From 20 feet, it doesn’t look like much. No, that’s not how I mean it. Walk up to this forest green-and-white Glasair Aviation Sportsman and you could be forgiven for mentally ticking off items on the seen-it-before checklist. Metal high wing. Composite body shell. Tricycle gear with artful fairings. Let’s see: Antennas on the outside mean this is probably the carbon version of the Sportsman, which replaces vinylester resin-infused fiberglass with lighter, stiffer carbon fiber to reduce empty weight and increase stiffness. Look again at the wing. Hmm, that’s a thicker strut; for sure this is the high-gross-weight version of the Sportsman. OK, getting the idea.

From 20 feet, it doesn’t look like much. No, that’s not how I mean it. Walk up to this forest green-and-white Glasair Aviation Sportsman and you could be forgiven for mentally ticking off items on the seen-it-before checklist. Metal high wing. Composite body shell. Tricycle gear with artful fairings. Let’s see: Antennas on the outside mean this is probably the carbon version of the Sportsman, which replaces vinylester resin-infused fiberglass with lighter, stiffer carbon fiber to reduce empty weight and increase stiffness. Look again at the wing. Hmm, that’s a thicker strut; for sure this is the high-gross-weight version of the Sportsman. OK, getting the idea.

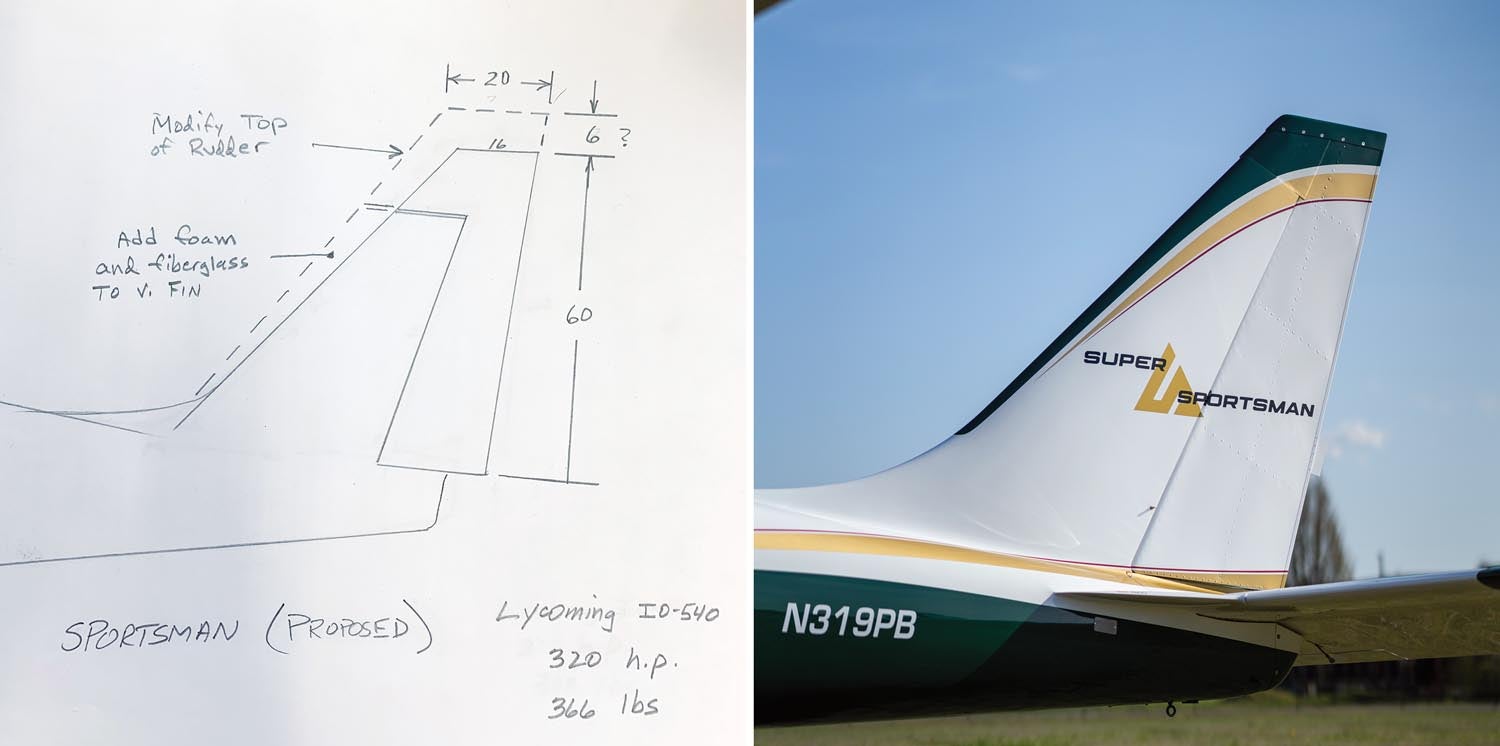

The sticker on the vertical tail says Super Sportsman but who’s to deny anyone a little hyperbole? Glance at the bottom of the cowling. Twin exhaust pipes. Interesting. Don’t most Sportsman aircraft (commonly fitted with the four-cylinder Lycoming IO-390 these days) have a single outlet, whether they’re trike or taildragger versions? Lift your gaze toward the nose. That is a very large three-blade Whirl Wind propeller, more like something you’d see on a Van’s RV-10 than a typical Sportsman. Your subconscious makes a faint noise, like the dog creeping up the stairs in the middle of the night. (It is the dog, isn’t it?)

Step a little closer and peer into the cowling inlets. Wait, what? A parallel-valve engine? Who would do that? Something still isn’t right. The rare Seattle-area sun reflects off the hangars and you can just see inside the cowling. One, two, three on a side. Excuse me? Six cylinders. What’s happening here?

Ted and Harry’s Power Adventure

Built by friends and work partners Ted Setzer and Harry DeLong along with Dr. Jose “Pepi” Borrero, the Super Sportsman is the result of a simple request for more power. Setzer is, of course, the name associated with Glasair from the very beginning along with Tom Hamilton. After they had fully developed the low-wing, composite two-place speedster from the humble (but still quick) original Glasair to the Reno-winning Glasair III, Hamilton and his staff were looking for a new design with an emphasis on utility and ease of construction. A high-mounted, constant-chord metal wing held in tight formation with a composite fuselage shell by a sturdy steel-tube cage made the GlaStar unique at the time.

