My neighbor, Ed, and I have a system: If he needs a part for his RV and I can help him, he pays me with food. Usually I get the better end of the deal: a home-cooked meal or a nice evening at J’s Bistro, the local five-star restaurant.

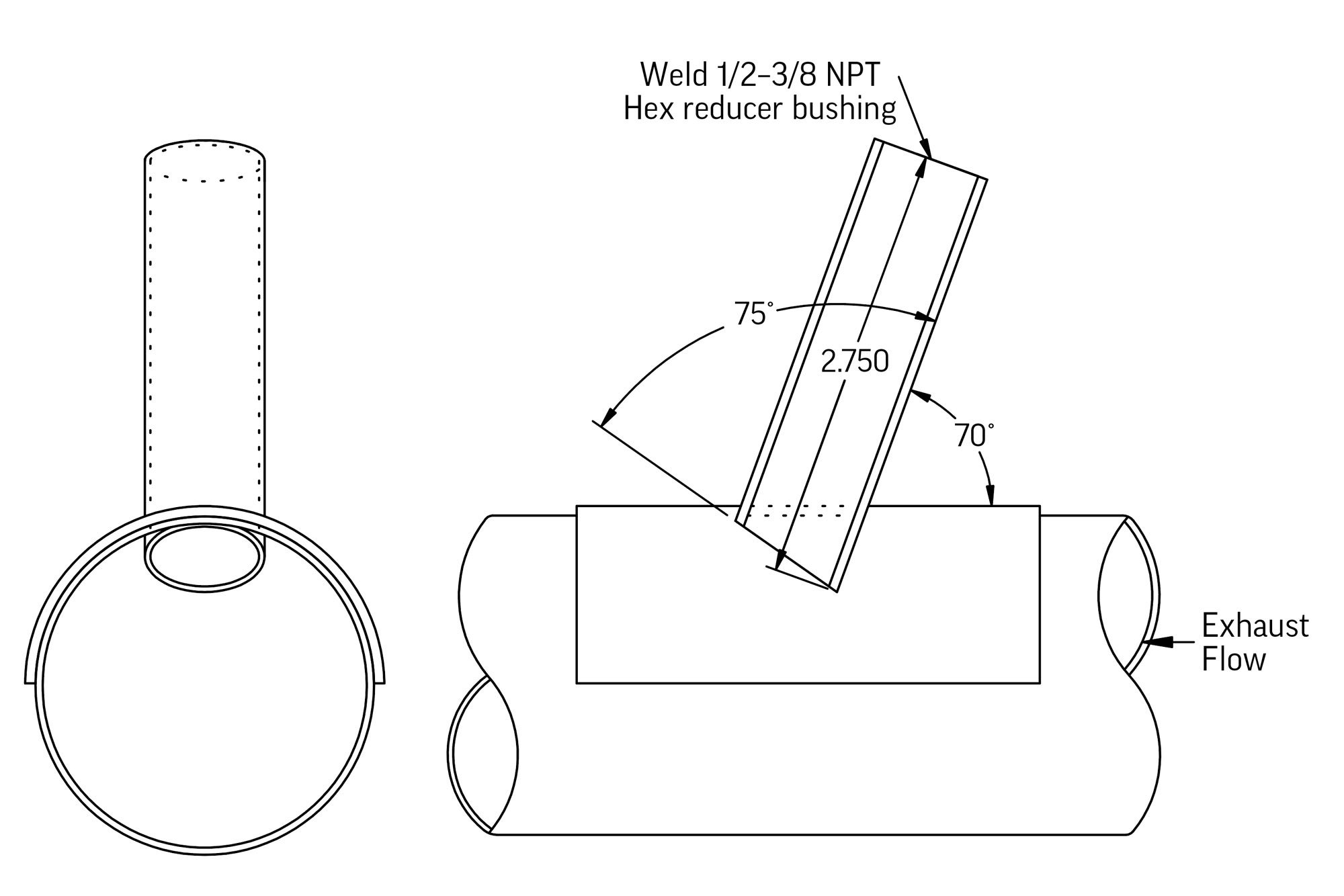

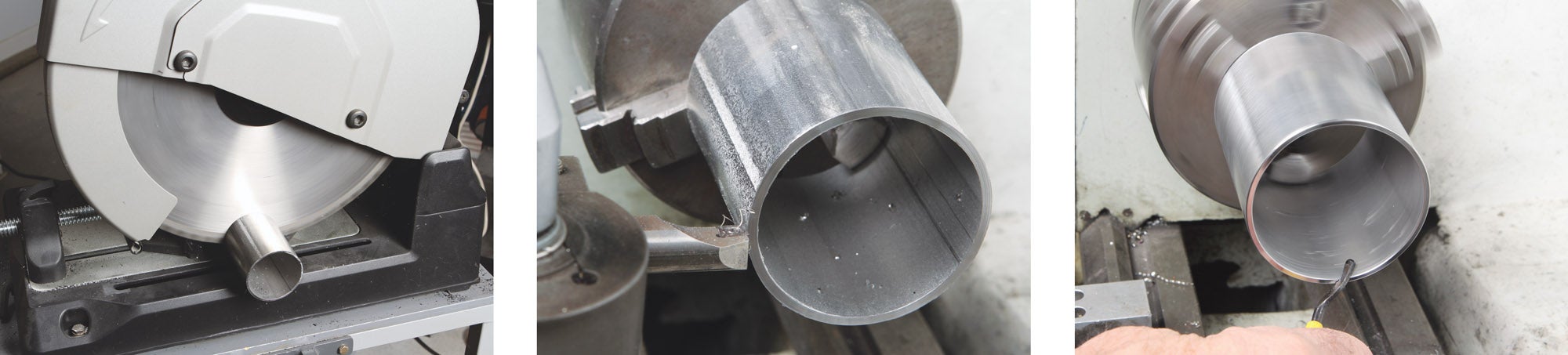

Recently, Ed needed a part to upgrade the installation of his crankcase breather/oil separator kit. Not being an RV guy, I didn’t know anything about the kit, but according to Ed, it is a popular accessory. In any case, the piece Ed needed was a weldment consisting of a tube with an NPT thread at one end and a half-round saddle at the other. The saddle end of the tube is beveled and gets extended into the exhaust stream of the tailpipe. The tube, combined with the rear-facing (to the exhaust stream) opening, create a venturi-effect vacuum source, the purpose of which is to evacuate fumes from the crankcase.

Most engines have some sort of system for this. Most cars (except electric) have a positive crankcase ventilation (PCV) system that uses the differential pressure (aka vacuum) from the intake manifold to recycle crankcase fumes (mainly blowby). My Jabiru has a bevel-ended, rear-facing draft tube that is connected to the oil separator. The end of the draft tube extends below the cowling at the firewall. It works on the same principle; the vacuum is created by the slipstream flowing around the tube. The basic difference is a draft-tube system generates very little vacuum compared to the in-the-exhaust system.

In between the draft tube and the engine is usually an oil separator of some sort. The separator condenses oil vapor back to liquid and either stores it until it can be manually emptied or, as in the case with the RV kit, there’s an option to plumb the condensed oil back into the crankcase. Regardless of type, the primary function is to vent blowby gases from the crankcase. Recycling oil or keeping the belly of your airplane clean—though highly appreciated—is a side benefit.

