Propellers are the final link in our power train, providing the ample thrust that delivers sought-after performance. While our focus here is on Experimental applications, an arena providing a plethora of choices ready for the evaluating, we also include the certified propellers that have long brought trust and resale value. But, for Experimental/Amateur-Built-category installations, we’ll cover noncertified propeller makers, which can produce a customized product, even for a specialized one-off application. There is a certain satisfaction in knowing you’re getting the optimum output from your tweaked propeller.

Propellers are the final link in our power train, providing the ample thrust that delivers sought-after performance. While our focus here is on Experimental applications, an arena providing a plethora of choices ready for the evaluating, we also include the certified propellers that have long brought trust and resale value. But, for Experimental/Amateur-Built-category installations, we’ll cover noncertified propeller makers, which can produce a customized product, even for a specialized one-off application. There is a certain satisfaction in knowing you’re getting the optimum output from your tweaked propeller.

How do you decide which is the best propeller for your aircraft? In most cases, you are being guided by recommendations of the aircraft designers and their choice of engines. If a certain prop has worked for other builders of similar airplanes, it’ll be a good place to start. Talk with users of a propeller you’re admiring and see how satisfied they are.

Terms & Features

Propellers are basically rotating airfoils, producing lift in a horizontal plane by the passage of air over carefully shaped blades. The ability to provide this force through an angle of attack is provided by the “pitch” of the blade, commonly stated in inches. The prop’s pitch is a theoretical distance the propeller would move forward in one revolution through a frictionless medium; a prop with 48 inches of pitch would advance four feet in perfect conditions. Twisting a screw into soft wood is a proper analogy, hence the origin of the British term “airscrew” for propellers.

Because propeller blades see varying airspeeds at various distances from the hub while spinning, they are designed to accommodate this with twisted shaping and varying thickness along their length—stated pitch is generally one measured at a point 75% of the distance from hub to tip. Farther outward, the blade encounters a higher “airspeed” and, like a wing’s airfoil, there’s a limit to how fast it can go without becoming transonic, where it’s no longer efficiently producing thrust as well as capable of generating hideous amounts of noise. Tip speeds beyond Mach 0.75 are generally undesirable.

Which leads us to the other specification applied to propeller design, the diameter of the prop disc. With a two-blade propeller, it’s a simple matter of measuring the overall length from tip to tip. In addition to limiting diameter to avoid excessive tip speed, consideration has to be given to ground clearance. While a longer propeller might be desirable to produce more thrust, the likelihood of damage from debris dislodged during run-up or from taxiing over uneven ground limits the diameter. A floatplane’s propeller can commonly have a greater diameter than one of its wheeled counterparts, thanks to its elevated position.

Static rpm refers to the engine speed demonstrated with the engine running at full power while sitting still. Generally associated with fixed-pitch propellers, a range of allowable static rpm is often shown on an airplane’s type certificate data sheet. If static rpm is too low, there may not be enough takeoff and climb performance, and if it’s too high the engine will overspeed during cruise or descent as airspeed increases and the propeller becomes unloaded. Reference is often made to a climb prop with less pitch to enable higher rpm at low airspeed or a cruise prop with more pitch to enhance level-flight speed.

