Many popular aircraft kits we can purchase today do not include an electrical system. This means the builder is generally left on their own to design and then assemble the many electrical parts and pieces that power the aircraft. This includes the instrument panel, avionic devices, wiring, switches and circuit breakers that comprise a complete aircraft electrical system. If this sounds like a significant and large undertaking to put this all together, then why do kit manufacturers not include the electrical parts in the kit?

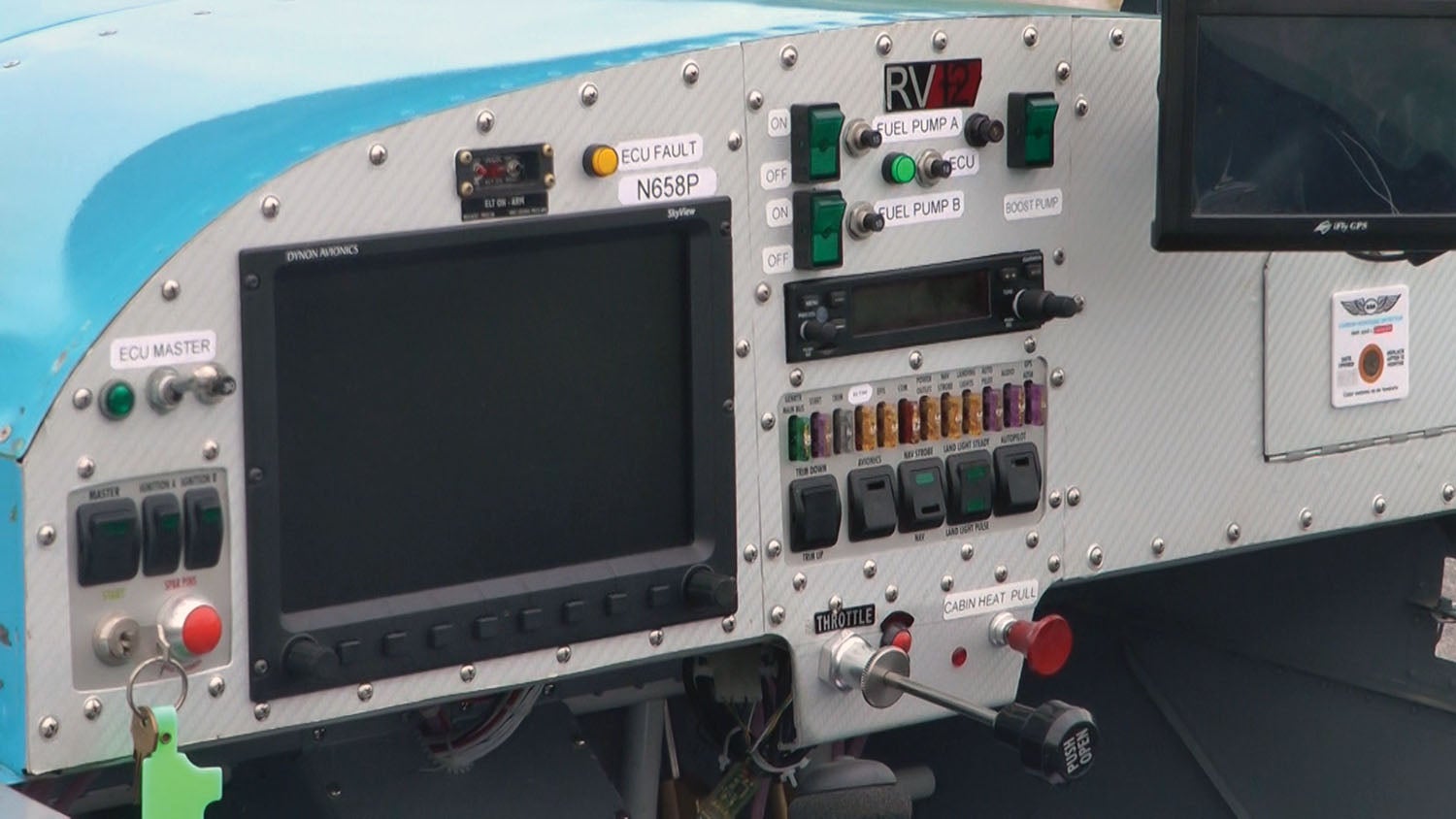

The thinking has traditionally been that all builder/pilots have their own idea of what the instrument panel should look like. The endless choices of glass panels, analog instruments, radios, transponders, moving maps and much more means that the manufacturer should not guess on what to include in an electrical package. The picture gets more complicated when they don’t know what engine will be used as each engine model will dictate a particular electrical wiring scheme. Unless your kit aircraft was designed around just one engine model and you don’t mind using a panel design that the manufacturer has chosen, you must be prepared to design and construct your own, custom electrical system. As an exception to this rule, Van’s Aircraft did a nice job of providing builders with a factory-selected engine and panel with their RV-12 kit.

This freedom to roll your own electrical system means you can make things very simple or very complex as desired. You have no doubt seen aircraft panels as simple as a few round mechanical gauges. At the other extreme we find builders that have chosen quite elaborate panels with multiple flat-screen displays and all sorts of digital readouts. Some have installed so many components that there is practically no panel space left at all! This wide range between simplicity and complexity of electrical components creates another challenge to reckon with: namely, the cost to build! On the simple side a panel can cost less than a thousand dollars. On the elaborate side a panel can set you back for as much as you spent on the airframe. The sky is the limit!

For many builders of kit aircraft, money is a scarce resource that must be budgeted carefully. I will go out on a limb and say that we could have a lot more builders and pilots in our hobby if the final aircraft didn’t cost so much. Kit manufacturers do a nice job of pricing airframe kits as competitively as possible and we clearly understand the price to purchase. What is not always clear is the huge price of that “not included” airframe component called the electrical system. When potential kit buyers discover that the final aircraft price is soon going to double when including the panel cost, I bet we lose a whole bunch of fellow builders. We cannot forget to remember that whether the panel cost is $1000 or $15,000—the aircraft essentially performs the same!

