AC-Aero USA LLC

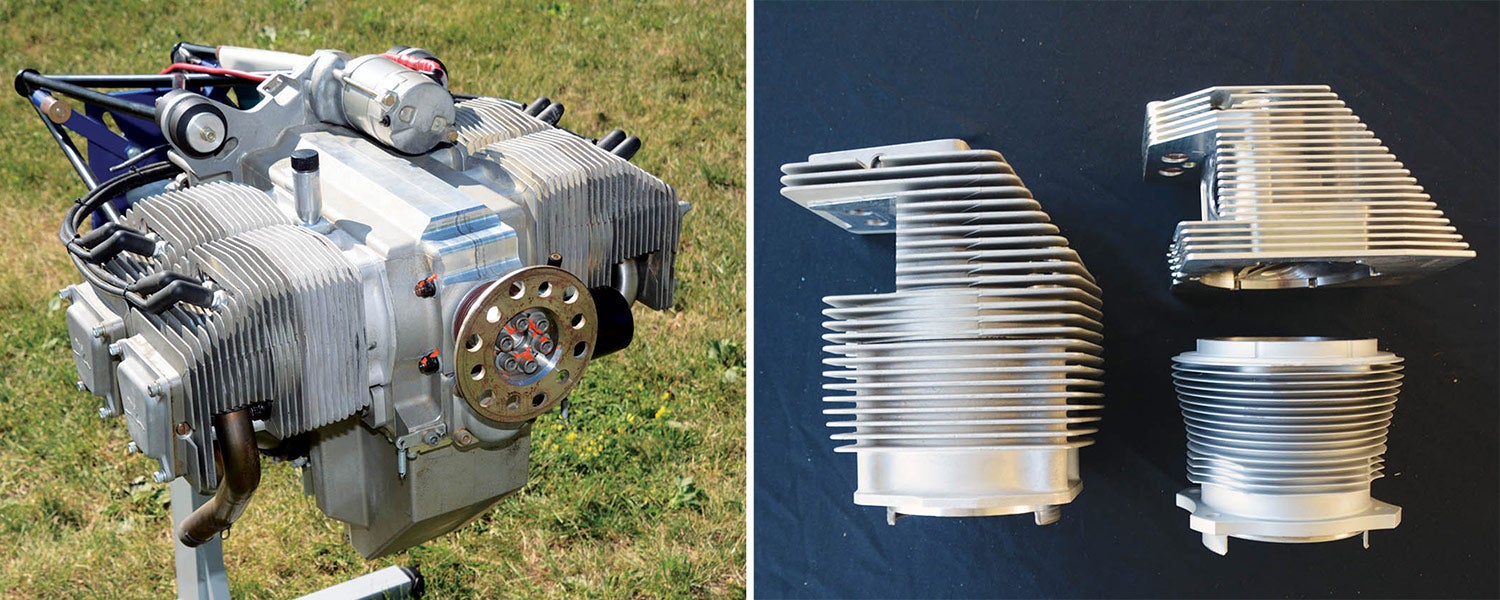

Longtime freelance engine designer Andy Higgs joined with businessman and Reno racer Karl Grove in 2021 to form AC-Aero. Their goal: Introduce new, non-certified engines with modern cylinder designs and increased displacements. Performance and efficiency were preeminent; affordability was well down the list, so the result was distinctly handsome but not inexpensive hardware.

Two very separate engine lines were developed. The first uses new AC-Aero water-cooled cylinders joined to Lycoming engine cases and a second, more radical, completely new HIGGS family of engines built around a unique combination of two- and four-stroke technologies, burning Jet A and organized into a wide variety of engine layouts. (These are discussed in the Circling the Airport section below.)

After COVID-driven delays getting cylinder sleeves in mid-2022, the AC-Aero liquid-cooled cylinders are in production with an approximate two- to three-month lead time before delivery. Multiple sets of these cylinders and complete engines built with these cylinders have been sold and Grove has raced his personal Lancair Legacy with such an engine at Reno. Well-funded early adopters willing to try something advanced and aware of the surprises and setbacks typical of new programs are a good fit for these cylinders/engines.

AC-Aero’s liquid-cooled cylinders are for four- and six-cylinder Lycoming architecture engines. They include the Legion stroker kits, which use a longer stroke crankshaft to gain engine displacement (409 inches for four-cylinders, 613 cubes for six-cylinders).

The liquid-cooled cylinders are identified as Gladiator (four-cylinder) and Centurion (six-cylinder). These are completely new cylinder bank designs, configured to run on standard Lycoming bottom ends. They turn a Lycoming into a liquid-cooled engine, in other words. Naturally, the AC-Aero cylinder design features a more modern combustion chamber along with a displacement increase. When the Legion stroker kit is combined with the liquid-cooled cylinders you end up with the Gladiator X440 four-cylinder and Centurion X660 six-cylinder engines. Yes, the numerals denote the resulting large displacement, which gives an idea of the power potential based on simple displacement alone.

Advantages to the new liquid-cooled cylinder banks are an advanced combustion chamber, tighter piston and piston ring tolerances for more power and less oil consumption, elimination of shock cooling, along with less weight compared to air cooling (yes, including the coolant, radiator and so on says Grove).

