Back when I was a much younger person and just starting to get interested in building a kit aircraft, a friend of mine announced his purchase of a complete new Kitfox airplane kit. (This was back in the 1980s, so this kit was nothing like the one you get today from Kitfox!) Well, I was a little jealous but happy that someone else was so enthused with the prospect of flying a kitbuilt airplane. Of course, I couldn’t wait for him to finish it. But years rolled by, it was never finished and he sold it to someone else.

What went wrong? Were the building steps too numerous, the tasks too difficult, the work not interesting or the instructions not clear? How could you not complete an object of your dreams? This friend was a very capable builder and had already earned his private pilot certificate. To sum it up: In his case, the project took too long to make reasonable progress, and then life got in the way.

This was my first exposure to a kit airplane project getting abandoned by its owner. I knew my friend’s building skills were much greater than mine, so I really had an awakening about the challenges of taking on such a project myself. There is a very important lesson from this that I want to share with first-time kit builders: Be honest when assessing your building skills as well as your expectation for the time and patience needed to finish the project. Some kits are very easy to complete and others are dreadfully challenging. (Repeat or second-time kit builders may consider this information obvious!)

Fast-forward 40 years from this story to now. Without a doubt, I am convinced my friend would complete a kit if he purchased one today.

So, what has changed over the years that gives builders a better chance to see their project through to completion? Plenty! Modern technology has made metal aircraft building significantly easier.

