We don’t normally think of hydropower as a path to Experimental aviation, but in Neil Wischer’s case, it was definitely the enabler. Starting with his grandparents’ and parents’ spinner-over-tail group for model airplanes, the youthful Neil found he was “the worst RC pilot ever” and ended up in the Navy where he got into the steam side of nuclear propulsion.

We don’t normally think of hydropower as a path to Experimental aviation, but in Neil Wischer’s case, it was definitely the enabler. Starting with his grandparents’ and parents’ spinner-over-tail group for model airplanes, the youthful Neil found he was “the worst RC pilot ever” and ended up in the Navy where he got into the steam side of nuclear propulsion.

Post-Navy this lead to nuclear power ashore, but when that turned too regulatory, he found it an easy move to operating hydroelectric plants. Today he’s at the dials at the Grand Coulee dam located on the Columbia River in Washington state.

If piloting model aircraft didn’t work out for Neil, the real thing did. Growing up in Wisconsin, Neil was taken to AirVenture every year where his family indulged in their RC activities and Neil naturally absorbed everything aviation. Or as he put it, “I just wanted to see the jets!” He took a couple of lessons as a teen but didn’t get his license before Navy life took over. Once his six-year enlistment was up and Neil was working nuke plants ashore, again in Wisconsin, his many aviation friends pretty quickly had him thinking airplanes once more and so he built a Sonex.

Saying he “just wanted a fun flier, a flatlands airplane,” Neil had his Sonex together in only a year, so his family’s aircraft building genes did eventually come through. He found the Sonex a fun, entertaining flyer, but deciding to move west to the Grand Coulee employment, Neil found himself looking for a more backwoods- and mountain-capable airplane.

Along the way a friend introduced him to the RV-7, “which was the cat’s meow,” but a GlaStar kit looked good, too, and ultimately he bought a partially built Murphy Yukon that still needed much work. Luckily Neil works a week on and a week off, so he is able to put solid blocks of time into his builds and he had the Murphy flying in 1000 hours of shop time. Neil also heavily credits being able to build at home. “This is key! Build at home!” he exhorts.

Already demonstrating an appreciation for adequate thrust, Neil figured the Yukon was less capable than its cousin, the Murphy Super Rebel, “so I put a 540 in it.” Neil still has the Yukon and flies it to AirVenture every other year, alternating with his RV-8.

While building the Yukon Neil found, like many others, that although he wasn’t building an RV he was using the Van’s Air Force forum for general information. This naturally kept him in the RV orbit and, voilà, in March 2015 he bought his RV-8 slow-build kit from a fellow who had lost interest. Neil had it flying the following July; he is nothing if not focused.

To be fair, the wings were finished when he bought the kit, but some of the control surfaces and the fuselage had not been touched. This suited Neil as he says, “The fuselage is fun, the wings are boring. Just rib, rib, rib.” Furthermore, Neil got the airplane painted and flying before finalizing the fairings; it’s clear that when Neil gets an idea he gets to building.

