 400 feet are going to get you in and out of just about any place an airplane can safely go.

As with the original S-20, flight controls are light and responsive, yet the plane is also quite stable, making it possible to fly hands and feet off the controls for a long time in smooth air. Unfortunately, we did not encounter any significant turbulence (can you imagine saying that?) during the test to see if that stability remained in unstable air. Stalls are a non-event if entered in a coordinated configuration and are easily recoverable if not.

If you are coming out of a less responsive airplane such as a Cessna 172 or Cherokee, you will have to dial back the muscle a bit to get in sync with the lighter control forces, but it shouldn’t take too long to make the adjustment. The bigger problem is that after you have flown the S-20 for a while, you won’t want to go back to the 172.

The S-20 with metal wings and a Titan engine is an impressive-looking plane with its 26-inch Bushwheels and Catto prop. Easy assembly and great backcountry performance should make this a popular kit.

Tailwheel handling was benign, with landings coming easily and visibility decent over the nose, even without S-turns. At my height of 6 feet 3, that may come easier to me than to shorter people, but the seats do rise as they come forward. Big tires that necessarily raise the nose will naturally decrease forward visibility. For those who wish, the S-20 in all versions is available as a trike, too. Please note, however, that the trike and taildragger use different main gear legs, so going back and forth will involve some extra cost for a second set of gear legs.

As with the rag-wing S-20, this plane likes a bit of rudder in the turns, but nothing unusual. The larger engine produced more yaw, as expected, requiring more rudder on takeoff and climb, but nothing that would raise any objection from most pilots. It was only the side-by-side comparison that made the difference noticeable.

Bottom line: This plane in either form flies well and does what you would expect it to do when you want it to. It does not throw you any surprises along the way. That is what I call a nice-flying airplane. I would expect nothing less from RANS.

This RANS 141 wing is assembled except for the skins. The ribs attach to the forward and aft spars with pull rivets, making assembly a snap. A parts board is in the background. This can be a good way to keep track of parts during assembly of your project.

Metal Wings

The idea of putting metal wings on the S-20 was obviously an outgrowth of the S-21 design process, that plane being all-metal construction. With the development of that new wing, it became apparent that the same wings could be substituted for the fabric-covered S-20 wings with only a slight change in performance and a big reduction in build time. As an added bonus, there was an improvement of 3 knots in cruise speed using the same Rotax engine. The metal wings do add some weight, but that will be less important with the likely coming increase in gross weight for Light Sport Aircraft.

As an interesting aside, during testing of the metal wings, airflow around the struts induced vibration in certain situations. Jury struts were considered but rejected when the problem succumbed to the addition of a strip of anti-skid tape to the bottom of each strut. It was just enough to change the airflow and dampen the vibrations. Eventually, the struts may not need tape. RANS will soon be testing a slightly reshaped strut that should eliminate the problem.

Here is a cross section of the forward spar. This is an extrusion that eliminates the need for nose skins and nose ribs, greatly simplifying the building process. Notice the notch in the top edge where the top skin slips into place.

The rapid build time for the new metal wings comes from the ingenious design of the main (forward) spar. It is a D-shaped extrusion that eliminates the need for nose ribs or any separate nose skins. It is shaped to take flat skins top and bottom that can simply be riveted in place with pull rivets. The rear spar is similarly designed to take the skins into preformed notches where they can again be secured with pull rivets. There are still ribs in the main body of the wings, but there are no cove skins or cove ribs to contend with on the aft portion. Position the forward and aft spars with the ribs that are also pull riveted in place, and then secure the top and bottom skins into preformed notches. I’m not sure how much simpler it could be.

Once you see how easy it is to put these wings together, you can see how a pair of them could be built in three or four weekends. That’s what you call quickbuild wings. Good luck finding another kit that can match that.

The Continental Titan engine is essentially a stroked Lycoming IO-320 with some other modifications to improve performance and reduce weight. Cruise speed is 126 knots and rate of climb is 1600 feet per minute. With a Rotax 912 ULS, cruise speed is 100 knots and rate of climb is 850 feet per minute.