A Quantum Leap for Kitbuilding

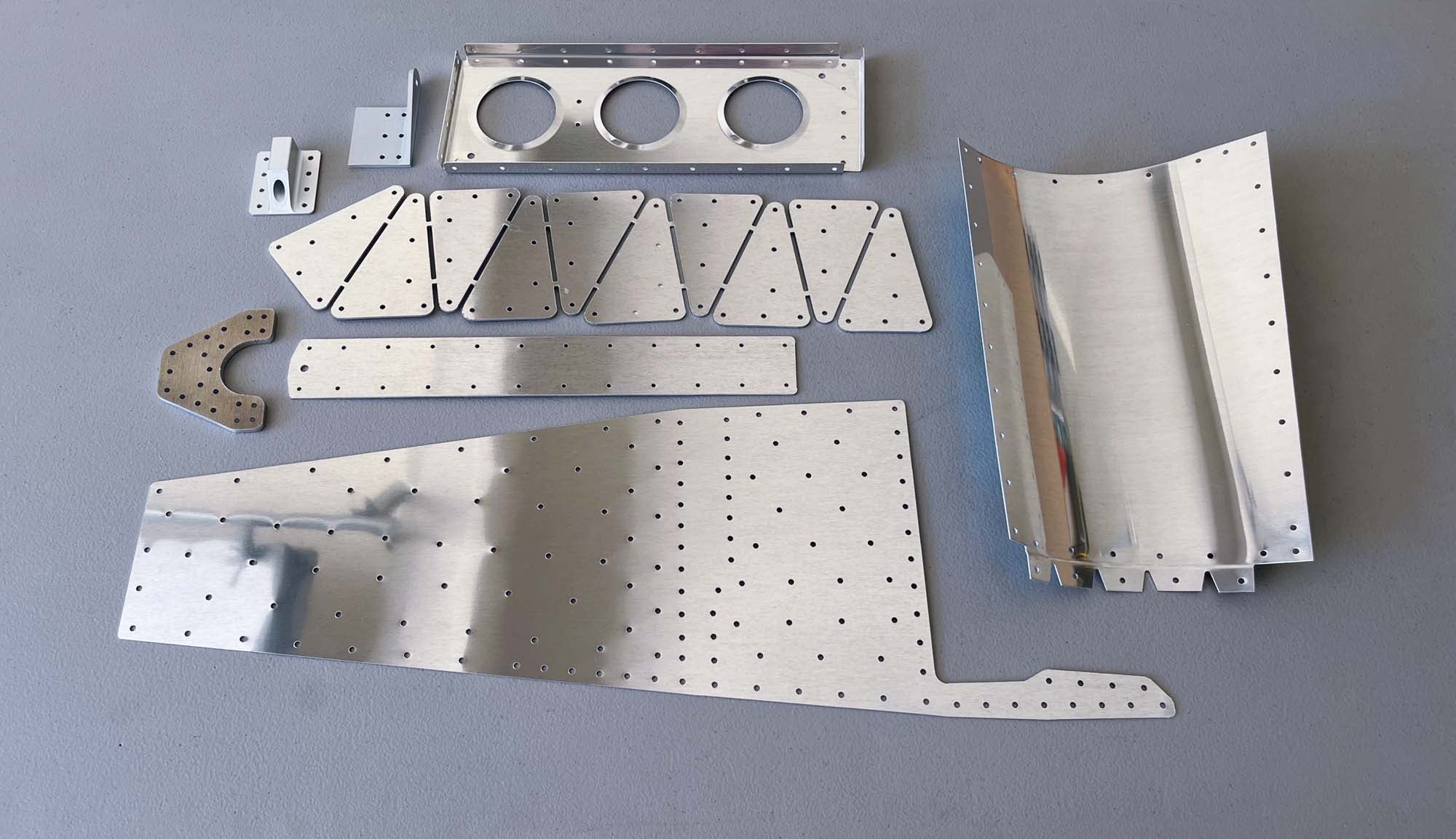

An aircraft kit is a box of a thousand parts that you must properly assemble. They must be fastened in the proper way and aligned precisely for the plane to fly safely and straight. The key to how easy and how fast these parts go together is determined by how much work the factory has done to create the parts. The more work they have done when forming those parts, the less work the builder must do.

This adds up to a lot of building time. For example, there are typically thousands of holes that need to be drilled in a metal aircraft. Make a mistake drilling a hole and you cannot undo it. Make several more mistakes and you need to replace that part. Ugh.

So, should you simply choose an aircraft kit that has plenty of pre-drilled holes? Unfortunately, that is not nearly enough.

Think of a metal wing. It has a skeleton, ribs and large sheets of aluminum skin. Everything needs to be attached with fasteners passing through the holes. Even if the manufacturer has filled the wing skins with predrilled holes, you are left with drilling the holes into the center of the rib flanges and the edges of the spars and outer skeleton. While you can use those skin holes to guide your drill for drilling the ribs and spar, you might not have them positioned accurately while drilling.

Is it really necessary to take the time needed to center each rib to get the exact center of the flange while drilling? A warped wing is caused by drilling just a little off-center. You cannot easily fix a misalignment after the holes are drilled.

So, what is the solution to save time while drilling and eliminate worry about poor alignment? It’s simple: Choose a kit that extensively uses matched-hole construction.

Matched-Hole What?

Matched-hole construction is based on very simple premise: If the kit manufacturer creates the holes in both parts that come together (for example, wing ribs and wing skins), all the builder has to do is fasten the holes together on those parts. Perfect fit and alignment between the parts are guaranteed because the holes are precisely predrilled in the correct position on each part.

Matched-hole construction has advanced to the point where it has completely revolutionized the tasks required to build a metal airplane:

- Drilling is greatly eliminated, saving hours of tedious work.

- The chance of making mistakes while drilling is substantially reduced.

- The precision traditionally required for building an airplane is removed from the builder and is replaced by the accuracy of the predrilled holes in the parts.

Now that you know that matched-hole construction exists, do you really want to build a kit that doesn’t have it?

I have built several aircraft kits: some without matched-hole, some with partial matched-hole and others with nearly complete matched-hole construction. Please take my advice that if you are a first-time builder, you should strongly consider choosing a kit with lots of matched-hole components. The advantage this type of kit has in completion success cannot be overstated.

Ask the Manufacturer

How can you learn if a kit uses matched-hole construction? Ask the manufacturer directly if this information does not appear in their sales literature. You’ll want to know what percentage of the components in the kit are made this way.

Remember, having holes predrilled in metal parts is not the same as matched-hole construction. All parts that come together in an assembly must have their holes predrilled in the proper position for matched-hole construction.

There’s nothing wrong with aircraft kits that require you to drill holes. However, you must consider your building skills (keeping everything straight before drilling) and time available as to whether this could impact your success. If you are a first-time builder and think maybe the challenging part of building needs to be minimized, you’ll want to take advantage of matched-hole construction. Plane and Simple!