Young whippersnappers with modern kits might not understand the process of “getting a canopy frame to fit” when dealing with a twenty (plus) year old project. You’d think that with a quick-build fuselage, the factory could have made a frame that matched their prototype and shipped that… alas, that is not the case.

Fitting the canopy frame on the F1 Rocket involves significant re-shaping (bending) of the forward canopy “hoop” using a 3/4” conduit bender mounted in a BAV (Big-A**-Vise), then cutting of the rear hoop and shaping it with a bending board and bad language before fitting it in place, holding everything with your three hands, and welding the connecting tubes back in place. Yup, an aluminum airplane project that requires you to know how to weld!

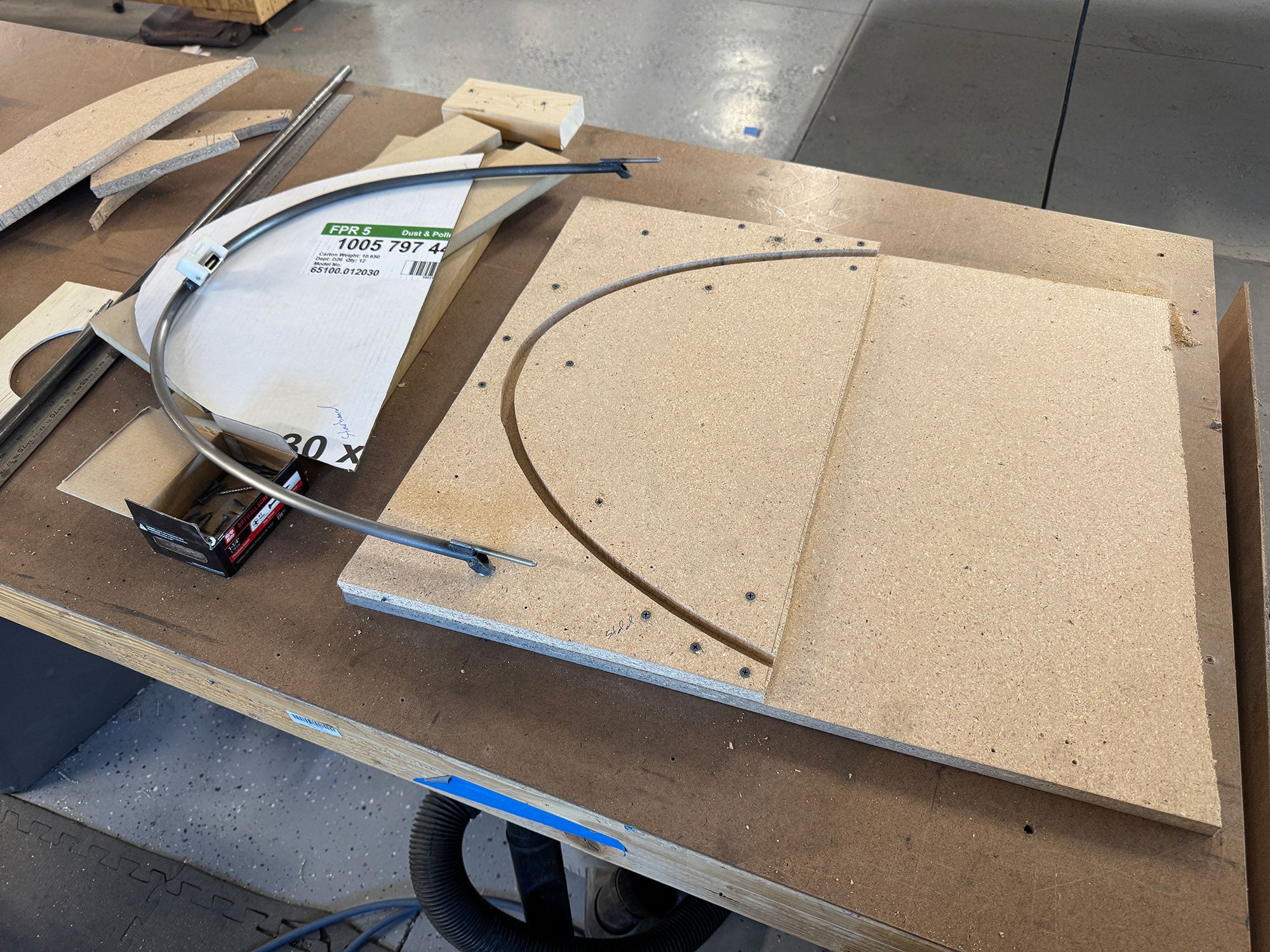

While the front hoop is made from 3/4” tubing, the rear is 1/2” and can be manhandled into shape with wooden block screwed in place on a building table. I dutifully traced the shape of the rear cockpit bulkhead, which mimics the shape of the hoop (but the hoop is 3/8” larger), then turned that into a bending board. And then the battle began! Like any good plan, it served well until first contact with the enemy—then all hell broke loose, and I found myself making up new blocks of different shapes on the fly, screwing them to the board as required to get the forces where I needed them.

By the time I was done, the hoop was properly shaped and welded back in place but my pretty bending board was much the worse for wear. It gave its life to build a nice airplane part and that’s all we can ask.