The takeoff might better have been described as a launch. With the new 150-hp Lycoming engine in my 700-pound RV-3, it was off in no more than half the 650-foot runway length and climbing aggressively at my normal 80-mph climb speed. At an altitude of perhaps 150 feet, the engine quit abruptly (whammy #2). The prop was windmilling, but the fire had gone out. First reaction: Fly the airplane! Second reaction: Where can I land? Straight ahead was a grain field with a sloping swale through it; not promising. Ahead and to my right was a flying farmer’s airstrip, but it was out of reach from my low altitude. However, there was a narrow headland/driveway at the end of the rows of nursery plants on that farm, and I had enough height to glide there. I made an approximate 90-degree right turn, a forward slip to pay off a bit of surplus altitude and speed, a drop-in over the 8-foot high fence row, and my wheels rolled on the acceptably smooth grass surface. Not a very long one, but smooth enough to apply even braking. Unfortunately, the left brake failed immediately and completely (whammy #3), raising doubt about being able to stop before running into some substantial nursery plantings (bushes) past the end of this headland. I applied full left rudder/tailwheel steering and balanced that with as much right brake as possible, and was just able to stop by swinging a bit to the right as I hit the narrow cross runway. Whew! That happened fast. Now, I noticed that the engine was still running at an idle. So, why did it quit so abruptly, and why did the brake fail?

The takeoff might better have been described as a launch. With the new 150-hp Lycoming engine in my 700-pound RV-3, it was off in no more than half the 650-foot runway length and climbing aggressively at my normal 80-mph climb speed. At an altitude of perhaps 150 feet, the engine quit abruptly (whammy #2). The prop was windmilling, but the fire had gone out. First reaction: Fly the airplane! Second reaction: Where can I land? Straight ahead was a grain field with a sloping swale through it; not promising. Ahead and to my right was a flying farmer’s airstrip, but it was out of reach from my low altitude. However, there was a narrow headland/driveway at the end of the rows of nursery plants on that farm, and I had enough height to glide there. I made an approximate 90-degree right turn, a forward slip to pay off a bit of surplus altitude and speed, a drop-in over the 8-foot high fence row, and my wheels rolled on the acceptably smooth grass surface. Not a very long one, but smooth enough to apply even braking. Unfortunately, the left brake failed immediately and completely (whammy #3), raising doubt about being able to stop before running into some substantial nursery plantings (bushes) past the end of this headland. I applied full left rudder/tailwheel steering and balanced that with as much right brake as possible, and was just able to stop by swinging a bit to the right as I hit the narrow cross runway. Whew! That happened fast. Now, I noticed that the engine was still running at an idle. So, why did it quit so abruptly, and why did the brake fail?

First, I need to back up a month or so and fill in many details that caused this incident and lead to its successful outcome. It all started with whammy #1, when my prototype RV-3 was damaged by “Lefty,” my only employee at the then fledgling Van’s Aircraft Company. It was the summer of 1976 and my one and only (prototype) RV-3 had suffered significant damage when the engine faltered during a touch-and-go landing on the 650-foot airstrip on my parents’ farm where it was based. It had impacted tall grain when it failed to become airborne at the end of the strip, coming to rest inverted about 150 feet farther on in a neighbor’s wheat field. Fortunately, Lefty’s injuries were minor, but this was the beginning of the fly-in and airshow season. I needed to get that plane back in the air ASAP. Fortunately, I was able to borrow my brother Jerry’s RV-3 to use in the interim and fly it in a couple of nearby airshows that I had scheduled. This was one of only a handful of RV-3s that were then completed and flying.

Unfortunately, because my RV-3 had a metal prop, the prop strike had bent the crankshaft flange beyond repairable limits. Fortunately, I had a brand new Lycoming O-320-E1F* lying in wait for my slowly gestating RV-4 prototype. So, along with repairing the motor mount, damaged wing, vertical stabilizer, new canopy, etc., I was able to install this spare engine in less time than required to locate a replacement crankshaft and overhaul the original O-290-G (125 HP) engine.

