AeroMomentum

We hope AeroMomentum doesn’t mind us characterizing them as a boutique engine maker, but they are a compact company centered on delivering modern, water-cooled, four-valve, high-efficiency engines. You could call them auto conversions, but AeroMomentum is not buying complete auto engines; they’re purchasing more of an industrial or long-block core engine from big automakers and finishing them off as aircraft powerplants at their facility in Stuart, Florida. Suzuki is the source of the 1300 and 1500 engines, while the others are non-Suzuki and cannot be revealed as part of the sourcing agreement. All engines are built from all-new parts.

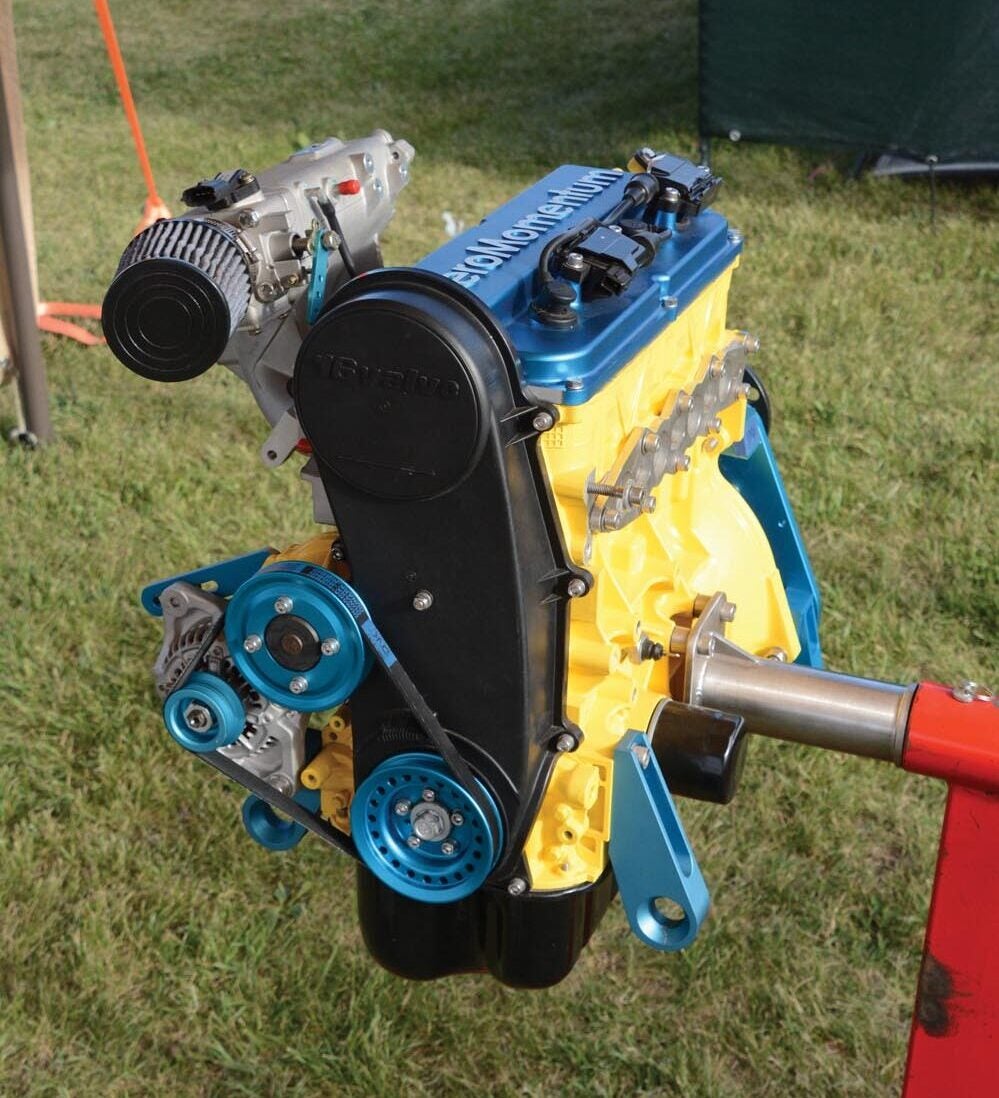

To that end AeroMomentum has their own PSRU, engine management, coolant plumbing, electrical system and mounting hardware—along with some firewall-forward kits. Internally there are cast-steel cranks, forged connecting rods and knock sensors; externally there’s Bosch engine management, sequential fuel injection and 65-amp alternators.

