Last time we met, the question was if the engines of the future had already arrived. This time I’d like to turn around and consider the ’ol ball and chains we’ve been flying for decades. Lyconsaurs, in other words.

Engineering Wise

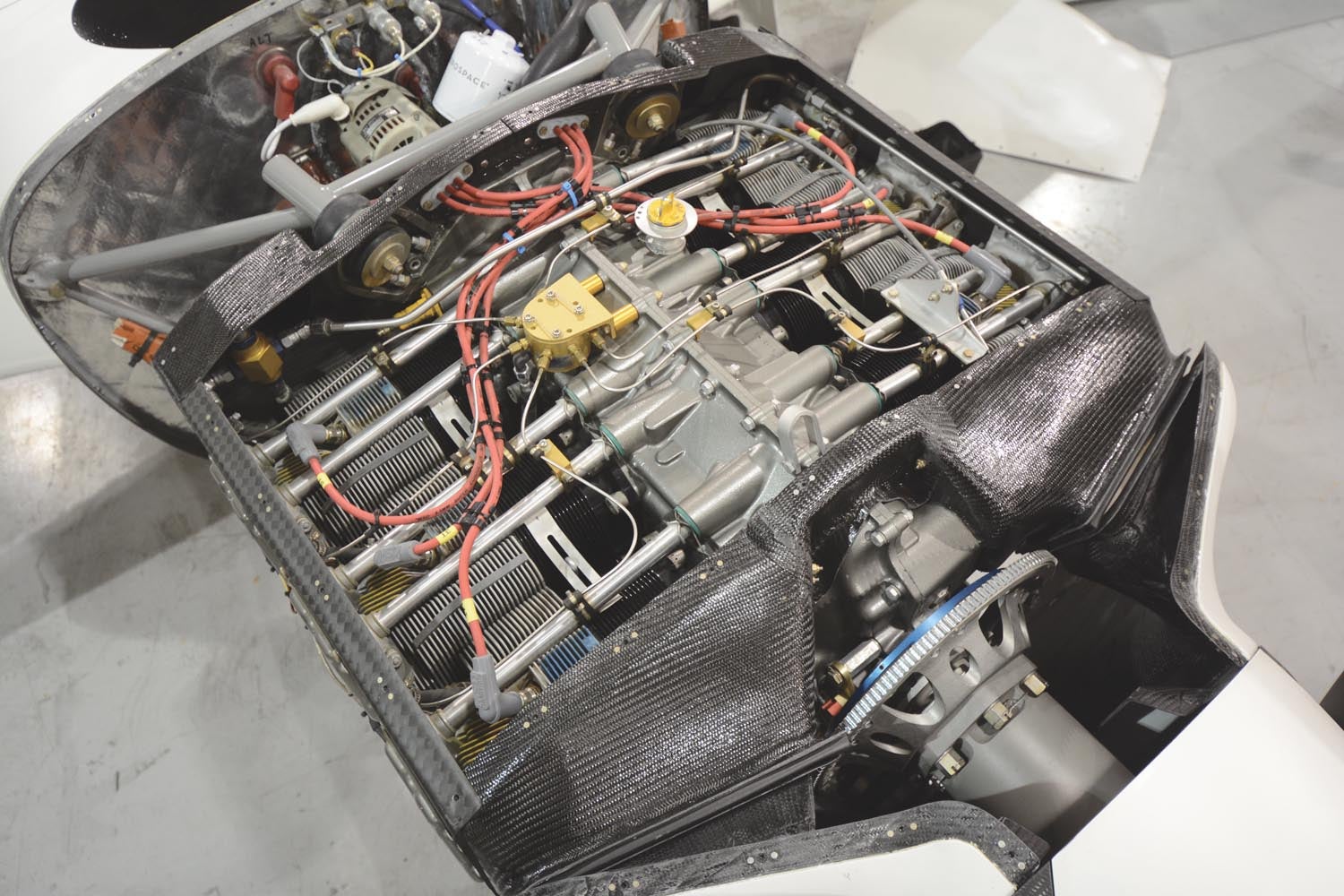

It’s popular to disparage these veteran engines, but from an engineering point of view they retain powerful advantages worth celebrating in our rush to the future. After all, should these engines fade from the scene, most of these attributes will be what we’ll miss and tell the kids about. Namely, the Lyconsaurs are large displacement, slow revving, simple engines with minimal parts count. These are good things (mainly). The big displacement means they make locomotive-like torque at low rpm, which translates into propeller-friendly crankshaft speeds so the weight, complexity and expense of a gearbox are avoided. Furthermore, their inherent low rpm and low specific output (power per cubic inch) puts minimal demands on breathing, so they do relatively well with simple two-valve layouts (no need for four valves or overhead cams). All this keeps the parts count low and should mean low cost. Should, except lawyers.

