If you’re looking for a good, efficient way to get oxygen into your system above 10,000 feet (legally, it comes into play at 12,500 and 14,000 feet, but many find it really sharpens you up and reduces fatigue above 10,000), the best way to do it is to buy a portable or installed modern system designed for general aviation use, and fly along with good blood oxygen using a nasal cannula. Yeah, they look funny, and after a while, your nose will itch—but they work, they’re efficient, and you can even build up a DIY version for less money that works fine too. After all, we’re homebuilders!

If you’re looking for a good, efficient way to get oxygen into your system above 10,000 feet (legally, it comes into play at 12,500 and 14,000 feet, but many find it really sharpens you up and reduces fatigue above 10,000), the best way to do it is to buy a portable or installed modern system designed for general aviation use, and fly along with good blood oxygen using a nasal cannula. Yeah, they look funny, and after a while, your nose will itch—but they work, they’re efficient, and you can even build up a DIY version for less money that works fine too. After all, we’re homebuilders!

But being a homebuilder means that you already are predisposed to be different, and many are former military pilots that remember looking like Maverick and sounding like Darth Vader. For them, that little cannula just doesn’t cut it—and it looks kind of silly too. Despite what common sense and engineering data say, using a military mask and helmet is cool and, frankly, a lot of what homebuilders decide to do is based on what might be cool.

But yes, there are legitimate reasons for using a military mask and helmet for some operations. First, cannulas are not intended for use at cabin altitudes above 18,000 feet. Very few homebuilders operate regularly in the flight levels, and homebuilts that do are usually equipped with pressurization and built in O2 systems, just in case. But some like to see how high their airplanes will go (I can tell you for sure that an RV-3 with an IO-320 and constant-speed prop is still climbing at FL230, and my RV-8 with an O-360 was logged in along the Gulf Coast IFR at FL220 a decade ago), and there are those rare days where despite giving away horsepower and true airspeed, you pick up a rip-roaring tailwind eastbound that you just have to surf.

Racers are often interested in a fully integrated helmet and mask to provide a good respiratory environment in case of fire and smoke. The same is true if you’re doing edge of the envelope flight testing of a new aircraft or aircraft systems. While it is unlikely that you will be bailing out of an experimental at HALO altitudes, the mask can actually serve as facial protection in case things go really wrong and you are “forced to jettison the aircraft” (as was written in a classic fighter pilot mishap report).

Military masks and regulators can also give you 100% oxygen in case you really need to wake up after a late-night EAA chapter meeting or… other such nonsense.

So, high altitudes, facial protection, and contaminated cabins (unlikely) are sometimes valid reasons to wear a full mask. OK, OK… looking cool—we’ll add that.

But short of rejoining the military, how can you integrate such a mask with a workable oxygen system? It’s not like you can go and buy one from Aerox, Mountain High (although MH does have a mask that works well with a helmet and their electronic pulse system—more on that later), or one of the other popular suppliers. But homebuilders are resourceful, and if you’re willing to skulk around the internet and are comfortable working with oxygen connections, it can be done for a reasonable amount of money—and provide several hours of entertainment as well.

Single or Dual Stage

The first thing to decide is if you want a high-pressure (tank pressure up to 2500 psi) O2 hose or if you’d be more comfortable with an intermediate pressure (50–70 psi) line in the cockpit. For those readers familiar with the history of SCUBA (air) systems, this is the old single-stage/two-stage regulator debate. A two-stage system reduces pressure at the bottle valve to something below 100 psi, then a personal regulator (usually a demand regulator) reduces it to breathable pressures near the mouth.

Standard inexpensive GA aviation O2 systems are different, of course. They operate primarily as continuous flow, using a “slow leak” orifice (controllable by the user to compensate for altitude) and some sort of collector (a bag or cannula chamber) to collect the O2 for each breath. Military systems tend to be demand systems, providing O2 when you inhale and stopping the flow when you exhale.

