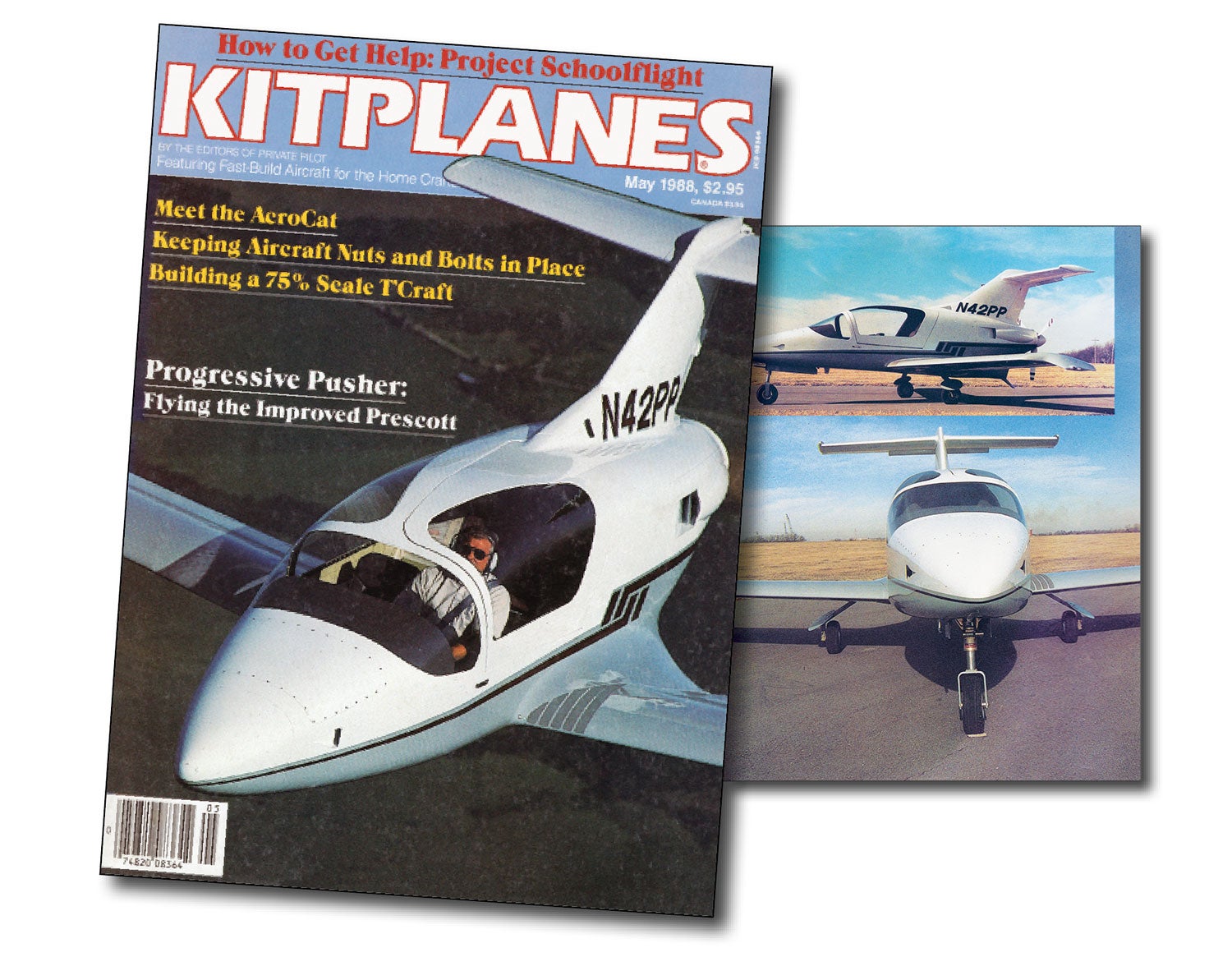

An impressively tight shot of the Prescott Pusher homebuilt made sure our May 1988 cover was dramatic. There, we promised a flight of the “improved” Pusher. We, along with many in the aviation-journalism world, were cautious in praising the prototype Pusher based on some oddball handling qualities. As LeRoy Cook, who penned this update, reminds us: “…we wrote in the October, 1986, issue of KITPLANES® ‘initial impressions…must be tempered with prototype caveats; refinements should tame some of the takeoff and landing quirks, probably through tweaking of the landing gear and tail, and bobweights can be added to lessen the light elevator’s sensitivity…we look forward to sampling future Prescott developments.’”

For this issue, Cook sampled a “frozen design” version of the airplane, which was the second prototype. Changes to the stubby-looking, four-seat pusher included the promised addition of elevator bobweights and the relocation of the main gear some 8 inches forward. The company also moved the fuel from under the passenger seat to out in the wing leading edges (increasing capacity from 45 to 56.5 gallons) and reduced the thickness of the windshield A pillars and removed the center strip for better visibility. LeRoy reported cruise speeds of 174 mph true at 73% power (from a 180-hp Lycoming O-360) and a “clean break” in the stall at an indicated 66 mph.

The big question was landing behavior, which he described thoroughly. “Aiming for an over-the-fence speed of 95 mph, the Pusher floated through the flare normally, rather than requiring forward pressure to keep the nose down as in the previous airplane. It is best to avoid full-stall landings, which tend to be firm as the airplane suddenly quits flying. The best technique is to land the Pusher like a jet, flying it onto the runway at about 75 mph, in a slight nose-up attitude well above stall.” Even as the Prescott had some improvements, it never really recovered from the initial impressions, and the performance (cruise speed against landing speeds) failed to impress.

In what would become a long-running debate in the composite world regarding material choices, Lancair’s Lance Neibauer weighed in on a feature penned by Ken Wheeler (of Wheeler Express fame) that Lance felt expressed “a degree of misinformation” in “comparing vinylester wet layup systems with high-temperature epoxy prepregs.” Neibauer continued, “It’s interesting to note that virtually all composite airframe systems being developed today by the aerospace, commercial and general aviation manufacturers are using high-temperature epoxy prepreg systems. The only areas where the old ‘boat technology’ systems of polyester/vinylester wet layup are thriving are with just that—boats—along with hot tubs and of course homebuilt airplanes.” Ouch. He admits that cost is an issue and concludes his letter by saying, “The homebuilt market was once an arena entered only by the diehard craftsman/tinkerer and his demands were few. Today those demands are many. As these planes become high performance, sophisticated machines, such demands as high quality, consistency and longevity become sincere. Expect to see more use of advanced composite structures in the future.” He was not wrong.

Elsewhere in the issue, Geoffrey Jones reported on the Swiss two-seat retractable homebuilt called the Cherry. The “wood-on-composite” design sported a very large canopy, for the “spectacular Swiss scenery,” we opined. It used a Continental A-65 to cruise at 125 mph with a fixed-pitch prop. Gross weight was 1211 pounds. Kit costs were estimated at $7000 with an expected build time of 4000 hours.

Back in 1988, loran was still a thing, with a company called STS touting its database-free Loran-C 110 for a mere $749. That would be almost $1800 today. Another sign of the times? We had 16 pages of free classified ads in the back of the issue. Oh, the days before the internet! Some things don’t change, though. Dave Martin, in his editorial up front, warned that someone had placed an ad looking to buy plans for a design that was no longer available at the same time placing an ad to sell sets of the same plans. Apparently, the perp managed to “sell” two sets (at $500 each) before purchasing a single one.