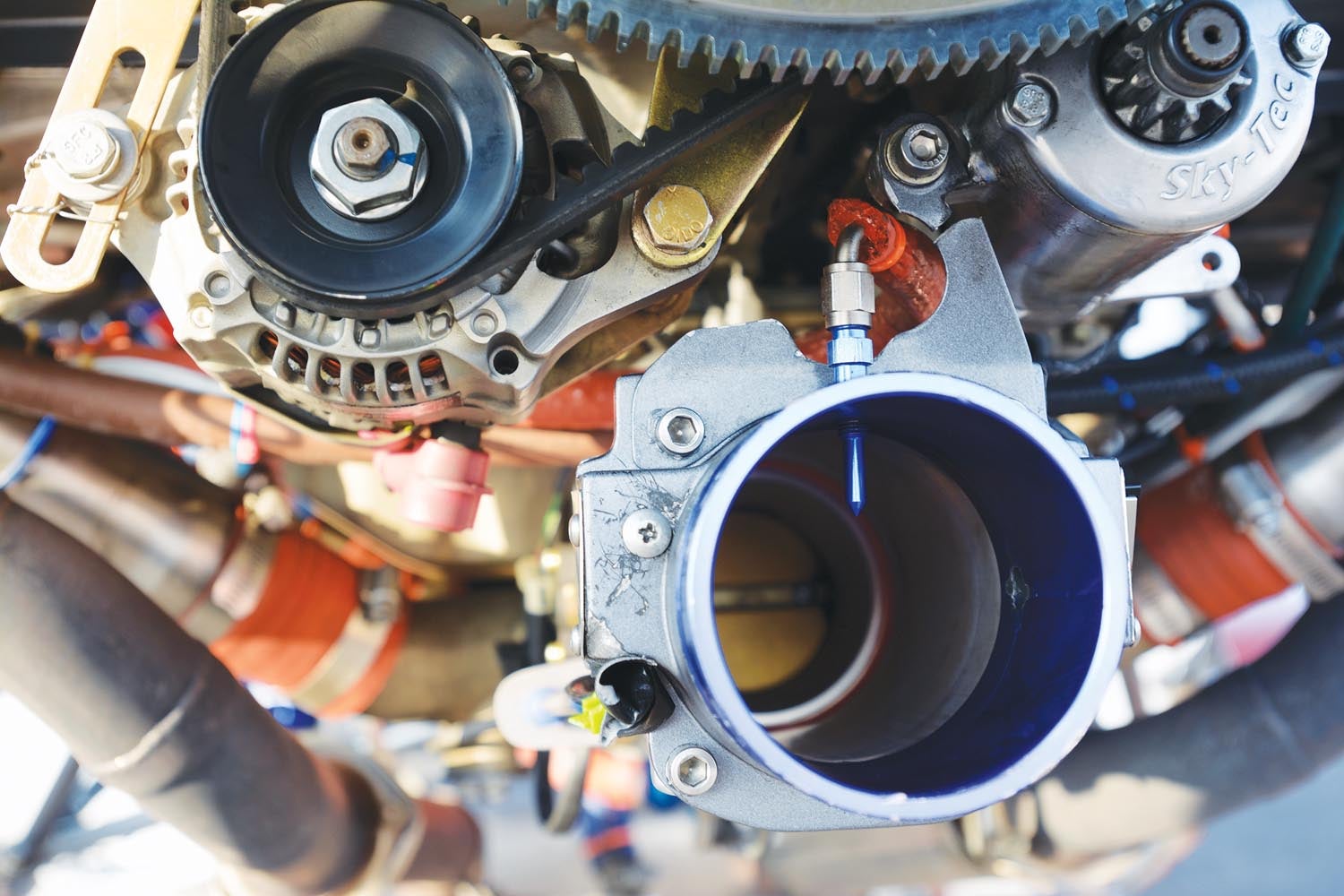

Toward the end of assembly, Neil “kinda thought of racing it.” He built a custom air box using a center-hinged butterfly valve that was selectable between filtered and ram air and used it while racing the first two years. Today he simply swaps his air box for a pure ram air inlet for racing and saves the air box for daily driver duty. The ram air does help, especially at race speeds; according to his EFIS he’s gaining more than 2 inches of manifold pressure around the pylons with his straight-in inlet.