AC-Aero uses a service center approach for engine assembly and installation. The first of these, Aircraft Service and Parts (ASAP) in Bakersfield, California, assumed responsibility for all of AC-Aero USA LLC in the U.S. last year, allowing Karl Grove to concentrate on marketing while George and Jacob Sturges from ASAP take care of daily operations. Customers can fly in to ASAP for turnkey installations. The best advice is to communicate with AC-Aero or ASAP directly as an amazing number of combinations and possibilities are on offer, from starting with rebuildable Lycoming cores to all-new engines. Furthermore, Andy Higgs lives in Japan and uses Japanese foundries and machining so there can be a wait for the next batch of parts.

BRP Rotax

A division of Bombardier, Rotax builds engines for the greater BRP empire including all sorts of light recreational vehicles such as side-by-side utilities, boats, personal watercraft, snowmobiles, motorcycles and light aircraft. Therefore, Rotax is a larger engine maker than it might seem at first, with first-rate production facilities and engineering, likely the best in aviation. Rotax has been the largest volume engine maker in general aviation for quite a while and by a large margin. They are seriously involved in light aircraft engines and intend to maintain their number-one position. By late 2022 the Rotax four-stroke engine fleet had accumulated 85 million flight hours and counting.

In the United States Rotax is represented by Lockwood Aviation Supply in Sebring, Florida, and Motive.Aero, servicing the Western U.S. from their base in Hurricane, Utah. Former distributor California Power Systems (owned by Aircraft Spruce) is no longer a Rotax distributor and Aircraft Spruce is selling what remaining Rotax inventory they have.

There is one hardware change in the 2023 Rotax lineup: an optional 24-volt electrical system on the fuel-injected engines. This is handy for the newer, electronically intensive airframes gaining popularity today.

Not a hardware change is the Limited Edition option for the 912 iS (and later the 915 iS). The attraction here is an extended warranty reaching all the way to TBO or five years, along with snazzy red valve covers, a certificate and 100- and 200-hour service kits. Expect a price premium of approximately $2100. Perhaps the best Rotax news as we go to print is after big price increases in 2022 so far there is no such increase for 2023.

So, the familiar 912-, 914- and 915-series engines continue mechanically unchanged. These relatively lightweight and compact engines use air-cooled cylinders and liquid-cooled cylinder heads and are designed for higher rpm than big-bore Lycomings and Continentals. Therefore they all include a built-in spur gear propeller speed reduction unit (gearbox) to optimize propeller rpm. All are dry sump and use hydraulic valve lifters; carburetor or electronic fuel injection are offered depending on the model and some are turbocharged.

Still the bestselling Rotax is the carbureted 912 series, available in 80-hp form as the 912 UL or with 100 hp as the 912 ULS. The 80-hp is most popular in Europe; the 100-hp variant remains the number-one seller in the U.S. Part of their European heritage perhaps, but Rotax engines do best on unleaded mogas because the lead in 100LL eventually fouls plugs and accumulates as sludge in the gearbox.

Rotax offers two turbocharged engines, the carbureted 914 and their newest powerplant, the 915 iS, which is entering its fifth year of production. The latter is definitely spendy but offers the best power-to-weight ratio in its class, along with a meaty 141 takeoff and 135 continuous horsepower up to 15,000 feet for excellent mid-altitude performance. By comparison, the 115-hp 914 will save you about $7000 by retaining carburetion in lieu of fuel injection, plus the 914 has a TBO of 2000 hours compared to the 915’s 1200 hours.

Continental Aerospace Technologies

Continental offers a surprisingly large number of engines ranging from legacy units such as the O-200 to a stable full of Jet A-burning piston designs obtained from German/Austrian programs. For a time, the big-bore IO-550 (and its turbocharged TSIO-550 stablemate) were popular for various Lancairs, but they’re now too expensive to purchase directly from Continental as certified engines. Typically, then, the 550s are appropriated directly from salvage yards or built to suit by custom engine shops so we have not listed these popular engines in the specification charts.

But Continental is very much in the Experimental market, with products under the Titan name. When Continental’s parent company purchased Engine Components Inc., it got the intellectual property and manufacturing ability to craft Lycoming clone engines. Since then, it has further developed these engines under the Titan banner, thus replicating Lycoming’s parallel-valve engine architecture but with numerous upgrades. Titans are currently offered in 340 and 370 cubic inch displacements. Power ratings range from 174 to 195 hp. Originally Titan offered the stock 320 and 360 displacements of these engines, but to reduce the parts count during COVID, in 2022 Continental Aerospace Technologies decided to pause the stock-stroke 320 and 360 Titans to concentrate on the 340 and 370 strokers. (A 340 is a stroked 320, the 370 is a stroked 360.) Sadly, the Titan version of the six-cylinder 540 is also paused for the same reason.

The remaining Titans come stock with upgrades not available elsewhere. For example, Titan sumps/intake manifolds are a magnesium version of the traditional “hot sump” casting, saving a meaningful 7 pounds. Optional sumps are either Titan’s vertical or Superior Air Parts’ cold air intake with a forward-facing throttle body inlet. There is no forward-facing hot sump or rear-facing sump of any kind on Titan engines.

Titan engines also feature steel insert crankshaft thrust washers. The original Lycoming design takes thrust loads directly by the parent aluminum of the case, which can gall if run hard before fully wetted during break-in or under very hard loads or extreme time in service. Titan machines their cases to accept the steel thrust washers first seen in Continental 470/520 engines to essentially eliminate this issue.

All Titan engines are statically and dynamically balanced, plus use roller valve lifters. Titans allow front or rear propeller governors as the customer specifies, as well. Also stock is Continental’s nickel-carbide cylinder treatment (NiC3) for a definite upgrade in durability and ccorrosion resistance. (More on this in a minute.) NiC3 also allows a five-year warranty against cylinder barrel rusting on all Titan engines along with their normal two-year or TBO warranty on the rest of the engine assembly. Warranties begin when the engine is put in service, not to exceed one year after purchase. TBO is 2000 or 2400 hours.

