When it comes to aircraft ignition systems, I’ve always favored having one magneto and one electronic ignition system (EIS). Many dual electronic ignitions require things such as separate power systems with backup batteries. I’ve seen several such installations come through the shop over the years that have a backup battery that’s never been changed or really tested. Many of the batteries have been fully depleted and if needed would never work. Perhaps over time I will change my mind.

When it comes to aircraft ignition systems, I’ve always favored having one magneto and one electronic ignition system (EIS). Many dual electronic ignitions require things such as separate power systems with backup batteries. I’ve seen several such installations come through the shop over the years that have a backup battery that’s never been changed or really tested. Many of the batteries have been fully depleted and if needed would never work. Perhaps over time I will change my mind.

With my preferred setup of one mag and one electronic ignition, in the event of cockpit smoke or fire, I am able to turn off the master switch and sort out the smoke/fire while not concerned about the engine as the magneto should continue to work. I’ve asked many owners if they’ve really run the ignition system solely on the backup battery in flight to determine if it works and for how long. So far, only one person has answered in the affirmative. As an example, I test my backup alternator for 30 minutes on every third flight, so I know it works. It probably comes from my data center background—backup systems should be regularly tested under a load.

In this case the customer indicated that one of the dual Light Speed electronic ignitions systems completely failed during run-up. It had worked on the last flight. There is a possibility it had failed during the last flight and the owner didn’t recognize it. There isn’t much drop in rpm if one of the electronic ignition systems is still running, as opposed to a magneto. With one magneto and one EIS, if the EIS fails it will be quite noticeable, especially in cruise flight. In fact, initially you might think the engine has failed. This is because the EIS is usually running with advanced timing, as much as 5–7° more at altitude than a magneto’s fixed timing of 25°. Less advance means less power, hence the very noticeable change in engine noise.