Since I had a hangar and shop available on the farm strip, I naturally elected to re-assemble the repaired RV-3 there and, of course, perform the post-repair flight testing there.

On the day of my intended test flight, my brother Jerry happened to be in town visiting and helped me with the final inspection and preparation. He inquired as to my intentions regarding taking off either to the north or south. My plan was north because of a very light breeze blowing from that direction. He rationalized that the breeze was insignificant and that the forced landing opportunities were better with a south departure. At that time of year, all of the surrounding farm fields were covered with crop growth that would preclude an uneventful emergency landing in them. He noted that about a half mile away and off to the right there was a clear headland/driveway area in a nursery farm field. That driveway had a fence row on one end and abutted a N-S airstrip that the farmer used when commuting from his other farms. I noted this, but not too seriously because I figured that, as an airline pilot, Jerry was just being overly cautious. Plus, you never take an older brother too seriously; they’re always trying to tell you what to do! After all, I was about to fly with a pristine new engine far superior to the self-overhauled engines I had been flying before. What could possibly go wrong?

I’ve already answered that question. Now, why did it go wrong?

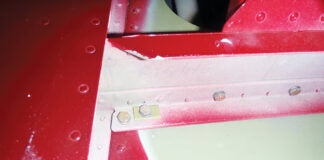

The failed brake was easy to diagnose. There was red brake fluid running down the landing gear leg. The leak occurred at an AN tube fitting where the brake line transitioned from the fuselage brake line hose to the ¼-inch aluminum tube line running down the landing gear leg to the wheel brake slave cylinder. The brake line had essentially sheared off its flared end where it had been attached with the B-nut. It was obvious that the flared end of the ¼-inch aluminum tube had been poorly formed. Fabricating a new brake line would be cheap and easy.

Ascertaining the cause of the disrupted fuel flow was more difficult. Disconnecting the fuel line revealed a healthy flow rate, and there wasn’t any foreign material or water found in the sediment bowl. The fuel lines were not blocked. All obvious indicators pointed to fuel starvation; but why?

Although my plane was only a half mile from home, there was no open pathway to taxi or tow it back home. Dismantling for trailer transport was not an appealing prospect. The farm strip was about 1400 ft. long, more than big enough by my standards at the time. After performing full-power ground run-ups, I chose to make a cautious takeoff and shallow climb to altitude for further in-flight testing before returning home. I found that if I maintained a shallow climb angle, the engine ran fine. After climbing to several thousand feet, I gradually increased the climb angle, and sure enough, the engine quit, but fired up again after lowering the nose to a glide angle and waiting a short while. Several repetitions of this convinced me that my carburetor wasn’t getting fuel, or passing fuel, at steep climb angles. After landing back at my home strip, I installed a fuel pump before again attempting flight.

How Many Mistakes Caused or Compounded This Problem?

1. Test flying from an airport with no runway length margin. I knew that the aircraft’s takeoff and landing performance was more than adequate for this short runway. I knew that my piloting skills and proficiency were up to the task. However, runways that short don’t offer any margin for error or irregularity. The wise option would have been that of erring on the side of caution and doing testing at an airport with a long runway, although not as convenient or economical.

2. Failure to perform a simulated (tail-in-a-hole) climb angle, full power, fuel flow test. New airplanes, or airplanes with new engine/fuel system installations, need to have a fuel flow test done while positioned at an angle simulating that of a full-power, high-angle climb. Either running the engine at full power and/or measuring a timed fuel flow through an open fuel line should verify adequate fuel flow for this flight condition.