The original, in 1994, was powered by a mere sprite of an engine, the 125-hp Continental IO-240. But homebuilders being what they are soon demanded (and got) more power. Most GlaStars were built with O-320s and O-360s. When the larger, longer, heavier Sportsman arrived in 2005, the 180-hp engine was the de facto standard but my own airplane, started in late 2005, carried the then-new IO-390. The airplane was comfortable with the new power—ostensibly 210 hp vs. 180—and tolerant of the extra weight—roughly 40 pounds more than the parallel-valve engine.

As you would expect, the 390-powered Sportsman picked up useful cruise performance, typically 140–145 knots true at altitude—though mine was a little faster, thanks Barrett Precision Engines!—plus greater takeoff and climb juice. It was such a happy marriage that the vast majority of Sportsman aircraft built since 2006 have the 390.

For some, that’s not enough. And yet, the 307 hp brought by the specialized IO-540 in the Super Sportsman wasn’t even the original goal. Ted Setzer picks up the story. “Harry and I were working with Dr. Borrero, who wanted a really powerful Sportsman. He’s a Glasair III builder with an impressive resume—two-time Sun ’n Fun winner for best low wing (1992) and best interior (1993). I have known Borrero for 35 years. He was talking about putting a turbine on the nose because he had also built a very fast turbine-powered Experimental,” Setzer recalls. “But we were concerned about putting that much horsepower into the Sportsman and what to do about the weight and balance.” Additional power is naturally destabilizing while additional “sail” area—from the necessarily longer cowling—ahead of the center of lift is also destabilizing. And just getting enough ground clearance for what had to be a large propeller was going to be a massive piece of work, especially since they felt a trike configuration would be the most desirable.

For some, that’s not enough. And yet, the 307 hp brought by the specialized IO-540 in the Super Sportsman wasn’t even the original goal. Ted Setzer picks up the story. “Harry and I were working with Dr. Borrero, who wanted a really powerful Sportsman. He’s a Glasair III builder with an impressive resume—two-time Sun ’n Fun winner for best low wing (1992) and best interior (1993). I have known Borrero for 35 years. He was talking about putting a turbine on the nose because he had also built a very fast turbine-powered Experimental,” Setzer recalls. “But we were concerned about putting that much horsepower into the Sportsman and what to do about the weight and balance.” Additional power is naturally destabilizing while additional “sail” area—from the necessarily longer cowling—ahead of the center of lift is also destabilizing. And just getting enough ground clearance for what had to be a large propeller was going to be a massive piece of work, especially since they felt a trike configuration would be the most desirable.