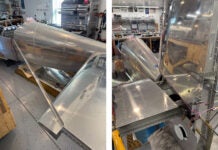

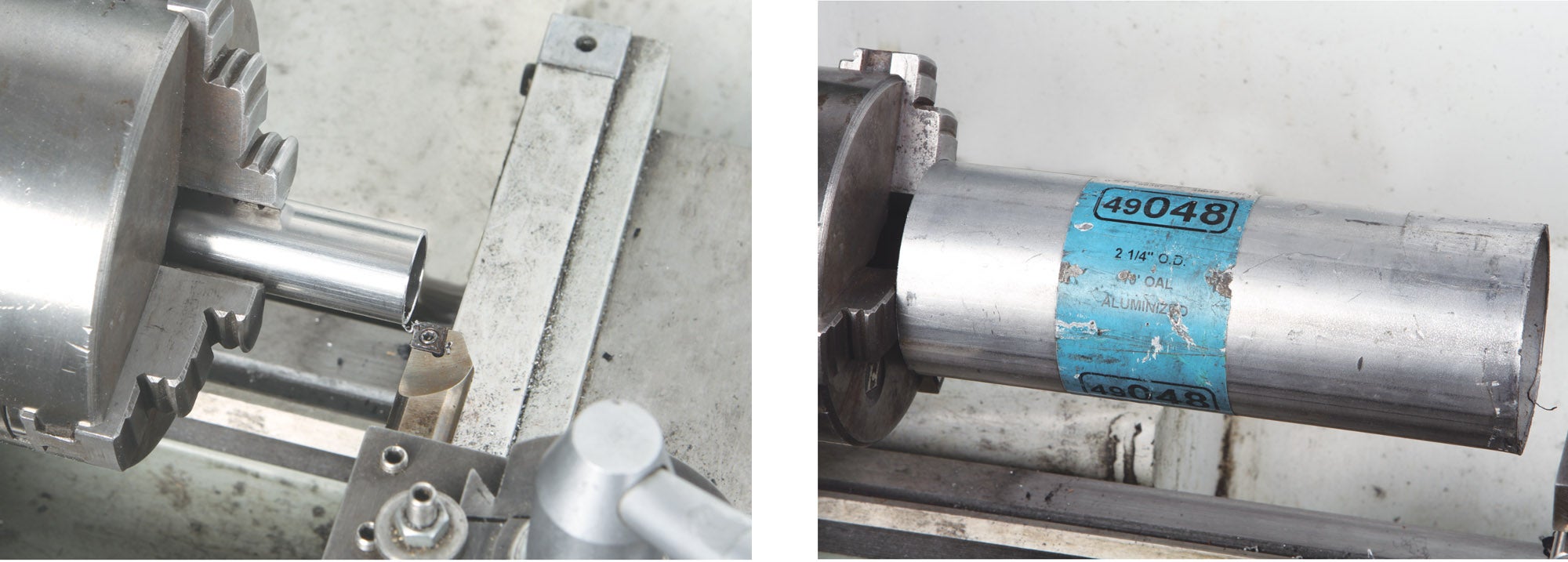

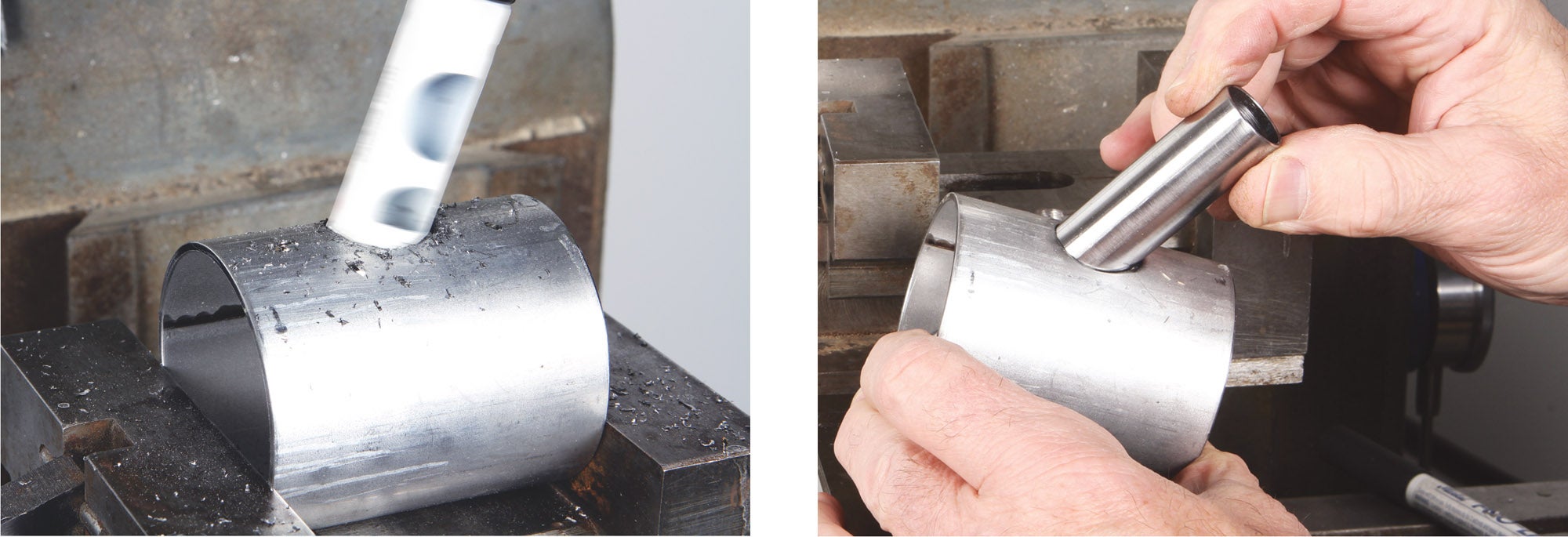

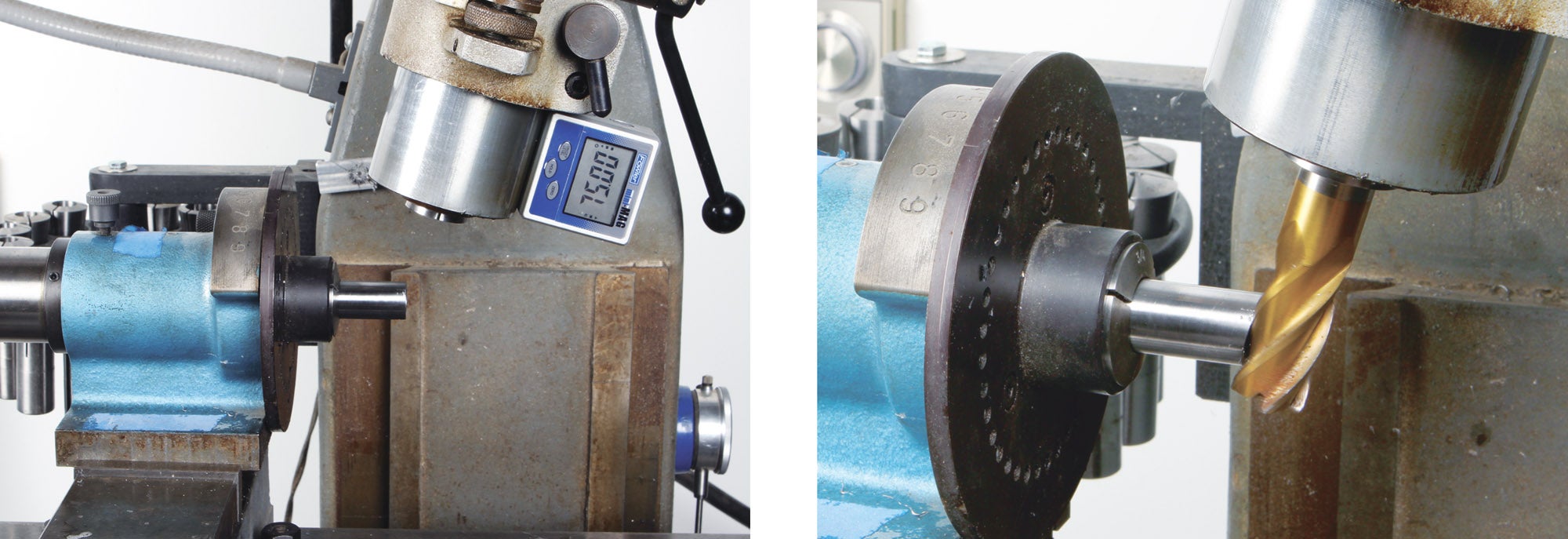

As far as specifications for making the part, the only thing we had to go on was a basic sketch. Ed rounded up a section of 2¼-inch aluminized steel exhaust pipe from a local muffler shop for the saddle—the ID of which perfectly fit the 2-inch OD of his tailpipe. We determined that the vacuum suction tube, the tube that gets inserted into the exhaust stream, was in the neighborhood of ¾-inch diameter. I’m calling this the IV tube because it looks like an oversized IV drip needle!

