If you read Paul Dye’s article “Automotive Plugs in Lycomings” in the August 2023 issue, you know that using inexpensive automotive-style single-electrode spark plugs in aircraft engines is officially a thing. Of course, auto conversions, from VWs to Corvairs and even the Ford Model A (Pietenpol), have always used auto plugs. But when you think about it, pretty much every new aircraft engine designed since 1975 uses auto plugs, most notably Rotax, Jabiru and ULPower.

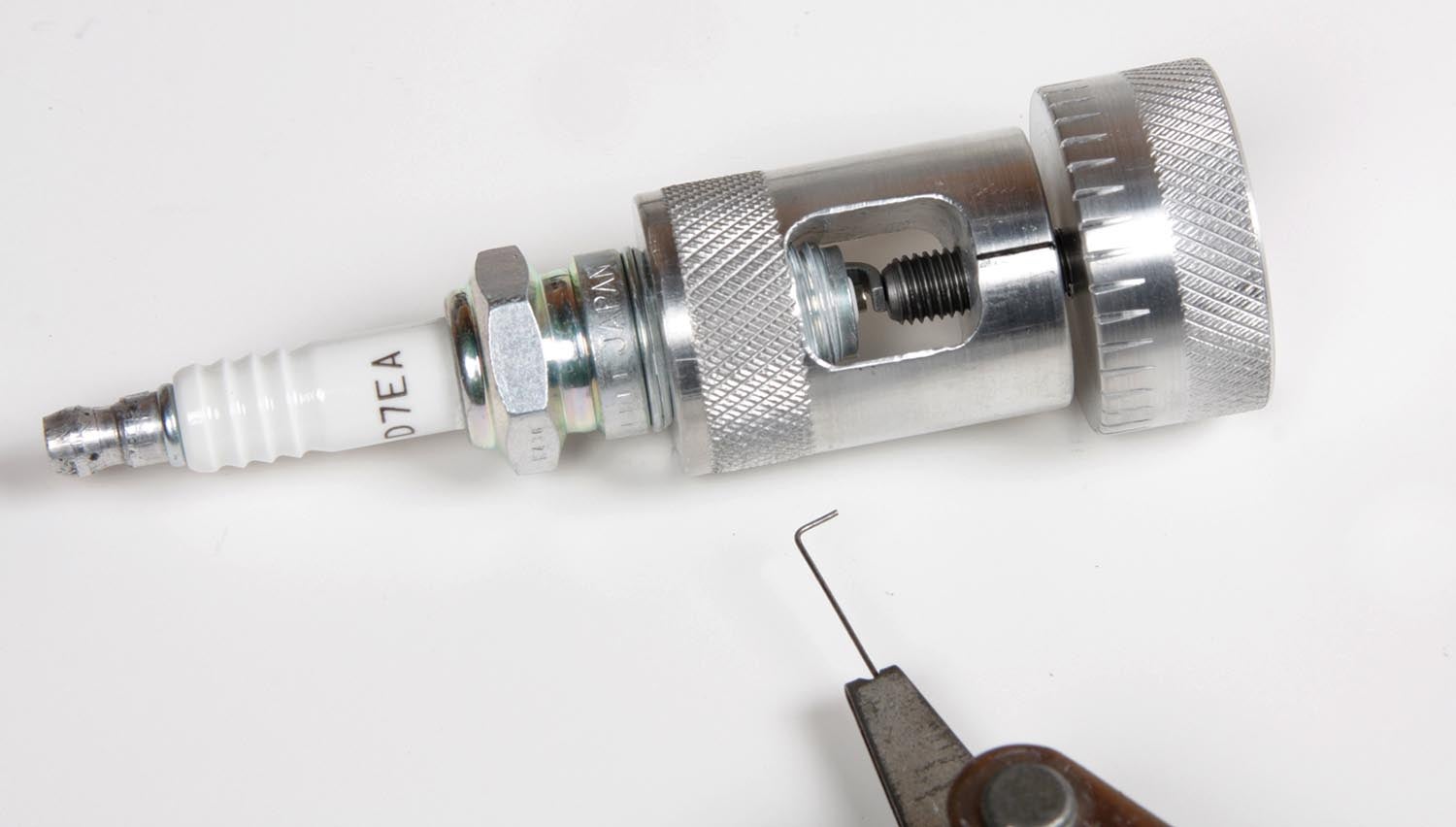

The NGK plugs (D9EA) that I use in my Jabiru 3300 come with a gap of about 0.026 inches. The maintenance manual calls for it to be between 0.022 and 0.024 inch. Gapping plugs is by no means a Ph.D.-level exercise, but doing a batch of 12 can be tedious. The most common gapping tool is probably the combo feeler gauge/electrode bender (see photo). This type of electrode bender is essentially a miniature blacksmith’s fork that allows you to lever the base of the ground electrode (also called the side electrode) to either open or close the gap to the center electrode. While they work as intended and are economical, it takes a bit of trial and error: Measure, bend, repeat, until you zero in on the proper gap.

Another option, which is posted on the NGK website, suggests tapping the electrode on a bench to adjust the gap. This method has the advantage of eliminating the risk of chipping the porcelain insulator—which I suppose could happen if you are careless or happen to be using a tool that’s too big for a 12mm or 14mm plug—but it seems no better than the trial-and-error procedure of the combo tool.