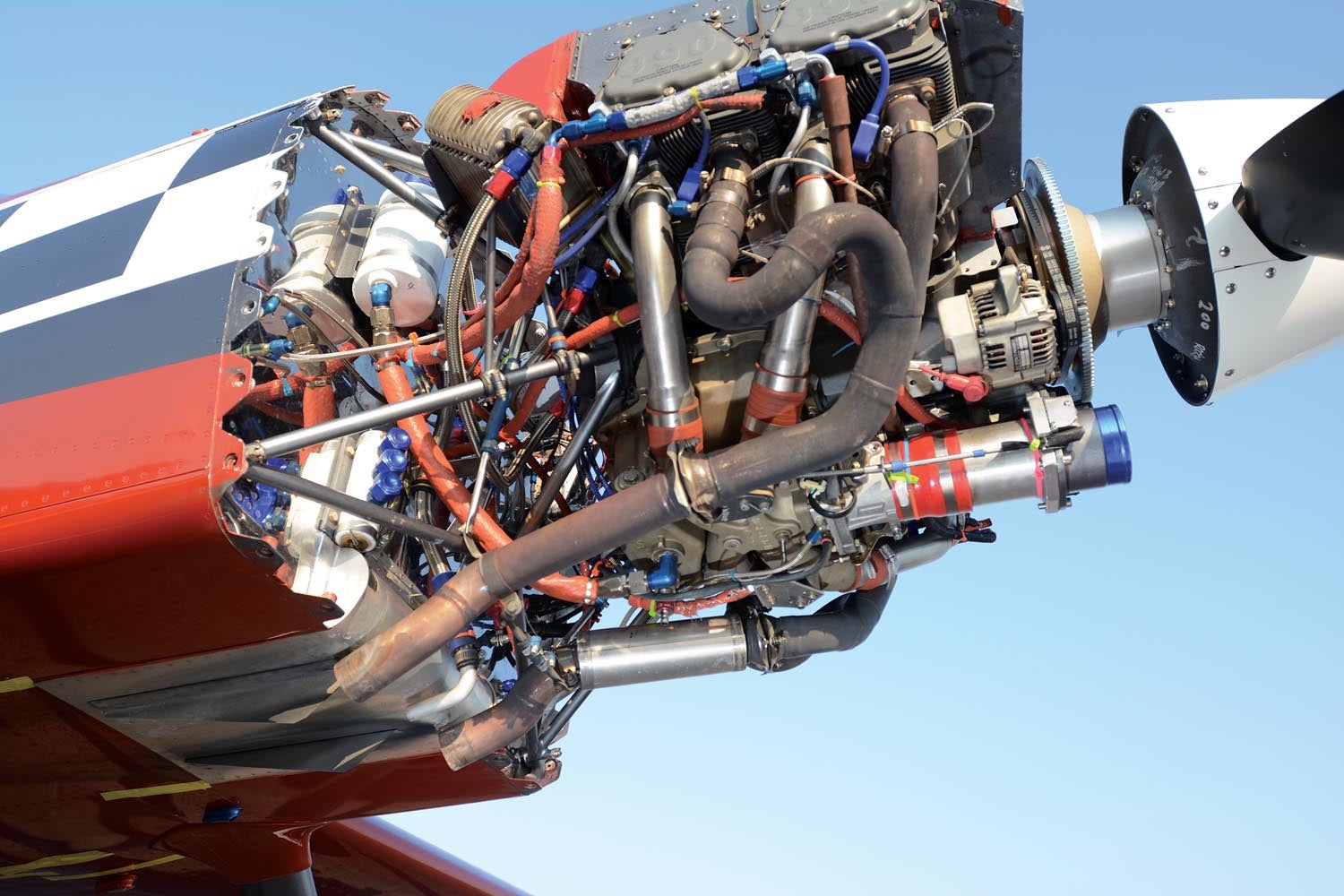

Engine

Now that we’re under the cowling, Neil has a somewhat interesting situation more akin to serious automotive racers rather than the casual RV owner gone pylon racing two weeks a year: He has a spare engine. Or at least did.