Continental, under Chinese ownership for several years, has been benefiting from substantial capital investment. They’ve been slowly (sometimes excruciatingly so) updating their production plants (on either side of Mobile Bay in Alabama) from a decommissioned Air Force base dating from the 1960s to new buildings with the latest computer controlled machining centers. Some of that move was held up by COVID—the German technicians needed to set up the new machining centers couldn’t travel during COVID for example—but the upgrades are now coming faster. Another stumble was that Continental’s nickel cylinder process went down for a while in 2022, but was back online by July of that year. This meant cylinders were available only with a thru-hardened iron finish for a while, but the NiC3 finish is now again available. So despite any rumors, Continental never stopped building Titan engines and parts are available.

Edge Performance

Taking up where Rotax leaves off is Edge Performance with headquarters and engineering in Norway and dealers worldwide. The North American distributor is Jason Busat doing business as BadAss PowerSports in Lacombe, Alberta, Canada. The U.S. dealer is Michael Busenitz at STOL Creek Aviation in Whitewater, Kansas. Their niche market is hot STOL sport and competition aircraft.

Using factory-new Rotax components combined with Edge parts, customer engines are built by its dealers to Edge specification. The number of combinations possible, along with the increased performance and often reduced weight, is impressive. As expected, big-bore kits are especially good sellers.

Three Edge engines—one naturally aspirated and two turbocharged—deliver much of what the hot Rotax market is after. Of the two NA options—the EP915ECi and 916ECi—the EP915ECi is the simplest and least expensive. It’s essentially a 912 ULS Rotax fitted with a 1484cc big-bore cylinder kit and Edge fuel injection to deliver 120 hp while saving about 5 pounds. Busenitz says the fuel injection really transforms the engine, helping to noticeably smooth the idle, quieting the PSRU so it doesn’t sound so much like a box of rocks plus it gives faster throttle response and typically a one gallon per hour better fuel burn. As for the 916, it uses larger cylinders yielding 1621cc but requiring case and head machining, so it’s more expensive and mainly seen as a big-bore kit rather than a complete engine.

Imagine Rotax’s carbureted, turbocharged 914 engine but with fuel injection and you have Edge’s most popular engine, the EP914Ti. It’s rated at 125 hp and is built from a Rotax short block fitted with the low compression 80-hp cylinders from the 912 UL. It’s an easy engine for a dealer to assemble as all they really need to do is dress the Rotax long block with their turbocharger, exhaust and Edge’s EFI fuel injection. As a result STOL Creek can sell it for less than the 914 Rotax. Topping the Edge line so far has been the turbocharged 912STi, comparable to the Rotax 915, except it weighs 25 pounds less, has more boost and thus jumps to 154 hp all while retailing for about $1500 less.

Coming in 2023 is the Edge 917 Ti. Designed to fit where the 914 Rotax does, this should be a popular choice. The 917 Ti is built on the 915 using Edge Performance EFI and other upgrades. Busat says the new engine will save 15 to 20 pounds off the 914 and while the official power rating was not set at our press time Busat is expecting 160- and 180-hp versions. Pricing is expected to be around 40,000 euros.

Other Edge advantages are that their electronic fuel injection is tunable by the customer or via the internet by Edge to include injector trimming for extra-close EGTs. Edge’s intake manifold features equal length runners, plus they also offer their parts as conversion kits for existing Rotax owners wanting to warm up their engines.

Edge pricing is up $1000 per engine this year, but as always fluctuations in the exchange rate plus Rotax pricing adjustments mean these often change. For sure best to call and get a quote when you’re ready. There is an Edge warranty. To simplify, everything is covered for one year, then four additional years on the non-Rotax parts. TBO remains the same as stock Rotax other than the 912Sti, which is 1500 hours until Edge has more experience with it. For more on the Edge process, see Eric Stewart’s story on Page 46.

HKS

Two-stroke engines, once the staple of the burgeoning ultralight craze, have almost all faded from the scene. But the time-tested HKS 700E two-cylinder remains available worldwide through Quicksilver Aircraft Northeast. Rated at 60 hp for 3 minutes and 58 hp continuously, it’s built by one of Japan’s pioneering tuning houses and can be found both on ultralights and very light sport aircraft. Buyers can choose between two gear ratios in the integral spur-gear propeller reduction box and expect a 1000-hour TBO. Definitely bucking the trend again this year, HKS pricing is unchanged (but shipping costs are up). The basic engine is $11,800, rising to $13,656 when fully dressed with its dry-sump oil tank, oil cooler and throttle cable.

Jabiru

Light weight, simplicity, affordability and snappy power-to-weight are Jabiru defining characteristics. On sale for many years—the company was founded in 1988—the Australian engine has also gone through rounds of development, now in its fourth generation.

The Jabiru’s turning point was the serious redesign of its fourth-generation cylinder heads to improve cooling. With overheating worries banished, the fourth-gen Jabiru has continued unmodified into 2023. Construction is heavy on aluminum through the crankcase and cylinders—silicon carbide and nickel coated—for low weight and rapid heat transfer. Jabiru has the parts mainly constructed by specialist machine shops in South East Queensland and South Australia, then assembles them in their own in-house facility before shipping U.S.-bound units to Arion Aircraft in Shelbyville, Tennessee.

