Back in 2008, George W. Bush was president and 100LL was $2.50 a gallon. Production of 80/87 had stopped the previous year, and this snot-nosed writer had been tweaking the FAA’s buttons for some 15 years.

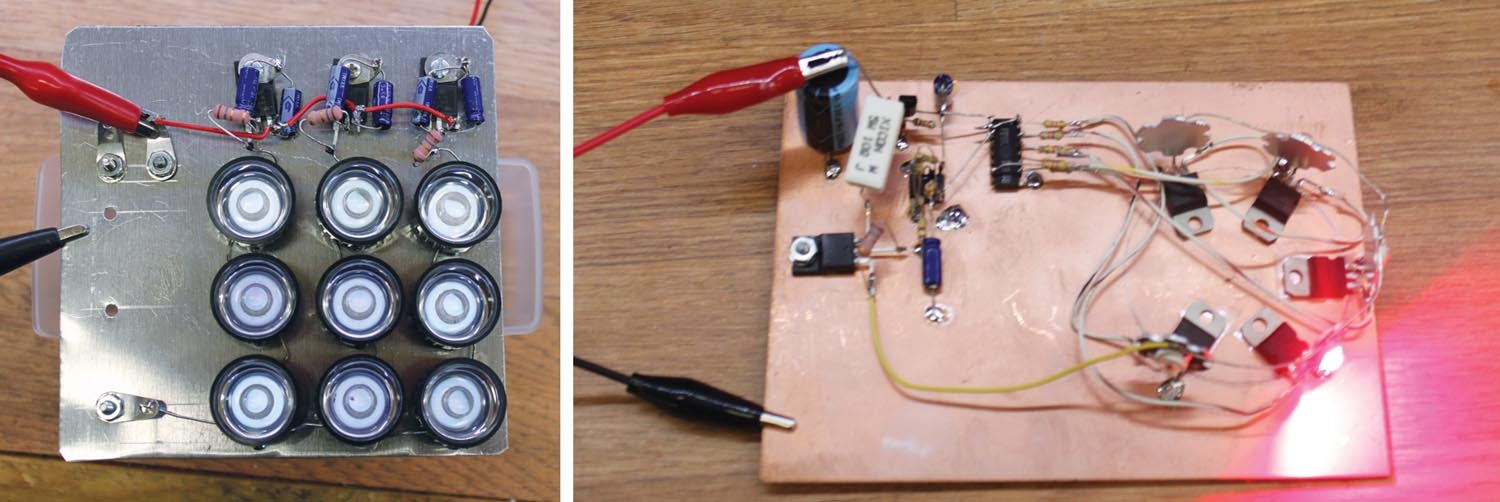

My earliest venture into lighting heresy was a three-month column in KITPLANES® (August, September, October 2008) on how to use these newfangled LED light sources for aircraft…specifically for landing, navigation and anti-collision lighting.

The LEDs I used for those articles were crude. We were still in the gallium arsenide era of LED technology. Gallium technology is fine, but you must remember that both gallium and arsenic are fairly “soft” elements that can’t take much heat. In addition, it took a lot of power to get decent light out of them, and a lot of that power was wasted as heat to get that light.

Now, I remand you to 1908 when researchers in the Curie labs noted that passing an electric current through a lump of carbide made the carbide glow (dimly). The effect was written in a notebook and put on a dusty shelf.

Enter 2020. Some researcher noted that carbide (yes, the very hard stuff we put on carbide grinding wheels and that was in the Curie labs in 1908) and silicon (beach sand, the very hard stuff we use for sandpaper) could be combined in a molecule. Passing an electric current through it not only made it glow, it made a brilliant light much more brilliant (watt for watt) than gallium arsenide.

A month or two later, we made the discovery that by changing the ratio of carbide to silicon, and by introducing some other elements, we could make very bright light of almost any color we wished, with minimal wasted electrical current as heat.

I brought these breaking new devices to you in my June 2022 column as landing lights and in my September 2022 column as a rotating beacon.

I now want to update those two columns, plus the three 2008 navigation light columns, with the latest developments. It will be a full house on how to light your aircraft from spinner to tail cone with state-of-the-art LED lights.

Not only that, I also want to talk about the possibility of remaking the September 2022 column as a replacement for the requirement for an aft-facing anti-collision/nav light.

Let me preface my comments by saying that the FAA has not substantially changed the requirements for navigation (position) lights for some 50 years. They still have to be red on the left (port) wing, green on the right (starboard) wing and white aft. The aft white light can be either on the vertical fin, the rudder or on both wingtips. What has happened is that we had incandescent lamps 50 years ago; LEDs were still laboratory curiosities. Current LEDs not only equal the old incandescent lamps for brightness, they far surpass them at a tenth of the amount of power needed.