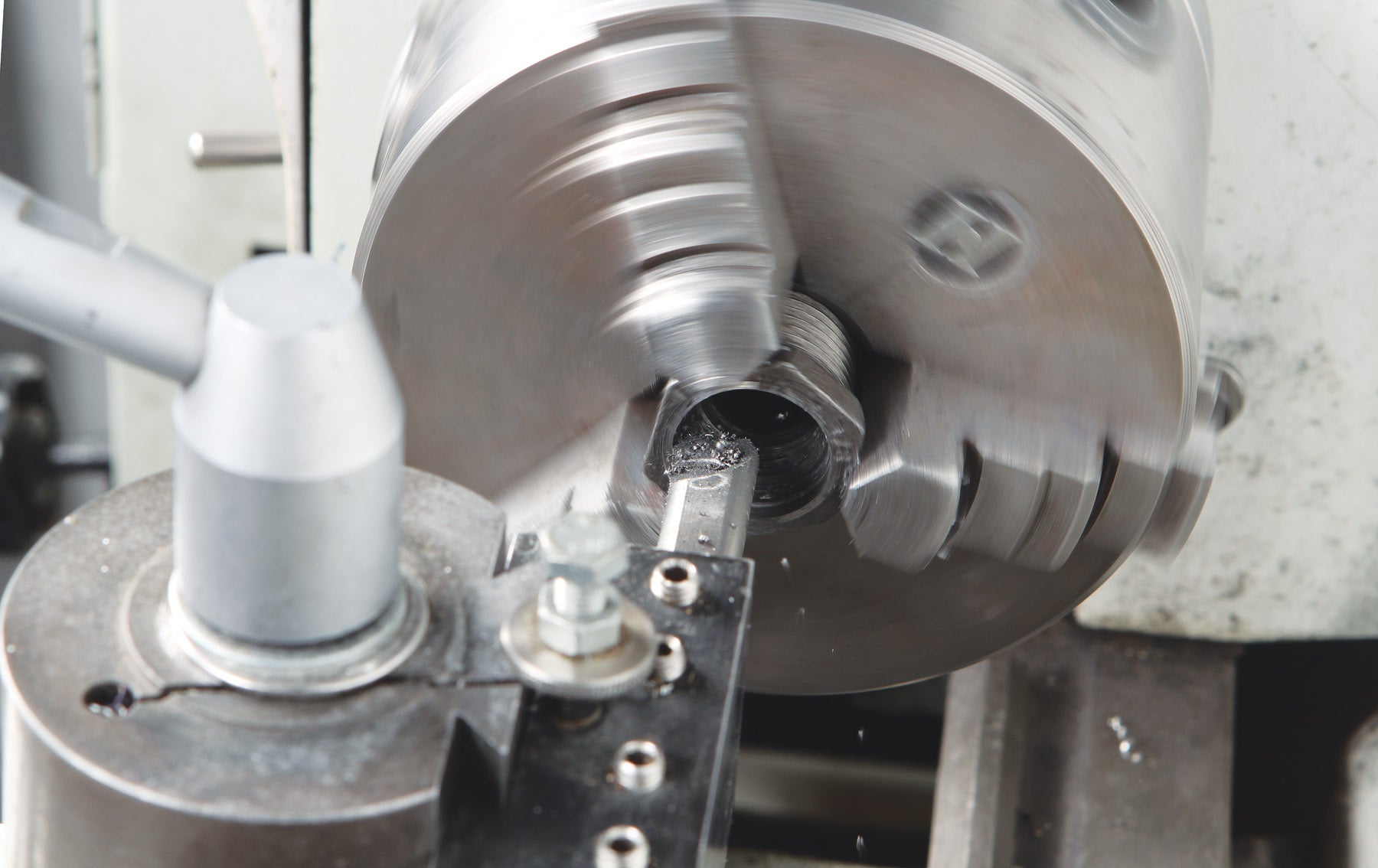

I happened to have a short length of ¾-inch stainless steel tube, so we were 90% there. One thing we needed was a ½-inch NPT thread to interface with the one-way valve that goes between the IV tube and the oil separator. Ideally, this should be stainless steel, but since our local hardware store only sells black iron and galvanized iron fittings, we settled on a black iron ½-to-⅜-inch NPT hex reducer. It was no big deal to make a second saddle (see the photos) and a spare IV tube just in case the iron fitting has problems. We have ordered a stainless steel reducer and will make another one in case Ed needs to do a swap-out sometime down the road.

That’s it for now! Time to get back in the shop and make some chips!