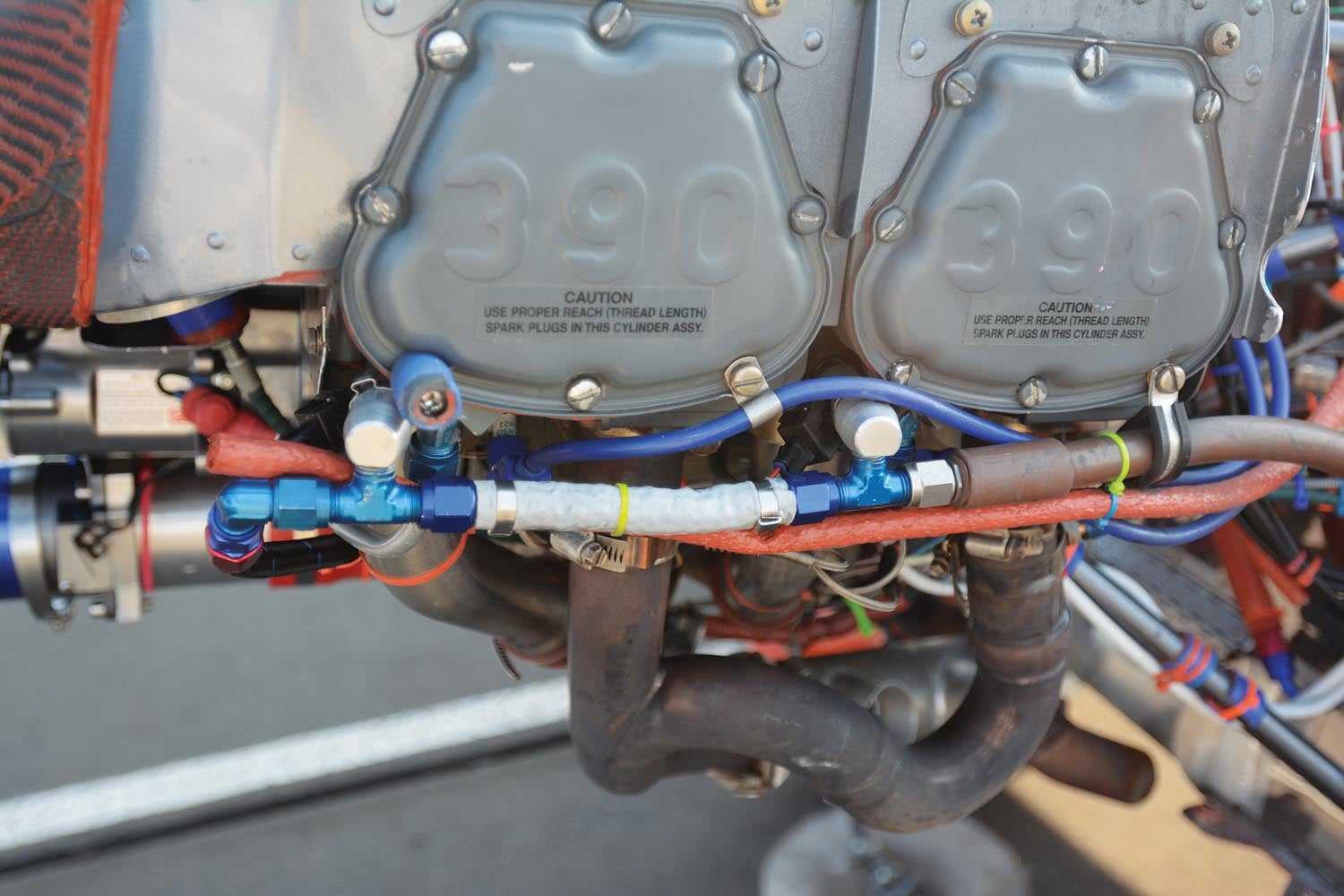

His RV-8 started with a 400 Superior, but those got recalled as you’ll recall. But he did race it his first two years, “and it had nitrous on it so it’s a wonder it didn’t break.” Well, Neil wasn’t spraying the 400 all that hard. He meant to replace it with a 390 Thunderbolt from Lycoming, but when the hot 10:1 Lyc took longer than three months to show up (we think Neil is occasionally impatient), he procured a stock Cirrus SR20 motor. That is, another 390 Lycoming. When the Thunderbolt showed up it became the spare, but more recently has become part of an overachieving RV-7 build Neil has on the side.

The Cirrus engine currently in the RV-8 has never been opened, but Neil did install dual EFII electronic ignitions. It’s a reasonably low-compression unit at 8.9:1 and it has performed flawlessly. If you look closely, you’ll see the -8 is equipped with a Christen inverted oil system, but the three-way valve is capped off as “I don’t like negative G’s anyhow. I don’t miss having inverted oil.” Which is good because the Cirrus engine isn’t machined at the vacuum pad where the inverted system would have its upside-down pickup. Also, the Cirrus intake manifold has a large air inlet in the sump (typically the choke point in standard-architecture Lycomings), but Neil runs the Superior cold air intake with its slightly smaller inlet passage for packaging reasons, so he rates his engine at 210 hp in naturally aspirated form.

Nitrous

Back in 2017 Neil’s concept for nitrous was simply trying to get back to sea-level horsepower to offset Reno’s 5000-foot elevation. “Really, this is pretty easy to do,” he notes. A relatively small amount of nitrous is required, so the more esoteric aspects of nitrous are avoided and this is what Neil ran his first two years at Reno.

In the beginning his Superior 400 engine was equipped with a Bendix-style, Precision-brand mechanical fuel injection. That fuel system has plenty of authority at the rich end such that Neil didn’t even bother adding supplemental fuel when spraying nitrous. Granted, he was only using 30 to 40 horsepower worth of squeeze (nitrous has more nicknames than a room full of gangsters), so not much supplemental fuel was needed anyway. The arrangement was super simple: just a single metered leak “fogger” nozzle mounted near the throttle and a simple ball valve to turn the nitrous on and off. Neil’s research had shown simple systems were the way to go when getting started with nitrous, and this rudimentary system certainly delivered the “let’s not mess with a lot of things” power addition he desired as he got used to Reno racing.