Having It All

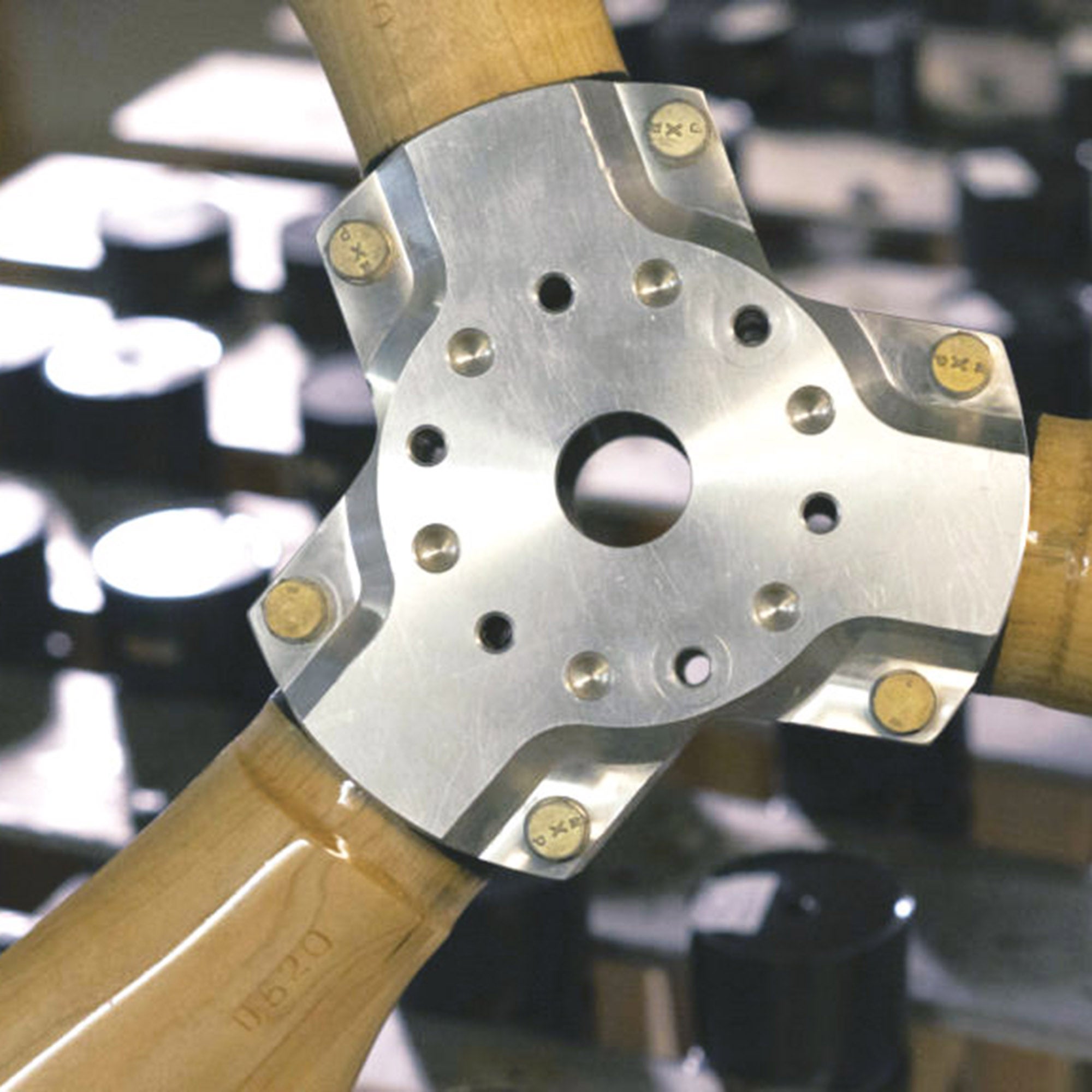

Changing pitch to meet varying requirements is the reason for having a ground-adjustable propeller, with blades mounted in a hub so they can be rotated to a desired pitch, thereby solving the fixed-pitch dilemma with little added weight. Better still is to have the ability to move blade pitch during flight, either mechanically or with an electric motor, thereby optimizing engine rpm as airspeed changes. Some propeller designs can actually flex slightly in response to the load imposed by airspeed variance, a simpler, but limited, solution.

And, of course, a continually adjustable propeller leads to the ultimate solution, adding a governor that will hold rpm to a constant engine speed, freeing the pilot from having to advance or reduce engine power to maintain rpm. Both complexity and weight are increased, as well as imposing an added maintenance burden, and not all engines can accept the governing mechanism.

Construction

Traditionally, propellers were constructed of laminated plies of durable wood, glued together and shaped into airfoil blades by hand. As aviation progressed and more horsepower was being delivered by ever-larger engines, steel or forged aluminum propellers took the place of wood, and adjustable, constant-speed and feathering features were added. Aluminum props are the norm today, but advanced composite construction is coming to the fore. Although more expensive, composite blades can offer unlimited life through repairs instead of being sacrificially filed away to smooth nicks, and they are lighter and more capable of complex shaping.