In the end, Setzer and DeLong took the “easier” path to more power by fitting the IO-540. Easy, in this case, being a wickedly relative term. Starting with a parallel-valve 540 like you’d find in the RV-10, Ted and Harry sent the engine to Ly-Con Aircraft Engines for a number of its specialty mods, including flow-matched heads, O-ring-sealed case halves and a number of Ly-Con’s other speed tricks. Surprisingly, it runs the stock 8.5:1 compression. But it’s also packing a fully digital SDS (Simple Digital System) electronic fuel injection and ignition setup. Naturally, to keep the SDS system working, the Super Sportsman has a redundant electrical system with two batteries as well as one 60-amp alternator and one 30-amp backup alternator.

In the Balance

Because Ted and Harry started with an engine some 60 pounds heavier than the usual Sportsman powerplant, engine location and weight reduction were paramount themes. First stop, then, is the engine mount, which is 2 inches shorter than normal. This moves the engine back toward the firewall—where things are, admittedly, getting a little crowded. Because the 540 is roughly 7 inches longer than the 390, the prop on the Super Sportsman ends up 5 inches farther forward. The reshaping and extension of the cowling is so artful that you’d have to park a Sportsman in the frame to really see the difference. In addition to being shorter, the new engine mount slightly increases the engine’s rightward cant by about 1°.

That firewall, however, isn’t what you think. Rather than stainless steel, it’s titanium. “I was looking for every place where we could save weight,” says Setzer. At half the weight, a feathery 2.5 pounds, it was worth the effort and cost. Also of assistance is the Whirl Wind prop, a 76-inch three-blade composite Series 330, which weighs a modest 55 pounds. One custom touch you might not notice is the 12-inch spinner. Whirl Wind produces spinners and backplates in 13- and 14-inch sizes but the Sportsman cowl wants a 12-incher. Solution? A custom carbon backing plate and modified carbon spinner.

Fuel Farm

Setzer and DeLong completed a couple of major changes to the Sportsman’s fuel system, which is normally comprised of two 15-gallon inboard tanks and two 10-gallon tanks near the tips. A 540 wants more than 50 gallons of fuel, so Ted applied a trick he’s been trying in custom Sportsman aircraft for years: a wet wing. Where the stock setup includes four welded-aluminum tanks slid into the wing, the Super Sportsman has the internal bays from the root rib out to the last rib before the strut crossover member, from main spar to aft spar, closed out and sealed with Pro-Seal. A similar approach is used near the wingtips for those tanks, which, as in the Sportsman, transfer fuel inboard through small cube-style pumps. Bottom line? The Super Sportsman’s wing carries 72 gallons of fuel.

But there’s more. Because the SDS fuel injection recirculates fuel past the pulse-style injectors and back to the fuselage, the Super Sportsman needed a place for the return fuel to go. One option is a duplex valve that manages fuel and return simultaneously but limits you to a left/right arrangement—no selection for both tanks. Instead, many builders opt for a specialized tank, which Ted calls a return and reserve tank. In the Super Sportsman, this 8-gallon vessel lives in the tail cone just behind the cabin. It receives fuel directly from both wing tanks simultaneously, sends the supply forward to a simple on/off valve in the center console, then to dual electric fuel pumps.

Those pumps move much more fuel than the engine consumes and that excess returns only to the aft-mounted tank. Fuel management is, therefore, easy—on or off. (Just remember to move fuel from the tips to the mains at some point.) Moreover, because there are low-fuel sensors in the lines coming out of the wing tanks, the return/reserve tank can act as a get-out-of-jail reserve, providing about 45 minutes at a low power setting. Counting the aft tank, the Super Sportsman carries 80 gallons of fuel. Even better, the reserve/return tank’s location helps move the empty CG aft.

Weighty Issues

There’s no fooling gravity—at least not for long. Despite Setzer and DeLong’s best efforts, the Super Sportsman checks in at 1540 pounds empty. A typical IO-390 Sportsman is closer to 1450. You can add a really nice, four-place interior, no skimping on paint, a strong avionics package and the more complicated fuel system to the penalty of the 60-pound-heavier engine.

Had it not been for a fanatical approach to weight savings elsewhere, this airplane would have been heavier still. The effort paid off. Right now, with a 2500-pound maximum weight, there’s plenty of room in the envelope. Take two 200-pound pilots and full fuel along with 80 pounds of cargo. Fill the seats with family—mom, dad, two kids—and there’s still room in the payload for 70 gallons of fuel, which provides greater endurance than most offspring will endure at a time.