Portable military O2 systems are available either way, but regulators designed for panel installation generally use a first-stage regulator on the bottle, an intermediate pressure line, and a second-stage reg at the user. Using a two-stage system keeps high-pressure oxygen lines out of the equation, so if a leak does develop, it is easier (and safer) to isolate.

Panel or Personal

For those raised in a military aviation tradition, a panel-mounted regulator will probably be familiar, if for no other reason than that is standard in altitude chambers and transport aircraft, as well as tactical aircraft up to the modern age. Later generation tactical aircraft are more likely to have a personnel-mounted second stage as part of the worn equipment—and this has pros and cons. While incredibly compact and light, it is also not as controllable. It is designed as a pressure-demand system, supplying 100% O2 at a pressure to the mask slightly above ambient at all times. This is good for feeding oxygen to the pilot, but not so good at conserving O2. The military really doesn’t care about conserving O2; they size the bottle for the length of the flight, and military craft are larger and heavier than the average homebuilt anyway, so what’s a larger bottle?

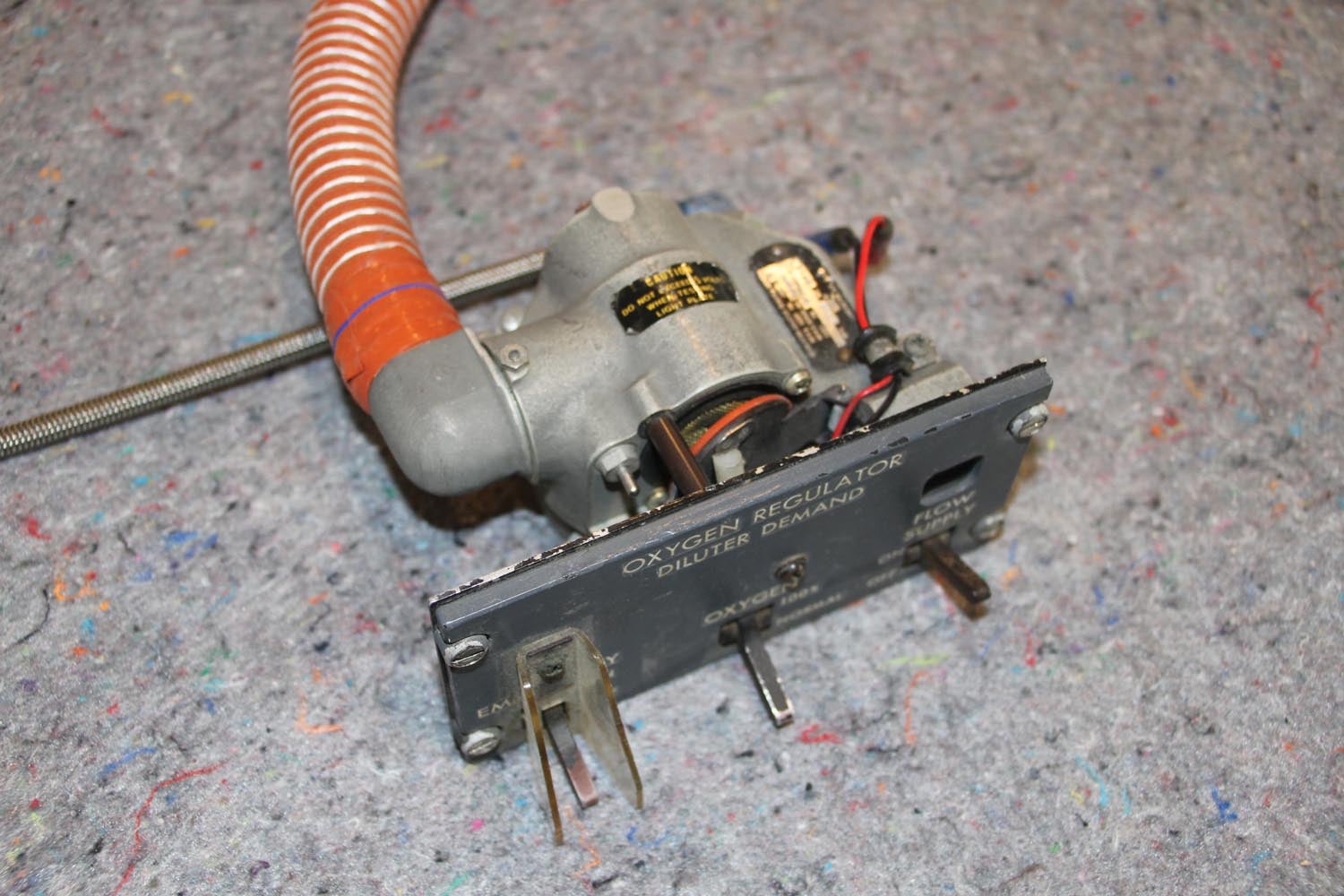

The panel-mounted reg usually has an On/Off switch and a selector valve for either diluter demand (in which the reg supplies a mixture of air and oxygen appropriate to the current altitude, on demand) or 100% O2. There is usually another selector for “Emergency” O2, which gives pure oxygen to the mask at above ambient pressures—similar to what you get with the personal-mounted reg.

Finding the Gear

