I can’t imagine any pilot getting their private certificate without an instructor who has pulled the throttle back to idle many times during training. Power failures on takeoff, in the pattern, on landing, during cross-country flight—all of these amount to training techniques that go back to the earliest days of aviation, when engines failed almost all the time!

I can’t imagine any pilot getting their private certificate without an instructor who has pulled the throttle back to idle many times during training. Power failures on takeoff, in the pattern, on landing, during cross-country flight—all of these amount to training techniques that go back to the earliest days of aviation, when engines failed almost all the time!

Engines have gotten far more reliable—even in the almost 50 years I have been flying. Back when I was a student, almost everyone in the pilot lounge had had an engine failure at some point—and mostly they were actual engine failures, like sucked valves, failed pistons or broken cranks. Nowadays, the basic engine has become much more reliable, but engine failures still occur due to ignition problems, carburation or fuel injection issues or the ever-popular “fuel starvation” emergency.

So we continue this short series on “off-nominal” situations in Experimental flight test, looking at the broad topic of power failures—how to identify them, what to do about them and, maybe, how to prevent them from happening in the first place.

Powerless

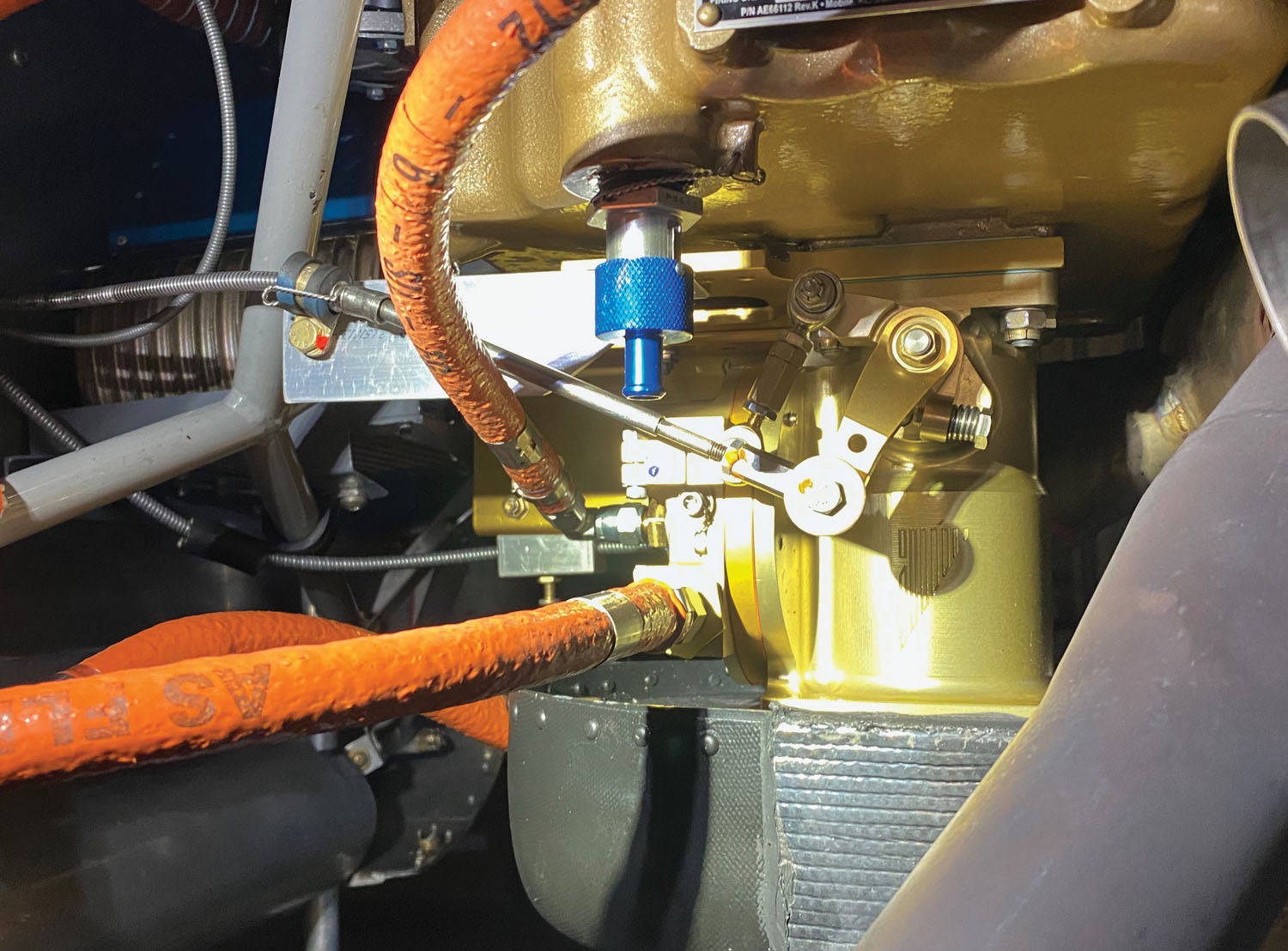

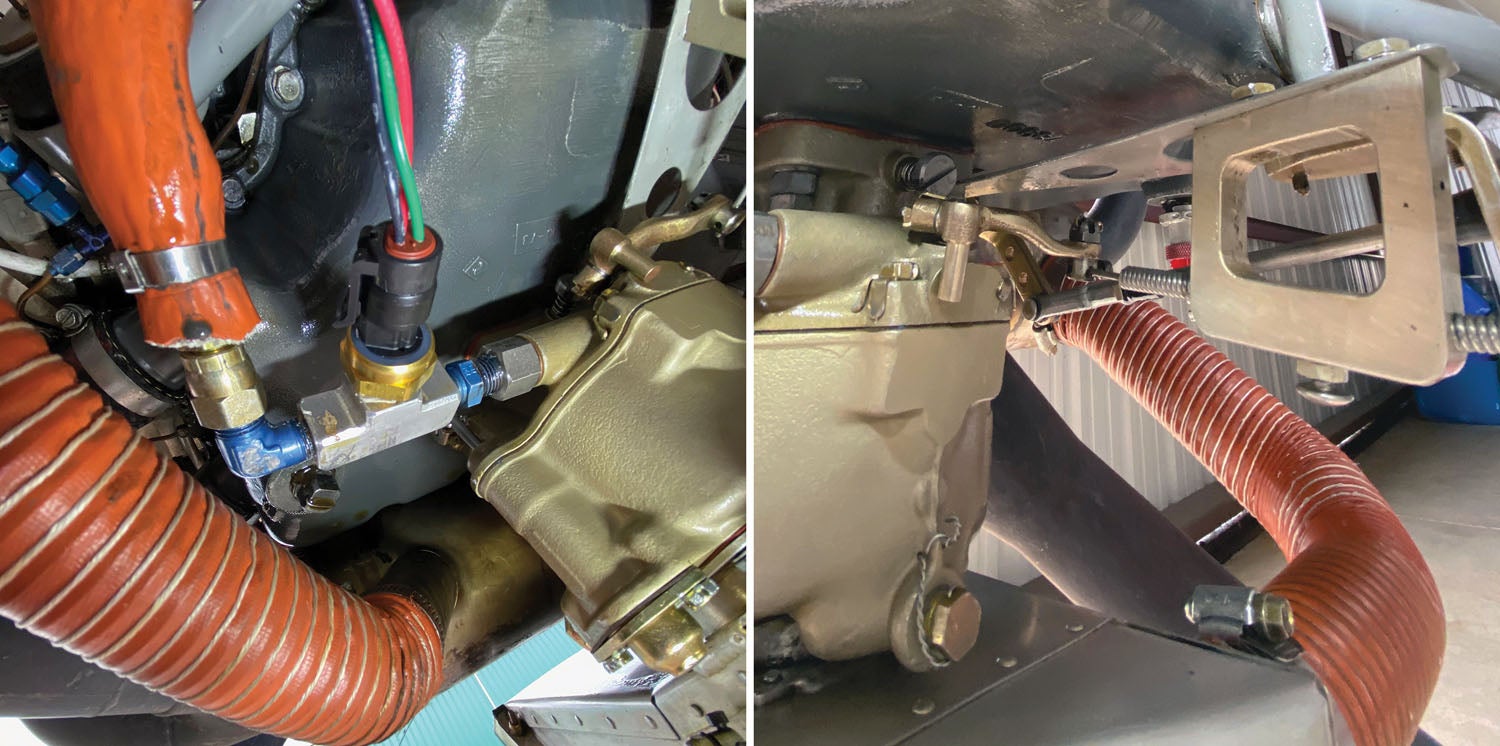

In most powerplant problems, you either have no power or reduced power. But it is also possible to be stuck at full power—so let’s talk about that one first. It is not unheard of for a mechanical problem either in the cockpit (the control itself), before the engine (in the cable) or on the engine side of the firewall (at the throttle body or carburetor) to cause the throttle to be stuck full open. This should be obvious but resist the temptation to yank on the throttle to get it closed. Any more than moderate resistance on the control should be enough to tell you to leave it alone. You’re better off, in this case, with more power than with none.

