For those of you in aircraft with magnificent audio systems—stereo music and multi-input switching panels that have push-button selection of your half-dozen headphone inputs—this one is not for you.

For my brethren and sistren with handheld VHF com radios and cellphone audio entertainment devices, stand by, this one is for you.

First of all, we need to understand what the requirements for aircraft audio are. For some long number of years (starting on December 17, 1903), there was no real requirement for protecting the pilot’s hearing. It was enough just to stay in the air without worrying about the well-being of the pilot’s hearing. Then along came WW-I and WW-II and noisy enough aircraft that we started to use headphones in military aircraft.

The civilian postwar aviation boom followed, along with disregard of high-decibel environments. This problem was “solved” by putting large speakers directly over the pilot’s head and driving them with multi-watt amplifiers that competed with the engine/exhaust noises that disrupted air-ground communications.

Sometime in the late 1960s, we noted that many of our pilot brethren and sistren were failing the FAA medical hearing test. Headsets became front and center, and sound-deadening headsets became the norm in almost every civilian aircraft.

Let’s back up a few dozen years and see where we came from and where we are going. Then I’ll give you a “screwdriver” design for a headphone audio panel. “Screwdriver design?” Yup. Screwdrivers can be used to drive screws. And pry open metal structures. And punch holes in oil cans. And half a dozen other applications that have nothing to do with threaded metal fasteners. So this design will be an electronic screwdriver.

Back in the 1920s, Bell’s telephones were all the rage. Every modern home had to have at least one of these electronic dinosaurs or you just weren’t “modern.” And each of the phones had two parts to it…an earpiece and a mouthpiece. The earpiece was a permanent magnet surrounded by a multi-turn cylinder of wire that would produce sound when an electrical signal was connected to the wire. Lots of trial and error produced an earpiece that was most efficient at 300 ohms of wire around the magnet.

Similarly, wire around a magnet wasn’t really efficient at producing electrical signals at the mouthpiece, but a small sack of “coal grindings,” with coal ground down to about the size of a grain of sand and metal plates on both sides of a linen sack of these granules, would produce enough signal to be heard in those 300-ohm earpieces. The telephone system was born (with one notable improvement…a very thin sheet of celluloid was put between the mouthpiece and the linen sack of coal dust to act as a “spit filter” to keep the coal dust as powder and not a brick of wet coal spit).

Along come airplanes. And headsets so pilots can hear and talk on the aircraft radio. Where to get cheap earphones and microphones? Bell’s suppliers are turning these things out by the millions. Let’s just use telephone earpieces and microphones for airplanes.

Two things to consider: Pilots need both ears to hear, so let’s just use two of Bell’s earpieces in each ear, wired in series for a 600-ohm earphone. And let’s use Bell’s carbon sack for a microphone with one notable exception: Pilots who are in stress situations tend to talk juicy, so let’s put a double plastic screen between the microphone and carbon sack.

Sometime around the start of the unpleasantness in Vietnam, somebody noticed that if one of the series-wired earphones failed, both earpieces failed. Somebody else noted that technology had evolved so that the little coil around the magnet could be done in miniature. Thus evolved the 150-ohm earphone impedance and the dynamic microphone of today’s headsets. (The electret microphone also came along about this time and solved the “juicy talk” problem, but that’s another story.)

