The spars and ribs on our F1 Rocket tail are 0.040” aluminum—too thick to dimple (well, you could dimple it, but you’d turn a nice straight spar into a pretzel…). You have to dimple the skins for this, so it needs to sit in a countersunk hole. The problem with a typical countersink bit is that in thin material, the nose will “wander,” and you’ll have a mess—an enlarged hole and an odd-shaped dimple.

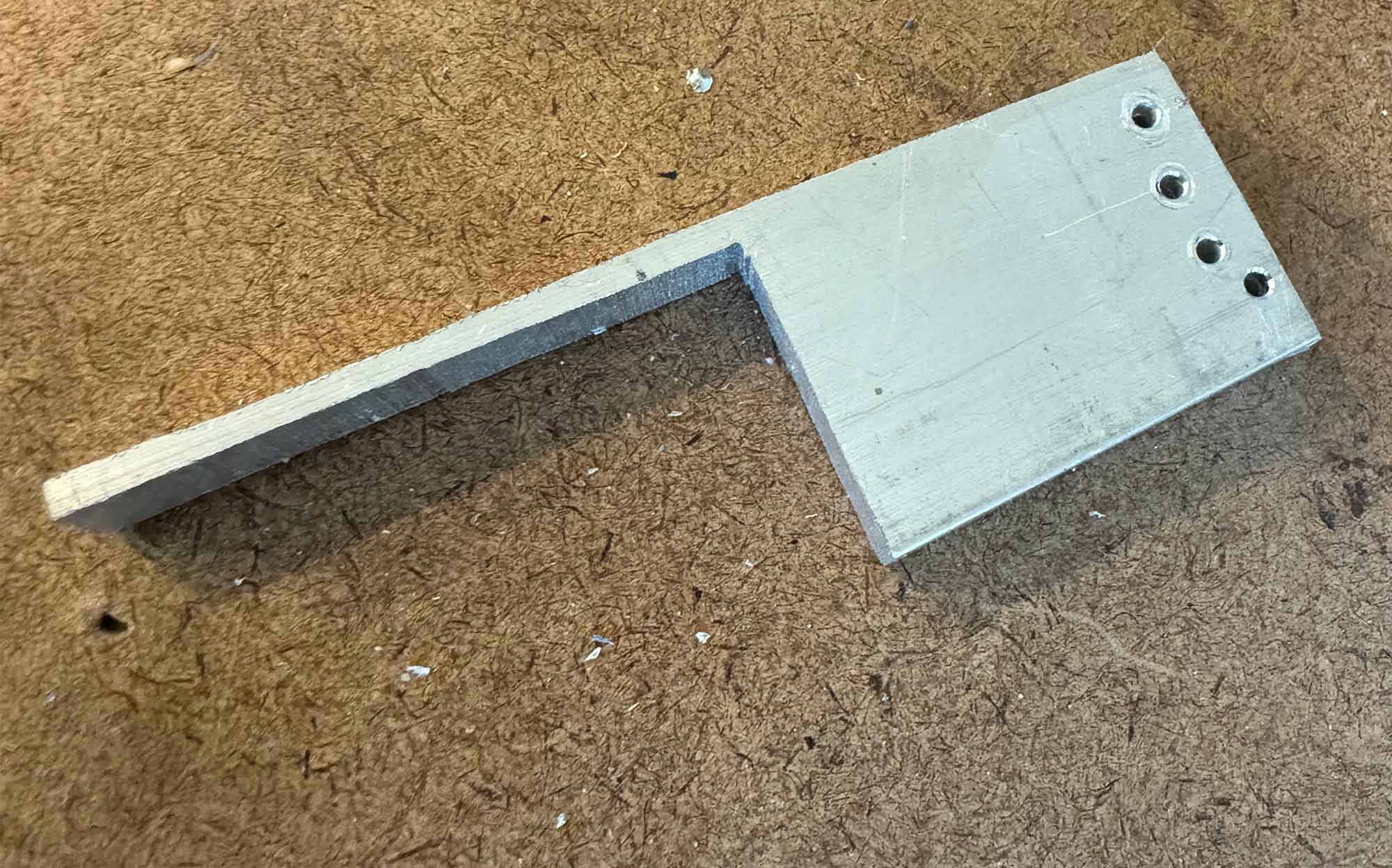