Blade Count

Increasing from two blades to three or more may be necessary to handle the job of changing higher horsepower into thrust, particularly if diameter must be restricted. However, adding blades seldom increases performance when engine power remains static. A three-blade replacement for a two-blade prop may offer better acceleration, and careful design can limit an extra blade’s inherent loss of cruise speed. The smoother purr of three or more blades is a plus, generating a lower-pitched noise signature. Some builders just like the look and are willing to pay for it.

Certified or Experimental?

Putting a type-certificated propeller on an Experimental airplane may seem like overkill, but frequently it’s the best way to go because of the convenience factor, especially if you’re using a certified engine. Or the support from a big-name supplier may appeal to you, with service available at approved prop shops with factory-supplied training and parts.

Even so, with E/A-B aircraft making up a healthy percentage of all new registrations, certified propeller manufacturers are developing non-certificated products specially designed for Experimentals, taking advantage of the freedom of the category to incorporate innovation into their certified propellers.

Certified Propellers

Beginning our annual perusal of what’s available for propeller selection, here are the latest updates from the world of certified propellers.

GT Propellers

The Tonini brothers, Alessandro and Paulo, operate GT Propellers in Riccione, Italy, producing natural wood/composite propellers with removable blades for easy shipment and replacement. The extensive GT product line extends from 60-hp lightplanes to 2500-hp Merlin engines in Spitfires, even high-altitude turbine-powered drones. Alex Tonini says GT is delivering propellers regularly to the U.S. and worldwide. GT has EASA and ENAC certifications.

Hartzell Propeller, Inc.

Hartzell Propeller, a global leader in advanced aircraft propellers for more than a century, continues to develop and grow its collection of robust propellers for kit aircraft builders and owners of Experimental aircraft.

For backcountry flying, Hartzell offers the Trailblazer and Pathfinder models, and Hartzell’s widely popular blended-airfoil (or BA) propeller can be found on a variety of kit airplanes. Its newest carbon blended airfoil is now available in a two-blade propeller with carbon fiber blades developed to mimic the current RV-standard two-blade metal propeller. The new Explorer was designed for cruise, making it a solid choice for cross-country flying, and the Talon has the same proven reliability as Hartzell’s Claw while delivering even higher performance, says the company.

Hartzell’s Manual 193 is the company’s information manual for Experimental aircraft, written specifically for the kit aircraft community. It addresses such things as propeller/engine compatibility, propeller integration for homebuilts and much more. Manual 193 can be found on Hartzell’s website by clicking “products” then “kitplanes” and scrolling to “download manuals.”

Hoffmann Propeller GmbH & Co, KG

In business since 1955, Hoffman Propeller builds wood-core blades enclosed in epoxy with nickel leading edges. The company’s headquarters are situated in Rosenheim in Upper Bavaria in the south of Germany. On a site of nearly 61,000 square feet, development, manufacturing and administration are accommodated, as well as a large depot for spare product. As company spokesperson Andrea Huber pointed out, Hoffmann Propeller holds all required certifications of national and international aviation authorities to design, develop, manufacture and overhaul propellers, including EASA and FAA approvals.

McCauley Propeller Systems

Now with more than 85 years in the propeller business, McCauley became a wholly owned division of Cessna Aircraft in 1960 and is the exclusive provider of propellers across the Textron Aviation line of airplanes. The latest new developments are props for the Beechcraft Denali single-engine turboprop and Cessna SkyCourier utility twin. McCauley makes fixed-pitch, constant-speed and fully reversible products, including the Blackmac STC’d replacement propellers.

MT Propeller, Inc.

German propeller manufacturer MT has steadily grown in prominence since its inception in 1981, building natural composite blades with hub styles up to an astounding 11 blades, for engines from 65 to 1500 hp. MT Propeller in Deland, Florida, provides American support and repairs. VP Peter Marshall reports that many new Rotax engine applications are now offered, including single-lever FADEC options. The MT is essentially the propeller of choice for the new Rotax 916 iS turbocharged four-cylinder.

Sensenich Propeller Company, Inc.