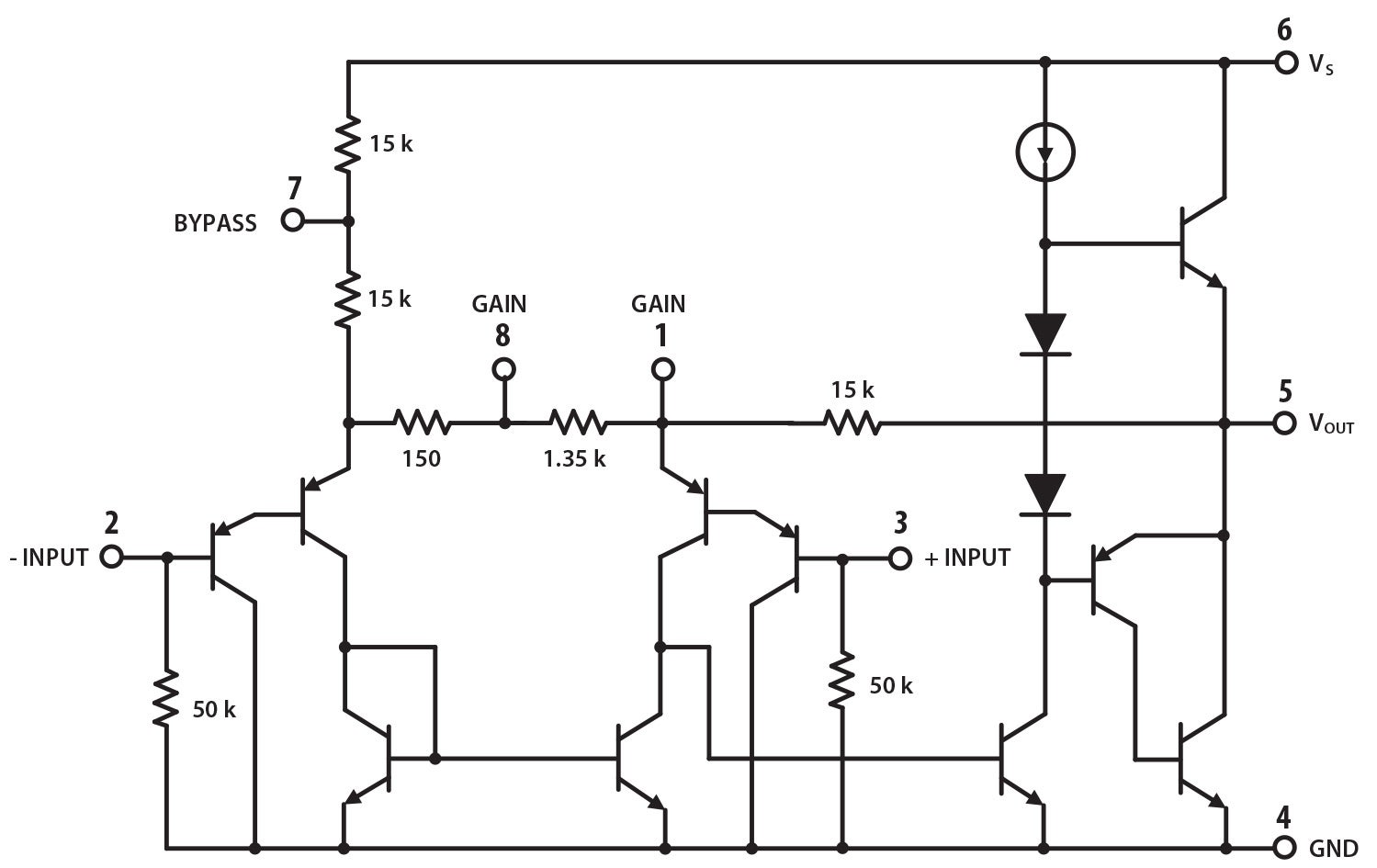

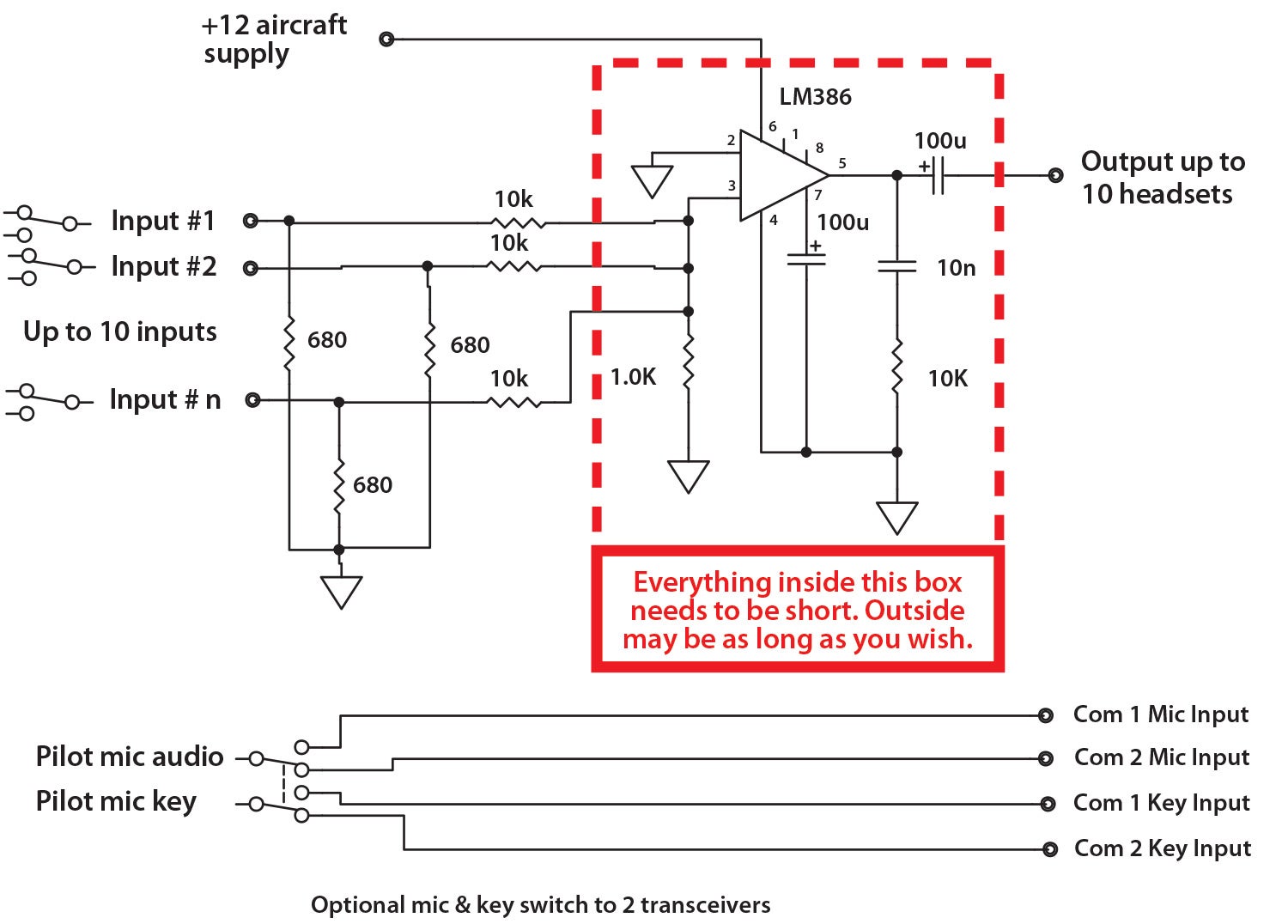

OK, hang on to your seats, here we go. I’m about to give you a minimalist audio panel for less than the cost of a Big Mac and fries. The heart of it is an integrated circuit (IC) that was new back in 1974 and is still being produced in the hundreds of thousands a year—and is likely to do so for the foreseeable future. That was 48 years ago, and the price back then (in 2022 dollars) was a bit over $10. Today that same exact IC (LM386) is available for less than a buck and a half in onesies from www.jameco.com. (Get their catalog for lots of inexpensive electronic parts. Nice people to do business with.)

The LM386 takes a relatively weak output from a handheld transceiver or a reasonable output from a panel-mount transceiver and supplies more than enough audio to drive up to 10 sets of 150-ohm headsets. That may be overkill (very few 10-place kit aircraft are being built today), but it can certainly handle the most common two-place homebuilt.

There is a downside, of course, but homebuilders are resourceful. So much so that I’m not even going to suggest to you how to build the enclosure for the audio panel. You know how much space you’ve got on your instrument panel, and I’ll simply show a schematic diagram and let you figure out the physical implementation for your personal situation. I will indicate on the schematic what some of the critical lead lengths are, but for others, whether you make them a few millimeters long or a few meters long will not be a big deal.

While I show “switches” as simple mechanical parts, you are free to use toggle, push-button or other switch configurations. This is a really bulletproof design that allows for most every configuration of components that you can imagine.

Stay with us for a bit and I’ll see if I can factor a really cheap intercom into this design in a future issue. Until then…stay tuned…

Jim,

I am a ham radio operator and am considering an aeronautical mobile operation with an Icom 706MKIIG. My current aviation radio is a handheld and am using an older David Clark headset. Will your audio system be compatible with the differences in the aviation and ham radio impedances for the mike and audio out?