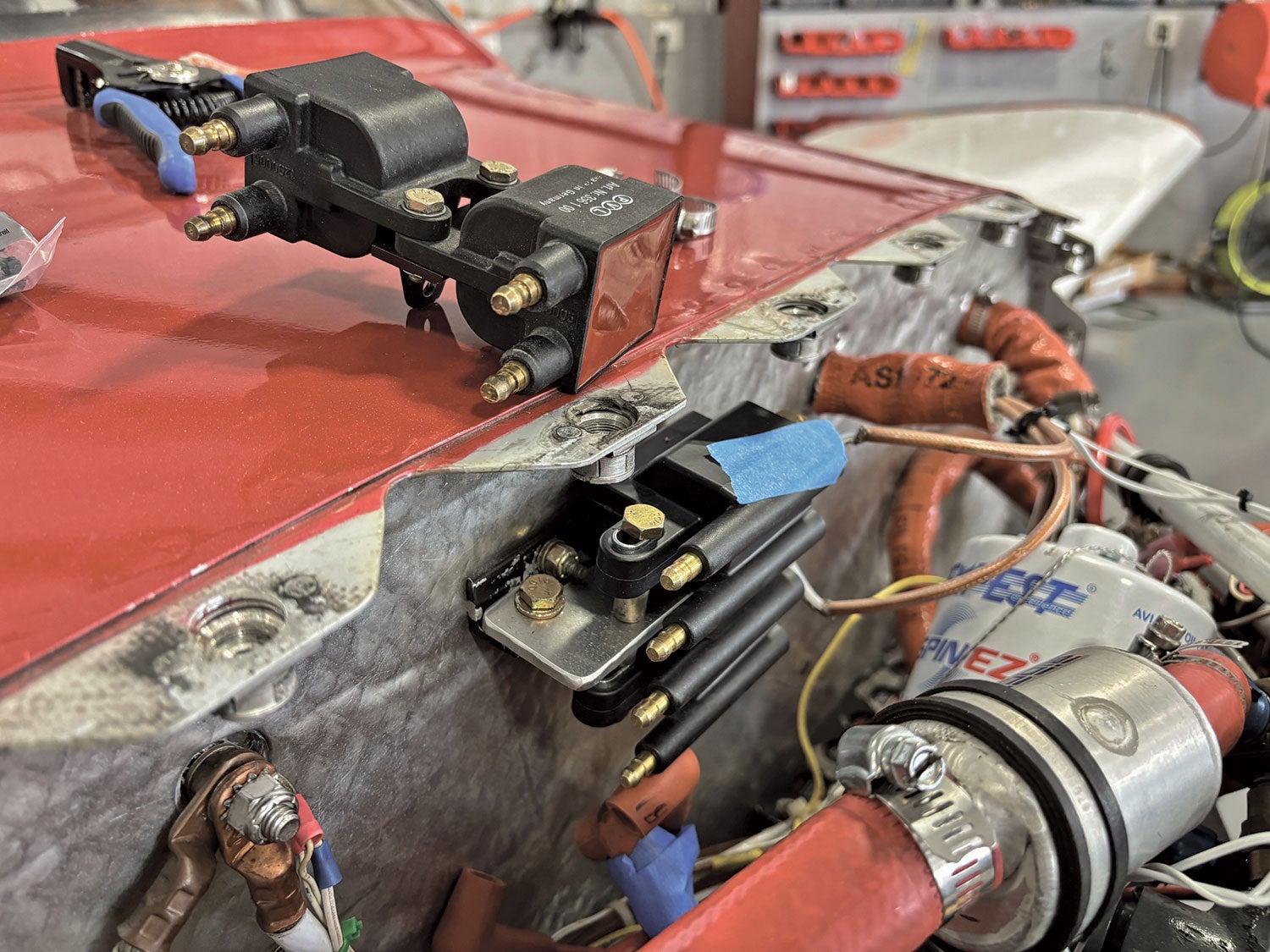

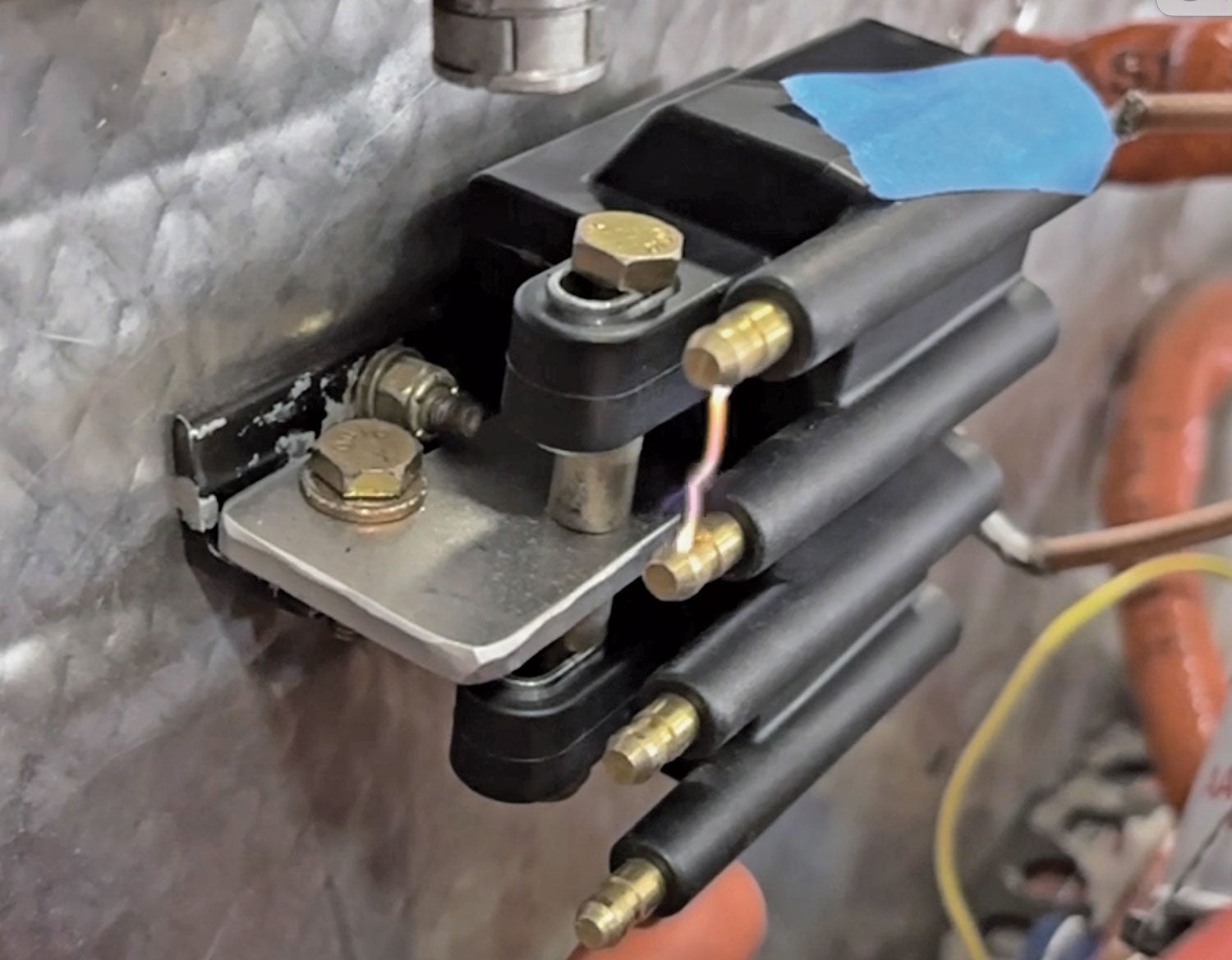

The Light Speed ignitions have three main components: the brainbox, which always requires a power source, the coils and the pickups. Of course, there are spark plugs and other associated wiring, but normally they are not the cause of a complete failure, except for the power source. In this situation, having two of everything should make troubleshooting easy.

When I troubleshoot any system, I usually try to start at the “halfway” point. This one had old-generation coils on it, and we’ve been seeing quite a few failures on those lately. For the Light Speed system, it’s very easy to visually see if the system is generating a spark. You want to be very careful with these next steps, or you could get hurt.

First, remove all of the spark plug wires at the coils to prevent inadvertent firing of the spark plugs as you rotate the propeller. Then check the resistance of the coils with an ohmmeter. Normal readings are in the 8KΩ range. In this case, all four coils checked OK.

The next step is to remove the spark plug from the Number 1 cylinder and place the piston at top dead center (TDC) on the compression stroke. With the master switch turned on, turn the ignition key to the Both position. The spark plug wires are left disconnected from the coils.

Now, slowly rock the propeller back and forth across TDC and you should see a spark across the coil terminals for the coil that is powering the Number 1 and Number 2 cylinders. Each coil fires two cylinders. In this case, with a dual system, we should have had two coils creating a spark, but we only had one coil creating a spark.

Next, move the prop 180° in the normal direction of rotation, which will bring it to TDC on the Number 3 cylinder. With the same rocking motion, you should see a spark from the coil that fires the Number 3 and Number 4 cylinders. We only saw a spark on one of the coils. Clearly, one system was dead, as the owner had stated.

