I didn’t buy this GlaStar intending to commit significant resources to the engine in the first year. Indeed, few of us intend to do that—but it happens. I always knew it was a possibility. My GlaStar’s Lycoming O-320-E3D, originally in a Piper Warrior, had seen service in three airplanes, completed a total of 5200 hours and had last been overhauled some 1200 hours ago. But that was also in 1983. On the other side of the ledger is the 150-hp Lycoming’s well-deserved reputation for longevity. The low-compression, carbureted 320 is an easygoing thing, cool running and about as fault-tolerant as any aircraft engine made.

I didn’t buy this GlaStar intending to commit significant resources to the engine in the first year. Indeed, few of us intend to do that—but it happens. I always knew it was a possibility. My GlaStar’s Lycoming O-320-E3D, originally in a Piper Warrior, had seen service in three airplanes, completed a total of 5200 hours and had last been overhauled some 1200 hours ago. But that was also in 1983. On the other side of the ledger is the 150-hp Lycoming’s well-deserved reputation for longevity. The low-compression, carbureted 320 is an easygoing thing, cool running and about as fault-tolerant as any aircraft engine made.

Which one of these controlling characteristics would prevail, I did not know. But I was willing to give it a shot. So for the first year I owned this airplane, I watched the engine carefully, extensively upgraded my engine monitoring instrumentation and endeavored to be keenly aware of trends. It had not been on oil analysis, but I worked back through the logs (which were complete!) and kept copious notes myself.