Sensenich Propeller continues to offer a broad range of propellers for Experimental and light sport aircraft, as well as standard certified airplanes, in fixed-pitch styles using wood and aluminum. It also offers ground-adjustable composite-blade propellers, so Sensenich is probably unique in working with all three materials. All production was consolidated at Plant City, Florida, in 2023, after a 90-year legacy in Pennsylvania.

For the STOL market, Sensenich has several new blade models optimized for Lycoming and Continental installations and three other blades geared for the Rotax/Edge and ULPower engines. Their certified composite propeller for Piper Super Cubs, released several years ago, is in the process of having its approval expanded to Cessna 172 and Piper Cherokee airframes. Also nearing certification is a 2F0 propeller series for classic aircraft powered by 65- to 115-hp Continentals and Lycomings.

CERTIFIED PROPELLERS

| Company | Date Founded | Certified/Experimental | Origin | Construction | Horsepower Range |

|---|---|---|---|---|---|

| GT Propellers +39 0541 69 33 99 |

1969 | Certified | Italy | Wood and Composite | 80 to 2000 hp |

| Hartzell Propeller, Inc. 800-942-7767 or 937-778-4200 |

1917 | Certified | USA | Metal and Composite | up to 2180 hp |

| Hoffmann Propeller GmbH Co. KG +49 8031-1878-0 |

1955 | EASA & Experimental | Germany | Wood and Composite | up to 500 hp |

| McCauley Propeller Systems 800-621-7767 or 316-831-4021 |

1938 | Certified | USA | Metal and Composite | 100 to 1200 hp |

| MT Propeller, Inc. 386-736-7762 |

1981 | Certified | Germany | Natural Composite | 65 to 1200+ hp Custom |

| Sensenich Propeller Company, Inc. 813-752-3711 |

1932 | Certified | USA | Wood, Metal and Composite | 50 to 275 hp |

Noncertified Propeller Suppliers

In the world of custom propeller building, it’s all about reputation and recognition. Many smaller prop companies offer a tailored approach to what the customer is seeking, even offering to tweak a propeller that’s not delivering desired performance. Experimental/ Amateur-Built certification gives us freedom to choose and adapt propellers to whatever combination of airframe and engine we can come up with.

We did not receive a response to our attempts to contact PowerMax Propeller in the Czech Republic. Otherwise, here’s an update on the many manufacturers supplying props into our Experimental space.

Airmaster Propellers, Ltd.

Coming up on a quarter-century of supplying electric constant-speed propellers from their Auckland, New Zealand, factory, Airmaster makes two- to five-blade hub designs. Martin Eskildsen says they now have a new DSD (Digital Servo Drive) that features a brushless motor capable of operating at a quick 5° per second, available on all Airmaster models. The pitch range goes from -20° to +85°, for feathering and reversing. Airmaster offers props capable of handling 50- to 350-hp outputs.

AXSport Aviation

Based in Cape Town, South Africa, AXSport Aviation makes three-blade carbon fiber-blade propellers for Rotax and Lycoming installations up to 180 horsepower, historically featuring electric constant-speed control. However, Donald Williamson reports that a long-awaited hydraulic propeller is in flight test. Meanwhile, AXSport is now using a new linear actuator on the Rotax gearbox rather than an electric motor in the spinner, for easier balancing.

Bolly Aviation

Bolly Aviation’s Peter Tapp reports that nothing has changed for 2025 in their ground-adjustable carbon fiber propeller line, still centered on the LSA and ultralight market. Furnished in two-, three- and four-blade styles, their Optima series props come in a Series 3 version for reduction-drive applications and a Series 5 for direct-drive engines. Bolly is headquartered at Virginia in South Australia.

Catto Propellers

Craig Catto is fortunate to now have his daughters working with him in the propeller business, which he founded in 1974. Their two- and three-blade maple wood core props have a fiberglass and carbon fiber overlay, primarily supplied as fixed-pitch except for a constant-speed model for canard airplanes. We were told that the product line is going to be expanding in the near future—possibly to include a new low-noise propeller Catto developed with the Sling Aircraft group—so keep an eye on the Catto website for updated news. Catto Propellers is still in Jackson, California, east of Sacramento.