3. Assuming that all similar carburetor and engine combinations function alike. I had installed the new O-320 engine without a fuel pump. This was based on the successful operating experience of Jerry’s RV-3 which had an O-320 engine without a fuel pump. It relied strictly on gravity feed from its single fuselage fuel tank. It functioned well in full power climbs, which are pretty steep in an airplane as light and powerful as the RV-3. So I had installed my O-320 without a fuel pump, reasoning that I would see the same results. The results were obviously different. Why? Without elaborating on technical details which I no longer have available, and perhaps never had completely understood, there were differences in the carburetors on these otherwise same basic engines. Even though the carbs were the same basic model, Marvel-Schebler MA-4SPA, they were of different serial number series and had different fuel jets and/or float levels. The engine that had operated successful without a fuel pump, on Jerry’s RV-3, had been configured for use on a high-wing airplane with a gravity feed fuel system (before it had been transplanted into his RV-3). It had been set up to operate with the relatively low fuel pressure provided by the “gravity head” of the high fuel tank. The carburetor on my RV-3 engine had been configured for the Bölkow-Messerschmidt 209, which is a low-wing airplane with fuel tanks in its wings. It required a fuel pump in its fuel system. Fuel pumps for a system of this type usually provide about 4-5 psi. Even that relatively low pressure is far more than the approximate 0.5 psi head pressure available in a gravity feed system. In a steep climb, the fuel pressure is lower still because of the relative heights of the engine and the tank, plus the fact that at full power, the engine required a high fuel flow rate. The low gravity-head pressure of my RV-3’s fuel system was insufficient in a steep climb condition. One size does not fit all!

4. Assuming that Lefty knew how to properly flare an aluminum brake line end. Because of the damage caused by the prior accident, the brake lines needed to be replaced. This relatively simple task had been assigned to Lefty. The brake lines were made of ¼-inch diameter soft aluminum tubing, a commonly used material for this purpose. Standard 37-degree-flare AN tube fittings were used. The problem was that Lefty either didn’t know the proper way to flare the tubing ends, or just wasn’t paying attention that day. The accompanying illustration shows the result, along with an illustration of a correctly flared tube end. Once the brake line had been installed, the inadequately flared end was not visible at the time of final inspection. The marginally flared tube end was apparently sufficient to hold the brake fluid pressure during initial taxi and engine check, but failed upon the more aggressive panic braking that accompanied the emergency landing.

It Could Have Been Worse!

The single most important factor in the successful outcome of this emergency landing was the preflight advice given by brother Jerry. His professional approach toward analyzing the situation and planning for contingencies had mentally prepared me for locating the best emergency landing option available. Without this pre-planning, it is improbable that I would have been able to scan and assess this landing option in the few seconds available. Have a plan, fly the plan!

Back to Whammy #1

Why had the RV-3 suffered its upside-down indignity in the wheat field at the beginning of this tale of woe? My memory is a bit vague, and I no longer have the engine logs to reference for verification. I believe that the O-290-G engine in the RV-3 at the time was equipped with a Lake Throttle Body Injector, rather than a Marvel MA-3SPA carb that is normally used on the Lycoming O-290 engine. The Lake TBI was an inexpensive aftermarket product that I had installed as an affordable alternative to a conventional fuel injection system that would support inverted flight operation. The Lake Injector worked OK but, at least in my application, had a non-linear fuel/air mixture at different power settings. I had learned to automatically reset the mixture along with power changes. Being less experienced, Lefty apparently wasn’t able to react as quickly, thus causing a power disruption and the unsuccessful touch-and-go. He had only recently been checked out (single seat check-out?) in the RV-3, and in retrospect, was underqualified to fly from such a short airstrip. I shouldn’t have assumed that he would be able to master the unique airplane and airstrip that had become second nature to me.

From my current vantage point, I can see that during that period, I was pushing the limits of time and finances to move as quickly as possible, and was probably not as careful as I should have been. But what might you expect from someone with the audacity to start a kit company with such limited talent and finances? The subsequent decades have in some ways been less exciting, but I can live without the need to create material for more stories like this. Uneventful test flights, of which I have done many since, are the best kind.

*During this period, it was rare for homebuilders to install new engines. They were much more expensive than the plentiful used engines available at the time. I had purchased this engine from an aircraft salvage company who had apparently acquired a half dozen or so of the O-320–E1Fs from Lycoming when the intended aircraft, the Bölkow-Messerschmitt 209, was taken out of production. As I recall, this engine cost me $3,800, and while expensive compared with a used engine at under $2000, it was much lower in price than the $6,000+ retail for a new Lycoming at the time.

Photos: Richard VanGrunsven.