Demand is good, says Arion, and with the long supply chain this means over a half year’s wait. Pricing remains stable, with perhaps a $100 increase since you last looked, and Arion supports the engine with a builder-assist program and a major overhaul program in-house.

Two engines are offered, a four-cylinder 2200 rated at 80 hp and a six-cylinder 3300 rated at 120 hp. Both are popular but the 3300 outsells the 2200 around 10:1 according to Arion. The 132-pound 2200 is found in the smaller Zenith and Sonex airframes, RV-12 and Titan Tornado, the bigger 3300 typically being seen in the Arion, larger Zenith, RANS and Van’s models.

Both are simple engines. A single Bing slide-type carburetor, mechanical fuel pump and inductive ignitions are used, along with fixed-timing ignition distributors. Both the alternator and inductive ignition are integral to the engine and both should be working as long as the engine is rotating.

Arion notes that attention to detail when installing a Jabiru is important. Engine cooling and tuning should be done in short, 10-minute flights. Adjusting the baffling and changing carburetor jets are the two main tasks to getting the Jabiru happy; when done correctly expect a 1000-hour TBO for the top end of the engine.

Lycoming

When talking about traditional big-bore general aviation engines Lycoming rules the roost. This is especially true in Experimentals as they’re generally the go-to four-cylinder choice on weight, pricing and overhaul cost advantages, plus they’ve cornered the all-important RV market.

Lycoming also has their own in-house custom Thunderbolt shop where two-person teams assemble customer-specified Experimental engines from all-new Lycoming and third-party parts. It is a rather popular source for enthusiast engines for both performance and aesthetic reasons. There are no technical changes to Lycoming or Thunderbolt engines for 2023. Recent changes have been a complete elimination of magnetos in favor of electronic ignitions on the four-cylinder offerings. The six cylinders will do the same shortly.

As for supply chain issues, Lycoming was especially caught up in trying to manufacture enough of their extremely popular 360/540 parallel-valve cylinders in 2022 and the situation continues. This will likely take another year to sort out as will the current backlog in the Thunderbolt shop, which has an order book with 300 engines in it. For now, figure on a year to get a new Lycoming engine (we’ve heard both shorter and longer terms, so we’re averaging it to a year).

Otherwise Lycoming reports the 390 angle-valve stroker “is selling like hotcakes” as the market looks to muscle up the four-cylinder platform for all it’s worth. The latest IO-390-C variant is rated for 215 hp, up 5 from the original Experimental-class 390. Of course, the 540 six-banger and its derivatives are selling well, too, but to the many fewer airframes needing that much power. So, from grocery getter to competition aerobatic thrust, Lycoming has the market covered starting with their 118-hp YO-235 cooking motor and ending with a 315-hp injected YIO-580 angle-valve derivative of the 540.