Culver Props

Alaina Lewis custom-builds laminated wood fixed-pitch propellers in her family’s shop at Rolla, Missouri, reporting a four- to five-month delivery time after ordering. Her beautiful two-blade props are legendary, using the same techniques that her grandfather employed 40 years ago. Culver builds propellers for engines up to 300 hp.

DUC Propellers USA, Inc.

With production based in the Beaujolais wine area of France near Lyon, DUC Propellers has a U.S. subsidiary in Sebring, Florida. DUC offers a wide range of general and light aviation props, as well as rotors and accessories, all made of forged carbon construction. Its Cobra, Tiger, Flash, Swirl and Windspoon designs are offered in ground-adjustable and variable-pitch styles, and DUC also has hydraulic and electric constant-speed propellers handling up to 315 hp. The electric props can be set up for in-flight adjustability when fitted with a control box for constant-speed operation.

With installations available out of its Florida facility, DUC has a network of 60 dealers in the U.S., according to Branch Manager Gaetan Fouozing.

E-Props Propellers

Produced in southeastern France, the E-Props propeller line is represented in the USA by Evolution Aircraft Inc. at Zephyrhills, Florida. The carbon fiber ground-adjustable E-Props are reportedly the lightest available, with a 68-inch model weighing only 4.6 pounds. Their ESR feature claims to allow only a 100 rpm rise from zero to 125 mph on a Rotax 9-series engine. Larry Mednick also reports E-Props now has a specifically made RV-12 prop assembly with a much more robust pitot system using ball bearings that does not rely on the spinner cone to support the pitot tube. Climb is improved by 200-300 fpm and cruise speed is increased by 6-9 mph. TBO is set at 4000 hours.

GSC Systems, Ltd.

Specializing in hard-rock maple wood fixed and ground-adjustable propellers to go on Subaru, Jabiru and VW engines in powered paraglider ultralights, GSC says they are still doing business from their plant in Vernon, British Columbia, Canada. GSC’s Tech series features an aluminum hub with individual blades for easier shipping, particularly on their three-blade configurations.

GSC also makes fixed-pitch props with hub thicknesses from 1.5 to 2.375 inches and diameters from 32 to 72 inches. With that kind of range, there’s probably something for your airplane and your engine in GSC’s catalog.

Hercules Propellers, Ltd.

Rupert Wasey’s Hercules Propeller company in Stroud, England, is currently expanding its offerings by obtaining a type certificate for Piper Cub and Stinson 108 props. Hercules also makes reproductions of propellers for the DeHavilland Tiger Moth as well as one-off propellers for Experimental-category aircraft. Their propellers are fixed-pitch wooden creations with urethane leading edge protection.