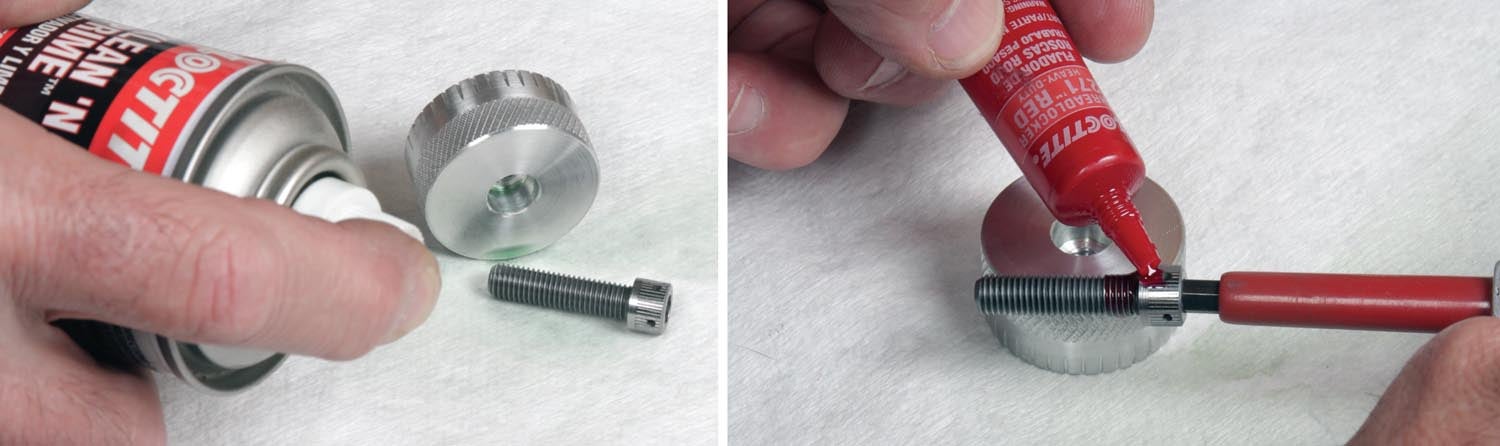

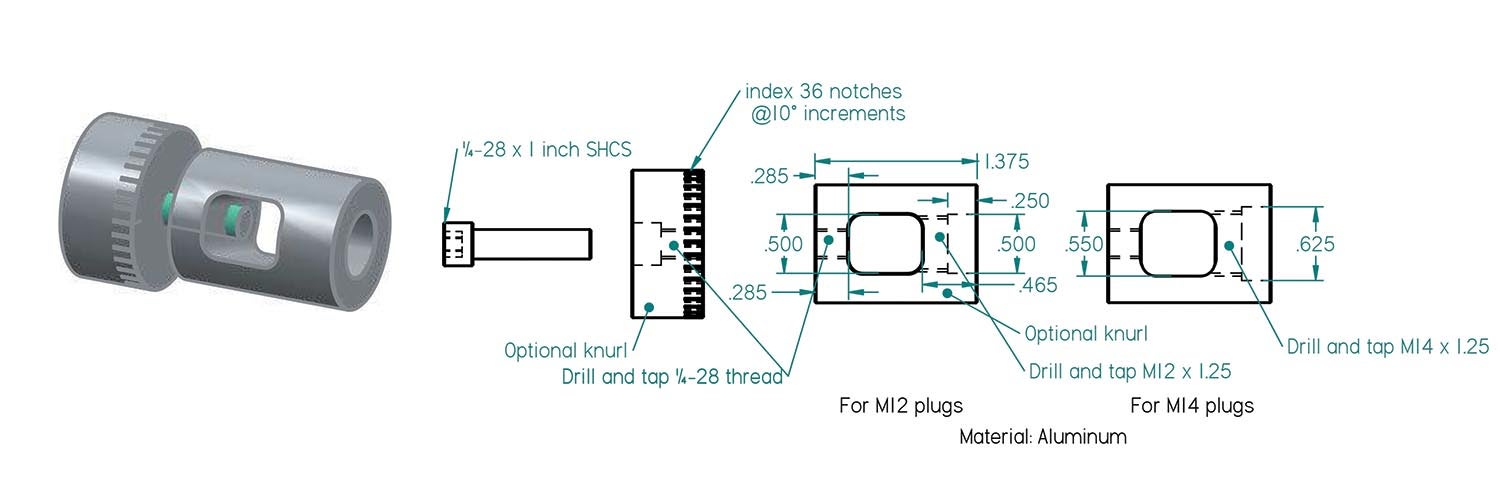

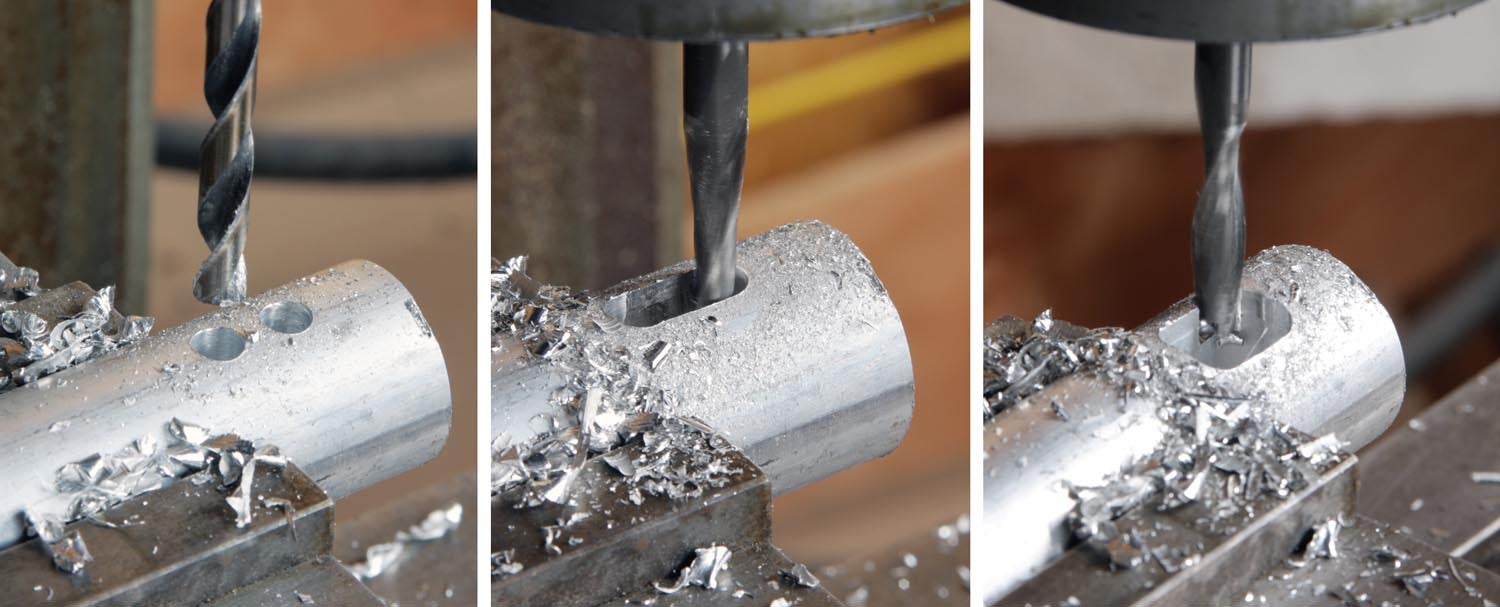

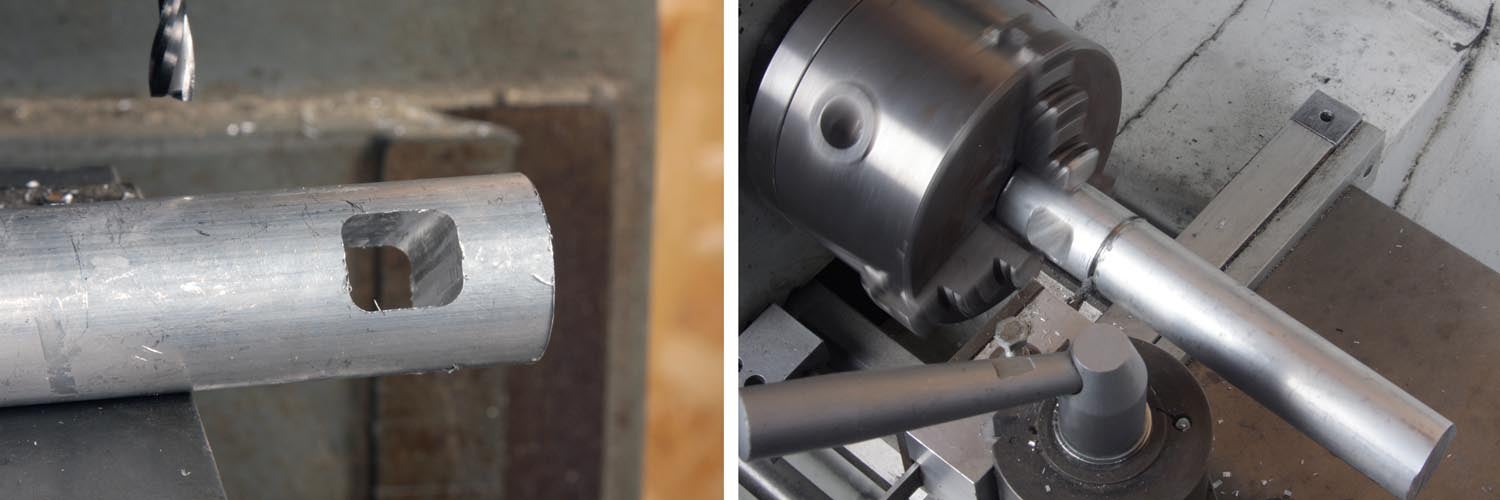

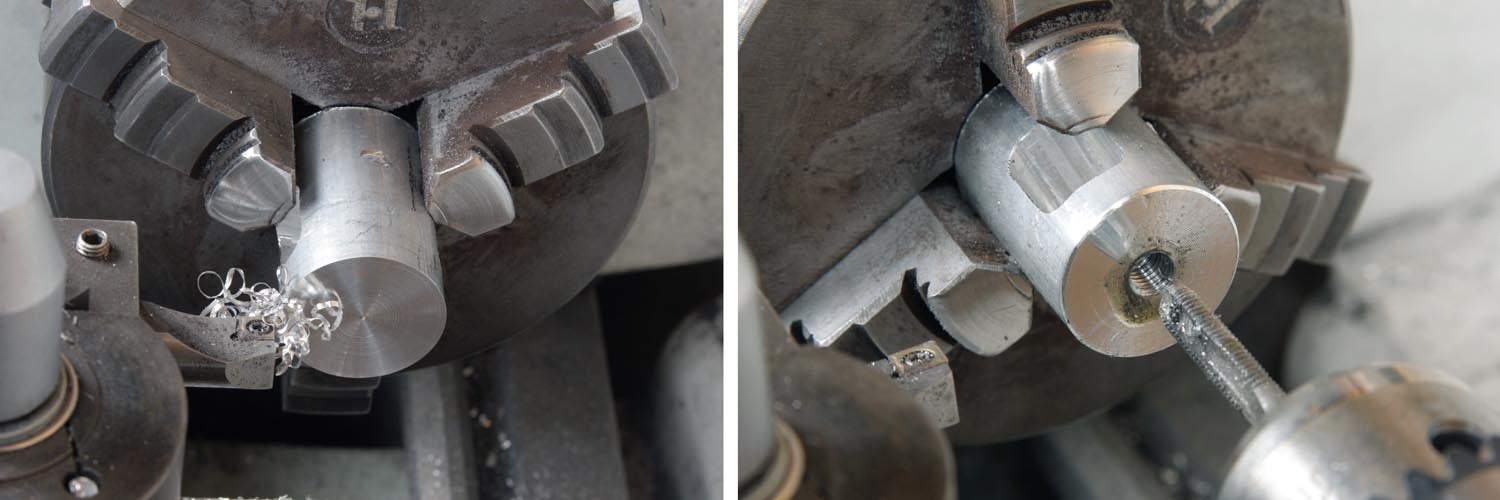

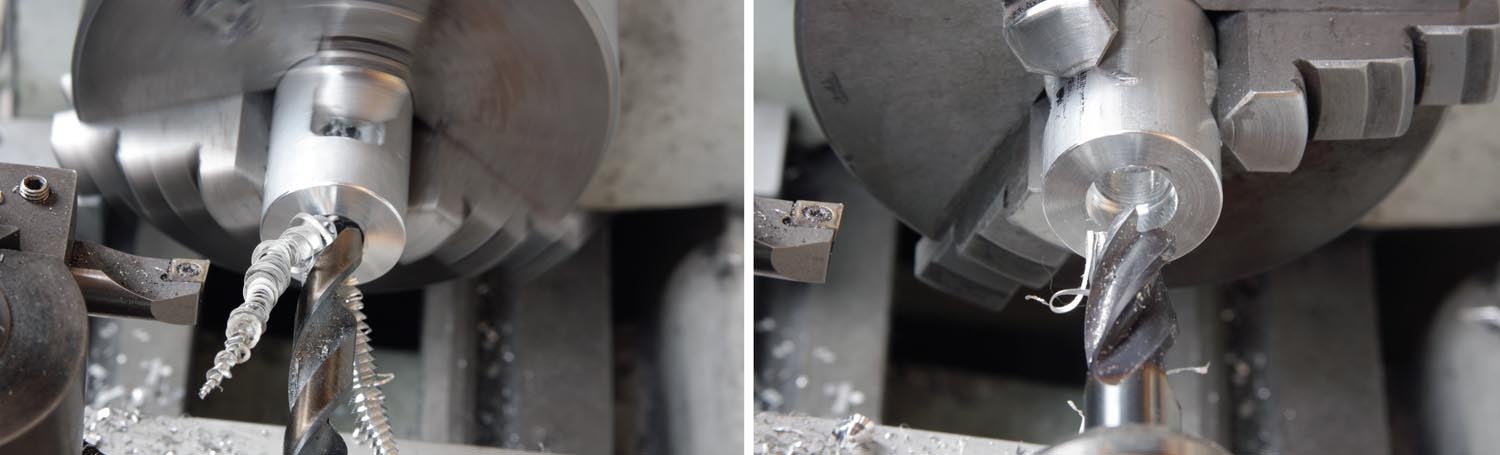

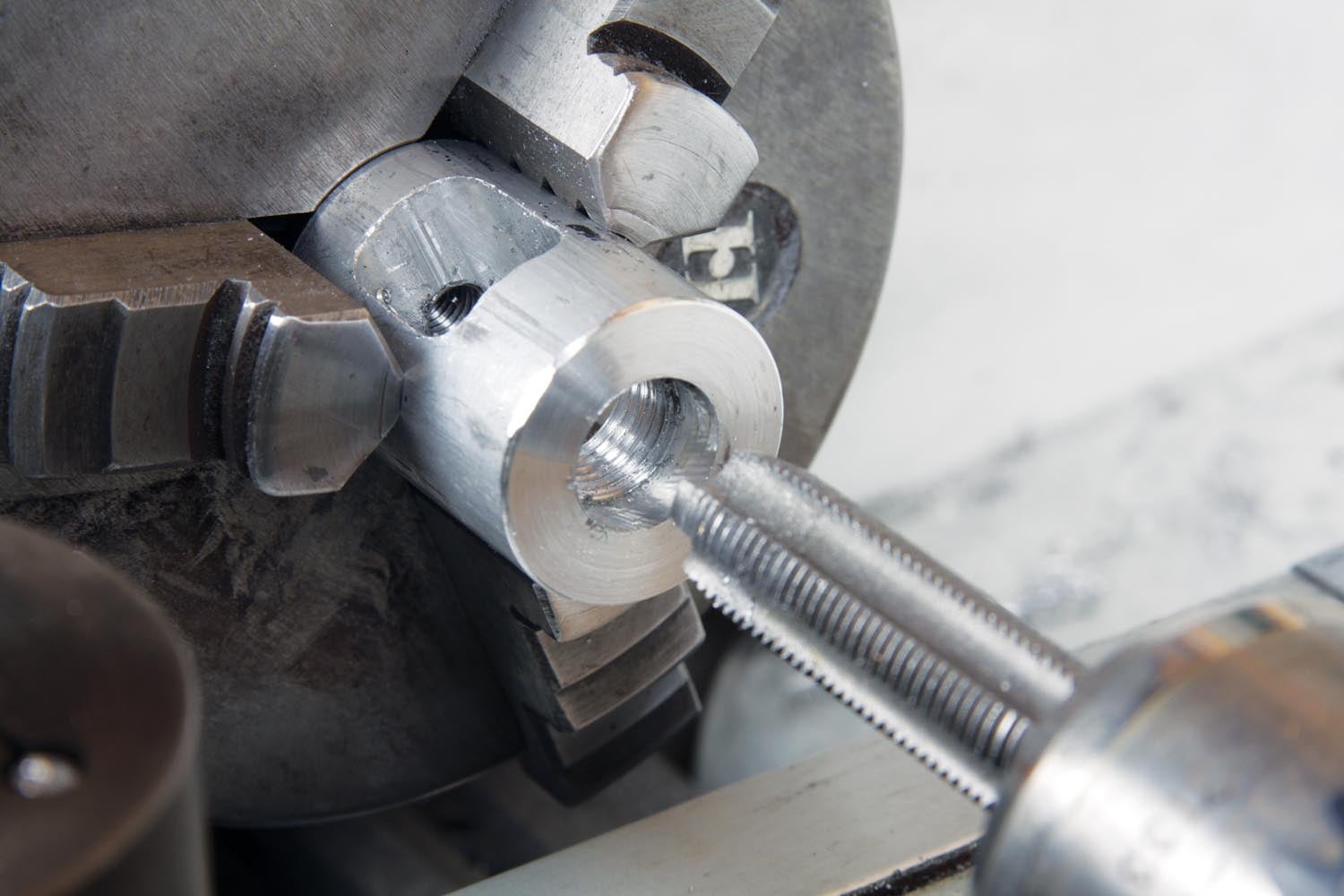

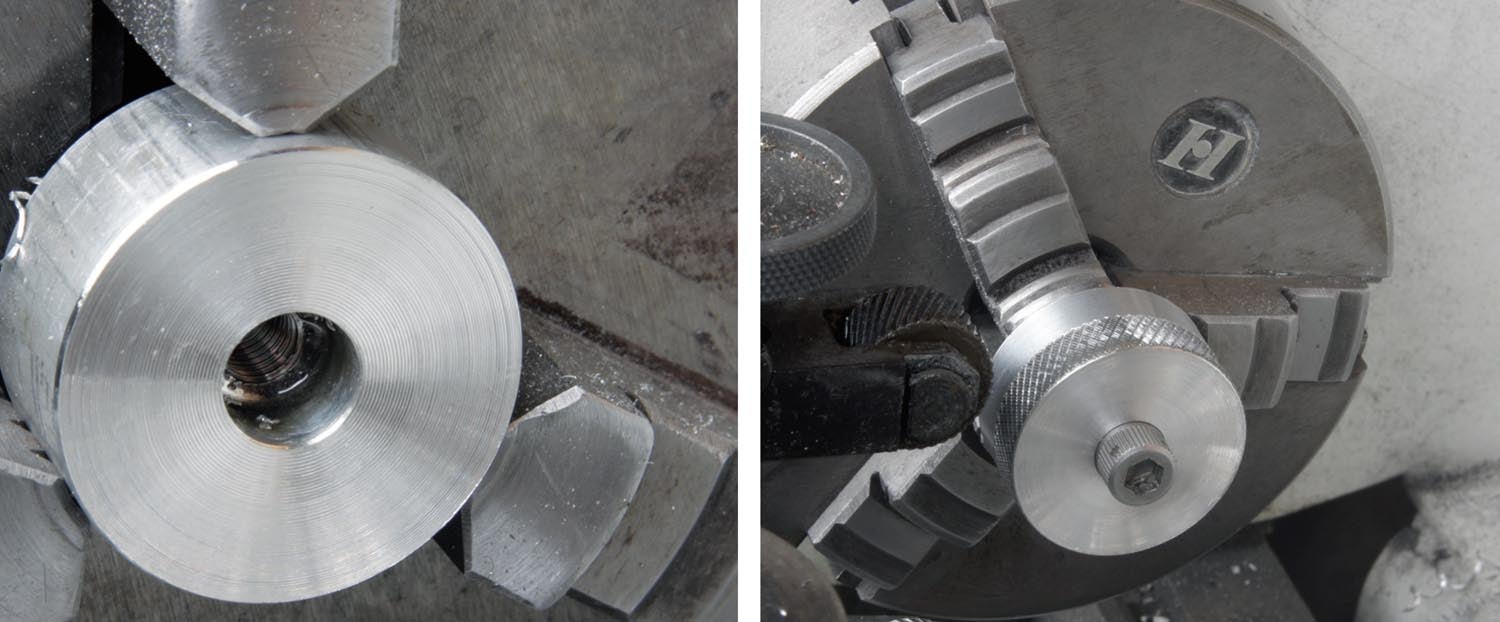