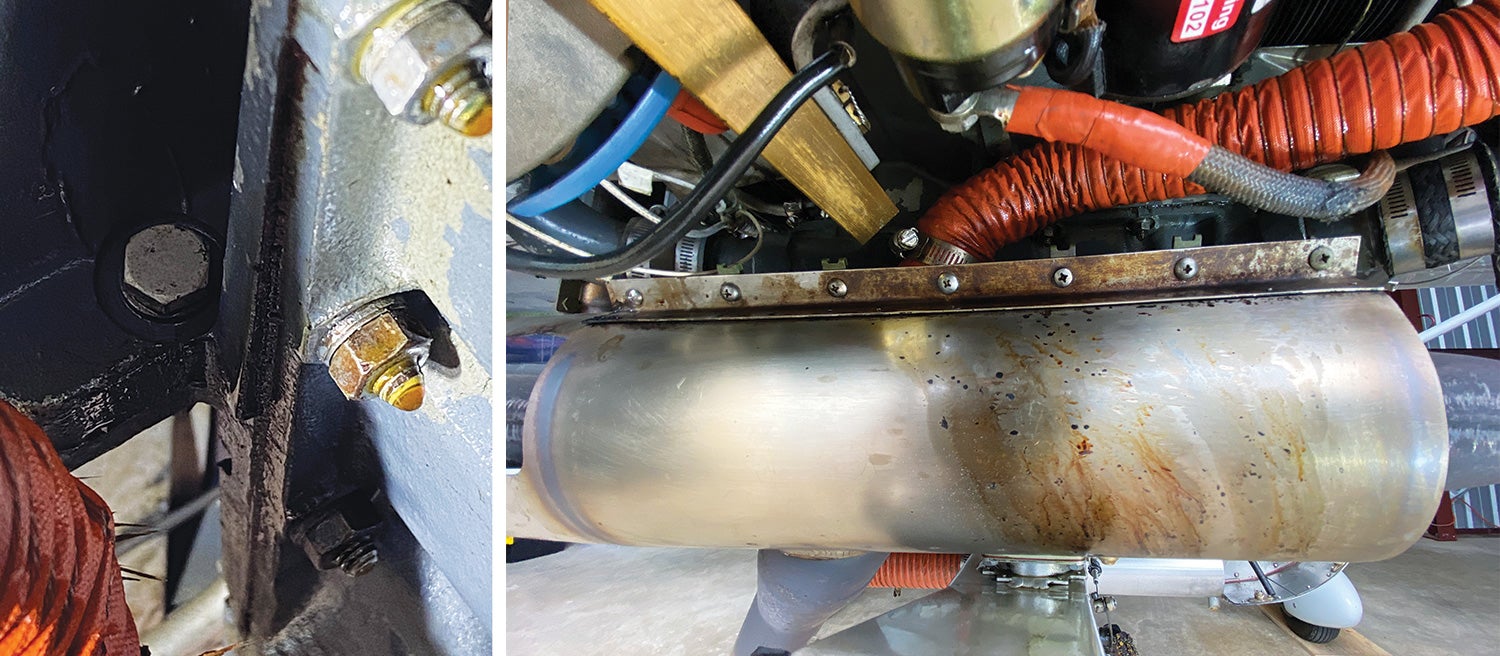

The first sign that age was a more decisive influence than reputation arrived right away. This Lycoming was a leaker. This is not surprising given that older engines that have gone through a period of low usage tend to do this. But I chased fitting leaks, desiccated pushrod seals, old rubber hoses on the cylinder drain-back lines and, finally, a weep at the top center case bolt. Generally, leaks at the spine suggest that the silk thread sealing the case halves has broken but, more crucially, the location indicated that there may be enough movement to imply case fretting. I thought I also saw evidence of other case leaks but never got far enough to thoroughly investigate.

The Tipping Point

What started this in motion was an exhaust leak. After replacing the gasket at the Number 4 cylinder’s exhaust port, I noticed a bit of port erosion, not uncommon in older cylinders whose previous exhaust leaks were allowed to fester. I tried a new gasket and some careful alignment of the components, but the leak remained. Oil leaks are a nuisance; exhaust leaks are something else and call for immediate repair. My research with those who’d tried it suggested that in situ port facing was a hit-or-miss solution, so the next logical step was to remove that cylinder to be sent out for repair.

What I found inside was more a chorus of gentle whispers than a riotous shouting of, “Overhaul me now!” Barrel corrosion, abnormal wear marks on the cam lobes and a substantial amount of combustion-chamber deposits met my gaze. None of those provided immediate cause for alarm. But when it came time to remove the piston pin, I found it would not shift more than an inch in each direction with moderate, um, encouragement. (The rod is a long arm to the big-end bearing and you don’t want to overdo it here.) There was also evidence on the piston of overheating sometime in the engine’s past.

Even before finding what I did, I was seriously on the fence about spending a lot of money for a single cylinder rework or even more money for a fresh set of cylinders and different pistons to raise power from 150 to 160 hp. (The compression ratio goes from the E3D’s stock 7.0:1 to a less tractor-like 8:5:1 to get that 10 hp, and it’s all done through the piston.) The logs revealed little about the nature of the previous overhaul. I didn’t know the crank-bearing sizes—were they stock or oversized from an under-ground crank?—and I didn’t know to what tolerances it was rebuilt in 1983. I’ve been down the road of trying “inexpensive” fixes on expensive machinery and it rarely ends well. I went home that night and consoled myself with an excellent local IPA—something I couldn’t legally do the last time this engine was overhauled—and started considering the options.

Growing a Decision Tree

The downside of owning an Experimental is that the choices are nearly endless. Most obvious was to replace like-with-like. Either overhaul my O-320, buy a new one or find a good used engine, perhaps plucked from another Cherokee. At the very least, I was planning to upgrade to 160 hp no matter which route I followed. After calling several suppliers for used 320s, I found few that would be a good fit, most of them still with the low-compression pistons and many with as many hours over as many years as the engine I already owned. Do you trade the devil you know for a fresh set of unknowns?

Then there was the O-360 route. If you know your Lycomings, you understand that the value of an O-360 is really close to an O-320. But the O-360, in addition to being more powerful and heavier, is also wider than the 320, so you must change the exhaust system at a minimum. In the GlaStar, you have to alter the baffling and make provisions on the cowling to clear the one rocker box. (Though some say you can bash in the metal rather than open up the fiberglass, which seems a bit crude to me.) The 360 also uses a larger carburetor with a different throat configuration, so there’s a good chance the airbox will have to be replaced or at least substantially reworked. And you have to be aware of prop differences. As much as I craved the upgrade all the way to 180 hp, I was hesitant to take on that much extra work. Swapping engines like-for-like is enough of a job all by itself. Since this happened in early summer, I’d hoped to be ready to fly again before my season closed in Oregon. An O-320, or similar, seemed the way to go.

Overhaul, New, Something Else?

In the accompanying series by Paul Dye (“Renewal”), you’ll see one way to go about an engine overhaul. But it’s important to note that he had excellent documentation on a first-run factory Lycoming, even as it was over the nominal TBO on hours. He knew where it started. I was not in the same situation since my engine’s documentation was relatively sketchy even though I had full logs (see “A Lycoming Lifetime,” below). The logbooks disclose few facts about the overhaul, and I’ve never found documentation featuring more detail in the trove of paper that came with the airplane. As best I can determine, that overhaul in 1983 included replacement of the camshaft with a serviceable unit and that the engine was given the treatment required to be called an “overhaul,” all done by a local A&P. It appears that the cylinders date from the original build, sometime in 1973 or 1974.