Shopping for a military regulator takes some research. Surprisingly enough, most searchers end up looking at the website for Flight Helmet, LLC (www.flighthelmet.com), which appears to be a surplus house dedicated to serviceable or collectable flight gear from all eras. The website is chock full of flight suits, survival gear, and helmets—but they also have an entire section dedicated to oxygen equipment. Years ago, we traded notes with the owner of the company and learned that he was, indeed, a former military flight crew equipment specialist. He had spent his time equipping pilots and preparing (and repairing) their gear. He was happy—at that time—to make sure that if you were buying equipment for actual use, it came checked out and functional.

Today the website still exists, and in fact they can provide factory new helmets and some new oxygen equipment. But there are other sources to check out as well. The ever-popular eBay site is a good place to start. Not just a place for individual auctions and deals, many companies use it as an online store without having to set one up for themselves. And if you search for “aviation oxygen regulators,” you’ll find many listings that appear to be from aircraft salvage companies. While some offer actual yellow-tagged units, most simply say “working when removed” or “removed during aircraft salvage,” which likely means there was nothing wrong with the component when it was removed; they were simply scrapping an entire aircraft.

Of course, this is a good place for a buyer to be wary—you might well be disappointed in your search and obtain a useless piece of shelf junk. But the prices are so much lower than if you went to an actual military supplier (remember those $600 aircraft toilet seats from decades ago?), you might find that you can actually afford the occasional dud and still stay within a reasonable budget.

