Just in this last few months (from June 2022), there has been a true revolution in the state of the art for power LEDs. Heretofore, we had been pushing silicon derivatives and “gallium XX arsenide” devices to their limits. We now have new limits that we get to push to the limits in future experiments.

Let me take you back a bit in history. Fellow by the name of Round in the Fermi labs in England in the late 1900s found that passing this new-fangled electric current through a lab sample of silicon carbide (what we use today as a carborundum grinding compound) would make the silicon carbide glow. Reversing the power supply leads would not make the carborundum glow. He noted this in a notebook and tossed it onto a dusty bench.

In 1927, a young Russian experimenter named Losev noted the same effect, only he pursued the phenomenon. The only results from his experiments are scraps and bits from his notebooks from a particularly nasty period in Russian history called the Bolshevik and Russian Revolutions.

Then along came Craford in 1972, Holonyak in 1982 and Nakamura in 1993, who took silicon, gallium, arsenic and their derivatives, which gave us early red, then green, yellow and orange, and then blue and white LEDs.

A few months ago, engineers went back to our roots and found that by going back to silicon carbide (refined a few dozen times), they could make brilliant colored and white lights with very low current levels. This development was more than enough for us to start making aircraft lights using fewer individual lamps and a lot less current (thus a lot less heat) than we had ever imagined.

Enough of the theories; let’s get right to the heart of the matter. For almost everything electrical on an airplane, we require it to run on a particular voltage (Allesandro Volta, Italy). Batteries, generators, alternators, motors, incandescent lamps, transceivers, transponders, receivers, intercoms and other avionics are all run from a specific voltage, mostly a “12-volt” system, which is actually between 12.5 and 14 volts in an operating aircraft. Voltage is measured from one point to another point. A battery, for example, is measured from its minus (-) terminal to its plus (+) terminal.

The ampere (Henri Ampere, France), on the other hand, has a specific measurement. It is exactly 6.2 x 1018 electrons passing by one point in a conductor per second (that’s 6.2 billion billion electrons). Not even Congress has started tossing spending numbers around like this.

The ohm is a derived number. Good old Georg Simon Ohm (University of Munich, 1832) figured out that a device that passed current when attached across a voltage would be calculated in ohms.

Now the basic secret of this new array of light-emitting devices is about to be revealed. While most aircraft electric devices (see above) are designed to be run on specific voltages, light-emitting diodes (LEDs) are designed to be run on specific currents. The difference between an LED running on milliamperes of current and amperes of current is generally less than 0.1 volts across the LED. If you try to run an LED from a voltage source and it varies 1% or 2%, you have the difference between the LED emitting almost invisible amounts of light at low current to one that emits very bright light at high current for a millisecond or so and gives up most of its expensive electronic smoke as dead.

The problem resolves itself, then, to providing our aviation LEDs with a current from a voltage source.

One solution is pretty trivial. A relatively constant voltage (say, 12.5 to 14 volts from an aircraft supply) to an LED that would like to run on about 50 milliamps (50 mA, or 50 x 10-3) amperes can be done with a simple resistor if it doesn’t matter too much exactly how bright the light is, just so it is illuminated. The data sheet for the LED says that it will be at about 3.3 volts at 50 mA.

Let’s split the difference. The median between 12.5 and 14 volts is 13.3 volts (surprise, surprise). Our little LED would like 50 mA. The LED voltage is 3.3 volts, so the voltage across the resistor will be (13.3 – 3.3) 10 volts. Therefore, to light this LED properly, we should use a resistor of (10 volts / 50 ma) or 200 ohms.

Unfortunately, resistors don’t come in every value. We have the choice of 180 or 220 ohms. Pick a choice. One will be a little brighter and one will be a little dimmer. You will never notice the difference. You also will probably not notice the difference between full alternator output of 14 volts and engine-off 12 volts. The eye has a remarkable capability of adjusting and integrating various light levels to a common level.