Things have been busy at AeroMomentum since 2022 with growth in the sport market along with much new business in more corporate/governmental endeavors, much of it overseas.

For we sport pilots the news is the 1.3- and 1.5-liter turbo engines are in production and shipping. Some of these engines gained a little power last year due to a new induction system with a larger throttle body.

Thus, for 2024 AeroMomentum’s lineup continues to range from a 1000cc three-cylinder, 1300cc and 1500cc four-cylinders to a turbocharged 2000cc four-cylinder.

There are many variations (more than we can list in the specification table) of the AeroMomentum engines because the 1.3- and 1.5-liter four-bangers can each be had in upright or heavily canted form, with either traditional Lycoming-spaced aft or AeroMomentum bed mounts, standard or high offset gearbox, plus each offers three states of tune and turbocharging. The upright or canted options are strictly for packaging ease in different airframes and make no difference in power output (but do in price). The power differences come from either stock engines or those with AeroMomentum’s more aggressive camshaft and head work. Most aft- or bed-mount engines fit under cowlings intended for Lycomings or Continentals, plus upright engines with large offset gearboxes fit under Rotax cowlings. But it’s best to confirm your specifics with AeroMomentum, of course.

All AeroMomentum engines use a helical, spur-gear prop reduction gearbox. It features custom 8620 alloy gears and, like many of AeroMomentum’s other parts, is designed in-house. (There’s no lack of engineering experience at AeroMomentum with Cal Poly, Harvard, UMass Lowell and NASA in the resume.) Parts are forged, machined, heat-treated and otherwise produced by out-of-house vendors then assembled at AeroMomentum.

AeroMomentum also offers various firewall-forward supporting parts such as engine mounts and cowlings, plus their Aero-Graph engine monitor.

ADEPT Propulsion Technologies

ADEPT is a South African company bringing a next-generation, liquid-cooled piston engine to market. Their engine is a clean-sheet design, a nearly flat, 3.2 liter (195 cubic inches), 120° V-6 featuring FADEC engine control. It sports a knock sensor allowing nearly any fuel, from 100LL to mogas laced with ethanol or methanol. Other features are liquid cooling, dry sump oiling with piston squirters, billet crankshafts and connecting rods and forged pistons, plus the same bore and stroke across all power levels. The differences are in the camshafts, injectors, computer mapping and other tuning factors. Turbo’d engines use a single turbo.

Power is rated at a base, naturally aspirated 260 hp, then through several steps to 360 hp in turbocharged form. A new 425-hp version was added for 2024 and will be built upon the first customer order. The 300-hp naturally aspirated engine has been deleted from the advertised lineup because it is so close to the 320-hp turbo engine, but ADEPT can deliver the 300-hp engine if desired.

ADEPT delivered a handful of engines to the U.S. for well-heeled, fast-glass aircraft customers and some of those projects are nearing flight. Additionally, ADEPT says they now have the ability to build 50 engines a year and is also still looking to move production to the U.S., according to ADEPT’s North American representative Lee Brinley. He also notes multiple efforts getting engine mounts, electronic compatibility and other integration considerations built for those fast-glass customers. An ADEPT engine is also powering the Klein Vision AirCar.

Look for ADEPT on display at AirVenture in 2024 as they are hoping to have some of their first customers flying by midyear.

Naturally the ADEPT V-6 offers the usual liquid-cooled advantages and is a foot narrower than a 550 Continental so reduced frontal area is possible. Of course, when making a new narrower cowling integrating a radiator is also required, but all told those flying high and fast should find advantages here. Not recommended for the casual kit builder, the ADEPT is an option for early adopters with the means to support something new.

Auto PSRU’s

Auto PSRU’s is not an engine manufacturer; they make spur-gear propeller speed reduction units. However, on a boutique basis they’ll help customers develop a firewall-forward fitment using one of their PSRUs.

