Building an airplane is, without a doubt, a daunting task. Whether you are starting with a kit, plans, or scratch-building, going from that first step to a completed airplane is a journey that few can understand-the scope and magnitude is simply beyond what most people have experienced. There are partially completed, abandoned projects in garages everywhere testifying to the time and complexity involved in such a project. On face value, when people think you are crazy for building an airplane, they may be right-but not for the reasons they think (“You mean you’re actually going to fly in an airplane built in your garage?”). The reason we are all crazy is because of the commitment it involves. The hours grow to months and several years before most see air under the wings.

The good news, however, is that while building an entire airplane is a seemingly impossible task, building airplane parts (by comparison) is not so hard. You can sit in your shop for an hour and turn a piece of angle aluminum into a bracket, or shape and sand a piece of wood into a rib gusset. Wiring up a single headset jack isn’t that hard, and neither is routing a flex hose from a fuel pump to a carburetor. Taken in little, bite-sized chunks, nothing about building an entire airplane is really that hard-as long as you don’t look too long at the big picture. It is sort of like trying to look at the sun with your naked eyes; quick glances work, but a long stare is simply impossible.

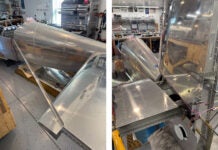

Fabricating parts can be quite enjoyable, but you must remain vigilant when using tools like this bandsaw to create complex shapes out of simple stock.

We’re deep into airplane number four in our home workshop right now. Kits vary in complexity and the tasks that a builder needs to complete. Some of the more advanced kits have very little fabrication-mostly you assemble finished parts. Others require you to shape parts from partially finished stock like U-channel and angle. Many of the parts that have to be formed over special dies or blocks are already done for you. Still older kits require you to start mostly with raw sheets of aluminum or wood, and everything must be laid out from plans by the builder. Our current kit is fairly complete, but a lot of parts have to be fabricated from channels and angles shaped specially for this design. Formers for the fuselage, for instance, must be cut from the lengths of broad C-channel, have their ends tapered appropriately, and pilot holes drilled for later assembly.

We spend a lot of time in the shop looking carefully at the plans and transferring measurements from the plans to the stock, then double-checking the work to make sure we haven’t dropped an inch, or read the plans backwards. My co-builder wife and I check each other’s work before we pick up a cutting tool-this has saved us from butchering the raw stock on more than one occasion. Even a career engineer can read shadow lines backwards-don’t think we can’t!

But aside from the gamesmanship of interpreting drawings and making sure you have garnered every last bit of wisdom from the printed page, fabricating parts is actually quite peaceful. Your scope narrows, you forget about issues like which EFIS to choose, or if you should put the throttle here or there-you simply concentrate on making the best little bracket you can. Reading the rule to the nearest sixty-fourth of an inch, making the Sharpie mark just so, then drawing a fine line and cutting right to the line-there is something Zen-like in the process. I enjoy using the tools at hand to create complex shapes out of simple stock, then finding that the care and patience pays off when the various parts fit together perfectly. You begin to see repeating patterns in the work-angles that show up again and again as you understand the taper of the fuselage or the sweep of the tail. Skewed flanges all work out in the end when you see the patterns in the designer’s work-a master plan that can only be understood when you have reached completion.

The thousands of individual parts allow you to celebrate an equal number (thousands!) of small victories in the building process. Instead of bemoaning the fact that you can’t see the light at the end of the tunnel for completing the entire airplane, you can leave the shop humming a happy tune because you finished a bulkhead, or a rib, or a fluid line. Optimist or pessimist, you have to find something to celebrate or you will never find the strength to continue down the road.

One day, you find that there is nothing left to fabricate, no parts left to combine into assemblies. You find that the workshop is too small to confine your creation-it is ready to fly free and explore the “delirious burning blue.” And when that time comes, you’ll look back on the joy of fabricating that firewall mounting bracket, or even the many hours spent preparing rib after identical rib. Fabricating parts is simple work, but rewarding. It gives you time to perfect the art and craft of building, time to think about the hurdles to come. But most of all, it connects you to other craftsmen (and women) spread across time and space-the few thousands who have walked the same path of fabrication, assembly…and flight!