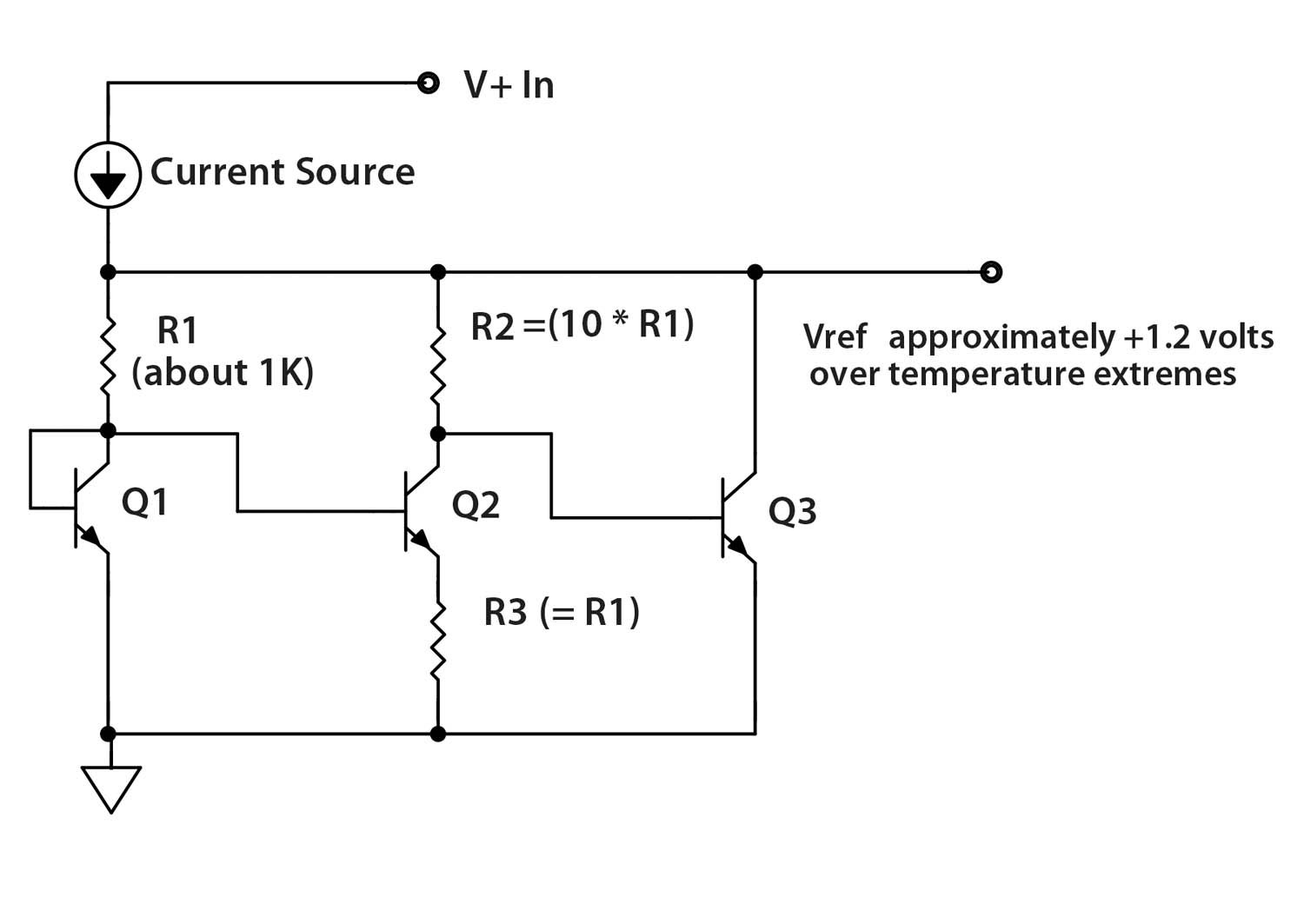

One last comment and I’ll shuffle this discussion off until next month’s discussion. In 1971, a particularly brilliant engineer named Bob Widlar,* who worked for National Semiconductor, developed a circuit that produced a reference voltage from a transistor configuration that relied on a balance between two ordinary transistors to produce a reference voltage that was independent of transistor specifications and (more important) ambient temperature from -40° F to 212° F (freezing point of alcohol to boiling point of water). Every voltage regulator since has used Widlar’s design, and it’s been used to produce hundreds of variations of voltage regulators.

We have a very recent development that converts a voltage regulator into a current regulator to drive our current-hog LEDs with one cheap electrical component. Details next month.

Also be with us next month as we transition to voltage-fed LED landing lights, navigation lights and other LEDs that you can feed with cheap voltage regulators and a single penny resistor.

Until then…stay tuned…

*Bob Widlar was a one-of-a-kind creative electronic genius.

- A particular local Santa Clara business peeved him. He brought in a group of goats that ate every bush and all the grass around their building.

- When he worked for National Semiconductor, the morning PA bulletins drove him nuts, so he brought in 12-penny nails and pinned the PA speaker with them.

- In 1967 (the year I graduated from San Diego State), Bob wrote scathing letters to several of the electronics magazines of the day detailing the reasons that a high-power voltage regulator would be impossible to design. A month after half a dozen magazines published his letters and articles, he announced the design of the regulator he said was “impossible” to build.

- After he retired to do private work, one company asked him to do a design. He backed his Mercedes and Lamborghini out of his garage and said, “I’ll do your design. Fill the garage with single malt Scotch.” And they did.

- Bob passed away of a heart attack at the ripe old age of 53 in Puerto Vallarta, Mexico. Some sources say it was after a couple of days of too much “Mexican lemonade.” Other sources dispute this.

Jim, I don’t know about the next generation of led, but Carclo Optics claims to have a 292×61 mm lens that is supposed to focus 1,200,000 lumins with a certain array of LEDs. I can’t imagine the amount of light that is or the power required. But I think it would be an interesting project.

Why not just put the LEDs in series instead of using electronics to give the voltage desired?

There is a cumulative voltage drop with each one in series as they are D.C.; eventually there would be no forward current and go from Dim to nothing.

I am not sure what kind of alcohol you enjoy (I am interested though) but I don’t think the freezing point of alcohol is -40°F.

You’re right the freezing point of 100% ethanol is -175f. For a freezing point of minus 40° f, the percentage of alcohol is around 65%, or 130 proof. Those figures are for alcohol mixed with water. Other ingredients like sugar and flavorings may modify the freezing point.

I found the information on a website called binwise, so I’m assuming the values are approximate.

Bacardi 151 (proof) slightly diluted could be frozen around minus 40 f.