The Kit

The basic kit for the S-20 Raven can be purchased either with the traditional fabric-covered wings or the new metal wings. Metal wings add $1,700 to the price, resulting in a total basic kit cost of $34,200. An engine kit for the Rotax will add another $7,000, and the Titan engine installation kit comes in at $12,500. A Catto prop is included in the Titan package, but a WhirlWind ground-adjustable prop and spinner will add another $2,230 to the cost of the Rotax package. Trike and taildragger gear are both available, but they are not interchangeable, the trike gear legs being shorter.

A fixed Catto prop pulls the Titan-engined S-20 through the air quite nicely without the complexity of a constant-speed prop.

The two engine options supported by RANS include the 100-hp Rotax 912 ULS at $19,701 and the 180-hp fuel injected Titan IOX-340-B4E3T4 engine at $30,571. These prices were in effect as we went to press in late 2018, but engine prices constantly change, so contact RANS for current pricing.

The Rotax has been around for a long time and should be familiar to most builders. It is smooth, reliable, and easy on fuel. It is, however, partial to auto gas, with shorter maintenance intervals for those engines that run mostly on avgas. Rotax maintenance is different than maintenance for Lycoming or similar engines and demands special training, special oils, and special tools, all of which are readily available. RANS does not officially support the fuel injected 912 iS engine at this time, but they are installing the 915 iS turbo engine on several ready-to-fly planes and will offer a fully supported install kit.

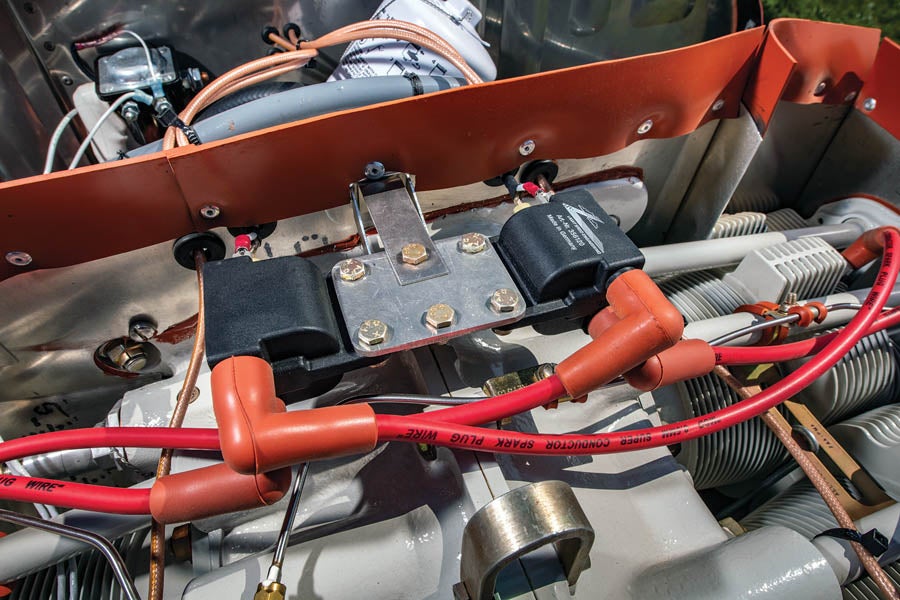

Dual Lightspeed ignition systems replace the typical Slick magnetos on the Titan IO-340 engine. Needless to say, a backup battery is a vital component of this system. Using pickups on the ring gear carrier allows Continental Titan to completely eliminate the magneto drives from the accessory case.

The Titan IOX-340 engine is essentially a stroked IO-320 Lycoming-type engine, but with a number of modifications to increase power and reduce weight. Many of these changes were pioneered by CubCrafters as it worked to strip weight out of its Carbon Cub line of planes. To be sure, the engine offered by RANS is not the same as the Carbon Cub CC340 engine, but the kinship is obvious. The substitution of traditional Slick magnetos with dual Light Speed ignitions is pretty easy to spot, but what may escape the casual glance is the magnesium accessory housing with no provisions or drive gears for magnetos, prop governor, or vacuum pump. This saves a lot of weight. With the track record of its major components now well established, this engine should become a popular choice.