You usually discover a jammed-open throttle when reducing power after initial climb, which means you are generally close to the airport. That’s good. Your response is to turn back to orbit the field so that you have a place to go, as with any powerplant issue. It’s going to be tough to land with full power, so you have to think, “How can I reduce power without pulling back the throttle?” There are really only two ways, three if you have a constant-speed prop. Pull back the mixture, turn off the ignition or pull back on the prop control. Pulling the prop back isn’t going to get you very close to idle power, but it might help a little. Pulling back on the mixture far enough will make the engine quit—but if you pull it back not quite that far, the engine is really going to be starved for fuel—which means it will produce a lot less power. For the moment, you’re not worried about things like CHT or EGT or engine roughness from a lean mixture.

How about ignition? Turning the ignition on and off is how power was controlled on the old rotary engines of WW-I. It does work, but it is not very precise. Back then, they had a “blipper” button on the stick that made it easy to cut the engine off and then get it firing again—the weird noise we associate with watching those early airplanes land. Doing it on your modern engine is much less easy—but if you get yourself set up to land, you can always cut the ignition and glide to a landing. You can do the same when you have the field made by pulling the mixture.

With a nicely balanced set of fuel injectors and electronic ignition, it is possible to get an injected engine to run smoothly way, way down in the powerband, and I have used this method with a stuck throttle all the way to landing. Also, remember that drag is your friend if you have too much power, so add all the flaps and gear to get you down closer to the desired approach speed. If all else fails, set up over the field and kill the engine. That’s why you practiced all of those engine-out landings, right?

The Red Knob

How about if the throttle is fine, but the mixture is stuck? Truth be told, this isn’t much of an event unless you happen to be already leaned way back to where you’re running rough. Fly with whatever mixture you have got to where you can land and deal with it on the ground. We used to run small engines on Cubs with no mixture control in the cockpit—just turn off the ignition to stop the engine. Likewise, a stuck prop control is not that big of a deal—the engine will do fine at most prop settings, so fly to a landing and deal with it on the ground.

Cables do go bad, by the way, and things can get stuck or over-centered if they are not properly adjusted. In a brand-new airplane, expect a stuck control to be a rigging issue—one that you should have found by inspection and/or ground runs. But everyone makes mistakes. If it is later in an airplane’s career, expect a cable going bad. That’s why we check cables during inspections.

Uh-oh…

What about a total power loss? You’re droning along in cruise and the engine sputters to a halt. Nine times out of 10, it has run out of fuel. Be calm, switch tanks, turn on the boost pump if you have one and wait for the engine to re-fire. All while flying the airplane, of course, and looking for a place to go. If the problem was that you ran a tank dry, you’ll soon be back in business. If you have run all tanks dry, then fly your new glider to a landing on the best surface you can find. In any case, your primary task is to fly the airplane!

The big question that always comes up with a total loss of power is, “What do I do if I don’t have a good place to land?” You might be over a city or mountains, so it’s a reasonable question and one that drives our thoughts on how we use Experimental airplanes. For this discussion, I have been assuming that we are early in a flight-test program, so it is reasonable to expect that you are close to your airport, close to another airport or over flat, unpopulated land. If you’re not, it’s fair to ask: “What are you thinking?”

In general, you have no business being over unlandable terrain until an airplane has been proven to be reasonably reliable. Yes, engine failures can and do occur at any time in an Experimental aircraft’s life, but the real high-risk exposure is early on when wiring and fuel systems are still vibrating and shaking for the first few hours of their operational life. Also, while you’re learning the systems, calibrating things like fuel gauges and flow instruments—yes, you’ve done a baseline cal on the ground, but keep validating the data while you’re in Phase I. Later on, engine stoppages are more likely to be fuel-supply issues. In short, there is no fuel in the supply. That’s a pilot problem, not an airplane problem. The good news is that it’s easily fixed before takeoff.

During testing, however, there is no reason to accept poor landing options. For most builders who live in densely populated areas and whose airports are similarly surrounded, first flight and Phase I testing will take place at a remote airport, as dictated by your local FAA and DAR, who have come up with your flight-test area. Yes, you will incur extra cost, schedule delays and inconvenience—but safety and lowering risk always costs something. This is something you can and should address on the ground by making the right decision before flight—there is no excuse for putting others at risk because of your convenience—and make no mistake, you put others at risk trying to land in a schoolyard, on a neighborhood street or on a four-lane boulevard with wires running across it. I can’t tell you how to land in those places reliably, except to never stall and lose control of the aircraft while you’re still in the air.

