In order to keep the airplane flying without big trim tabs hanging in the breeze, you have to keep things straight and precise during construction. For homebuilts that require a jig for building wings, the manufacturer usually provides plans or suggestions for building the jig, and often the specified material is wood because it is readily available, inexpensive, and easy to work with. But this presents a problem if the workshop is located in an area with large swings in relative humidity—such as my hangar on the outskirts of Portland, Oregon, where I’m building a GlaStar.

The GlaStar wing jig design calls for a 16×2-foot workbench made from 2×4-inch lumber with 4×4-inch vertical wood posts at the ends. Even if the workbench is constructed level and square, and the posts are plumb, it will only stay that way until moisture changes in the wood cause something to come out of alignment. The brackets holding the GlaStar’s wing to the wood post incorporate a plumb bob, making it easy to confirm alignment before any work. If the plumb bob is off its mark, the builder must make adjustments to the jig to bring it back into alignment. Sometimes this can be tricky if the misalignment is in several places.

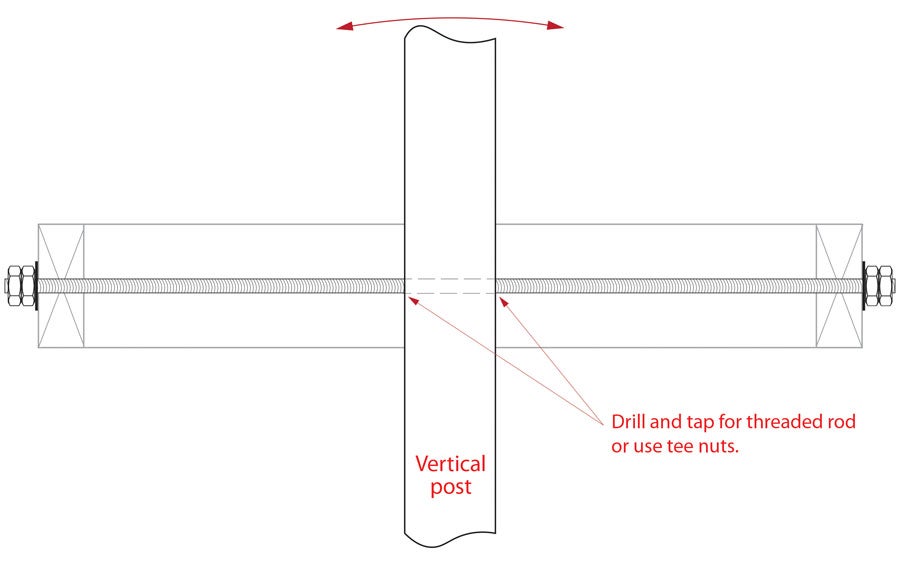

To minimize the potential for warping, I used steel posts and also constructed a simple mechanism that allows easy initial adjustment of the posts and any future adjustment if the wooden workbench on which the posts rest pulls them out of alignment.

Each post is held in position by two 3/8-inch threaded rods that pass through holes tapped in the post’s centerline—one at the top of the workbench, and one at the bottom. The two rods are perpendicular to each other. The post is tightly sandwiched between wood members parallel to the threaded rod, which makes the assembly tight enough to hold everything firmly in place, but still allows for movement along the rods. Each end of the rod has a large washer and a pair of jam nuts.

Adjusting the angle of a post only takes a turn of the jam nut. In the photo with the arrows, turning the top nut clockwise will lean the post to the right.

Home improvement stores typically sell a 36-inch threaded rod for about $4. You’ll need eight nuts and four fender washers per post, so the cost is very low.

Aluminum posts can also be tapped for a threaded rod, but a wooden post can be used for the jig, too. You’ll need to drill a hole through the wood post slightly larger than the threaded rod, and use a pair of tee nuts fastened to the post over the ends of the hole.

Hi Omar

How high was your table?

Ben

Ben, the top surface is at 35 inches.