The big displacement and low specific output are also prime ingredients for durability. The Lyconsaurs can run near their rated power for far over 1000 hours, something your car engine might have more difficulty with than you think.

Often overlooked is the low-rpm nature of our big engines means reduced friction. That’s a big plus in fuel efficiency—the most fuel-efficient engines in the world are extremely slow-turning ship engines chugging out 100,000 horsepower at a leisurely if unstoppable 100 rpm or less—a feat supported in no small way by copious turbocharging. In airplanes the modest 2300- to 2700-rpm operating range is still low enough to keep friction and internal engine stresses manageable for the long haul. Good stuff.

Still in the good column, the Lyconsaurs are air-cooled, meaning the elimination of coolant leaks, water corrosion, galvanic action from dissimilar metals, coolant chemistry, pumps, hoses, clamps, radiators, their ducting and shutters and associated maintenance. Installing these simple engines in an airframe is straightforward as the prop simply bolts on the end of the crankshaft and it doesn’t take much engineering to have cooling air ram in the front and exit somewhere to the rear.

In short, the big, slow Lyconsaurs are a good fit for simple light aircraft. They should be inexpensive, durable and easy to maintain. In many respects their worst inherent characteristic is they’ll never be the last word in fuel efficiency (unless turbocharged) because there are always many cubic inches to feed.

On the Other Hand

Of course, there are inherent engineering challenges to the Lyconsaur layout (we’ll get to the practical and business-case issues in a minute). For starters, the attribute of air cooling is also a deficit. Air-cooled engines expand and contract like balloons compared to their more thermally stable liquid-cooled cousins. All sorts of details are affected, such as stud torque holding the crankcase halves together, but the biggie here is piston-to-cylinder wall clearance. You can pitch a dead cat between a cold Lyconsaur piston and cylinder as there’s so much clearance. As in you can literally hear the pistons clanking over at the top of their stroke when rotating a cold Lyconsaur around by hand. This translates into reduced piston ring seal with attendant loss of combustion pressure and increased oil consumption and contamination. And yes, it also leads to my pet behavior of warming up my hot-rodded Lyconsaur before hitting the throttle for that first takeoff of the day, and there’s shock cooling to consider as well.

Even worse, cooling, specifically exhaust valve cooling, is mediocre in air-cooled engines as their power density rises. Hence the typical stuck valve stories we’re all familiar with and probably the Lyconsaur’s biggest black mark when it comes to reliability. This limits an air-cooled engine’s specific output; push it hard and adequate cooling requires increasingly more careful engineering. It can be done as demonstrated by the huge air-cooled radials that put out 1 hp per cubic inch 70 years ago. But even then, this was only for takeoff and reliability wasn’t exactly stellar.

The other baked-in reality of Lyconsaurs is their expansive cylinder diameters, often in the 5-1/8-inch neighborhood. Even with two spark plugs per cylinder, this is an Olympian expanse to light on fire, something not helped by their now-ancient combustion chamber shapes. Devoid of quench area—a close approach of the piston dome to the cylinder head to squish the air/fuel mixture into a roiling mass instead of a lazy puddle—combustion in a Lyconsaur is more a close-cropped prairie fire than an energetic fireball. Power and fuel economy suffer while demand for anti-knock capability of the fuel increases, a characteristic come home to roost in the current quest for a 100LL replacement.

Rarely discussed except by engineering nerds, Lyconsaurs are mechanically noisy. Their big, loose-fitting parts literally clank and clack to the point they confound vibration-sensing knock sensors used with contemporary auto engine management systems. That and they are preordained to burn oil.