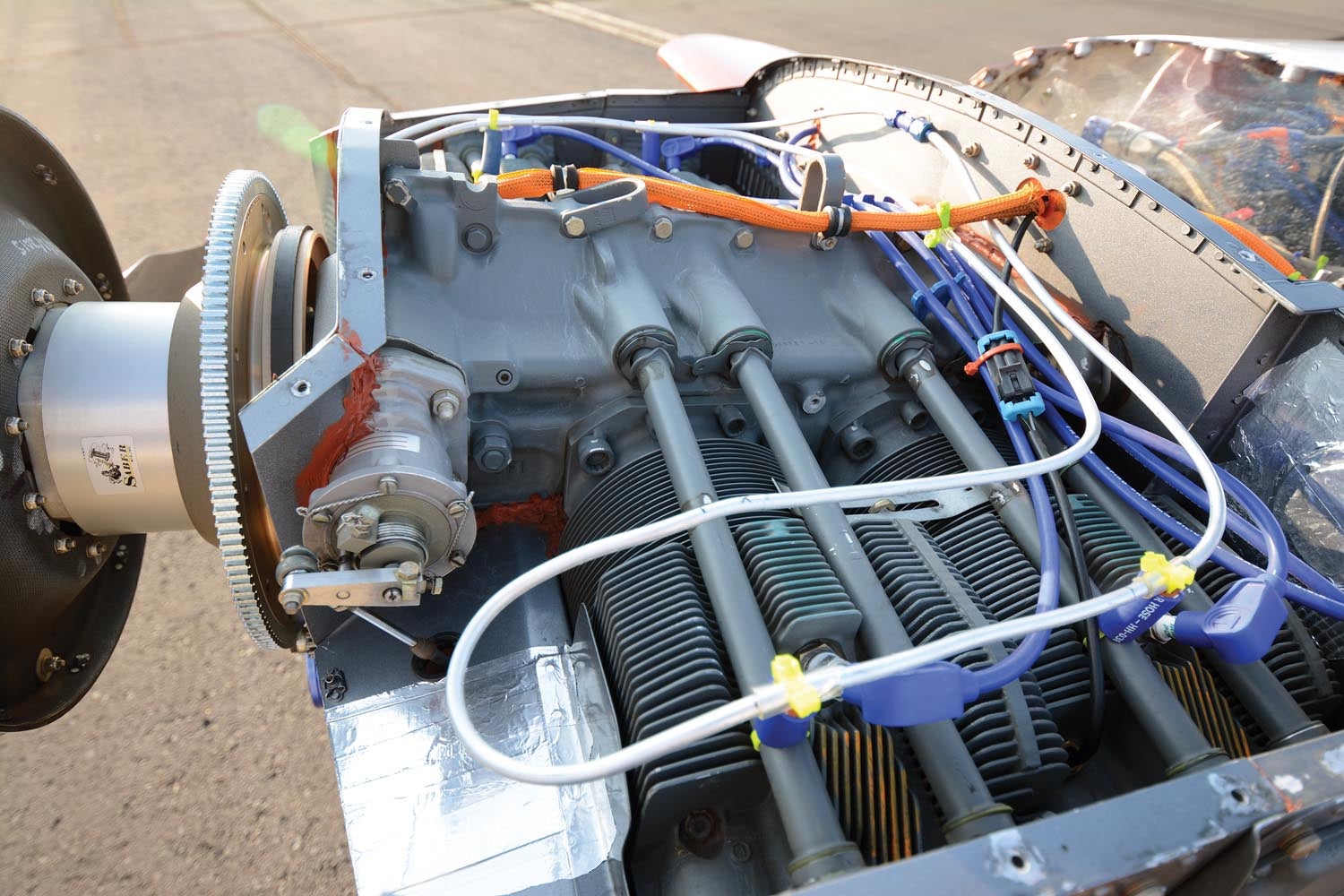

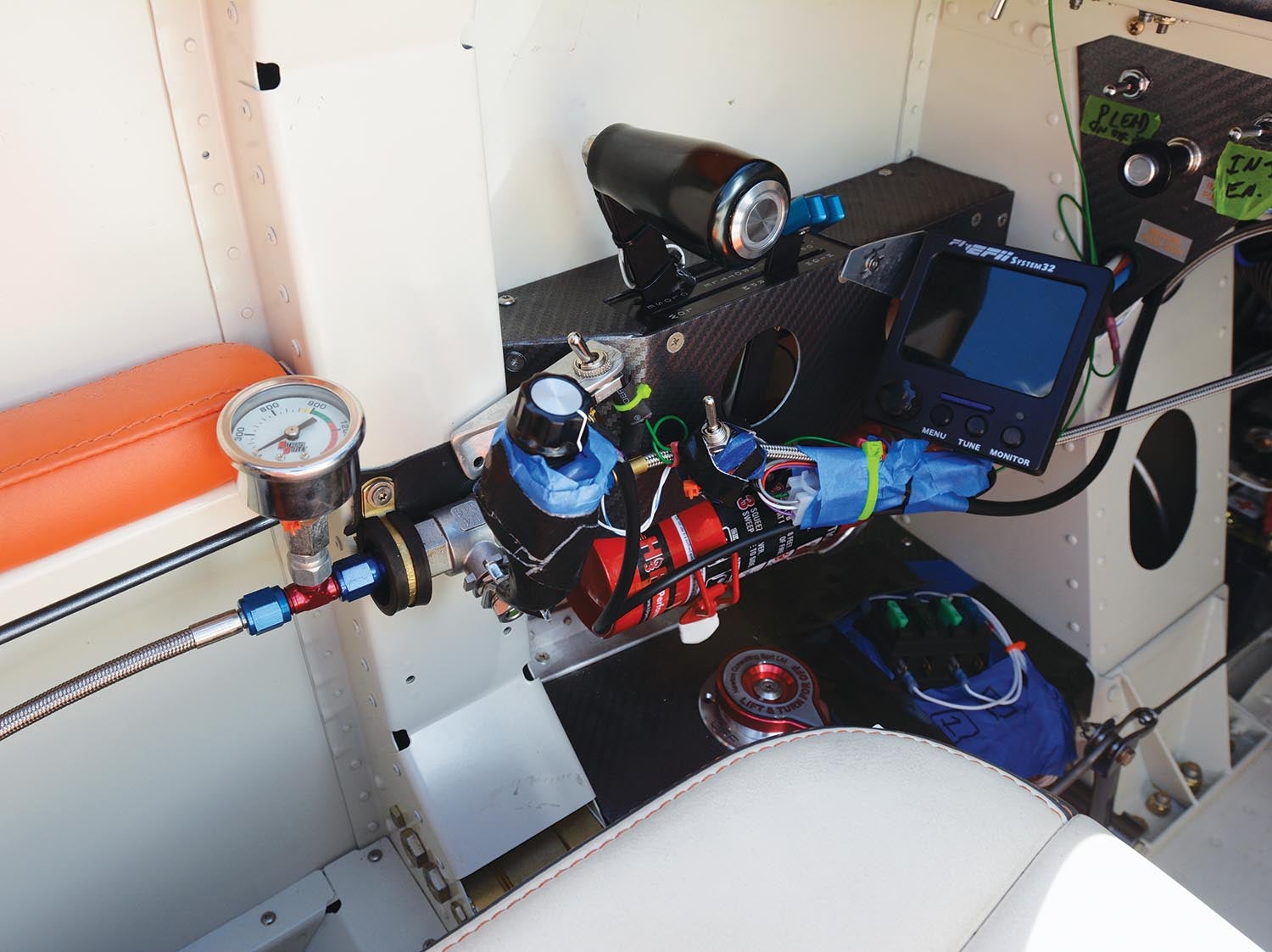

In 2019 Neil upgraded to EFII’s then-new System32. This is a fully electronic engine management system incorporating both the dual EFII e-ignition he had been running, along with electronic fuel injection. Thus, the Precision fuel servo, flow divider, diaphragm pump and so on were removed.

What went in was EFII’s dual electric fuel pump package, along with System32’s dual computers, electronic fuel injectors, cockpit controller, fuel lines and other supporting parts. With this change, instead of a single high-volume lawn sprinkler at the throttle body, Neil could simply administer the nitrous system’s additional gasoline requirement through the engine’s regular electronic fuel injectors. This is a “dry” manifold system, so there is no nitrous/fuel bomb in the inlet tract, plus the supplemental fuel distribution is more even than typical fogger systems that admit the supplemental gasoline via a single lawn sprinkler injector somewhere in the inlet tract. The nitrous gas can also be piped to each inlet runner (often the priming port on Lycoming cylinders) in such a system. That gives the ability to tune nitrous delivery cylinder by cylinder, but for other reasons we’ll get to in a minute, Neil has stuck with the single nitrous fogger at the throttle.