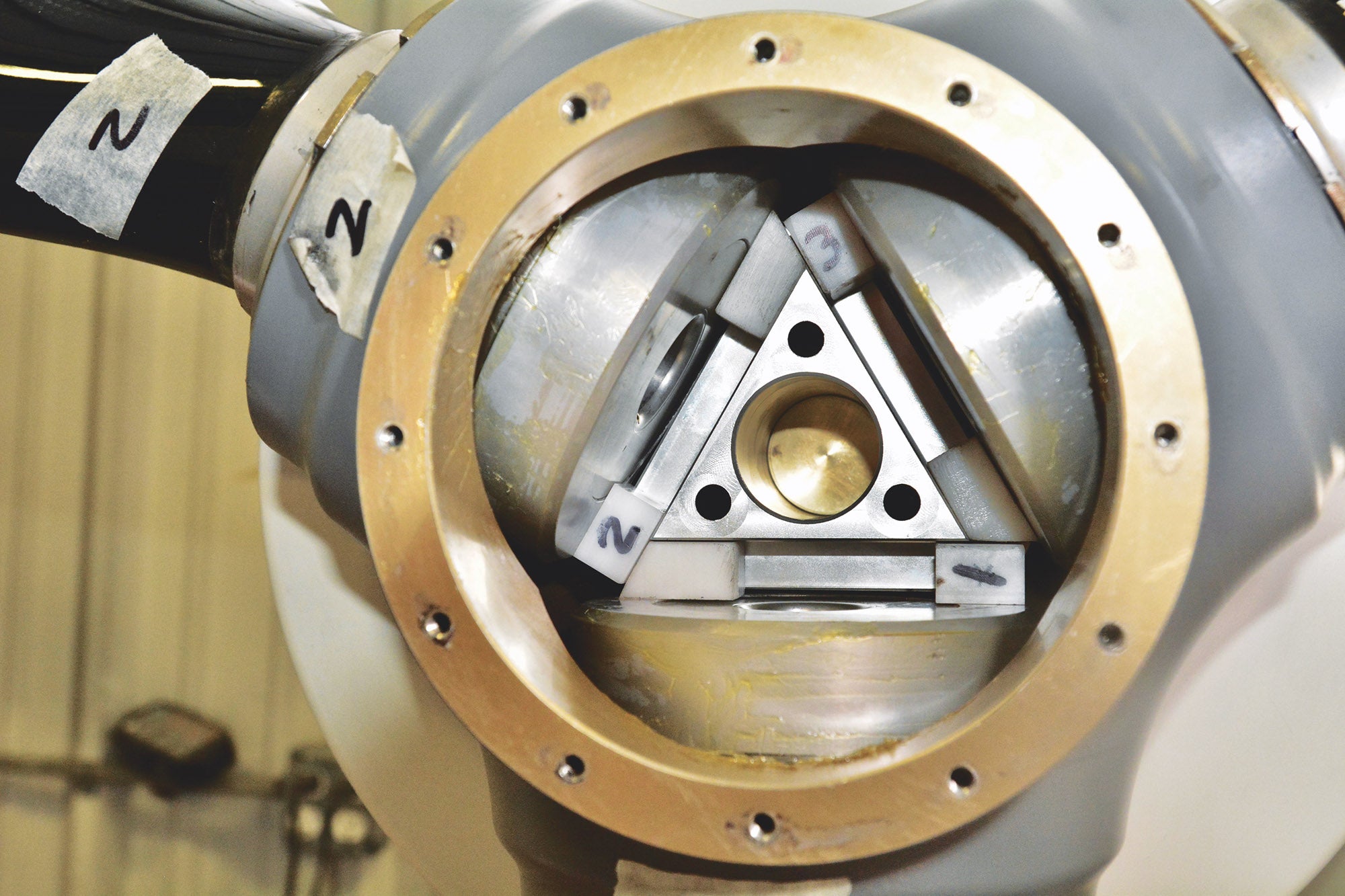

Ivoprop Corporation

The Ivoprop series of carbon fiber adjustable-pitch propellers are unique in their use of integral torsion rods that flex to change pitch, using electric motors actuated by cockpit controls. This makes the prop assembly basically one piece from the hub outward and contributes to weight reduction on all sizes. This system is used with both the in-flight-adjustable and ground-adjustable versions.

Ivoprop has offerings across a wide range of engine power. The Medium line is for engines up to 150 hp, while the Magnum props can handle up to 700 hp. The lighter Ultralight model (as well as the Magnum line) can be had with two, three or six blades, while the Medium comes with either two or three blades. In business since 1986, they are headquartered in Long Beach, California.

KievProp America

Despite difficult wartime conditions as Ukraine resists Russian invasion, Kiev Propellers is still in production and the dozen or so workers at the factory are busy on the line, according to Ted Bryant at KievProp America in Cambridge, Maryland. Orders are being filled in two weeks routinely, and he has some limited inventory on hand in the U.S. There are new products under development, Bryant says, but flight testing is currently hampered by the closed airspace over Ukraine.

Performance Propellers USA, LLC

As of late 2024, Performance Propeller, based in suburban Chicago, is not taking new orders due to a relocation. President Dominic Flamini says, “After 30-plus years in the Experimental aircraft community, we would like to see the Performance Propeller product continue, so we are currently exploring the possibility of finding someone that we could pass the brand along to, continuing the Performance Propeller series.” Interested parties can contact them at flyperfprops@gmail.com.

As of late 2024, Performance Propeller, based in suburban Chicago, is not taking new orders due to a relocation. President Dominic Flamini says, “After 30-plus years in the Experimental aircraft community, we would like to see the Performance Propeller product continue, so we are currently exploring the possibility of finding someone that we could pass the brand along to, continuing the Performance Propeller series.” Interested parties can contact them at flyperfprops@gmail.com.