What’s It Like?

Hopping into the Super Sportsman reveals not much out of the ordinary. You do notice the Advanced Flight Systems AF-5800 touchscreen EFIS on the left and might note the unusual on/off fuel selector. And the small electrical knob where the mixture control ought to be is a good giveaway that there are electrons in charge of the engine.

Thanks to the SDS injection and ignition, the engine starts immediately, hot or cold. In fact, it acts just like a car. During taxi, the Super Sportsman doesn’t feel particularly nose heavy and the run-up is straightforward except for the need to verify that both fuel pumps are working, both parallel ECUs are active (there’s one primary and one standby with automatic switching) and that the engine runs properly on either ignition system. The Whirl Wind prop is hydraulic so you cycle that during run-up. But there’s no mixture to fuss with; just check that the Mixture Adjust knob is at the 12 o’clock position. One more glance at the panel to make sure there are no battery or charging-system faults and you’re ready to go.

Much to his credit, Ted did not try to influence performance with an abnormally light fuel load for our test flight. We were carrying full inboard fuel (52 gallons in the wings) plus the ever-present 8 gallons in the reserve/return tank, so with the two of us and no other cargo the Super Sportsman weighed 2260 pounds on the ramp—240 pounds under max. I searched my memory banks for the difference in feeling in my own Sportsman between light and fully loaded takeoffs and came back with a notable but not drastic difference. So I was expecting a sporty takeoff.

I got one. On the audio recording, you can hear the engine spool up and then nothing more articulate on the commentary than a “woo hoo hoo. Yeah, baby.” Then a few seconds of laughing before I had the presence of mind to say, “That is ridiculous, Ted” and begin recounting instrument readings and more detailed observations.

What actually happened is the Super Sportsman came to life, the big Whirl Wind grabbed a bunch of air and we shot down the runway like a no-joke performance car. Normally you’d lighten the nose at 45 knots indicated (KIAS) and wait a beat for the 131 square feet of GA(W)-2 airfoil to get its act together and then enjoy a dignified but strong ascent into the sky.

Nope, not here. The big-engined Sportsman shot through rotation speed just as I was noticing the fact, I did a half-hearted rotation to climb and then it just stuck its nose into the air and did the deed. It took a moment for me to recalibrate my inputs to how quickly the airplane was accelerating and get the one notch of flaps (a common GlaStar/Sportsman takeoff tactic) stowed and then allow the airplane to continue accelerating. By the time it had reached 80 KIAS, the VSI was still showing more than 2000 fpm.

One important aspect of all this is that while stuff happened quickly on the takeoff and initial climb, I had no trouble tracking the runway centerline or maintaining control once airborne. Credit the extra 6 inches of rudder and fin. There was more than enough authority to keep the ball in the center with not much more concern than a lower-powered Sportsman, which itself is well behaved. I’ve flown a few light, high-powered airplanes that were far more demanding in this realm—they made their high power-to-weight ratios known in the early phases of flight. Not here.

Keeping Cool

It’s one thing to shoehorn a big engine onto the front of an airplane designed for a smaller one. Quite another making it happy there. During our initial climb, we started to see a couple of the CHTs rise, despite climbing at 100–110 KIAS and just 1800 fpm. Here’s where the SDS’s manual mixture skew comes in handy. Without reducing manifold pressure (but maintaining the 2500 prop rpm we’d chosen after climbing through 500 feet), a couple of the cylinders reached 410° F and were still climbing. But a quick tweak on the SDS mixture knob brought an extra 1.7 gph of fuel—the temps stopped climbing and eventually settled right around 405° for the rest of the climb to 9500 feet msl. This Sportsman was fitted with a fuel/air meter and we found it happy in the climb with an air-fuel ratio (AFR) around 12:1. Ted admitted that all the programming they’d done on the SDS had taken place in cooler weather, so perhaps they ended up on the lean side of ideal for warmer climates.

It’s worth noting here that the Super Sportsman is not the first GlaStar-class aircraft to have an O-540 on the nose. Cameron Fraiser was part of a group build in 2012 to put an O-540 on a GlaStar, which, when on straight floats, cruised at 100 knots true. He said that weight-and-balance weren’t their biggest issues; keeping the engine cool was. Thermodynamics don’t lie: Horsepower is heat.

Cruise After the Climb

Ted and I trucked our way up to 9500 feet at an average of 1200 fpm for a spot check on speed. Here’s where the Super Sportsman reveals the realities of aerodynamics, especially in a utility-biased airplane. Remember, too, that the Sportsman has the same wing as an airplane designed around a 125-hp engine and that the generously sized cabin and baggage area do it no favors in terms of wetted area.