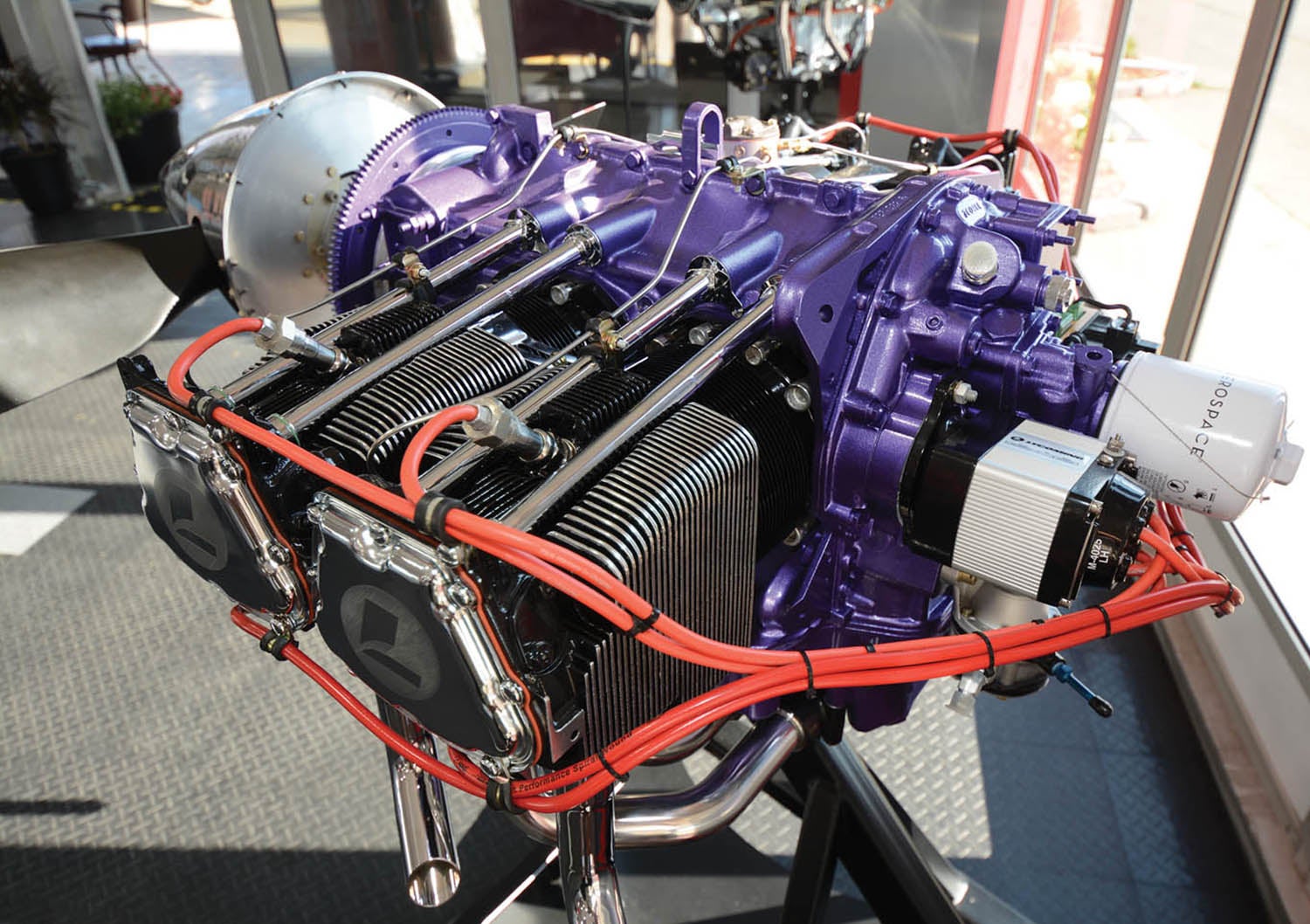

The Thunderbolt brand is literally its own special space within the Lycoming factory in Williamsport, Pennsylvania. Certified engines travel down Lycoming’s regular production line while in the Thunderbolt shop small teams build engines for the Experimental market. The idea is to offer a premium engine, along with an extensive line of custom touches for increased power or appearances. Therefore, Thunderbolt engines carry a price bump over stock but include balancing to tighter tolerances, cylinder head porting for easier breathing, your choice of Airflow Performance or Avstar constant-flow mechanical fuel injection, Lycoming’s EIS electronic ignition, dynamometer break-in and a fair number of paint color choices.

From there the options are nearly limitless, including many more colors, chrome detailing, high compression pistons and so on. The most common option in Thunderbolt engines is compression bumped to 10:1, with the caveat that 100LL fuel is then required (no mogas). As for the engines offered, Lycoming lists their familiar 235, 320, 360, 390, 540 and 580 cubic inch designs in their Thunderbolt lineup. That’s every Lycoming save the eight-cylinder 720.

And as we note every year, to put things in perspective Lycoming holds one major trump card in the time-tested nature of their powerplants. There are so many Lycs flying the company estimates the Lycoming brand accrues 1 million fleet hours monthly.

MWfly

MWfly engines are organized under two general headings, the blue painted SKYline for cruising and the red painted REDline for performance. The physical differences between them are few and more typically found in the computer software for more rpm and power.

These engines are thoroughly modern, horizontally opposed, liquid-cooled, single overhead cam, electronically fuel-injected designs with dual ECUs as standard equipment. Engine rpm natively tends to the 4000 to 4500 rpm range and a PSRU gearbox is a common fitment.

In the last year MWfly redesigned the cylinder head (and valve covers) for reduced weight and increased efficiency. Labeled Spirit to differentiate them from their earlier selves, the new designs have re

alized a 10% increase in fuel efficiency. A Production Organization approval has also been obtained from EASA, the first step toward certification in Europe.

In the works this year is a possible turbo-normalization option, but more immediate is a hydraulic constant-speed propeller using Sensenich blades. It fits the 122, 135, 140 and 160 geared Spirit engines.

Of course, MWfly is hardly a household name with American airport bums, but the naming of Nic Dawson as their North American distributor last year has helped. He’s in Wentzville, Missouri, as MWfly U.S. LLC. Also, MWfly has been shipping engines since 2013 (about 300 to date), with approximately 100 examples flying in Europe, plus the company continues showing vitality.

Dawson reports firewall forward kits are available for most Zenith 650/750s plus a couple of Sonex models and the Just Aircraft Highlander. Typical with European engines, he prefers to keep general pricing information in euros until it’s time to provide a custom quote as the exchange rate fluctuates. A good illustration is that MWfly raised their prices approximately 10% recently, but the strong dollar has pretty much erased the increase to U.S. buyers.

He notes the MWfly engines typically end up running between $23,000 and $27,000, depending on the model, with accessories around $3500 for a total cost of $30,000 or a bit more. Also, the 135- and 160-hp direct-drive engines garner much attention but are high-rpm units for helicopter use only and can’t be used in fixed-wing applications.