Hi Jim! Always fascinated with your articles in Kitplanes.. The above project inspired me to ask you this question: I am a hearing impaired pilot. Is here some way to modify the above circuit to light up a LED or similar bulb when someone is speaking on the frequency? This would enable me to transmit with confidence that I would not cut someone already speaking on the frequency off. I would be willing to pay you for your advice, suggestions, schematics, recommendations, etc. Thanks!

Frank A Pisz piszfa@gmail.com or piszbeth@realtime.net

Hi Jim, can this be used with a push to talk, for a hand held radio? I’m building an ultralight and want to use a carry on hand held radio. Will your audio panel work as an interface between a push to talk button on the control stick and the hand held radio. My Vertex Standard, Pilot III, came with a splitter cable that allows me to connect my head set to it. I have tried various commercial PTT cables that allow me to connect to the DC head set and the splitter cable. None of them would key my radio. If not can an adapter be made for such an operation? Looking for schematics if available.

Hi Pat Stallings….

Thanks for the question.

Unfortunately, coming from an engine mechanic, the question resembles “How can I change my sparkplugs?”

The answer, of course, is that the question is so fundamental as to not be specific to the article as to be generic and requires a horrific amount of background work and a twenty-page article.

Here is my best advice. Go to your local amateur radio (ham) club and see if you can find somebody who is conversant with aircraft radios. That person should be able to answer your questions in half an hour, and will probably volunteer to help you with the problem . Most of us are more than happy to work with problems like this, but a half an hour discussion and problem solving verbally translate to a twenty page article.

Jim, my electronics-fu is getting pretty old. What’s the capacitor marked “10n”? I’m thinking it’s just a typo and the actual is 10 uF.

No typo. The electronics world is actually coming into the metric world (as is every other nation except Liberia and one little tiny burg over between India and Pakistan). N is nano 10^-9 and is halfway between micro and pico.. The old designation would have been .01uF.

Best to you and yours