The rest of the kit is identical to the original S-20 kit. The fuselage is a metal tube structure covered with fabric. The metal wings greatly reduce fabric work, but to escape it entirely, a builder will have to switch to the all-metal S-21. I for one enjoy fabric work, so I would need some other reason to pass on the S-20, but tastes vary. Just keep in mind that just because fabric work is different doesn’t mean it’s hard. Fabric systems include the standard Superflite system or the optional Oratex system. Oratex costs more but offers the advantage of not needing priming or paint, thus saving a lot of time for the builder. It also saves weight. The disadvantage of Oratex is that you can’t really duplicate the glossy look of a nice paint job without painting it.

Strips of anti-skid tape on the underside of the struts are used to tame vibrations that turned up during flight testing of the 141 wing. Eventually, the struts may not need tape. RANS will soon be testing a slightly reshaped strut that should solve the problem.

There are two firewall forward packages available, depending on whether you want a Titan engine or a Rotax engine. The Titan kit should work with similar Lycoming or Superior engines, but you may be a need to do some customizing to make all the little things work. The Rotax kit is designed to work with the 912 ULS.

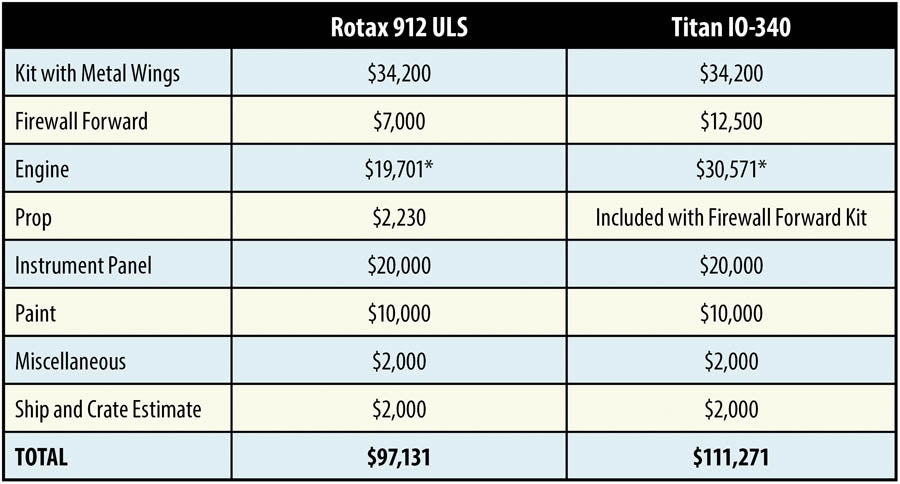

Typical construction costs are shown in Table 2. Needless to say, these costs can vary depending on how you decide to equip your panel, whether or not you decide to paint your plane yourself, and other factors. The good news is that the kit is fairly complete, so you won’t get sucked into a project that ends up costing you a lot more than you budgeted because of items that were not included.

Big Flaps and plenty of deflection provide the lift and drag needed to make a steep approach into a short airstrip. Flaps are activated with Teleflex cables similar to the steering cables found on many boats with outboard motors. This is another feature that greatly simplifies construction.

Going with a used engine could also produce some big cost savings but entails a certain amount of risk. Painting the plane yourself could also save several thousand dollars. A frugal builder could likely get the S-20 Rotax down to $75,000 or maybe a bit less. An equally careful builder could build the same plane with, say, a used Lycoming O-320 for perhaps just a few thousand more. On the other hand, a nice custom paint job and a fancy IFR panel could add another $10-20,000 to the price listed below.

A $9,950 quickbuild option is also available. If going with 141 wings, the wings are prebuilt and the fuselage, tail group, and doors are built and covered. Time savings is about 300 hours. If going with fabric wings, the wings, fuselage, tail group, and doors are built and covered, and the build time is cut in half.