Given his now finer control over the engine’s management, Neil concluded exactly what any hot rodder would: He could safely run more nitrous. A lot more nitrous. Instead of merely nitrous-normalizing for altitude, he moved on to supercharging the engine with a serious dose of the gas. Additionally, unlike any other motorsport we know of, Reno racers “spray” nitrous for the entire race—a hair-raising 10 minutes. That’s ages longer than automotive drag racers or even record setters on the salt flats of Bonneville. This means balancing the amount of nitrous assist against the duration it can be applied as there is only so much room or weight tolerance for nitrous bottles in a little RV.

Neil has certainly experimented with the number and distribution of nitrous bottles as he figured out his combination. The first year racing he fitted two 15-pound nitrous bottles. The second year he had three 15-pound bottles in order to maintain higher bottle pressure longer. The third year it was four 15-pound bottles and by the fourth year he arrived at his present solution of two 20-pound and three 15-pound bottles. That’s a total of 85 pounds of nitrous on board.

During qualifying, where Neil might run the nitrous for only a lap and a half, he could run over 200 hp worth of nitrous assist, but so far has limited himself to a 175-hp shot. For an entire race—again that’s 10 long minutes of boost—Neil says he must run below a 175-hp shot or he’ll run out of the giggle gas. In practice this means he’s stuck to 150 hp of nitrous when running it the entire race.