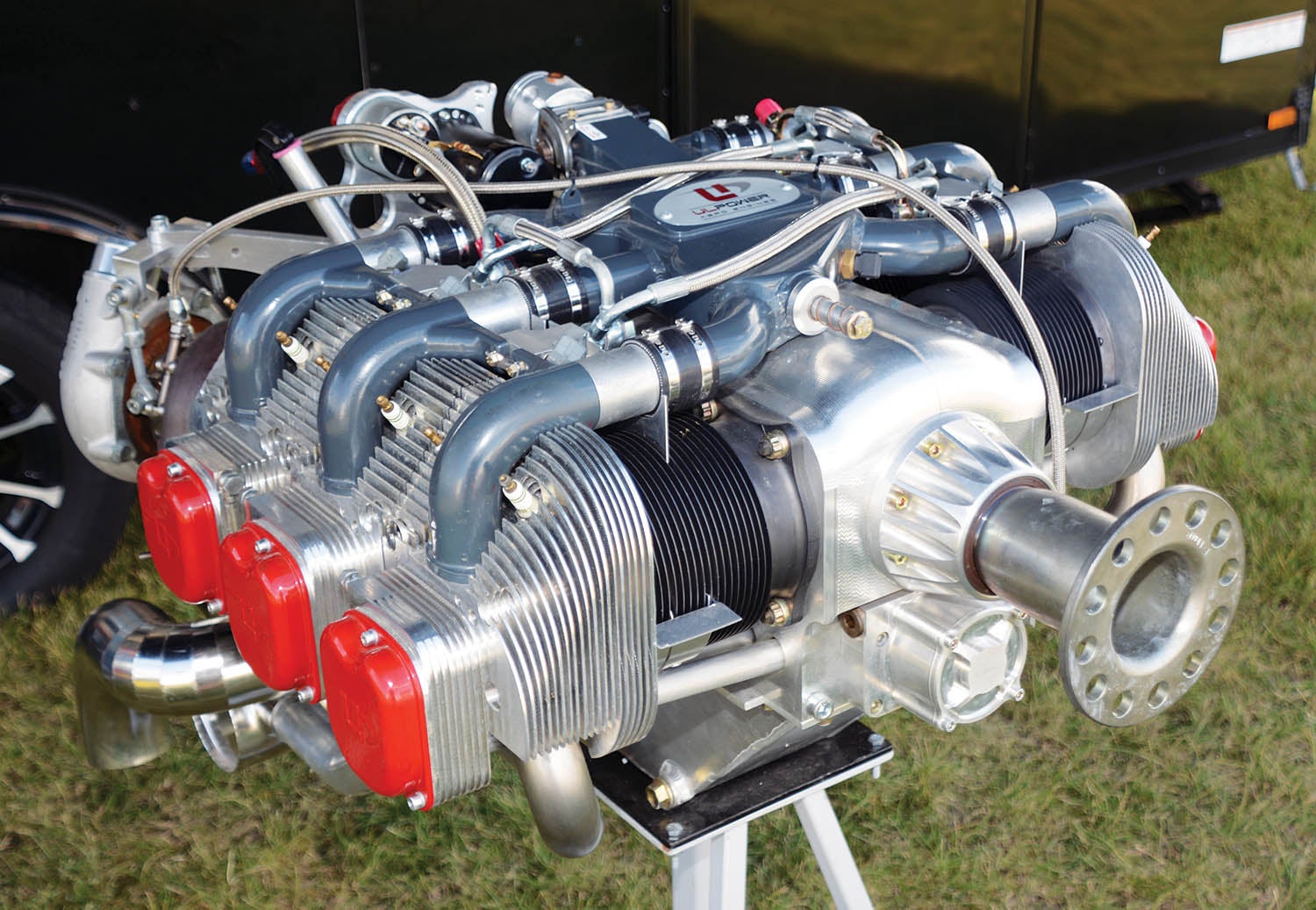

ULPower

ULPower continues its strong entry into the sport aviation mainstream. Their line of mechanically conservative but electronically contemporary engines is wholly their own design and is seeing sales grow from their initial light aircraft entry point to such popular platforms as the RV series. For 2023, ULPower is focusing on delivering 16 different engines, but their not-so-secret news is they have a second turbocharged offering coming in 2024 based on their 350i platform. They’re also working on 87 octane versions of some engines for fuel-limited areas of the world.

A consortium of several Belgian industrial firms make up ULPower. Their engine line is built around one air-cooled cylinder design and either a standard or long stroke crankshaft. Arranging the number of cylinders and strokes, along with aerobatic oiling mods and a helicopter variant, has yielded 16 engines arranged in four basic engine families. This gives a surprisingly wide range of displacement and power options ranging from 97 to 220 hp.

The 520T turbo 220-hp six-cylinder introduced in 2021 continues to headline UL’s offerings. No wonder as it muscles out 220 hp up to 15,000 feet. The prototype turbo engine was flying in an RV-4 in 2021 and has since gained an electrically adjustable four-blade Airmaster propeller to fully capitalize on the power available at altitude. ASTM certification has also been obtained for this engine, making it available for use on European certified airframes.

A relatively new company by aviation standards—the first ULPower engine was built in 2002 and the company legally formed in 2006—it does beg the question of how many fleet hours have been logged. The best information available comes from Turkish drones, which use these engines. They’ve run “many thousands of hours” without incident, but they also employ an aggressive 500-hour overhaul schedule. We don’t have a definite number of ULPower engines flying in the U.S. But judging from ULPower’s Facebook page and anecdotal reports, the engines are well established and interest is growing in the RV ranks. In any case, ULPower lists a TBO of 12 years or 1500 hours.

A measure of the RV interest is that the U.S. distributor, Robert Helms, had his firewall forward specialist develop a Lycoming Dynafocal adapter mount. This is a tube weldment sandwiched between the ULPower engine’s Jabiru-based engine mounting plate and a standard RV-6 engine mount; it adds the necessary four inches or so required to balance the lighter Belgian engine under the stock RV cowl.

To offer a general description of the ULPower engines: They’re an interesting combination of traditional horizontally opposed, single camshaft, pushrod activated overhead valve, air-cooled, direct-drive layout and electronic engine management as all are electronically fuel injected and sparked. Thus, there is no mechanical fuel pump. A single computer is stock, but dual ECUs are optional with CAN bus interfacing to Garmin, GRT and now Dynon. Dual electronic ignition is standard and a steady supply of electrons is mandatory as demand is 21 amps running and 50 amps of charging. These engines also run more cleanly on 93 octane unleaded gasoline, but many owners run 100LL due to availability.