Performance Props’ laminated wood propellers originated in 1988, growing to a line of two- and three-blade props suitable for 50- to 300-hp installations. Due to their blades’ ability to flex, Performance Propeller customers are said to get a good all-around propeller, versus a straight cruise or climb prop.

Peszke S.C.

Peszke Propellers is completing a 25-year history of producing composite-blade ground-adjustable propellers in its factory located at Korczyna in southeastern Poland. Part of 2XP Technologies Sp, the company builds carbon fiber three-blade props capable of handling up to 160 hp, its B-Line products. Other offerings are an F-Line folding propeller for motorgliders and P-Line fixed- and adjustable-pitch propellers for ultralights with up to 60 hp.

Powerfin Propellers

Our inquiry about Powerfin Propellers near the end of 2024 yielded a response that said, “As of January 2024, our order books are closed while we relocate.” No further information was available at press time. Powerfin has served the ultralight and LSA market with ground-adjustable carbon-fiber props since 2008.

Prince Aircraft Company

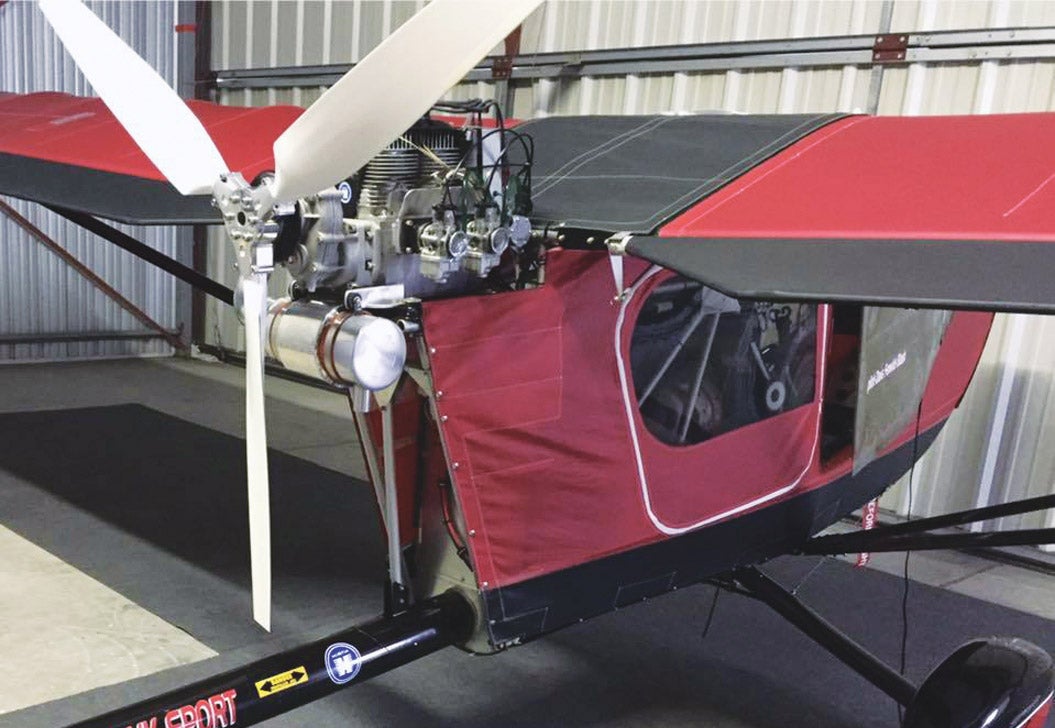

The ebullient Lonnie Prince reported business as usual when we checked in with him, still building his trademark scimitar-shaped wood-composite propellers that can respond to airspeed changes with up to 4 inches of pitch change. Lonnie has been making props since 1979 and is now quoting a seven-week lead time for new orders. His factory is in downtown Whitehouse, Ohio.