I didn’t really know the condition of this engine other than what I could see. Still, I started there, calling Barrett Precision Engines first. (They built me a magnificent IO-390 in late 2005 and were amazing to work with—before the sale, during the build and afterward as well.) We talked about upgrading to 160 hp or even a little further, just as we discussed obtaining a long-stroke crankshaft to make this a 340. The starting point, especially for an elite shop like Barrett, was very reasonable to do a high-compression O-320, just under $25,000 with all the accessories new or overhauled and brand-new cylinder assemblies. (Incidentally, these prices were obtained over the summer of 2020 and are likely to be obsolete by the time you read this; all manufacturers have seen price increases going into 2021.)

But here was a catch. We didn’t know the true condition of the crankshaft or cam. If either one of those needed replacement, we’d be getting close to $30K. What’s more, while my O-320’s crank was hollow, allowing for the future fitting of a constant-speed prop, the case was not machined for the governor. Rhonda Barrett told me, “We could probably find someone to do that work while we’re overhauling the cases, but I don’t know what that would cost.”

While Rhonda was working up her quote, I contacted Lycoming and Superior. A factory-overhauled Lycoming O-320 with the higher-compression pistons was quoted at $28,400, but that was for an engine spec with a prop governor pad—in this case, the front pad, which I thought would be a somewhat easier fit on a GlaStar than the rear governor—and a hollow crank for a future constant-speed prop. Still carbureted, still with magnetos. From Superior came a quote of just under $29,600 for an O-320 at 160 hp with mags and the ability to use a constant-speed prop in the future. Lycoming’s was a factory-overhauled unit that may have some used parts, but in all likelihood was a new engine. The Superior was all new and benefitted from having roller cam followers, a feature I wanted.