ULPower is doing well regarding supply chain issues. The core engine parts are made in-house by the Belgium companies and the engine accessories are automotive or motorcycle parts produced in immense numbers. As always, like other European makers ULPower pricing is dependent on the euro-to-dollar exchange rate, so watching the market—favorable to dollars these days—and planning well ahead is good advice here. Prices did rise recently by approximately $2000 per engine, an amount that would have been higher except for the unusually strong dollar.

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

| AC-Aero USA LLC | ||||

| LEGION 409 | direct | 228 hp | 290 lb w/o fuel system, starter, ign. | $62,350 |

| LEGION 440 | direct | 250 hp | 325 lb w/o fuel system, starter, ign. | $73,850 |

| LEGION 613 | direct | 342 hp | 400 lb w/o fuel system, starter, ign. | $91,350 |

| LEGION 660 | direct | 375 hp | 440 lb w/o fuel system, starter, ign. | $101,650 |

| GLADIATOR 344 | direct | 200 hp | TBD | $101,650 |

| GLADIATOR 390 | direct | 220 hp | TBD | $59,850 |

| CENTURION 583 | direct | 350 hp | TBD | $86,850 |

| GLADIATOR RS-440 | direct | customer specific | customer specific | $100,000+ |

| CENTURION RS-660 | direct | customer specific | customer specific | $150,000+ |

| BRP Rotax | ||||

| 912 UL | geared | 80 hp @ 5800 rpm, carbureted | 130 lb w/ exhaust, internal alternator | $17,258 |

| 912 ULS | geared | 100 hp @ 5800 rpm, carbureted | 137 lb w/ exhaust, internal alternator | $20,585 |

| 912 iS | geared | 100 hp @ 5800 rpm, EFI | 155 lb w/ exhaust, internal alternator | $23,754 |

| 914 UL | geared | 115 hp @ 5800 rpm, carbureted, turbo | 155 lb w/ exhaust, internal alternator | $33,737 |

| 915 iS | geared | 141 hp @ 5800 rpm, EFI, turbo, intercooled | 185 lb bare, approx 245 lb installed | $40,353 |

| Continental Aerospace Technologies | Note: All prices subject to change based on specific final configurations. | |||

| OX-340-BDJ2T8H | direct | 174 hp, carbureted, light fixed-pitch crank | 253 lb, w/ P-mags, fuel system, starter, mag sump | $36,000 |

| OX-340-BDJ3T8H | direct | 180 hp, carbureted, light fixed-pitch crank | 253 lb, w/ P-mags, fuel system, starter, mag sump | $36,000 |

| OX-340-JDD3T8H | direct | 180 hp, carbureted, solid-flange crank | 257 lb, w/ P-mags, fuel system, starter, mag sump | $36,000 |

| OX-340-JDE2T8H | direct | 174 hp, carbureted, solid-flange crank | 257 lb, w/ P-mags, fuel system, starter, mag sump | $36,000 |

| IOX-340-BDD3T8H | direct | 180 hp, injected, light fixed-pitch crank | 261 lb, w/ P-mags, fuel system, starter, mag sump | $41,500 |

| IOX-340-JDD3T8H | direct | 180 hp, injected, solid-flange crank | 273 lb, w/ P-mags, fuel system, starter, mag sump | $41,000 |

| IOX-340-JDE3T8H | direct | 180 hp, injected, solid-flange crank | 250 lb, w/ Lightspeed, fuel system, starter, mag sump | $40,942 |

| OX-370-ADD7T8H | direct | 187 hp, carbureted, constant speed | 265 lb, w/ P-mags, fuel system, starter, mag sump | $37,500 |

| OX-370-JDD7T8H | direct | 187 hp, carbureted, fixed-pitch | 260 lb, w/ P-mags, fuel system, starter, mag sump | $37,000 |

| IOX-370-CDB1T8C | direct | 195 hp, injected, CS, counterweighted | 287 lb, w/ mags, fuel system, starter, cold air sump | $43,500 |

| IOX-370-CDB1T8H | direct | 195 hp, injected, CS, counterweighted | 268 lb, w/ mags, fuel system, starter, mag sump | $42,000 |

| IOX-370-CDD1T8C | direct | 195 hp, injected, CS, counterweighted | 284 lb, w/ P-mags, fuel system, starter, cold air sump | $45,000 |

| IOX-370-CDD1T8H | direct | 195 hp, injected, CS, counterweighted | 268 lb, w/ P-mags, fuel system, starter, mag sump | $43,500 |

| IOX-370-CLD1T8C | direct | 195 hp, injected, CS, counterweighted, front gov | 287 lb, w/ P-mags, fuel system, starter, cold air sump | $45,500 |

| IOX-370-CLD1T8H | direct | 195 hp, injected, CS, counterweighted, front gov | 273 lb, w/ P-mags, fuel system, starter, mag sump | $45,000 |

| IOX-370-RDD1T8H | direct | 195 hp, injected, fixed-pitch, counterweighted | 275 lb, w/ P-mags, fuel system, starter, mag sump | $44,000 |

| Edge Performance | ||||

| EP915ECi | geared | 120 hp @ 5800 rpm | 125 lb | € 28.00 |

| EP914Ti | geared | 126 hp @ 5800 rpm | 150 lb | € 28.50 |

| EP912STi | geared | 154 hp @ 5800 rpm | 150 lb | € 33.50 |

| HKS Co. Ltd and www.quicksilverne.com | ||||

| 700E Twin | geared | 60 hp @ 6200 rpm (3 min), 56 hp @ 5800 rpm continuous | 121 lb w/ carburetors, fuel pump, dual CDI | $13,656 w/ exhaust, oil tank/cooler |