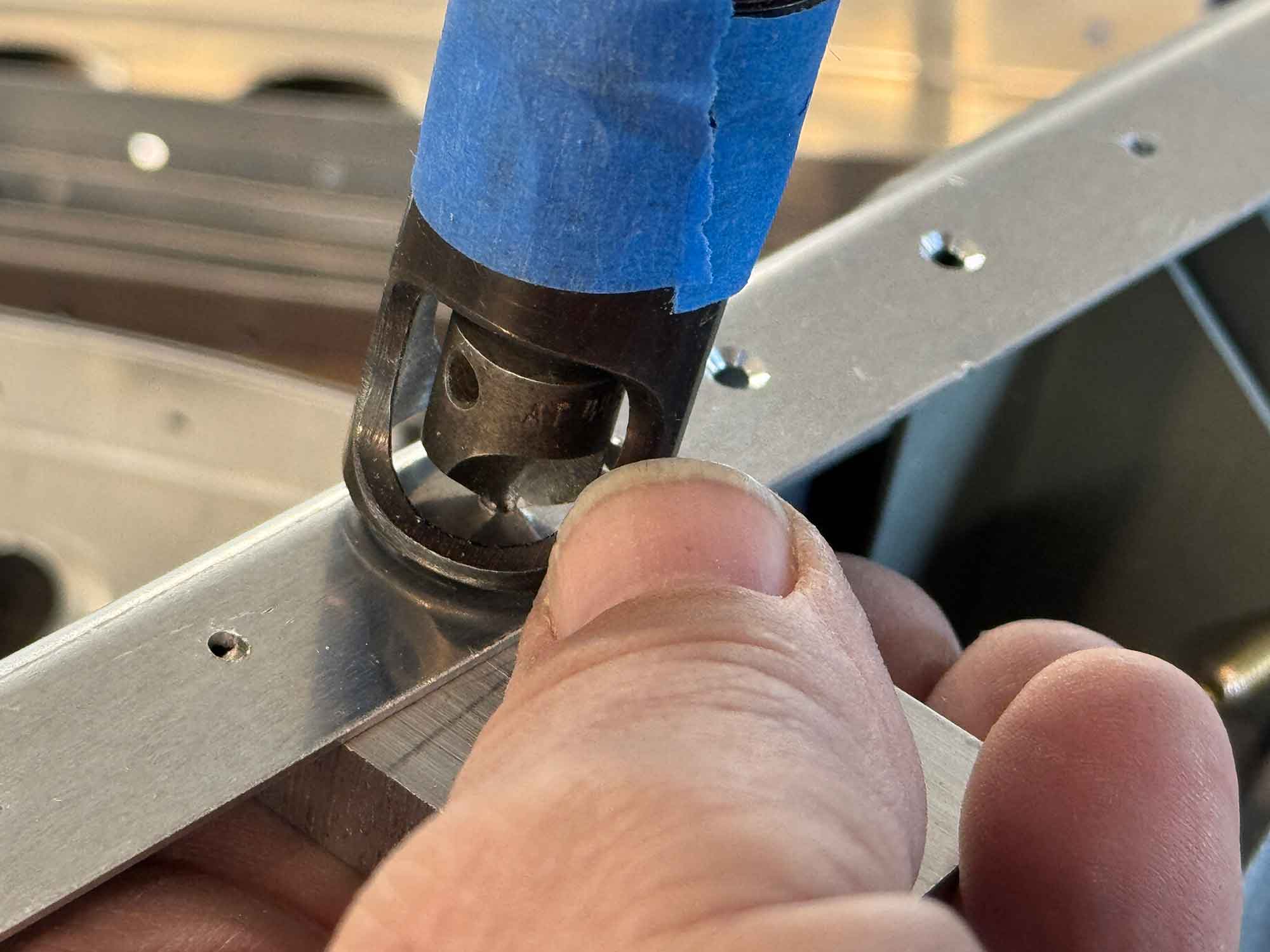

Fix this with a “countersink block”—a thick piece of aluminum (or hard piece of wood) with some holes that are the same size as the nose piece of your countersink bit—in this case, #40 for 3/32” rivets. More mass is better for stability. Hold it behind the workpiece tightly, and the bit won’t wander! You’ll get perfect countersinks every time if you practice a bit on scrap first.

Now my countersinks will look a lot better!

Thanks!