Details matter when figuring how much nitrous to run for how long. For example, as the pressure drops in the nitrous bottles (they start out at a nominal 900 psi but non-linearly lose pressure as nitrous is consumed), the volume of nitrous flow slows and so only 75% of the bottle contents are usable. Once past, say, the first 10% of the bottle’s contents, the air/fuel mixture gets increasingly richer and toward the bottom half of the bottle, egregiously so.

At least the nitrous system is still mechanically pretty simple. As noted, the supplemental gasoline required when spraying is added by the engine management system, so no additional gasoline system hardware is required. As long as the fuel injectors are large enough to handle the total flow, the only extra item in play is computer software.

On the nitrous side Neil has elected to keep things more mechanical than he could have, mainly for durability and consistency. As nitrous changes state from liquid to gas (when sprayed), it has a powerful cooling effect. This is great to avoid detonation, but when flowing large amounts of nitrous for extended periods, the nitrous lines and controls can get cold enough to freeze. This includes solenoid valves, so Neil avoided solenoids by using that dead-simple ball valve in the cockpit to manually control nitrous flow. All the nitrous bottles feed into a single line—which Neil controls with his ball valve—which then flows to the injector at the throttle body.

To accommodate the big transition from naturally aspirated to nitrous assist during the race starts, and because the nitrous and gasoline mixture grows richer as bottle pressure drops, some way of regulating fuel flow on the fly is required. System32 can accommodate this via the fuel trim knob on its controller, and for nitrous hits up to 125 hp this works well enough, says Neil. But as nitrous loads increase, the fuel trim knob gets a little slow to respond (because it’s adjusting the fuel map inside the computer and some latency is a given). Neil found that when spinning the fuel trim knob aggressively during starts, he couldn’t just give it a half twist and have it land at a predictable amount of fuel enrichment. He might aim for a 20% increase and hit 30%; the fuel trim knob wants to be turned more slowly and needed visual tending that Neil didn’t have time for when trying to start a race with seven other airplanes flying formation.

Potentiometer

The answer was a bit of hardware EFII used while developing System32. It is a second, standalone potentiometer with its own knob. This potentiometer modifies the System32’s fuel signal output, so it takes effect downstream of the computer and thus gives an immediate linear response. Its authority is plus or minus 50% of the fuel commanded by the System32 computer, so it’s a powerful tool. It’s not needed for any normal daily driver operation, but it’s proven popular with EFII’s nitrous racers who value its rapid response.

To calibrate the potentiometer Neil calculates his engine makes 210 hp naturally aspirated at sea level, so he sets the potentiometer to be at its mid-travel (neutral point) at 250 hp. From there turning the knob full rich gives him 50% more fuel, or enough for 375 hp. Turning it down all the way gives 50% less fuel, or 125 hp, which more than covers the range of power available while running nitrous.

Powering up at the start of a race is done in the air, coming down the start chute in line abreast formation. Just before “You have a race” comes over the headphones, Neil dials the potentiometer for a serious increase in fuel, well more than the engine needs at the moment. Then, when he opens the ball valve to allow nitrous flow at the instant the race starts, he flicks the potentiometer fully open. This gives about 250° F cold of peak on his EGTs, so “it’s pig rich coming on the bottle. From there I dial the potentiometer down.”

As the race progresses and bottle pressure drops, Neil gives the potentiometer a series of tweaks to lessen the additional fuel and keep the air/fuel ratio optimal. This can be as much as three adjustments per lap, so Neil is still a busy man flying, racing and adjusting the fuel. By the end of the race, fuel flow is reduced by 5 gph, or about 50 hp, says Neil. He also notes his fastest lap is the first because he’s got the bonus of the downhill start, plus the nitrous system is at its highest pressure.

Ignition Retard

Another necessary function is ignition-timing retard. At low combustion-chamber pressures, a generous amount of ignition timing “lead” is useful, but as cylinder pressure rises so does the speed of combustion. Therefore, anything that significantly raises cylinder pressure—turbos, superchargers, nitrous—definitely necessitates reducing ignition-timing advance to avoid detonation. Obviously this is impossible with conventional magnetos with their fixed timing, but it’s just another function with electronic engine controls.

With System32 an ignition retard function is built in to the hardware and software, and for those interested in using it, EFII supplies a wire marked “Ignition Retard” in the wiring harness. All the end user needs to do is connect a powered switch to the wire; when 12 volts is applied, the ignition retard is invoked. This works perfectly for Neil. As with his manual ball valve, the computer doesn’t know when the nitrous is flowing, so rigging a toggle switch to the ignition retard wire got him in business. All he has to do is remember to turn it on when engaging the nitrous.

Neil starts his racing week at Reno with a conservative 4° to 8° of ignition retard from the base ignition map, and as long as the CHTs remain calm he sneaks a degree or two less retard as the week progresses.