Let’s Talk Models

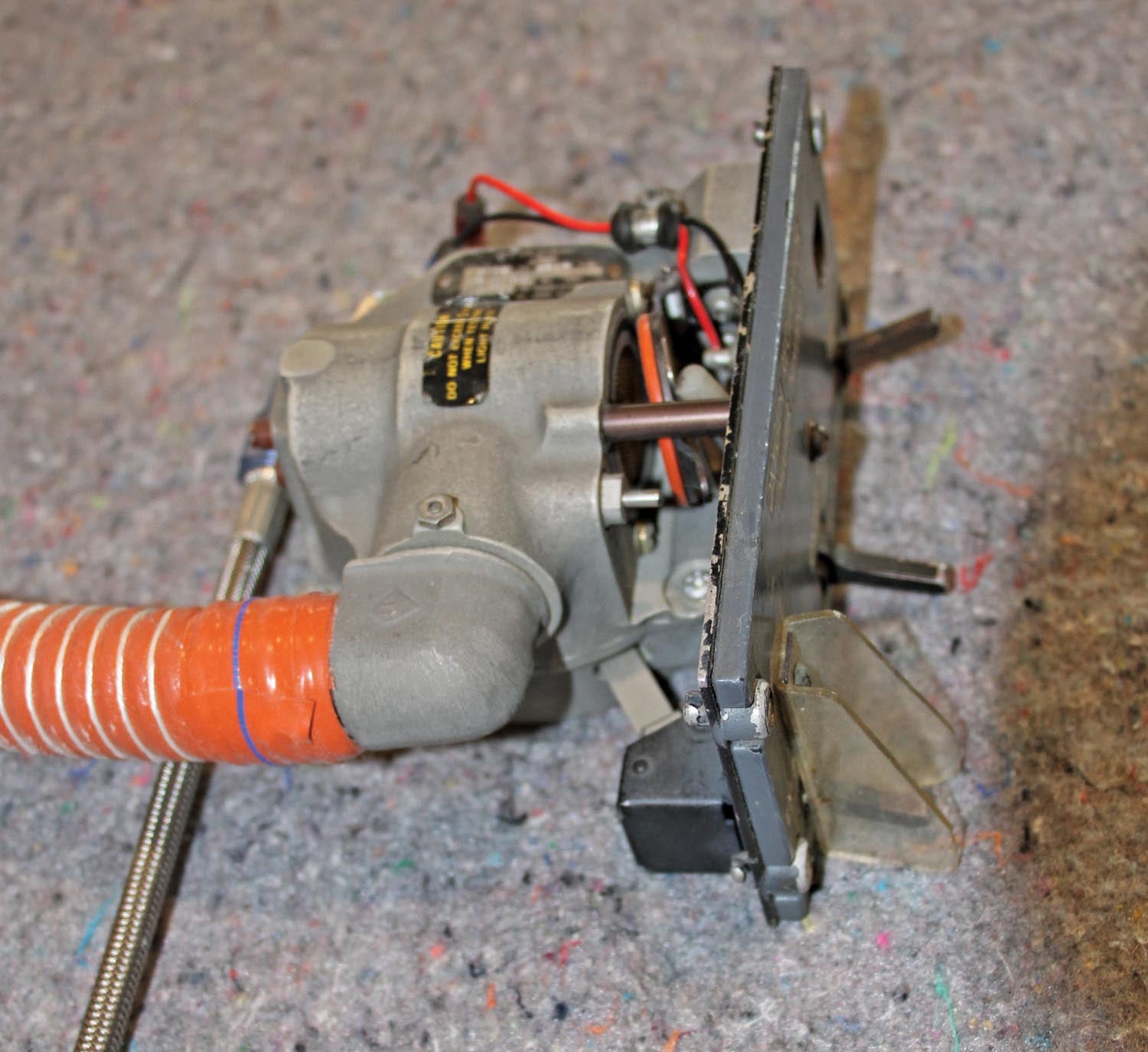

In building up systems to use in specific flight tests, we acquired two different second stages: a CRU-79/P, which is a personnel-mounted compact regulator used by the Navy, and a Scott/AVOX 28000 panel mounted regulator. As we talked about earlier, the first one is very small and easy to mount, but less controllable and somewhat wasteful. The other has multiple modes and can be set up to be reasonably efficient, but you have to put up with a larger package.

Deciding which is appropriate will come down to your planned mission. If, for instance, you want to wear a mask for protection and oxygenation for the length of a Reno pylon race, the CRU-79/P is probably a perfect choice. If you are looking for something to give you good, safe O2 at altitudes for long cross-country flights while catching great tailwinds, the 28000 is probably a better option. Neither requires power—both are purely mechanical devices (although the panel mount might have wires for panel lighting, a nice feature that doesn’t affect its ability to deliver O2 but does make it more visible at night).