At our first stop, with the SDS mixture control now back toward the zero point (biasing neither rich nor lean from the map), we saw 154 KTAS on 17.6 gph with an AFR of 12.1:1 with the throttle wide open and the prop set for 2500 rpm. Yeah, that’s really rich. No one would cruise at that setting. There’s a simple solution: Press the LOP button.

Doing so has the SDS computer quickly lean the mixture to a preset level determined during testing. In this case, fuel flow dropped to 13.6 gph and the AFR moved to 15:1. Run the math and that works out to about 65% power if you assume the engine, running lean of peak, is capable of a specific fuel consumption of around 0.42 pounds of fuel per horsepower.

Eventually, the Super Sportsman settled into a 151 KTAS showing with no other changes. We tried a few other prop settings with the expected slight decreases in speed and fuel flow. You may be wondering: If a 210-hp Sportsman can do 145 KTAS, why isn’t the Super Sportsman faster? It’s likely a few reasons, including airfoil selection—remember the airplane’s roots as a low-powered design—wetted area, wing angle of incidence and even prop selection. This Whirl Wind comes straight off the RV-10 bill of materials; it’s possible a prop optimized for the Super Sportsman might bring some speed.

Regardless, the engine was perfectly happy at its computer-commanded lean-of-peak setting. “[The SDS is] really a great system,” says Setzer. “You can adjust each cylinder individually to balance fuel flows.” As expected, CHTs came down to the mid-300s at LOP fuel settings and a slightly cooler-than-normal atmosphere at 9500 feet. And aside from a slightly nose-low attitude in cruise—compared to the regular Sportsman—the airframe seems perfectly content with this much power.

Coming Down

I was expecting the big-engine beast to show its fangs during the landing and, even more so, in an aggressive acceleration on the go part of the touch and go. Aside from feeling a tad heavier in pitch and a bit more trim stable than a regular Sportsman, itself a pretty conventional airplane, the Super Sportsman landed just like its brethren. On one departure, I purposely kept the nosewheel off the runway and was aggressive with the throttle. Just as the nose began to jink left, a modest amount of right rudder pulled it back in line and the airplane’s acceleration meant it was ready to fly almost immediately. I didn’t provoke it much further but considering I used maybe a third of the rudder travel (and pulled out of it fairly quickly), it’s clear the Super Sportsman won’t demand much more of a pilot than the 210-hp version.

Making One Yours

Perhaps you’re wondering where you can get your own Super Sportsman. Well, you probably can’t. Considering the extensive build time and the value of Ted’s and Harry’s expertise around Sportsman aircraft and building generally, the asking price of $389,900 for this airplane isn’t all that stratospheric. It’s well equipped, beautifully built and thoroughly considered—and far more finished-feeling than you would expect. It’s a testament to the margin in the basic airplane and the build team’s willingness (and ability) to construct a series of mods that added nearly 100 hp without making a dog’s breakfast of it.

Without throwing mud on the Super Sportsman, it’s fair to say the overall performance profile has some nice things to say about the basic, four-cylinder Sportsman. It doesn’t have the six-banger’s cackle-inducing runway performance but it’s a well-rounded machine whose kits are still in production from Glasair Aviation. Can the ultra-modded version still be a validation for the out-of-the-crate version? Seems to be the case.

For the Super Sportsman, the extra power would shine the brightest on floats. Seaplanes have different expectations for cruise velocity, plus strong acceleration and a perky initial climb mean a lot more when the lake is smooth but the atmosphere hot and sticky. Here, an overabundance of power is the starting point. Before you ask: Yes, all the hard points for floats are installed.

As a landplane, this Sportsman has such good climb its performance envelope would favor high-altitude use—maintaining a good true airspeed there and, more important, getting to altitude quickly enough to be worth the effort. (Nothing worse than scrabbling for altitude at 300 fpm.) In fact, Ted and I discussed this very point and he reminded me that during the development of the Glasair III, they considered doing a turbocharged four-cylinder to get better high-altitude performance from the II. After long discussions about heat and turbo complexity, they decided that they’d turbo it the old-fashioned way, with cubic inches—and the IO-540-powered Glasair III was born. History, sometimes, does repeat.

Photos: Jon Bliss and courtesy of Ted Setzer

Great story Marc … although I’m not sure I’m ready to fund the cost of converting my existing Sportsman for the word’s “Super…”. But it is tempting!