Ultra-Prop, LLC

Formerly known as Competition Aircraft, makers of the Ultra-Prop composite-blade propellers for ultralights, trikes, gyrocopters and powered parachutes, the four-decade-old prop company has moved from Utah to Holly, Michigan, near Detroit. New owners Rick and Linda Hayes have plans to release a new ground-adjustable three-blade aluminum-hub 68-inch propeller specifically for Rotax 912 installations, along with a smaller powered paraglider propeller, both with quick-change pitch blocks.

Warp Drive, Inc.

Warp Drive carbon-fiber ground-adjustable propellers have evolved from small two-blade systems for powered-parachute and gyrocopter installations into four-blade units suitable for aircraft powered by Lycoming O-320 engines. They are also providing props for Verner radial engines and airboats as well, up to 215 hp. Warp Drive has been in business for more than 35 years, based in Ventura, Iowa.

Whirl Wind Propellers Corporation

Now part of the Hartzell Propeller family, Whirl Wind Propeller products are being made in a dedicated new building on the Hartzell campus at Piqua, Ohio. Available in ground-adjustable and constant-speed models, Whirl Wind blades are built of carbon fiber with nickel leading edges. Whirl Wind’s 300 and 330 constant-speed series are designed for the most punishing aerobatic maneuvers, available in two-blade and three-blade styles.

Woodcomp Propellers

Located in the Czech Republic, Woodcomp makes variable-pitch propellers for Rotax and Lycoming installations up to 160 hp and other engines up to 350 hp. Their blades are of wood/composite construction. Woodcomp’s Filip Tocik says the product line was unchanged this past year, but they have plans to introduce a new model in 2025. The company has now been in business for 25 years.

NON-CERTIFIED PROPELLERS

<<!doctype html>

| Company | Date Founded | Certified/Experimental | Origin | Construction | Horsepower Range |

|---|---|---|---|---|---|

| Airmaster Propellers, Ltd. +64 9 833 1794 |

2000 | Experimental | New Zealand | Metal and Composite | 80 to 350 hp |

| AXSport Aviation +27 82 780 7111 |

2015 | Experimental | South Africa | Carbon Composite | 80 to 200 hp |

| Bolly Aviation +61 8 8380 8396 |

1995 | Experimental | Australia | Composite | up to 160 hp |

| Catto Propellers 209-754-3553 |

1974 | Experimental & ASTM | USA | Composite | 65 to 300 hp |

| Culver Props 573-364-6311 |

1983 | Experimental | USA | Wood | up to 300 hp |

| DUC Propellers USA, Inc. 863-991-0113 |

1997 | Experimental | France | Composite | 40 to 315 hp |

| E-Props Propellers +33 4 92 34 00 00 |

2008 | Experimental & Ultralight | France | Composite | 150 to 300 hp |

| GSC Systems, Ltd. 250-549-3772 |

1984 | Experimental | Canada | Wood | 35 to 115 hp |

| Hercules Propellers, Ltd. +44 1453 885 853 |

2008 | Experimental | United Kingdom | Wood | Custom |

| Ivoprop Corporation 800-FOR-PROP or 562-602-1451 |

1986 | Experimental | USA | Composite | up to 700 hp |

| KievProp America 410-221-8009 |

1970 | Experimental | Ukraine | Composite | 40 to 200 hp |

| Performance Propellers USA, LLC 630-551-8733 |

2009 | Experimental | USA | Wood | 50 to 300 hp |

| Peszke S.C. +48 664 990 378 |

2000 | Experimental | Poland | Wood | up to 160 hp |

| Powerfin Propellers 435-627-0942 |

2008 | Experimental | USA | Composite | up to 160 hp |

| Prince Aircraft Company 419-877-5557 |

1979 | Experimental | USA | Composite | 100 to 300 hp |

| Ultra-Prop LLC 248-266-4286 |

1984 | Experimental & Ultralight | USA | Composite | up to 100 hp |

| Warp Drive, Inc. 641-357-6000 |

1989 | Experimental | USA | Composite | up to 180 hp |

| Whirl Wind Propellers Corp. 619-562-3725 |

1995 | Experimental | USA | Composite | 80 to 400 hp |

| Woodcomp Propellers s.r.o. +42 283 971 309 |

2000 | Experimental & EASA | Czech Republic | Wood and Composite | up to 310 hp |