Adapt and Overcome

If you are going to build up a system, it is highly likely that you will find the need for various adapters and receivers that might not be obtainable at a reasonable (or any) price. This is when it is handy to know how to use a lathe—or have a friend who can do so. Hoses come in different sizes, and hose ends vary between different era masks, regulators, and receivers. If you want to keep your mask “stock” so that you can use it for that F-16 ride when it’s offered, you will probably need to machine an adapter to make it work with a different era hose end. Once again, you might very well be able to find exactly what you need in terms of “ends” at www.flighthelmet.com, but this is homebuilding, so don’t be afraid to turn a few adapters if necessary.

Building an Example

Living near the Sierra Nevada and often needing to be in the middle or eastern part of the country, I wanted to have a diluter-demand system for my RV-8 to catch that occasional high, rip-roaring tailwind to take me across the Western mountains. That means altitudes in the flight levels, which are above cannula territory. Yes, you can buy some very good systems for use with lighter masks, but the cost might well give you a nosebleed before you leave the ground, so let’s see what I built.

I already have an HGU-55/P helmet and an MBU-12/P oxygen mask, both functional and converted to civilian communications. I usually use the helmet for testing flights, with a boom mic instead of the mask. The end of the mask hose is a typical 3-pin bayonet fitting.

I found a yellow-tagged Scott/AVOX panel-mount diluter-demand regulator on eBay from a salvage company whose business, apparently, is taking apart old Boeings. The price of the regulators I saw varied between $60 and $150, and it is probably not necessary to point out that you oftentimes get what you pay for. In good condition, it checked out fully functional when I connected it to a 50-psi oxygen supply. As a bonus, the panel lighting even works! The intermediate oxygen pressure connector on the back was for a 5/16-inch flareless aviation connector—problematic because we just don’t use these much in GA. The output to the mask is a large-diameter hose opening measuring 7/8-inch O.D.

The first thing I needed was a compact first-stage regulator to mount to a portable bottle with a CGA-540 gas valve. A little internet searching turned up medical regulators that were perfect for the job, and I settled on a MERET CGA EMS BRUUT. This came equipped with medical standard DISS fittings, which have built-in check valves so that you can connect and disconnect oxygen hoses without turning off the bottle valve. Of course, those don’t really attach to anything we’d use in aviation, so an adapter was necessary. More internet searching for “DISS to NPT” adapters turned up machined adapters for a few dollars; the shipping, of course, costs more than the part. Going with 1/8-inch NPT fittings gave me an entry into the 37-degree AN flare fitting world. I happened to have a nice length of steel-braided, Teflon-lined hose with AN4 straight ends, but if you don’t, you can easily have one built, or get one from the usual supply houses (Aircraft Spruce and Summit Racing are two examples).

Fitting the intermediate pressure hose to the second-stage regulator was more of a challenge since flareless -5 fittings are pricey. What I wanted to do was get out of that world as quickly as possible and into something I could use, so more internet searching lead me to MS21900—the part number that adapts from flareless to AN. Not that I wanted to part with $50 to buy one…but the actual spec is available online at www.everyspec.com, and it showed me that the body is a standard straight 1/2-inch x 20 threaded fitting. This allowed me to go to my lathe and make a simple cylinder with a female 1/2-inch x 20 on one end and a female 1/8-inch MPT hollow on the other. The 1/2-inch x 20 side needed a relieved space at the open end for an O-ring, which you slip on the male end (the part attached to the regulator) in order to seal. Screwed together, I now had a 1/8-inch NPT female on the back of the reg, and it was easy to attach a straight NPT to flare AN nipple.