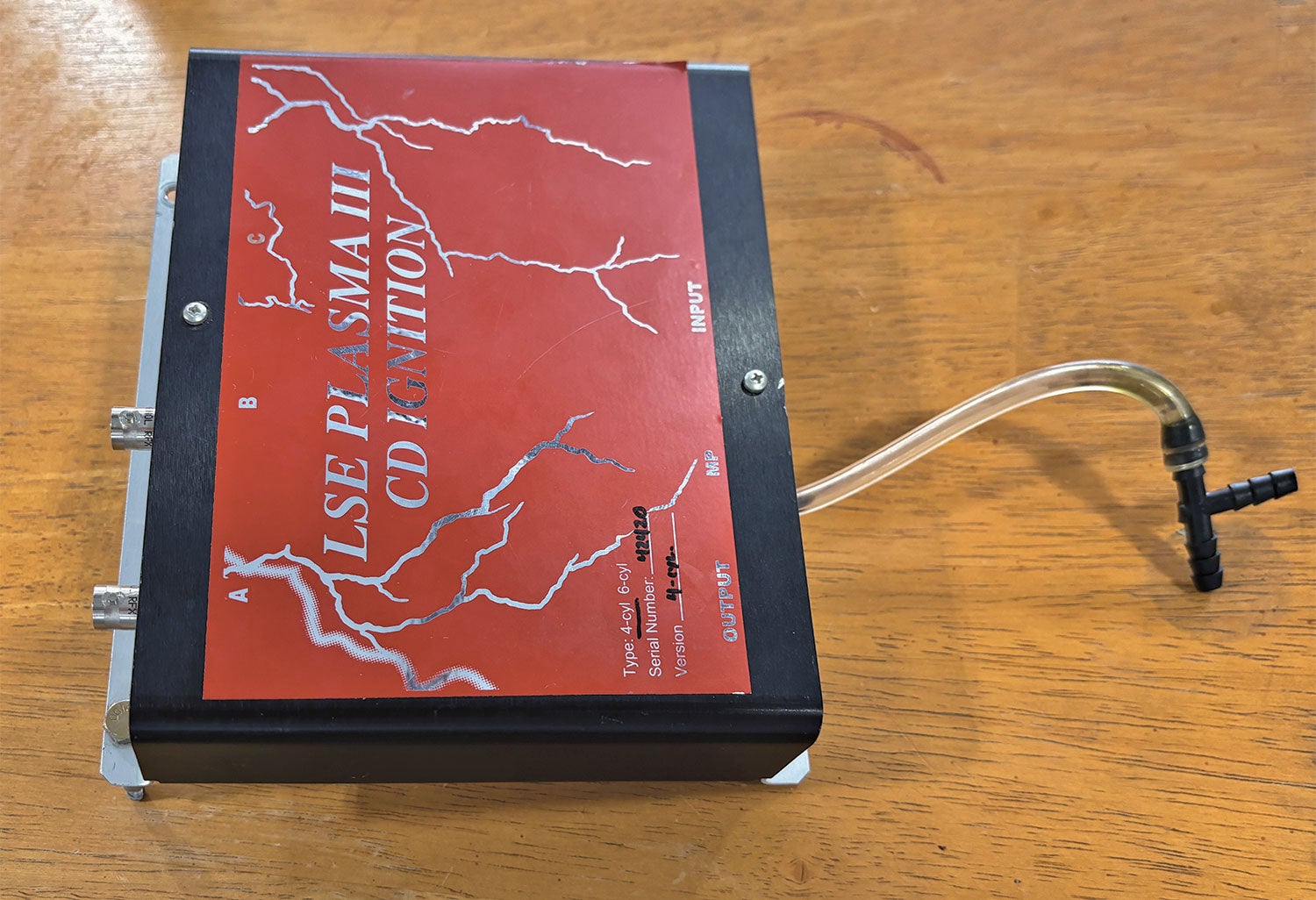

After verifying that power was properly connected to the brainbox of the failing system, we moved the RG-400 wires from that system to the coil that sparked and repeated the test. No sparks were observed. We placed wires from the good system over to the other coils and now they sparked. Clearly, we had a failed box.

So, what’s the fix? In this case we are going to install the new-generation coils on the good ignition side as a preventative measure. Plus, they have a higher-energy spark. After discussions with the owner, we decided that rather than fix the failed box, we are going to put a different electronic ignition on the second side, for about the same price as a magneto. The new electronic ignition system will be an E-MAG, which only requires power for starting, and once above 1000 rpm it will generate its own power. So now we have some extra reliability, and the owner should see the same performance he had prior with two electronic ignition systems.