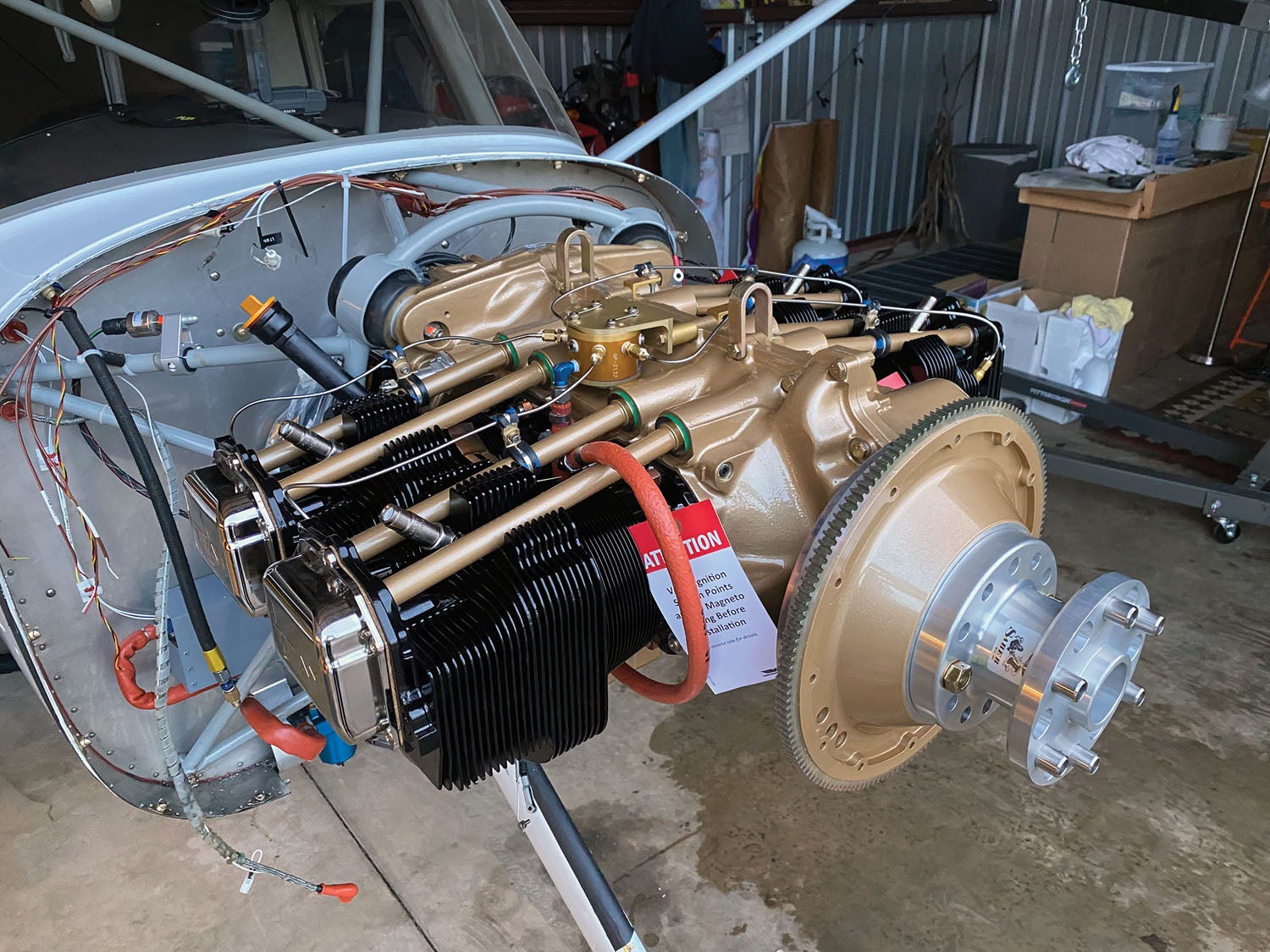

Then Came Titan

I admit to being lured by the proclamation on Continental’s Titan website that the X-320 and X-340 engines start at $26,400 and $28,100, respectively. Such a small price delta to the 340 began arguing strongly in its favor. Something else did, too: It’s very close to the same physical size as the O-320, meaning I could add displacement (and power) without having to replace my exhaust system, baffling and other systems. At first, this seemed like a drop-in replacement, including the carburetor, and I was ready to go for a carbureted O-340 as a straight swap for my elderly Lycoming.

Not so fast, Rhonda Barrett reminded me. First of all, the 340 uses the carburetor from the 360, which has a larger inlet bore but, worse from my perspective, is taller. (There is a spec of the 340 that can take the MA-4SPA carburetor, the same one used on the O-320, but I later learned that the 340 runs better with the larger MA-4-5 carb.) I knew the design of my GlaStar’s airbox would not tolerate either of these changes, so, right there, a new airbox was on the table. Second, more power was going to mean more heat. My O-320 had the common seven-row oil cooler mounted to the aft baffle behind the Number 4 cylinder. I thought, just maybe, that I could get away without changing the cooler.

Bill Genevro, of Airflow Systems, a seller of Experimental-class oil coolers and accessories, shared his experience and suggested that not only would the seven-row be insufficient, but the 10-row cooler recommended by Titan might also be a little iffy. He suggested moving up to a 13-row cooler to be safe. No way that was going to fit on the aft baffle.

Injecting Mayhem

At about this point, I realized that building a new air-induction system would be the same amount of trouble for a carburetor or a fuel-injection servo. As it turns out, the Airflow Performance FM-150 that’s the preferred servo for the IO-340 is the same size as the MA-4-5 carb (and, for that matter, the Bendix RSA and equivalent injector throttle bodies). In this case, the difference in total price between an O-340 and the IO-340 is $1200 from Titan. Of course, that’s not the lot of it, since you have to change fuel boost pumps—fortunately, I didn’t even have one, so it’s a matter of adding a $410 Airflow Performance pump—and, likely, the engine controls. I was able to salvage my throttle cable but had to buy a new mixture control. So $1200 becomes $2000 once I’ve purchased a Van’s Filtered Airbox and spent the time modifying it. But I’m getting ahead of myself.

At the bottom line, the injected IO-340 priced almost dead on $30,000. (A brief reminder that this was the 2020 price; Titan, as well as many engine makers, raised prices for 2021.) Overhauling my O-320 could have been the least expensive route but came with several unknowns that could have taken the final tally to within earshot of a new engine from the major sources. So it was the extra displacement and the promise of 180 hp from a 150-hp-sized box that tilted me at the Titan IO-340. An order was placed and my job stripping the 46-year-old Lycoming off the firewall began.

What To Keep, What To Change

As I suggested at the outset, a like-for-like change to an O-320 would be the fastest, easiest route to a fresh engine. I could keep all the basic hardware and just hit the items needing to be refreshed. Instead, I opened a can of worms. And not just a home-cupboard-sized can, one of those huge tins you see in a commercial kitchen.