Another consideration is that ultimately nitrous flow is regulated by a replaceable jet fitted in the fogger nozzle at the throttle body. The jet is manually selected and changed before flight. Thus, Neil has to decide on how much squeeze he’s going to use prior to the race. This need to preselect the amount of nitrous assist is an inherent drawback compared to turbos, superchargers, increased displacement or almost any other form of hot rodding where the pilot can simply move the throttle to adjust his power. Nitrous is an all-or-nothing power adder. It is used only at full throttle, so it has a Dr. Jekyll and Mr. Hyde personality unique in power tuning.

Water Cooling

With more combustion mass comes more waste heat to reject, and in time-honored Reno racing tradition Neil uses spray water to augment engine cooling. Actually, he uses two such systems. One sprays onto the cylinder heads, the other is directed onto the oil cooler. Each system is completely independent of the other with its own water reservoir, plumbing, nozzles, pumps and switches.

The oil cooling system was built by converting the existing 3-1/2-gallon smoke oil tank to water. This system was already plumbed, so it became a relatively simple thing to clean out the smoke oil, fill the tank with water and change the discharge hose from the exhaust system to the oil cooler spray nozzle. Sometimes, Neil will engage this system before a race to prechill the oil before the heat of battle. He also reports switching it on—rarely—during hot-day climbs around Peavine Mountain as the race planes form up prior to the start.

The main, or cylinder head, cooling system is a temporary item consisting of a 7-gallon tank nested into the forward baggage compartment during race week. In a way this system also augments the oil cooling because the oil cooler is mounted to the rear cylinder baffles, so some cylinder spray water finds its way to the oil cooler. Interestingly, unlike most racers, Neil doesn’t bother with distilled or otherwise purified water. He uses plain old tap squeezings and puts up with the water spotting inherent in mineral-laden water, saying it’s just once a year and he can clean up after the races anyway.

Performance

In naturally aspirated trim Neil’s RV-8 runs pretty much like any other RV-8, as the airframe is near stock and the 390 engine is otherwise standard stuff. Neil figures his -8 yields about 205 knots down low at full throttle. That’s sea level at 19 to 20 gallons an hour fuel burn, running full rich at wide-open throttle. He’s not ironclad on those numbers because “I’m rarely there” running so hard, so low.

The fastest lap he’s turned around the Reno racecourse, which is nominally 5000 feet elevation, is 272 mph (Reno gives lap times in mph, not knots) with the nitrous engaged and the 100LL flowing well over 30 gph. For all-out speed, running straight and level, Neil figures he can wring 250 knots (287 mph) out of his combination. That’s fast enough for the airframe and as Neil understands, about as much as he’ll get from engine power as he reasonably can’t carry more nitrous. Any faster is going to require aerodynamic mods that aren’t likely, given his RV-8 needs to function normally in the real world 50 weeks out of the year, and it’s up against its structural limits anyway.

As for weight, the nitrous system adds 190 pounds to the airplane, so it’s like carrying a passenger. In fact, most of the weight is aft in the baggage area, so it at least favors an aft CG, which is definitely faster than the nose-heavy variety. As Neil puts it, “Having it tail heavy isn’t all that bad. The 390 is a nose-heavy weight…not a fully nose-heavy CG, but it does like to turn better [when the nitrous system is taking up the rear seat/baggage area]. There’s also another 90 pounds in the spray-bar water and associated plumbing. But the weight does go away during the race. It’s kind of a dog when fully loaded at the takeoff and climb [with the nitrous and] 10.5 gallons of water at takeoff, and it’s all gone when landing.” Of course Neil tankers just enough fuel for the race, plus a reserve in case of a closed runway or other problem. That’s typically 10 gallons per side, so there’s a little extra weight there, too. “I’m under gross, but if I put full fuel in, I probably wouldn’t be!”

Next

At this point Neil’s goals are to continue having fun, run the perfect qualifying lap, try some different propellers and ultimately make incremental improvements. His RV-8/nitrous combination has already seen its big jump in speed, so it’s little things from here on out. In Neil’s words, “The goal is to just go faster every year. Oh, I like beating other metal airplanes or whatever, but you’re really competing against yourself. So, it’s just setting a personal best each year…to not do a bunch of parade laps. If you’re coming every year and running the same speed, that’s not really racing anymore. And it’s getting tougher now.”

Absolutely , amazed . What a great article ,Neil has done a fantastic job on his 8 . Thanks for sharing .

Tom! What a well written article!!! It is a piece that both an engineer and a shade tree airplane builder can understand and enjoy. The only problem was cleaning the coffee off my screen after reading the line about nitrous having more nicknames than a room full of gangsters. Well done!

Steve Ashby