This month’s column is the start of a new series based upon feedback from KITPLANES® subscribers who said they missed my contributions. Thankfully, Marc Cook is welcoming me back!

This month’s column is the start of a new series based upon feedback from KITPLANES® subscribers who said they missed my contributions. Thankfully, Marc Cook is welcoming me back!

It seems to be a natural human quest for our machines, whether horse drawn or supersonic—the endless search for more power and more speed.

The holy grail is certainly Reno, where those who dare get to showcase their achievements. Many engines and airplanes have been designed to win those races, with some engines only built to last for one or two races. It is an expensive quest.

For many non-racing pilots, the lust for power and speed can also be fulfilled by utilizing high-end racing engine builders to provide souped-up engines for their amateur-built aircraft—even if the extra power is only wanted to offset a heavily built plane. That was the scenario for one of our RV-10 customers.

The RV-10 was beautifully built, with every rivet filled so that it looked like a glass airplane. The addition of an air conditioner and some extra goodies, including a 28-volt electrical system (28-volt batteries are big and weighty!), were obviously going to make the airplane heavy, so extra horsepower was the solution. A high-end racing shop built an IO-540 with 10.5:1 pistons and some other tricks to increase the output to 300 horsepower. Of course, to handle the high oil temps associated with high compression, two large oil coolers were installed, adding to the weight problem.

It has been my experience over the years that eventually someone has to pay the piper for these changes. Remember, race engines are built for one purpose—to win the race. Not for longevity. While a normal-rated Lycoming engine will usually make it to the 2000-hour TBO, it seems that increasing the compression above 9:1 will shorten the life, sometimes by half.

This particular owner has been a longtime customer, and after around 600–700 hours we started to notice the compressions dropping off. Two years ago we recommended that the top end should be looked at, so the owner took it to his home base shop, where they removed all of the cylinders to rework them. Paperwork reflected that they were honed and reinstalled with new rings.

During the condition inspection the following year, cylinder 3 tested at 24/80 and cylinder 6 at 48/80, after having flown about 60 hours in the last year. Borescoping did not indicate any serious problems, but we recommended that he have those cylinders looked at. The shop that did the original work recommended that the owner just continue to run on mineral oil. While I didn’t agree, the owner had a longtime relationship with the shop and wished to abide by their recommendations.

During this year’s condition inspection, our initial run-up was surprising in how fast the starter spun the engine. I probably perform over 300 IO-540 engine starts per year, so when one stands out it kind of raises a flag. During the compression checks, cylinder 3 tested at 15/80, and cylinder 1 tested at 45/80. The others were in the 60s. Retesting after another engine run brought cylinder 3 up to 18 and the others only slightly so.

We spent a lot of time with a borescope and more compression tests to see if we could determine any causes. Clearly there was some pitting on the cylinder walls. Some of you may know that Lycoming cylinders have a .005-inch choke at the top of the cylinder. Compressions were the lowest when I had the piston right at TDC, which is where you should see the highest reading. I could get a higher reading 5–10° off of TDC. To me, that meant the choke area was problematic, which is not unheard of in high-compression engines. The engine now had approximately 1000 hours on it.

I was uncomfortable with the engine. It clearly needed further investigation, including cylinder removal. This time I had a stronger conversation with the owner and recommended a reputable engine shop. He agreed, and flew it there immediately. The results were shocking.