So now I had oxygen flowing from the bottle to the output of the regulator, and 7/8-inch ID hose slid onto that. The other end of the hose needed to attach to the mask hose, and while you can buy the appropriate bayonet fitting from Flight Helmet, LLC, I already had my lathe set up, so I turned an adapter that received the mask hose end and terminated in a 7/8-inch ID end (with a little bulb) that fit on the hose coming from the regulator. Cutting the three openings for the bayonet fittings took a little drilling and Dremel work, but only about half an hour—less than it would have to figure out how to do it some fancy way. How does it stay tight and seal? The end of the oxygen hose attached to the mask has a spring-loaded concentric center section; the act of pushing it into the adapter tensions it against the bayonet pins and seals it. So the depth of the adapter is important!

It’s also important to remember that when working with oxygen, you never want to introduce hydrocarbons into the equation—so if you use cutting oil, you need to remove all traces of it. If you are reusing AN fittings from your parts bin, clean them up, just in case they have ever come into contact with oil or fuel. Remember, O2 systems must be squeaky clean, or you can have a terrific fire that will easily simulate an explosion. No sparks—use brass for moving parts.

Fully Functional

Since this is a one-human system, and the RV-8 is a two-seater, there is plenty of room to put the bottle in the back seat, strapped down with the harness. The regulator can sit in the passenger footwell, doing a very good imitation of being mounted on a side console. The bottle is turned on before takeoff, but the regulator has its own On/Off switch for oxygen flow, so the system is easily isolated. Just check all of your connections before flight to make sure they are tight and don’t leak.

As stated up front, this is not a terribly efficient oxygen system—you’ll use more than you would with a standard GA setup. Getting an oxygen fill-up at a typical FBO is expensive, considering the actual cost of O2, but since this is a specialized system for specific tasks, I don’t usually fill it away from home.

Is It Worth It?

In the end, the easiest thing you can do if you want reliable O2 at reasonable cruising altitudes is to buy a portable GA system from any of the popular vendors. There is no integration, you can wear a cannula, and your body gets the “O’s” it needs. If you really want to wear a helmet and mask combo but don’t want to do any work, you can also buy a mask-based system from Mountain High that works with their electronic pulse controller. The mask is designed to be used with a set of straps that go around your head, but if you want to use it with a helmet, Flight Helmet, LLC will modify the standard Mountain High mask with bayonet fittings…for a price. This is the system I use in my own little jet, which is equipped with a built-in, hard-plumbed Mountain High bottle and valve. It is very efficient.

If you just want to have a fun project and use your old military mask and helmet, you can go the route we’ve described here. It’s fun, it’s interesting, it looks cool… and it works. It can also be done cheaper than buying a full mask system already built up, so long as you are good at shopping on the internet and are willing to spend some shop time working on it. We’ve got a variety of O2 systems at our disposal and use all of them for specific jobs. You can determine for yourself if it’s worth it to go military—or just suck down the oxygen as the GA world intended.

Hello Paul,

I have invented the EAV http://www.escapeairvest.com

It is primarily or getting people out of a smoke filled environment. I have a mouthpiece and nose clip just like for diving but i have some customers asking for the nose and mouth cover mask. As it is on demand this would have to be a very good seal s the regulator sits on top of the bottle.

Any suggestions would be welcome if you know where I could purchase a cost effective mask

Hello Gary – I think that “cost effective” and “Aircraft” don’t go very well together – in order to find a good, tight-fitting mask from an aviation supplier, you’ll probably be spending at least $500 – and that is before you adapt it for your system. A military mask is going to cost considerably more, and will still require significant adaptation. As a former firefighter and technical diver, I am aware that when it comes to masks, you do get what you pay for, and a mask designed to keep smoke out has to fit very well – which means it will have to be sized for the particular person using it. I am sure you’e aware of these challenges, and are looking for a good working alternative, but I doubt that you’ll find it in an aviation mask.

These type of articles never address oxygen generating systems (OBOGS). Maybe they don’t exist for GA or are rare, but these seem like the best of all worlds. Never fill an oxygen bottle again (yes, you have to replace the molecular sieve… tanstaafl) and wear your preferred delivery system, cannula or mask, with as much oxygen as you need on any, and more importantly every, flight.