The only Sun ’n Fun I have missed since I have been working with Kitplanes has been the ones affected by COVID—but this year, a combination of things made it OK for me to stay home and let Marc Cook and the gang handle Florida without me. When I lived in Texas, it was hard not to try and attend with one of my own planes—but flying all the way from the west coast is a two-day trip (each way), and then I still might not make it into Florida due to weather in the pan-handle. So instead of hot and steamy, I stayed in the “winter of the century” here in the Sierra Nevada and enjoyed cold and snow. But that doesn’t mean that I didn’t commit acts relating to aviation.

The first and biggest reason I passed not going to the show was because we are finalizing paperwork and ground testing on the electric Xenos, getting the flight test plan in shape and flying the other airplanes when I can to get the skills back up for flight testing. That means doing lots of slow flight and stalls, plus shooting engine-out landings to make sure I have knocked the rust off from a winter that has seen us go weeks without opening the hangar doors. Now that the storms are leaving a day or two gap between them (although they are still coming), we’re getting up and burning Avgas and JetA so that I’ll be ready to simply let the electrons flow through the motor in the eXenos when we’re ready.

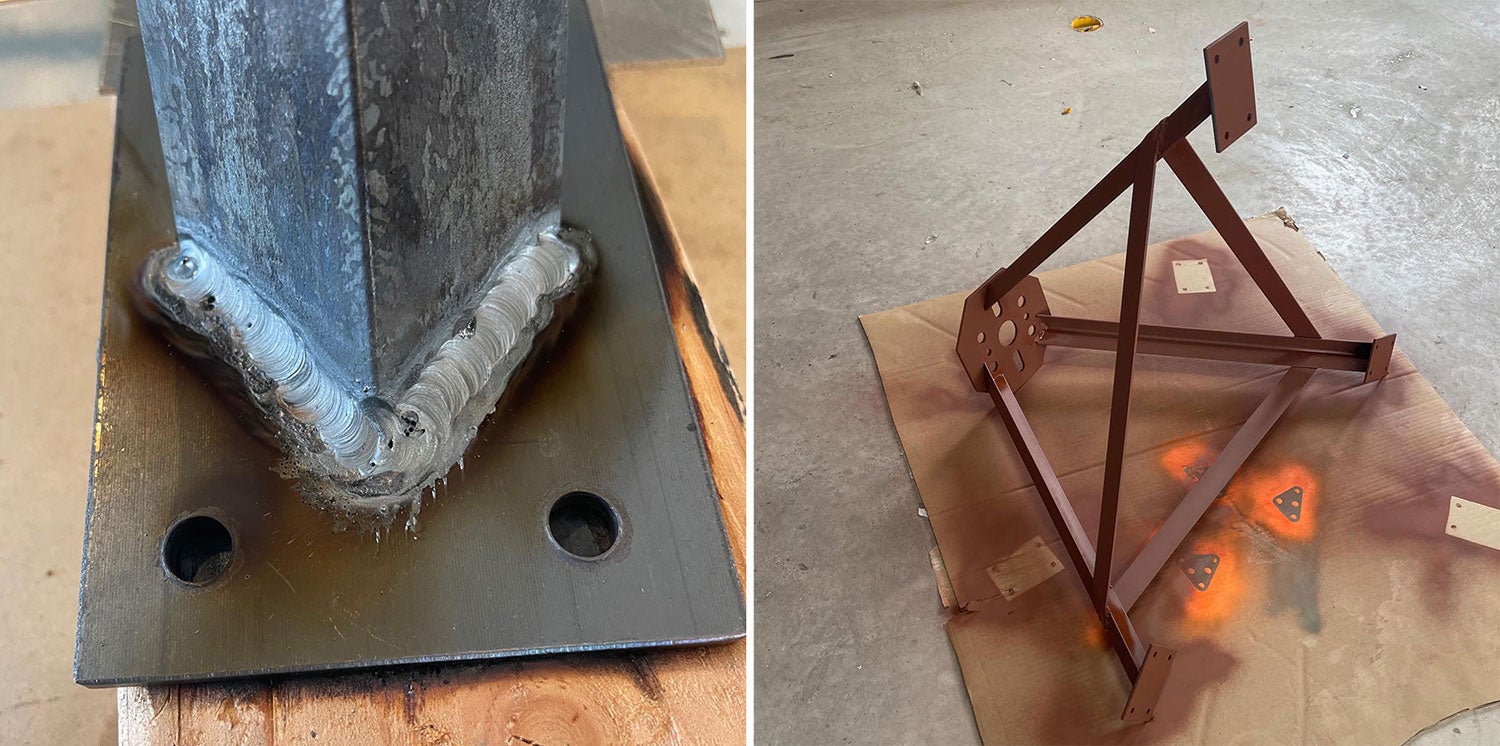

But flying isn’t the only thing keeping me busy—there is always something to do in the shop. I’ve been learning how to weld (a skill most guys learn in high school shop, but hey, I was taking math and physics, finishing a pilot’s license, and working on airplanes—one has to have priorities…), and felt that I’d stuck enough scrap together, so it was time to build something. I’ve borrowed a neighbor’s engine stand for past motor work so thought “hey, I can build one of those!” I actually started with a beautifully machined top plate from a machinist friend, and figured that all I needed to do was stick some legs on it. I used some pictures from the internet for design inspiration, and made up my own dimensions after discovering a nice piece of angle steel in my hangar corner that had been used for landing gear alignment.

Then of course, I changed my mind about welding to that gorgeous plate, so I crowned a piece of 1/4” steel (again—having a machinist friend is really handy!) and did some cutting and milling to make a plate to which the legs are welded—then the really nice plate is bolted on top of that!

Casters are really cheap on Amazon it turns out, and they come with mounting bolts—some steel flat sick from Ace Aviation Supply (and they think they are just a hardware store) completed the bill of materials, and the TIG torch got a workout. Some primer and pant, and voilà—proving once again that time in the shop is always useful. Not that fly-ins aren’t useful as well….but I’ll get my fill at AirVenture!

And with the welding project out of the way, its back to prepping for that eXenos flight… now where is that EAA Flight Test Manual again?

I have wanted to make a stand like this for a long time. How about some drawings of your build?

Well to be honest, I didn’t do any drawings – I looked at an add for one on the web to get ideas and a couple of key dimensions – its 24” tall (the welded structure is 20” and the casters add 4”). The angle of the legs turn out to be about 37 degrees from vertical. The top plate basically mirrors a standard prop flange. The horizontal braces were just cut to fit. My top plate was 1/4” thick, the legs are 1-1/2” angle steel, all three cut from a single 6” length (because of the angles on each end, the are roughly 22” each). The bottom plates that the casters mount to are 3” wide by 4” long, cut from 3/16” stock.

My Dad’s ultimate insult to my welds was: “Well, it appears to be stuck together.”. His were always so damned pretty.

Hi Paul:

Thanks for your dims!

Your welds look fine to me.

Regards,

James

Welding is a skill I am late to as well. Took a Welding and Casting class in college for engineering, and we did Stick, TIG, MIG, and Oxy, and it turns out I’m a natural. Plenty of uses for welding including car repair, building airplanes, and making useful things. So now I need to get myself a decent enough welder and get to work.

Practice makes perfect, as long as we don’t repeat our mistakes. Good looking stand Mr. Dye. Lakeland was good, just no rain to keep the dust and pollen at bay. Went to a HS mini reunion over in my old stomping grounds on Madeira Beach. Missed seeing you and Miss Louise. Already planning my trek north to OSH on 7/11….Blue Skies my friend

Jerry Fischer