Considering a professional-grade grinder costs several hundred dollars, the $50 price for a typical home shop 6-inch bench grinder is an amazing bargain. And while the “general purpose” wheels and cheap tool rests leave something to be desired, with a few bucks spent on wheels and rest upgrades, these low-cost marvels can easily tackle any home shop grinding task.

The author’s home shop grinder is an inexpensive 8-inch “no-name” grinder fitted with CBN wheels (fine grit on the left and medium grit on the right) and two Veritas adjustable tool rests.

Grinding wheels intended for steel are made with an aluminum oxide grit embedded in a vitrified ceramic binder. Like sandpaper, grinding wheels use numbers to define the grit size—40 to 60 for coarse, 60 to 80 for medium, etc.—but it’s the hardness, or friability, of the ceramic binder that really defines the utility of a grinding wheel.

A harder, less friable, wheel will last a long time, but it may not be particularly good for sharpening tools. The grit on a hard wheel tends to wear down to the point where it loses its ability to cut, and the wheel is considered “glazed” over. In order to restore the wheel, it is necessary to use a dressing tool to refresh the surface and expose a fresh layer of grit.

The custom shapes on these lathe tools were roughed in with a medium-grit wheel and then final edge sharpening was done using a fine-grit, white aluminum-oxide K grinding wheel.

On a “soft” wheel, the vitrified ceramic binder is more friable, which means the binder that holds the abrasive grains together fractures more easily. On softer wheels, this fracturing happens continuously as you grind, which simultaneously exposes a fresh layer of grit. Always having fresh grit means the grinding wheel will cut faster, cleaner, and cooler. But it also wears down faster. How friable a wheel should be is a matter of practicality. Too soft and the wheel can wear down very rapidly and lose its shape. Too hard and you sacrifice cutting efficiency.

Dressing tools are used to refresh a glazed or worn grinding wheel. The Norton stick (right) and diamond face tool (center) only refresh and square wheels. To dress a wheel round, you need a single-point dresser mounted in a fixture that can track perpendicular to the wheel.

The hardness ratings for ceramic grinding wheels go from A to Z, with Z being the hardest, or least friable. In my experience, wheels with hardness ratings of I or J are good for general machine tool sharpening. Some retailer sellers and online sites, Amazon in particular, may not provide the manufacturer’s hardness rating. So look instead for “recommended use” for high speed steel (HSS) or for sharpening woodworking gouges and planes.

An assortment of grinding wheels. The pink wheel on the left has a softness rating H, and is highly friable. The white wheel has a K rating, which makes it a bit more durable, but still quite friable. The next two wheels have N and P ratings and require dressing with a diamond tool to refresh the cutting surface. Not all grinder wheels are vitrified ceramic-bonded. The wheel on the far right is a resin-bonded wheel.

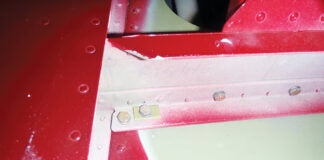

his close-up shows a groove worn into the face of this soft grinding wheel. Soft wheels are useful because they can be quickly dressed to make custom profiles.

Every grade of hardness also comes in coarse-, medium-, and fine-grit options. Most machine tool reshaping can be done on a medium wheel with the final edge sharpening done on a fine-grit wheel. For everyday retouching of a cutting edge or drill bit sharpening, a fine-grit wheel is all you use. A coarse wheel would be handy to have around to mount on the grinder as needed for heavy material removal, such as putting the clearance angle on a new parting tool or making the initial point on a new tool blank.

An inexpensive diamond-point dresser in a truing fixture. Note the dresser is angled down slightly and just below the centerline.

The fixture is shop made, with a protruding lip that goes against the back edge of the tool rest. The rest is adjusted so the diamond tip just touches the wheel.

A few years ago, I bought a Jerry Glaser 10V woodturning gouge (10V is a super-tough tool steel). I found my regular grinding wheels were overmatched for sharpening that tool. After doing some research, I equipped my home shop grinder with cubic boron nitride (CBN) -coated steel grinding wheels. CBN is second in hardness only to diamonds. I can’t say they will last forever, but after several years of regular use, they’re still as sharp as ever. The wheels were expensive ($200+ each), but they’ll probably be the last grinding wheels I’ll ever need. For everyday use they have numerous advantages: They cut fast with little pressure, and the wheel is always true and balanced. An added benefit is, compared to ceramic wheels, there’s no risk of them shattering, which is why there are no guards on the outside of my grinder.

The Veritas is one of several tool rest options available to upgrade a bench-mounted grinder. Yes, I’m grinding off the hard edges on the end of a half-round file. It’s a great tip from Tom Lipton.

The tool rest is just as important as the grinding wheels. Unfortunately, the flimsy stampings that often come with inexpensive grinders are nearly useless. Toss them as soon as practical and invest in, or make your own, high-quality tool rests. My home shop grinder is equipped with Veritas tool rests. They are easy to adjust, and you can purchase a jig for sharpening chisels and plane irons. I have them wing-nutted to the bench, so when I need to set up a special fixture for sharpening gouges or whatever, they can be quickly removed.

Next month, we’ll try something completely different: spinning!

![]()

Bob Hadley is the R&D manager for a California-based consumer products company. He holds a Sport Pilot certificate and a Light-Sport Repairman certificate with inspection authorization for his Jabiru J250-SP.