For builders who want extra power and the better rate of climb and cruise speeds that come with it, the Titan S-20 will be hard to beat. It has the added benefit to some of being a more familiar engine type than the Rotax. On the other hand, the Rotax is very smooth, less expensive, and gives away less in the performance department than you might think. Either way, it is hard to go wrong.

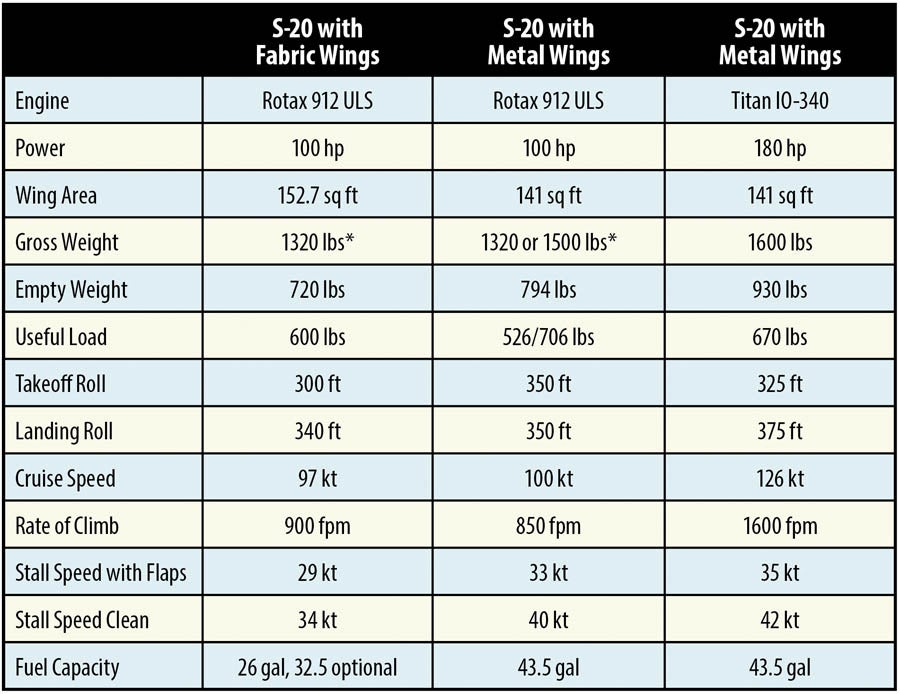

S-20 Raven Specifications

*Gross weight limited by current LSA rules to 1320 pounds.

Table 1: The S-20 Raven is available in multiple configurations. Performance varies depending on engine and wing selection.

Builder Support

The S-20 kits are on the approved National Kit Evaluation Team (NKET) list with the FAA, so if you do not use commercial assistance, you will have no problem maintaining the plane’s majority amateur-built status. The assembly manual is all online now, with no paper copy available unless you print it for yourself. This allows RANS to update everyone’s instructions immediately, rather than depend on mail distribution for that. They also post useful information regularly on the RANS Clan forum (www.ransclan.com). Forum members can often help builders sort out construction problems quickly without going to the factory support line. For those who need it, the factory offers telephone support every weekday afternoon from 2 to 4 p.m.

Lightweight, adjustable seats slide up as they move forward to improve visibility for different sized pilots. Behind these seats is a very large baggage compartment that will hold lots of camping gear for your next adventure.

In addition to offering ready-to-fly SLSA versions of the S-20, RANS also offers an ELSA option for customers in the U.S. The additional cost is $1,000 and includes a pilot operating handbook, maintenance manual, and letter of authorization (LOA). Before ordering, make sure you fully understand the difference between E/A-B and ELSA.

Typical Construction Costs

*Engine prices were in effect as we went to press in late 2018. Contact RANS for current prices. Table 2: Cost comparison for an S-20 Raven with a 100-hp Rotax 912 ULS or 180-hp Titan IO-340.

If you are looking for a 2-place utility airplane that is easy to build and fun to fly, the RANS S-20 in any of its versions is worth a hard look. It will also make a good trainer if you or someone you care about wants to learn to fly. For more information call RANS at 785-625-6346 or visit www.rans.com.