Time to talk about the “parts” portion of my column tagline. I’ve been a professional buyer for over seven years and while I still have a lot to learn, I thought it’d be fun to shed some light on how things are purchased in aviation and offer up some tips for those of you buying from home to support your build.

I’d say the most challenging part is planning, which is easier done with a software system in place. Unfortunately, said program might not be accessible or practical to use at home, but this will give you an idea of how and when purchasers are triggered to buy. Let’s start with how Glasair Aviation did things—where I learned to procure through a fire hose. We used an Enterprise Resource Planning (ERP) system, which companies often adopt to track business activities across all departments.

Every morning I’d print a report that showed what I needed to buy to support demand, which took into account not only current stock but also lead times and safety stock levels that were manually implemented. If I remember correctly, it was set to ensure we had two “ship sets” of Sportsman kits on the shelf at all times. This means that ideally we should have everything that wasn’t a big-ticket item (engines, propellers, instrument panels) on hand so that we could assemble or sell a Sportsman kit on any given day.

Lead times were updated to the best of our ability using recent quotes and I’m sure a buffer was tacked on to ensure we got a more reliable view of when we could expect to see material. Safety stock levels were set on certain items that could really derail us if we ran out. For example, when we hit, say 100 AN3-6A bolts, the system would trigger me to buy more. We wanted at least 100 on hand at all times in case bolts wandered off or a lot of orders came in, leaving us short for an upcoming Two Weeks to Taxi build.

Then there were consumables, which were mostly, well, consumed by the composites department. Every week or so, our composites lead would email me an Excel spreadsheet that listed everything he needed me to purchase. The ERP system can’t really take into account resin levels or nitrile glove count, so he and I managed those outside the system. He pulled all necessary information, such as part numbers, from a master spreadsheet that had our vendors tabbed at the bottom. Each vendor tab listed common items we bought from them. He’d paste the info into another Excel spreadsheet, add quantities next to each line item and send it to me. And of course, if he needed something that wasn’t included in the master list he’d include a link to Aircraft Spruce or wherever I could find it.

This is something builders could do—create an Excel spreadsheet with vendors and part numbers, as well as links to the type of gloves you like and so on. This helps prevent rework. If you’ve done your research and found the cheapest option, add it to the list and review it in six months or a year to ensure you’re still getting the best deal. We all know how easy it is to place an Amazon order three or four days in a row—we want to avoid this in aviation so as to avoid wasting time, getting stuck mid-project and paying more for shipping.

More Tips and Tricks

Now let’s talk about my current company, which uses a System Applications and Products (SAP) ERP system. I’m still triggered to buy based on current sales, lead time and safety stock level, but my focus has narrowed tremendously. I now only procure aluminum plate, sheet, coil and extrusion, which is obviously far fewer items than in my previous role, where I recall buying hunting arrows from Cabela’s for the servo tab pushrod in the Sportsman and a soccer net for a makeshift cargo net in the Merlin LSA. If that doesn’t scream “Experimental” I don’t know what does. My company has also broken the full purchasing process into five teams that tackle different tasks, from making the initial buying decision to creating the purchase order (PO) and tracking it.