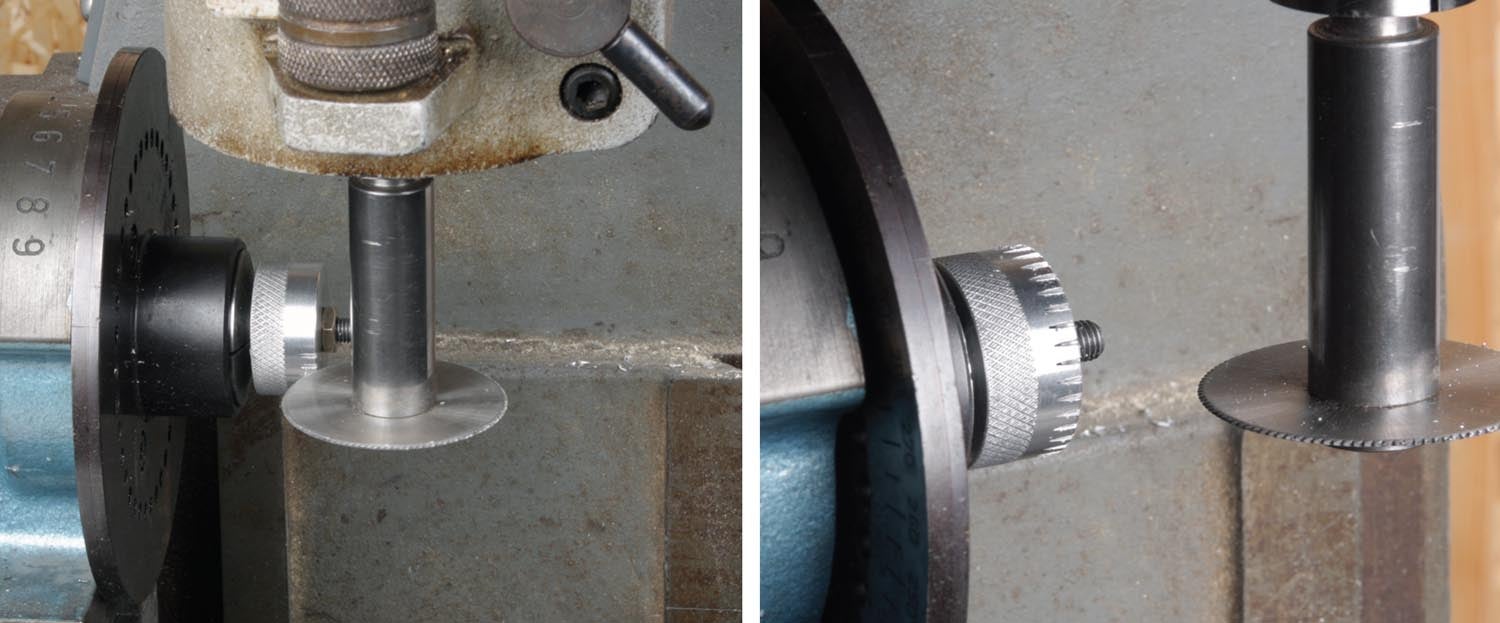

This month’s project is a plug-gapping tool that minimizes trial and error and eliminates any risk of porcelain damage. There are a number of variants of this design available commercially, but none of them feature a way to actually measure how much adjustment is being—or has been—made. By including