Financially Speaking

Interestingly, more than any engineering, it’s probably the Lyconsaur’s entrenched financial characteristics that protect it in the real world. If nothing else, we can all agree the Lyconsaur is the devil we know. They’ve been the general aviation standard since WW-II—that’s getting to be the best part of 80 years, or four generations of owner/pilots—and they are simply how things get into the air for the most part. A long-mature ecosystem of repair and overhaul shops is built around servicing these engines. There’s a supply of core engines to be rebuilt and the parts to do that with are still in production. More specifically to us, rebuilt Lyconsaurs have always played a part in powering Experimental aircraft, a phenomenon regaining popularity today in the face of the steeply rising price of new engines.

If the Lyconsaurs go far in defining the zeitgeist of general and sport aviation, they are at the end of their development trail, at least for any meaningful improvement in power, economy or cost. Tepid but continuous development of these engines over the decades means the modern Lyconsaur is already well developed with little engineering overhead in which to improve.

On the other hand there is small hope of all-new, dedicated aircraft piston engines to replace them. The Lyconsaurs are hemmed in by their entrenched supporting production and overhaul businesses, along with a smothering regulatory environment unsuited for the development of all-new engines at anywhere near affordable prices. There’s no tailwind from the stagnated market for aircraft piston engines, either. Annual engine sales are less than small, with no hope of meaningful economies of scale, and while brave individuals have labored mightily to produce exciting new powerplants, they’ve done so only at huge expense. Their efforts have therefore achieved boutique status occasionally or disappeared into the military-industrial complex’s opaque but vast drone budget.

The Future

Lyconsaurs will remain viable for many years, likely to the end of general aviation as we know it. They’re here, well sorted and getting us aloft daily, more than you can say for some of the pretenders and thus worth everything to those of us who fly.

But, Lyconsaurs will increasingly share the market with Rotax and auto-based engines. (I’m not holding my breath for small turbine replacements even if such engines would be fantastic, and electricity awaits a high-density storage breakthrough.) If there’s a momentum to change from the Lyconsaur standard, it revolves around fuel. By this I don’t mean the coming 100LL replacement, but rather the price of fuel and thus the drive for greater fuel economy. The smaller-displacement, higher-revving, water-cooled, gearbox-equipped engines nipping at Lyconsaurous Rex do have the unquestioned advantage of notably better fuel efficiency, and as the cost of fuel becomes a greater part of affording aviation, these more efficient engines are going to factor more strongly to the enthusiast. Whatever replaces 100LL promises to be significantly more expensive than the blue stuff no matter what the cheerleaders say, if only because I’m an optimist with experience. Add $2 to every gallon of gas and even big-block fans such as myself will be thinking of engines that do essentially the same job for 3 or 4 gallons an hour less. Switching general and sport aviation to Jet A is the standout idea in reducing fuel cost, but this also requires the enormous expense of all-new engines and greatly expanded Jet A infrastructure.

In the meantime, I’m enjoying the Lyconsaurs. You can call them old-fashioned, but there’s much to love about big, simple, slow-turning engines, especially when they are so widely distributed and supported. If we were somehow starting from scratch today it’s likely we’d invent engines surprisingly similar (witness the ULPower lineup), albeit with a few improvements. Higher compression, free-flowing exhaust and lean-of-peak cruising would be sure to factor in and those are things we can do today. See you at the gas pit.

These large displacement engines are well developed, and very reliable, with the small changes over 75+ years.!

Able to run without external electrical power adds to the reliability, even if magnetos don’t put out the hottest spark vs other electronic ignitions.

The carburetor or Rochester fuel injection operate without external power as well vs automotive EFI.

My high wing Cessna uses gravity fuel flow , so no fuel pump to fail, and I don’t have to switch tanks very 30 minutes.

Oh, and my 1961 Cessna has Johnson bar flaps….mechanical, no electrical power needed…more reliability.!!!

Some more thoughts;

The Rotax 9xx series has been very successful and has proven reliable and fuel efficient;

small displacement, high revs, water cooled, internal electronic ignition…..a very nice package !

Another old technology that is new again is the DeltaHawk 2-stroke, turbo-supercharged diesel.

It started with 1930s Detroit Diesel truck engines , a supercharger 2-stroke , large displacement engine.

DeltaHawk uses mechanical FI, so no external needs, and has one lever, fuel control, since there is no throttle.

In fact, the only way to shut it down is the pull the fuel shutoff lever..!!!

There is also the Adept 3200cc V6 with figures of between 260 and 320 hp , better fuel efficiency , liquid cooling , fuel injected and is about 50lbs lighter than the equivalent power Lycoming ..