Back to the injection upgrade. I spent a couple of short days mocking up the boost pump location on my firewall—not the ideal place but acceptable if you build a heat shield and feed it with cooling air. Then a hard line and measurements for a new flexible hose between the pump and the mechanical fuel pump. For these projects, I left the Lycoming in place so I knew where hard parts needed to go.

The biggest challenge was the airbox. My GlaStar had a carb-heat box resembling something from a Cessna, with a Brackett filter in the center of the cowling below the spinner. I didn’t want to do bodywork, so the side-mounted NACA inlet commonly used by GlaStars was off the table for a moment. Instead, I bought a Van’s Filtered Airbox ($190) and proceeded to modify it with a fiberglass “funnel” to match the existing hole in the cowling. To get that far, I needed to borrow a non-working Bendix RSA injector body for the mockups.

And, of course, because the GlaStar uses vinylester resin, that’s what I had on hand. Only the Van’s FAB’s lower section is made with epoxy—you cannot mix them. Call it $200 in composite supplies I didn’t already have, as well as several days of fitting, glassing a little here and there, waiting for the cure, sanding, glassing a little more here and there, waiting for the cure, sanding…you get the idea. I have 20 hours into this part of the project and I could probably spend another five or so making it look really spiffy.

While waiting for the epoxy to cure, I worked on the revised oil cooler mount. A 13-row unit is much bigger than the seven-row that was in there, so I had to fabricate a firewall mount and carefully position the cooler where it wouldn’t get in the way of the breather system, engine controls, engine mounts, fuel lines and other subsystems. One complication: Because of COVID-19, Airflow Systems was out of stock on the 2006X cooler. The thickness and width are the same as the smaller cooler, it’s just taller—so I could approximate the bigger cooler’s footprint and work ahead; Airflow has full dimensional drawings on its website, which I used liberally. Still, I was hugely relieved when the real item came and everything fit.

I used Airflow’s 4-inch aluminum ring and their 4-inch aluminum doghouse, but had to modify the existing aft baffle face heavily. The oil-cooler upgrade was nearly $1400 in materials, including the cooler from Airflow, new hoses from TS Flightlines (more on those later) and various fittings, SCAT hose and clamps from Aircraft Spruce & Specialty. I wasn’t sure if the engine would come with fittings for the oil cooler, so I bought new ones; turns out it had them already installed.

Hoses & More

I both wanted and needed all new hoses for this installation, which added about $800 to the total, including one fuel line, two oil lines and one line each for the fuel- and oil-pressure sensors. (The line from the fuel pump to the servo and from the servo to the flow divider come with the engine.) I also opted for TS Flightlines’ clever “red cube” mount for the fuel flow transducer. More on the design of these hoses in the next installment, where I have more space to geek out over their fluid-carrying awesomeness. One last thing relating to the fuel system: I had to buy a new pressure probe, since the one for the carburetor would be out of range with fuel injection. That’ll be $129, please.

With the two major system changes moving toward completion, I turned to other projects. This GlaStar is 18 years and 600 hours old, so it was never a consideration to reuse the rubber engine mounts. I also needed to modify the baffles—changing the oil-cooler feed was one impetus, but the decision to go with a prop-governor pad on the front of the engine caused a cascading number of small mods to the fixed baffling. In retrospect, I think I’d rather indent the firewall slightly and use a rear governor on the GlaStar—assuming the baffles are already made.

The fixed baffling was in overall good shape but kind of battle-scarred, so I cleaned it up and sent it off to be powder coated. In the end, with new engine mounts, new hardware, new baffle seals and refinished “tin,” I had almost $700 into that part of the project.

I feel like Columbo saying, “Just one more thing,” but I also had to send my prop spacer back to Saber Manufacturing. The IO-340 comes with either 3/8-inch or 1/2-inch prop-bolt bushings. Naturally, my engine had 7/16-inch. (Really?) Fortunately, Sam Tilleman at Saber was happy to open up the engine-side holes—thankfully there’s plenty of meat there—for a reasonable $150.

Something to keep in mind as you mentally tally the costs of the conversion. Some of these items would normally be replaced at engine-swap time, and they’re no more expensive for the IO-340 than for the O-320. And for builders not yet flying, planning for the IO-340 would prevent a great deal of this back and forth, and present a much more palatable bottom line. The fact that the 340 is massively cost-competitive with smaller, less-powerful engines is a strong inducement to consider it new or as a retrofit.

Next time, a quick wrap-up of the installation, preparation for the first start and, if the weather gods and Mr. Murphy are willing, getting this GlaStar back in the air.

Photos: Marc Cook and courtesy of the manufacturers