Here is an example to help illustrate this idea: A builder reviewed his wish list for his forthcoming panel with me and worried that things were getting out of hand cost wise. If everything on the wish list was to be included, it would set the project back a year for funds to become available. Looking at the wish list, I noticed a $3000 device that eliminated the need for circuit breakers. Quite an ingenious design, it was a computer box that managed all circuits electronically and displayed their status on a screen. Playing devil’s advocate I asked, “How does this make your aircraft fly any better? Is there something wrong about using fuses and circuit breakers that you are not telling me? Aren’t they as reliable and foolproof as they have ever been?”

I also noticed a wish list option for a module that contains a set of preinstalled switches that eliminates some of the wiring the builder has to perform. More than $500 could be saved by replacing this device with a handful of individual switches and some builder time to wire and mount them individually.

My point was to make sure he considered the tradeoff between delaying his project and spending money he did not have in order to include these devices. A handful of circuit breakers, fuses and switches properly installed would allow his build to move forward and not break the bank.

There are many other examples of cost-saving possibilities regarding the choices we make for the instrument panel. Remember that aircraft have been flying safely long before integrated circuits became a household term. If you need to trim an out-of-control budget in order to save your aircraft project and get it done on time, the electrical system and panel are areas that you can streamline without changing the performance of your aircraft. Use the internet to Google “Experimental aircraft panels” to see hundreds of pictures of panels that others have built. This is one way to learn of the choices available in order to have the power to control your panel budget.

I personally love high technology in the cockpit and embrace the latest innovations especially when it comes to safety and convenience. A glass panel that integrates engine monitoring, flight data, navigation and circuit breaker status may be on par with the panel of a jet fighter. If personal funds are not a limitation, then using the best of these products furthers the technological envelope—a good thing.

But it is quite possible that many budding Experimental kit builders will jump ship if an impression exists that an expensive panel is the norm for aircraft construction. Many of these high-tech innovations do little to impact the flight capabilities of the aircraft when all is said and done. Bells, whistles and high-tech comforts all have genuine value. But when it comes down to it—we should not have to break the bank in order to fulfill our desire to build and fly today. Plane and simple!