(Just as aside, I reviewed all those 50-year-old documents from the FAA. For the most part, they are dog-eared pages with indecipherable scribbled comments in the margins. The “official” .gov regulations have half the right side of the page chopped off, so you can’t get the real numbers if you wanted them.)

Fasten your seat belts, inflate your G suit, and here we go. Obviously, we can do far better than what I told you in 2008; I can even do better than what I told you a couple of months ago.

In all development, there comes a time when experimental products become commodities. The Wright brothers’ 12-horse engine gave way to the Curtiss 25-horse engine and then the Curtiss classic OX-5 90-horse engine. We were then in commodity off-to-the-races time. Bigger and more powerful, cheaper and cheaper—that’s the progress of product development.

I believe I’ve told you in prior columns that when I was doing my antenna research work for NASA back in the late ’60s, I was paying $15 (2022 equivalent) for a uA709 integrated circuit. Ten years later, that same IC upgraded (LM324) was twice as fast, twice the bandwidth and $2. Today the same exact part is two bits (25 cents) from a dozen sources.

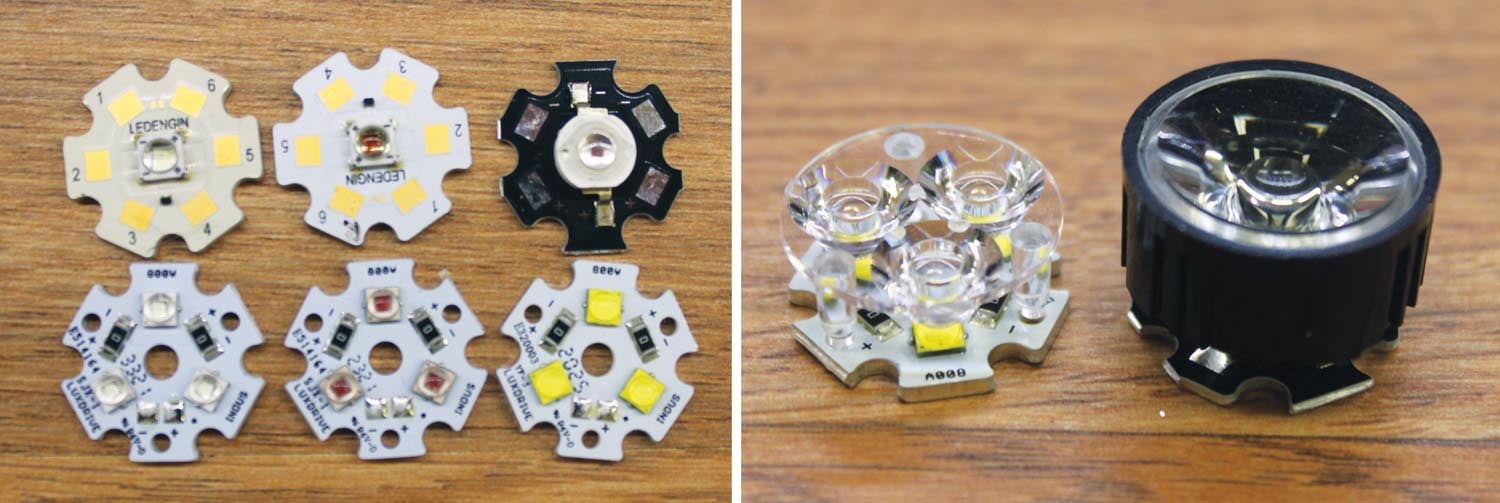

What happened to these LEDs from 2008 and 2022 was that I was intrigued by what was state-of-the-art and available at the time. I then did a deep dive into what is currently on the market and found that I could get three times the light and half of the heat loss plus focusing lenses for peanuts that would give me light beamwidths of wide, medium and narrow—for less than the same price as the ones I used back this summer.

For those of you who want to get a head start on the project, I urge you to do a web search on Cree XP-E2, both the cool white and red/green varieties in the three-up version(s). Maybe, just maybe, we can light up your homebuilt for about 10% of what you would pay for a commercial device.

Next month should be interesting. It is going to be a blow-by-blow interchange with a VariEze owner who had a strange interference problem with his com radios. We’ll cover how we solved it, what we did to solve it, how a particular manufacturer stood up and said that it was their problem and what they did about it to keep their customer happy.

Stay tuned…