a graduated scale (each mark = 0.001 inch) on the handwheel, you can quickly and precisely gap a batch of plugs. You still need a feeler or wire gauge to confirm the adjustment, but so do the commercial tools.

Bending a spark plug electrode is no different than bending any metal: There will always be some springback. You always have to lever the electrode a wee bit more than the target gap to account for springback. Having a graduated scale takes the guesswork out of how much extra adjustment is needed to account for springback.

On the D9EA plugs for the Jabiru (and D7EA plugs for the VW), I found the typical electrode springback to be 0.002 inch. Given that the factory gap is 0.026 and my target gap is 0.022, I bring the screw in contact with the electrode, mark the scale with a pencil or piece of tape and advance the handwheel six marks (= 0.006 inch). Back the screw off and check the gap, and it’ll be right on the 0.022 gap.

If your situation involves increasing the gap (e.g., Rotax), this gapping tool might still come in handy for those times when you overshoot the target gap and need to tighten it up a bit. Bending and re-bending the electrode a few times is not likely to hurt anything, but it will certainly save trial-and-error time.

A note on the math: The handwheel turns a 1/4-28 socket-head cap screw. I selected that thread pitch because it comes pretty close to giving an even number of 0.001-inch graduation marks on the handwheel. The math is pretty simple: 1 inch ÷ 28 threads per inch (TPI) = 0.0357 per one rotation of the handwheel. Yes, the 36 graduation marks are in fact 0.00099 inch apart, but in the home shop we call that close enough!