Realistically their offering today is a 375-hp at 4500 rpm Chevy LS-3 crate engine mated to their PSRU and everything else (centrifugal clutch, fuel injection, ignition, alternator, cowling and so on) for Van’s RV-10s. With post-COVID supply chain issues and inflation this is now a $59,700 package, but at least the Chevy crate engine takes only three weeks to arrive at AutoPSRU’s.

Previous Subaru packages are now discontinued due to a lack of suitable Subaru engines. Likewise, their Mazda 13B rotary engine kits see sporadic interest and are typically a co-production with Atkins Rotary/American Rotary in Oregon.

If a customer has a Mazda or Subaru engine and wants just the 250Z gearbox, AutoPSRU’s can supply them at $15,400. They also offer their 300Z gearbox with a 7.0-inch vertical offset for use on small V6 or inline engines up to 320 hp; it’s $16,400. AutoPSRU’s can help with the entire firewall-forward engineering if fitting either their 250Z or 300Z gearboxes.

Viking Aircraft Engines

Viking has a unique place in the engine market. Citing the unquestioned mechanical superiority of contemporary automotive engines, they buy used Japanese and domestic auto engines and convert them to aviation use.

Their chief enabler is their own gearbox with a 2.33:1 gear ratio along with a catalog of over 45 firewall-forward kits fitting especially Zenith and RANS, plus Sonex, Kitfox, Murphy Aircraft, Van’s, GlaStar and others. Given the low cost of used engines, Viking leverages that into some of the least expensive engines in the Experimental neighborhood, and “overhaul” costs are bargain basement as well. Typically it’s simpler and less expensive to simply replace these engines rather than rebuild them.

One twist of using used auto engines is Viking will change its engine lineup as the engines become available or fade in number. Thus, the 110-hp engine is no longer available, but in later 2023 Viking added two engines, the V-140T and V-175. The V-140T is the 1.2-liter three-cylinder turbo found in Chevy Trax, Trailblazer and Buick Encore and slots between Viking’s 130- and 150-hp Honda offerings. The 140-hp GM engine is direct injected, spins a balance shaft and supports a constant-speed propeller. That strongly promotes more relaxed and fuel-efficient cross-country cruising as the rpm can be lowered while maintaining boost. Viking sells this engine with gearbox (PSRU), integrated exhaust manifold, computer, wiring harness and starter for $16,500.

The V-175 is a considerably larger 2.0-liter Honda Civic/HRV four-cylinder and is Viking’s second most powerful engine. Viking rates it at 175 hp at 5800 rpm and sells it also with gearbox, exhaust manifold, computer, wiring harness and starter for $17,500. This has to be the cheapest 175 hp in aviation history.

Viking’s entry-level offering is a 90-hp version of a three-cylinder, DOHC, 12-valve Mitsubishi. Fitted with Viking’s own gearbox (climb or cruise gear ratios can be ordered; it can also work in pusher applications), the combination weighs but 159 pounds and posts a particularly muscular low-end torque curve when augmented with the lower of the two gear sets. This engine is aimed particularly at the Zenith CH 701.

For its best-selling 130-hp engine, Viking starts with the direct-injected Honda Fit four-cylinder powerplant. Geared and with unexpectedly good low and midrange thrust, the combination weighs 220 pounds. Because the Fit engine has its exhaust manifold integral with the cylinder head, the engine is not a good candidate for turbocharging, but the gasoline direct fuel injection gives in-cylinder cooling allowing a high 10.8:1 compression ratio for increased efficiency. By venting crankcase blowby to the atmosphere, Viking escapes the valve deposit issues found in automotive GDI applications.

The 150-hp, 1.8-liter engine is another Honda four-banger. It uses port fuel injection and has gained considerable popularity because it offers a 20-hp bump for just 24 more pounds and not that much more cost than the Mitsubishi 1.3 liter.

Viking’s top offering is the 195-hp version of the turbocharged Honda Accord engine. Naturally, this also gives a fat low-end torque curve (there’s nearly 440 pound-feet of torque at the prop at only 1250 rpm). This engine is also augmented by Viking’s gearbox and Honda’s gasoline direct injection. Weight naturally rises to 260 pounds but either 100LL or mogas can still be run. As with other small-displacement, liquid-cooled engines, Viking specifies lead-scavenging additives with these engines if run on 100LL avgas.