It’s hard to deny that rubber hose is still a popular choice for many homebuilt fuel systems. It is relatively inexpensive and very easy to install. Compared to other options such as rigid aluminum tubing, it has one major shortcoming: It has limited life and cannot be considered a permanent part of the airframe. All rubber hose must be carefully inspected and replaced periodically. Only the best hose available should be installed in your aircraft so that you get the longest life between replacement intervals.

Rubber hose that can be used for aircraft fuel lines is not created equal. Your local auto parts store will usually carry both the best and worst quality of rubber hose in their inventory. They stock this variety because they’re supplying replacement hose for high-tech automotive applications as well as lawn mower engine repairs. It is up to us homebuilders to understand and identify the best hose products. All quality rubber hose will have markings that repeat along the outside. We simply need to understand these identifications to determine if we are getting the good stuff. If the hose has no markings—do not use it—there is no way to know what you are getting!

There are at least two characteristics of rubber hose that really make a difference for our aircraft: pressure rating and permeability. Pressure rating is easy to understand. If you have a carbureted engine, the typical maximum fuel pressure may be just a few psi inside the fuel line. However, a fuel-injected engine requires much higher fuel pressure—50 psi or more. You need to equip your aircraft with hose that can reliably handle the fuel pressure demands.

Permeability is the ability of the fuel to bleed through the walls of the rubber hose into the atmosphere. Yes, actually quite a bit (gallons) of fuel is continually lost from the walls of rubber fuel lines and escapes as vapor into the air as a function of time. This is a big deal for several reasons. First, no one wants to throw away good fuel. Second, the environment really pays for that entirely polluting vapor. And third, as fuel bleeds through the walls of the hose it breaks down the rubber compounds. This is the reason the hose deteriorates. So it follows that if we can reduce permeability we will save money in lost fuel, save the environment big-time and best of all: Make the hose last a long time! Most modern hoses have been formulated to possess this trait of low permeability, but some of the less expensive versions (lawn-mower grade) are still very popular. You can recognize deteriorated fuel line as it becomes stiff and starts cracking when flexed. Nobody wants to replace hose any more often than necessary.

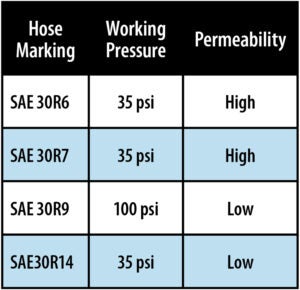

Is the pressure rating and permeability of a hose listed on its jacket? Usually not! Instead, a numbering system is in place that provides this same information. In the U.S. an industry standard group (SAE J30) has created a number of rubber hose standards that manufacturers utilize when making hose. These standards are documented and published so everyone can determine what pressure ratings, permeability, compatible fuels and other characteristics are assigned to a specific hose type. Those standard hose types are often printed on the outer covering of the rubber hose stock at the auto parts store. The last piece of the puzzle is to be aware of the popular standard hose types that are applicable for use as fuel lines in our aircraft.

The standards and ratings shown are very approximate and not all inclusive. Hose diameter and other factors will alter the pressure limits. Double-check and verify these specifications by using Google (e.g., “SAE 30R9 specs”) to view the standards from official documents and vendors online.

Another option for labeling rubber hose is shown in the top sample hose in the photo. Here, the manufacturer has chosen to supply their brand name and part number with no mention of an SAE standard. By Googling their website information (Parker 39706 Superflex) we find all of the specifications for this hose. This is necessary when the hose exceeds or falls between defined industry standards.

There is a popular European standard (DIN 73379) for hose construction with these markings:

- DIN 73379 2B, which is nearly similar to SAE 30R7 (low pressure) and

- DIN 73379 3D and DIN 73379 3E, which are nearly similar to SAE 30R9 (high pressure).

One idea to take away from this entire discussion is to avoid hose marked with SAE 30R6 and SAE 30R7 because of their high permeability and resultant short life. This is the lawn mower hose and will require more frequent inspection and replacement intervals than the others.

The next time you purchase rubber hose for your fuel system, be ready to demand and identify the “good stuff” from your auto parts dealer or online store. Make that hose last as long as possible!

Excellent article – many thanks Jon!

If a builder goes through all the trouble and expenditure associated with building an aircraft which – presumably – he himself wants to fly, it would be a mistake to skimp on fuel hoses. Why not use the best available, which is not rubber or nylon, but teflon (PTFE). Aeroquip 666/667 hose is made to hold up to any type of fuel one would think of using in an aircraft, and is a much better choice than any rubber hose.

If the builder intends to use MOGAS, it can be done quite safely, especially if 666 hoses are used, and seals and other flexible parts of the fuel system are made from eg. Viton™ fluoropolymer elastomer.

The Parker Super-Flex hose depicted contains a fluoroplastic inner liner. This is what makes it a low permeation hose construction. I believe the cover is CPE (chlorinated polyethylene) and is both fuel resistant as well as ozone resistant. You get many of the benefits of PTFE without all the cost. Braiding adds burst strength and resistance to fatigue failures. It’s a very good hose and what I use on my aircraft.

Does fuel hose pressure rating take into account “fatigue ” created by a regular pulsating pressure as may be found in injection systems. It seems that the pressure ratings are for static pressure only.