| Jabiru AU and www.flylightning.net | ||||

| Generation 4 2200 (4-cyl) | direct | 85 hp @ 3300 rpm | 136 lb w/ exhaust, carb, starter, alternator, ignition | $17,900 |

| Generation 4 3300 (6-cyl) | direct | 120 hp @ 3300 rpm | 184 lb w/ exhaust, carb, starter, alternator, ignition | $20,900 |

| Lycoming | NOTE: (S) for standard Lycoming configuration (T) for Thunderbolt version | |||

| YO-235-EXP | direct | 118 hp @ 2800 rpm, carburetor, parallel valve | 250 lb w/ mags, fuel system, starter | $31,300 (S) $33,300 (T) |

| YO-320-D1A | direct | 160 hp @ 2700 rpm, carburetor, parallel valve | 255 lb w/ mags, fuel system, starter, CS | $40,000 (S) $45,000 (T) |

| YIO-320-DIA | direct | 160 hp @ 2700 rpm, injected, parallel valve | 270 lb w/ mags, fuel system, starter | $43,000 (S) $48,000 (T) |

| YO-360-A1A | direct | 180 hp @ 2700 rpm, carburetor, parallel valve | 285 lb w/ mags, fuel system, starter | $40,000 (S) $45,000 (T) |

| YO-360-A4M | direct | 180 hp @ 2700 rpm, carburetor, parallel valve | 285 lb w/ mags, fuel system, starter | $40,000 (S) $45,000 (T) |

| YIO-360-M1B | direct | 180 hp @ 2700 rpm, injected, parallel valve | 290 lb w/ mags, fuel system, starter | $43,000 (S) $48,000 (T) |

| YIO-360-A1B6 | direct | 200 hp @ 2700 rpm, injected, angle valve | 325 lb w/ mags, fuel system, starter | $51,500 (S) $56,500 (T) |

| YIO-390-A3B6 | direct | 210 hp @ 2700 rpm, injected, angle valve | 315 lb w/ mags, fuel system, starter | $52,500 (S) $57,500 (T) |

| YIO-390-EXP119 | direct | 215 hp @ 2700 rpm, injected, angle valve | 315 lb w/ mags, fuel system, starter | $55,500 (S) $60,500 (T) |

| YIO-540-D4A5 | direct | 260 hp @ 2700 rpm, injected, parallel valve | 400 lb w/ mags, fuel system, starter | $67,700 (S) $72,700 (T) |

| YIO-540-EXP 9:1, 10:1 cold air induction | direct | 285–300 hp @ 2700 rpm, injected,parallel valve | 400 lb w/ mags, fuel system, starter | NA Varies |

| YIO-580-B1A | direct | 315 hp @ 2700 rpm, injected, angle valve | 440 lb w/ mags, fuel system, starter | $80,100 (S) $85,100 (T) |

| MWfly | ||||

| Spirit 100 Direct Drive | direct | 100 hp @ 3400 rpm | 178 lb dry, no accessories | € 17,600 |

| Spirit 115 Direct Drive | direct | 115 hp @ 3400 rpm | 178 lb dry, no accessories | € 19,800 |

| Spirit 122 Geared PSRU | geared | 122 hp @ 4200 rpm | 190 lb dry, no accessories | € 20,900 |

| Spirit 135 Geared PSRU | geared | 135 hp @ 4700 rpm | 178 lb dry, no accessories | € 23,100 |

| Spirit 135 Direct Drive (helicopter only) | direct | 135 hp @ 4700 rpm | 190 lb dry, no accessories | € 24,200 |

| Spirit 140 Geared PSRU | geared | 140 hp @ 4200 rpm | 190 lb dry, no accessories | € 26,400 |

| Spirit 160 Geared PSRU | geared | 160 hp @ 4700 rpm | 190 lb dry, no accessories | € 29,700 |

| Spirit 160 Direct Drive (helicopter only) | direct | 160 hp @ 4700 rpm | 178 lb dry, no accessories | € 28,600 |

| ULPower | ||||

| UL260i 4-cyl | direct | 97 hp @ 3300 rpm / 82 hp @ 2800 rpm | 159 lb w/ accessories, oil and exhaust | $22,000 |

| UL260is 4-cyl | direct | 107 hp @ 3300 rpm | 159 lb w/ accessories, oil and exhaust | $23,000 |

| UL350i 4-cyl | direct | 118 hp @ 3300 rpm | 173 lb w/ accessories, oil and exhaust | $25,000 |

| UL350iS 4-cyl | direct | 130 hp @ 3300 rpm | 173 lb w/ accessories, oil and exhaust | $26,000 |

| UL390i 6-cyl | direct | 140 hp @ 3200 rpm / 130 hp @ 2800 rpm | 220 lb w/ accessories, oil and exhaust | $31,000 |

| UL390iS 6-cyl | direct | 160 hp @ 3200 rpm / 140 hp @ 2800 rpm | 220 lb w/ accessories, oil and exhaust | $32,000 |

| UL520i 6-cyl | direct | 180 hp @ 3200 rpm / 169 hp @ 2800 rpm | 238 lb w/ accessories, oil and exhaust | $33,500 |

| UL520iS 6-cyl | direct | 200 hp @ 3200 rpm / 182 hp @ 2800 rpm | 238 lb w/ accessories, oil and exhaust | $34,500 |

| UL520T 6-cyl | direct | 220 hp @ 3700 rpm | 280 lb w/ accessories, oil and exhaust | $43,500 |