The “In Between”

No power or stuck-on power are the two easy cases, and I’ve had them both. The judgment is easy—there is not a lot to figure out. But what about the intermediate cases like partial power loss? This can come as a sudden onset of noise and vibration, literally with a bang as some critical part of your engine departs the assembly. Or it can come as a slow drop-off of power with rough running. In any case, the first thing to do is keep flying the airplane and figure out where you’re going to go if you don’t have enough power to keep flying. This rule is true if you’re in cruise, on descent or on the initial climb from the runway. Fly the plane, and go for the best landing surface that you know you can reach. Remember, the airplane is expendable, you’re not. Keep flying it until it stops moving.

Managing the rough engine is now a matter of trying the different controls you have. Throttle, mixture, prop, carb heat (if applicable, or alternate induction air), fuel selector, fuel boost pump, ignition—that pretty much covers it for most planes. Move each through its range and see if it makes a difference. Engines that were running fine and then suddenly aren’t have suffered a failure—or a passenger bumped something. Yup, I’ve seen ignition switches bumped to off, mixture controls changed with a sudden grab in turbulence. In many cases, you’ll be able to restore things and continue on your way.

If it’s not a misconfiguration but a real failure, your job is to find a way to make the best power you can. That could be running on one ignition if the other has lost its timing. There have been cases of one mag or ignition system failing adversely—meaning not just off but firing very late or very early, causing loss of power or engine roughness. Testing each ignition source independently gives you a chance to see if that’s the case.

Work through each subsystem as methodically as you can. If it’s not ignition, it could be on the fuel side. Try alternate air or carb heat, and if you have a carb, give it a second to see if carb heat is doing the trick. Although carb icing is usually gradual in onset, you may have been too busy on other tasks to notice. You could have an obstruction ahead of the carb or throttle body, so turning on carb heat or alternate air could be your fix. Remember, the engine needs four simple things to run: fuel, air, compression and ignition. All but compression are things you can control from the cockpit. So try them all, one at a time, and note the response.

Partial power losses on takeoff happen more than you think—and it is often caused by a fuel-pump issue—this is why we run a boost pump (if we have one) in parallel to the mechanical pump (if we have one) on takeoff. If you sense a sudden drop-off in power, check to make sure you haven’t forgotten the boost pump. But first, get the nose down. It should go without saying—though here I am saying it!—that you already have a plan for takeoff power rollbacks. You know where in the process you can yank power and land on the remaining runway. You know the point at which you need to get the nose down and find the best possible spot straight ahead. And you know when you have enough altitude (given the runway, winds, terrain, etc.) to even think about returning to the runway. Make that plan ahead of time and follow it.

Instrumentation Errors

What about things like EGT increases or decreases, off-scale CHTs, oil temperature problems or oil pressure problems? In flight test, it’s likely you (or the computer) are watching these parameters closely. That’s not a bad thing, but the first rule in spacecraft systems monitoring is to always quickly ask if the instrument is lying to you. Oil pressure rarely goes from fine to zero in an instant—unless you also blew a part of the engine off, and that will be so noisy there will be little doubt. It also doesn’t typically flick from 80 psi to 2 psi and back to 80 psi in the matter of a second. CHT or EGT anomalies? Same thing—instant changes are usually instrumentation. If they wander off high or low—look into it, but first ask yourself, “Is the engine running smoothly?” If it is, then don’t touch a thing. Start thinking about the problem. Don’t make the (potential) problem worse by sudden action when no action is required. The main purpose of the engine is to provide power for flight—if it is doing that, use that power to get to a safe landing and then troubleshoot.

Let’s repeat that as we finish talking about engine issues: The place to troubleshoot is on the ground. So long as the engine is providing enough power to get to a safe landing on an airport, don’t try to make a full diagnosis or mentally flick through the parts catalog in flight. When you know that nothing can be fixed from the cockpit, get on the ground and deal with it there. Do it calmly and, whatever you do, don’t guess at the solution and make matters worse.

I’ll wrap this up next month with a look at distractions and “minor” emergencies, as well as some consideration of the worst-case scenarios, which, thankfully, don’t happen very often. But that doesn’t mean we should pretend they won’t ever, so I’ll see you in a month for the rest of this story.

Photos: Kevin Wing, Marc Cook, Paul Dye.

The only off-nominal engine behaviors I encountered during were rough idle due to foul plugs, accidentally reduced the mixture control instead of the throttle, or forgetting to lean the engine during a high altitude climb (to 9500ft). I never learned about engine failure on take off. The only practice engine failures were planned and to perform the emergency procedure for max L/D for engine out landing. All the other real engine emergency procedures were learned from the safety webinars hosted by EAA and AOPA. The emergency turn due to the engine out at takeoff was never discussed, or even tested by the DPE.