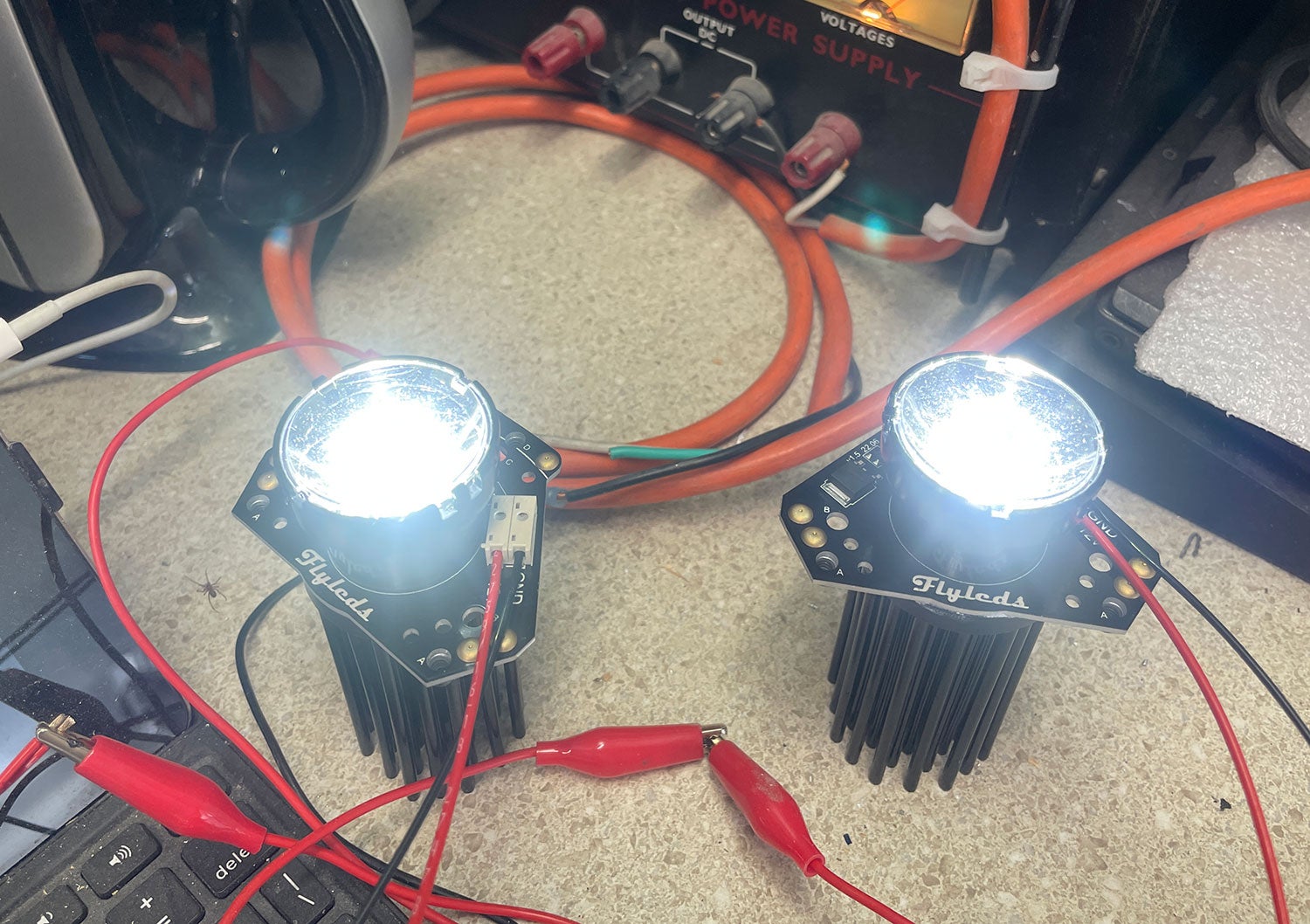

One of the things I brought back from AirVenture last week was a kit from Flyleds to build two LED landing lights that we’re going to use simply as Wig-Wags on the eXenos to make it more visible. One of the things that make FLyleds fit into the budget for homebuilders is that they aren’t finished lights—they are kits. In the case of these lights, you ned to attach nut plates to the main board, fit the heat sink and lens mount to the same board and then install the lens and wires. It really only took about an hour to do the whole thing, and that included reading the instructions twice before I started, just to make sure I didn’t build myself into a corner.

It doesn’t include the extra half hour I spent machining a special die for my rivet squeezer, however. The lights use two single-leg nut plates, fastened with AD3 dome-head rivets, and anyone who has used one-leg plates knows that the rivet hole closest to the screw hole is hard to set because it is so close to the “nut.” FLyleds addresses this in their instructions, basically saying that only one rivet (the outer one) is required. But heck, there’s a rivet hole and I wanted it filled!

So out came a piece of 4130 rod, which got chucked up in the lathe. I cut down the stem (I make squeezer dies often enough I free-hand them, except for measuring the tail diameter), then I cut it off to the right length, turned it around so that the lathe chuck was gripping the tail, and (after flattening the end) cutting a steep taper so that it would fit in the narrow space. I made the flat setting face just a bit bigger in diameter than the shop head it would create, and it worked great to set that one rivet! I added the little friction clip, and added it to my collection of special squeezer dies. I bet this one sees service again in the future.