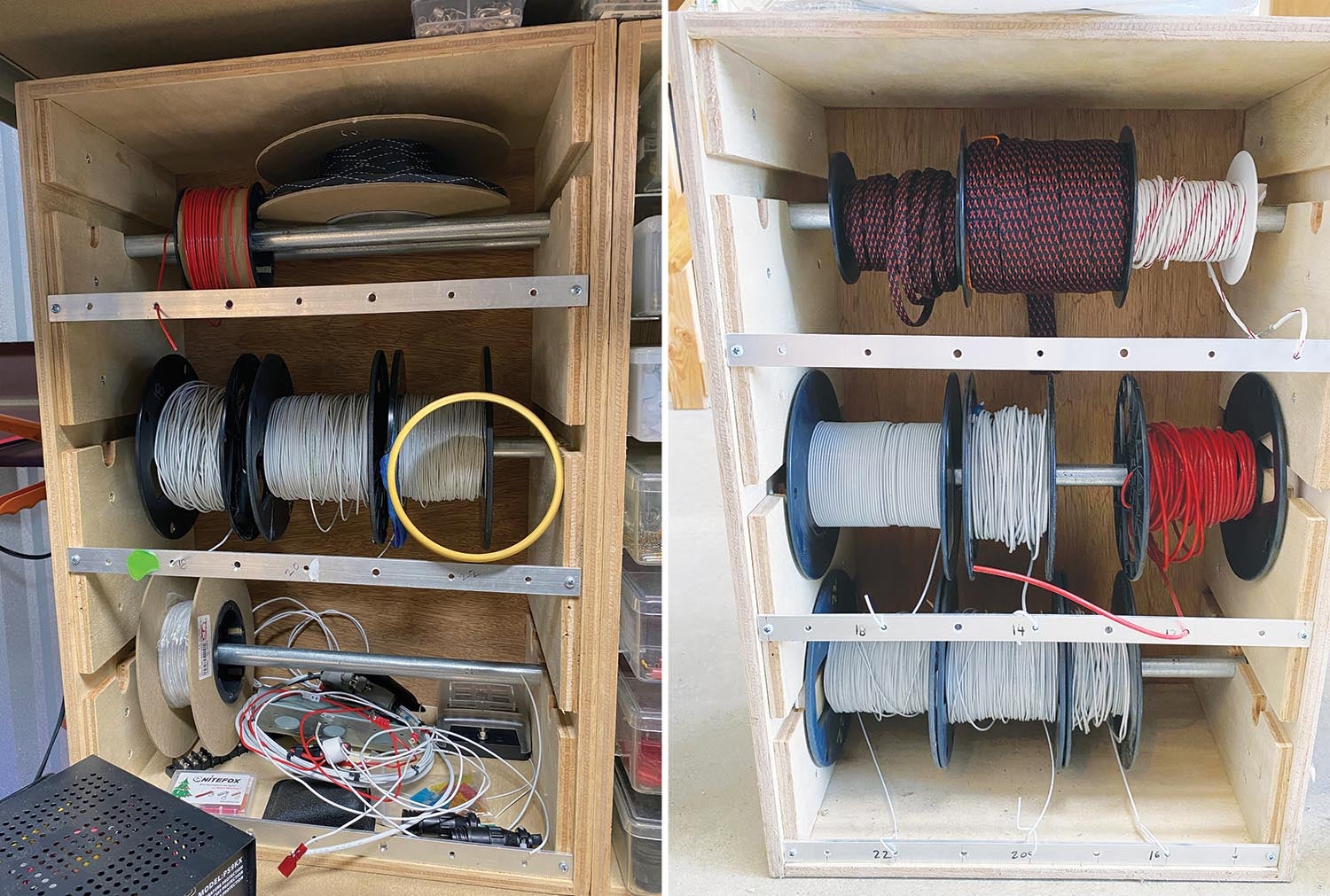

One of the main ways to have better control over your inventory is to establish some sort of visual signal that tells you you’re getting low on a part and should buy more before you’re SOL. I’ve seen companies implement a two-bin Kanban system, where you store fasteners or whatever items in both bins and pull from one bin until it’s empty. You then move the other bin in its place and start planning to place an order to replenish stock in the empty bin. If this is too much work, you can simply start a list on your phone or on paper of what you need. Creating a photo album in your phone of what you need has also proved helpful, especially if you need a pic of the label showing the vendor part number to be able to find what the heck you’re looking for.

Lastly, start paying attention to lead times and price breaks. Unfortunately you probably won’t be ordering a large enough quantity of material to warrant a price break, but it can happen. Buy more, save more. Lead times are ever-changing, but if you find your wing kit has a five-month lead time and think you’re five months away from being done with your tail kit you can plan accordingly.

Keep It Clean

While there was a time when my desk was a mess and my computer monitor was adorned with sticky notes with Cessna 172 V-speeds and various acronyms, I’ve since cleaned up my surroundings. It pays to keep your workstation organized and distraction free—it’s made it easier for me to keep track of things and focus on the task at hand. How many times have you repurchased something because you thought you lost it, only to find it during a cleaning frenzy? I know I have. There’s a reason aviation and aerospace companies encourage employees to keep a clean workstation—it increases productivity and results in fewer mistakes, which ultimately means cost savings.

I suggest investing in a label maker for your hangar or garage, especially since very similar items can have vastly different strengths. You can also make note of expiration dates on sealants, glues and goos. Be realistic about when you’ll need something—avoid buying and opening Pro-Seal only to have it expire before you get your money’s worth. Have a designated spot to keep your safety glasses, ear protection and masks and keep an eye on essentials, such as paper towels, popsicle sticks and Scotch-Brite pads.

Unsolicited Advice

If you don’t know where to find something, don’t be afraid to ask in your builder group. Chances are someone there has found what you’re looking for from a non-traditional source—helpful when that traditional source is heavily backordered or doesn’t carry what you’re looking for.

Finally, I hate to say it, but the squeaky wheel gets the grease. When I followed POs from “womb to tomb” (a questionable expression I can’t get away from in this business) at Glasair, I had to not only create the PO but track it to ensure it would arrive on time. This often meant I had to call the company behind it and ask for a status update. It never hurts to email or call to check on the status of an order. Just remember, there’s a real person on the other end of your laptop or cellphone. And believe it or not, people are more willing to help you if you’re nice. Customer service representatives and account specialists will gladly “waste” an hour helping a nice person because it allows them to avoid calling the jerk who left them a nasty voicemail. Food for thought!

Photos: Omar Filipovic.

I actually have been using the “tow-bin” system as you call it, for groceries, toilet paper, and other consumables around the house for years.

I have had those moments where I found myself waiting on a tool or piece of material. But you can also sometimes move onto other parts of a project while waiting too.

I also have a binder where I keep reference sheets, spec sheets, lists, etc. Helps to stay organized.