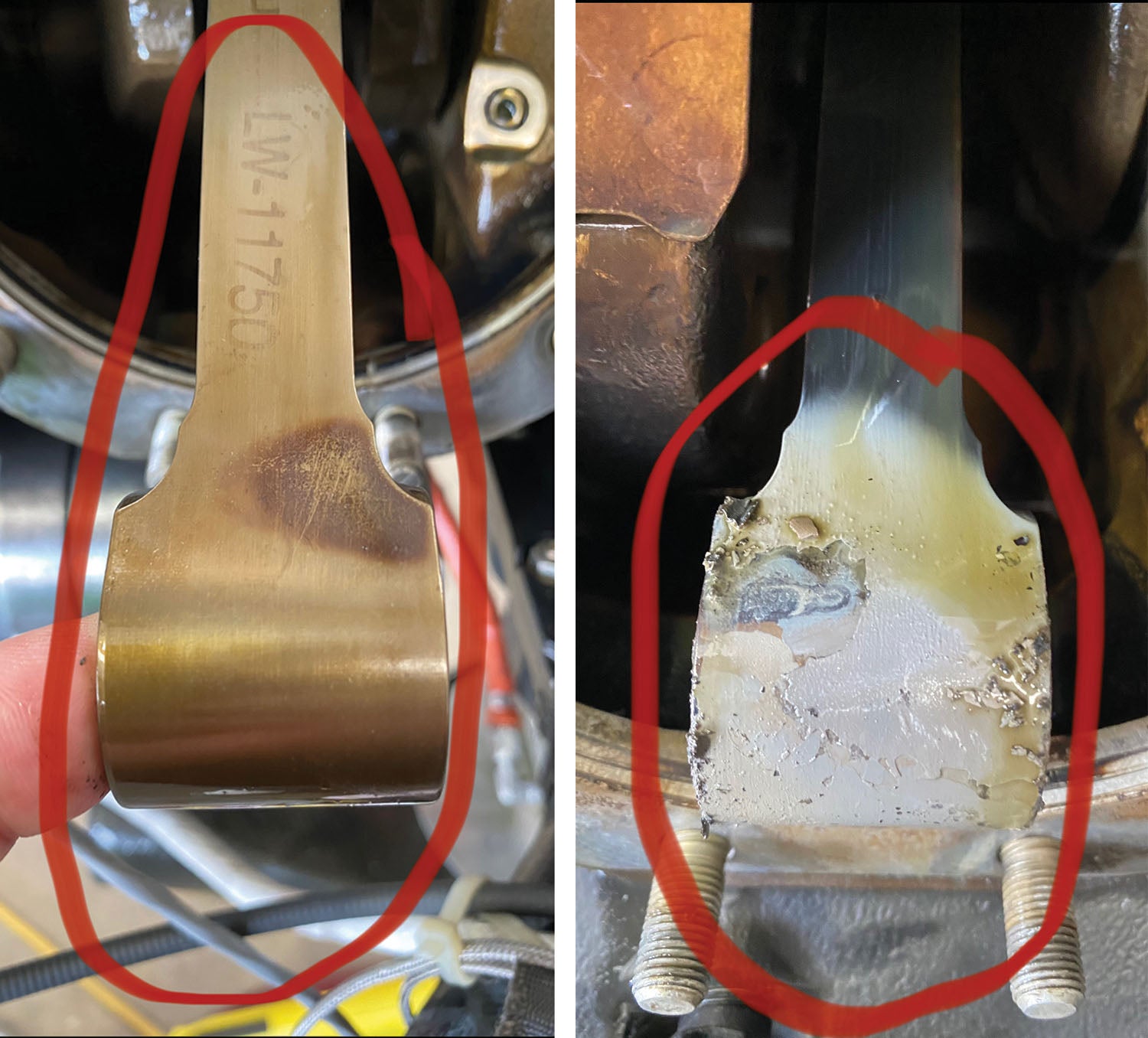

Cylinders 2, 4 and 6 were removed first. They all showed that there was no choke left in any of the cylinder bores, with some excessive pitting (Yes, there were some periods of inactivity of the aircraft, and it is routinely based in Florida). The connecting rods on cylinders 4 and 6 were severely burnt, and the piston squirters were not installed. Piston squirters are usually installed in high-compression engines to squirt oil at the base of the piston to help with heat. Now the engine pretty much needed a complete teardown.

Out of curiosity I looked at the work order for the top overhaul two years earlier, to see if by chance oversize rings were installed. They were not. However, something really caught my eye: There was a line item for CamGuard! CamGuard should never be added to a newly overhauled engine as it will prevent a proper break-in.

Lessons to be shared: First, everyone should be prepared for high-compression engines to exhibit early wear and not make TBO. Second, I’m a firm believer that engines “talk” to us long before they catastrophically fail. In this case, it was two years of worsening compressions and starter spin-up faster than normal. Clearly, this engine was just a few hours from a serious failure. I was very thankful the owner accepted my recommendations. By the way, so is he!

Lastly, for those of you who don’t fly regularly and use additives such as CamGuard or AvBlend, be sure to wait until the break-in process is complete. I personally recommend no additives until at least 100 hours.