OK, name the most recognizable aircraft ever: Wright Flyer? Spirit of St. Louis? P-51? I’d wager that a survey would place the Fokker Dr.I Dreidecker (Triplane in German) in at least the top three. The association of Manfred von Richthofen and his nome de guerre, “The Red Baron,” with everything from Snoopy to pizza has ensured that his red triplane is firmly ensconced into society’s imagination well beyond military history.

OK, name the most recognizable aircraft ever: Wright Flyer? Spirit of St. Louis? P-51? I’d wager that a survey would place the Fokker Dr.I Dreidecker (Triplane in German) in at least the top three. The association of Manfred von Richthofen and his nome de guerre, “The Red Baron,” with everything from Snoopy to pizza has ensured that his red triplane is firmly ensconced into society’s imagination well beyond military history.

A bit of the backstory: Anthony Fokker, the Dutch aviation pioneer as well as aircraft designer and manufacturer, developed the Dr.I after viewing a captured Sopwith Triplane in April 1917. The Dr.I has a steel tube fuselage and tail feathers with wooden box spars and ribs. Each wing is built with a single spar running wingtip to wingtip. The closeout of the landing gear axle creates another smaller flying surface that produces lift as well. The thick cantilevered wings were repurposed from a government-mandated collaboration with Hugo Junkers. Interplane struts were not needed from a structural standpoint but minimized wing flex and calmed the apprehensions of the pilots who thought the plane looked too fragile without them.

The Dr.I featured technology ahead of its time such as balanced control surfaces. The first prototype aircraft were sent for combat evaluations in September 1917 and were highly endorsed. These initial tests came to an end when both aircraft were lost in combat later in the month. Production orders were placed and many pilots loved the three-wing creation. However, with the pace of technologic developments, the Dr.I was soon outclassed. While it was wonderfully maneuverable, powered by the Oberursel UR. II (a clone of the Le Rhône 9J) and with the drag of the third wing, it was significantly slower than the more powerful Allied aircraft it faced.

Concerns of shoddy workmanship and structural failures resulted in a pause of production in November 1917. Although these issues were addressed, they continued to plague the design. The Dr.I was withdrawn from frontline service the following summer, and production ceased after a total of 320 airframes were produced. Three were known to have survived the Great War, but ultimately they were destroyed in WW-II. Today the only existing flying Dreideckers are replicas and reproductions. While Manfred von Richthofen is forever associated with the Dr.I, in reality he flew one for only 19 of his 80 confirmed combat victories.

Build Your Own

If you want to build and fly your own Dr.I, what are your options? It depends on how close you would like to get to the original. There are a few kits available, including one from Airdrome Aeroplanes. They are a viable option but differ from Anthony Fokker’s design in ways that make them easier to build and fly. As one tries to get closer to the original construction, you have to refer to blueprints or plans. There are very few options in this area as well, but some of the more accurate plans are produced by Ron Sands. Bear in mind that these are not entirely true to the original blueprints, but overall they are close. Deviations include the aircraft having a more rearward center of gravity as the rear fuselage was made with thicker tubing versus the original, and the landing gear is shorter.

There are several other options. On the plus side, WW-I replicas are certainly easier to build and cheaper than subsequent warbirds, and the Dr.I structure makes it easier than most WW-I replicas to disassemble and trailer to airshows.

The majority of Dr.I replicas being built or flown are powered by a variety of modern engines. Horizontally opposed Lycomings are sometimes buried under the cowl, or a radial is used from Warner, Verner, Rotec or Continental. However, a few aircraft are powered by rare and very difficult to come by rotary engines. Temperamental and finicky to run, it takes a rare personality to fly behind such labor-intensive motors—someone who is driven by a passion for history and a love of original aviation.

All of this brings us to a very specific airplane owned by Chris Hill of Griffin, Georgia. A graduate of the Air Force Academy and a former B-52 pilot, he’s been in love with WW-I aviation since he was a child and dreamed of someday owning his own Dr.I. In 2013 his dreams finally came true when he had the opportunity to buy a recently completed replica powered by a Lycoming O-320. Constructed from scratch by Jim Bruton over an eight-year period, it was finished in 2012. By following the Sands plans, it is very close—but not identical—to an original. These subtle differences take a compulsive eye to pick out. For example, the middle and inboard aileron hinges are one bay inward compared to the original, causing the control cables to have some friction if overtightened. The landing gear is also slightly different. The gear in the Sands plans is 3–4 inches shorter than the original, but the gear on Chris’ plane is 2 inches shorter than the 1917 version. The tail skid pivots 10–15° to each side, creating a quasi-steerable skid as a concession to modern airfields.

At the same time, some changes were made during construction to keep this DR.I even closer to the original. The mid-wing cutout is tapered rather than remaining as thick as the airfoil. There is a skid rather than a tailwheel and, of course, no brakes. Ash wingtip skids were installed to try and minimize damage if there is a ground loop.

Yipes, Stripes!

You’ve probably noticed that the paint scheme is rather striking and different from the standard Red Baron motif. In part, this was to distinguish it from the crowd, but also to pay tribute to the numerous other Dr.I pilots in WW-I. The serial and registration numbers were chosen specifically in honor of Werner Voss, who was killed in a legendary seven-versus-one dogfight on September 23, 1917, in which he brilliantly used the renowned maneuverability of the Dr.I against numerous British S.E.5a aircraft. The number is written in the European fashion of having the day then the month listed, so it is 239/17. This serial number actually falls in a window of time when Dr.I production was halted, so it isn’t a number that was ever assigned to an actual aircraft.

The black and white paint scheme on the cowl mimics Jasta 2’s (famous for Oswald Boelcke) squadron motif. The cross on the horizontal surface of the tail mirrored the scheme of another Jasta 2 Dr.I pilot, Paul Bäumer. This combination of subtle touches was designed as an amalgam saluting all the Dreidecker pilots and an homage to Voss rather than any specific aircraft.

Walking around the Dr.I, the first thing that strikes you is how tall it is—9 feet 8 inches high! The airfoil is quite thick, and the interplane struts are surprisingly thin. Peeking over the coaming into the cockpit, you’ll notice it doesn’t have a panel and the instruments are scattered about, very much like the original.

The control grip has an “H” appearance, with the two vertical limbs being wooden grips. This is an early hands-on-throttle-and-stick (HOTAS) system that allows the pilot to keep his hands in one place. The left-hand grip pivots fore and aft, controlling the throttle, and there is a main trigger at the right-hand fingertips that fires both guns simultaneously (or would if they were real). There are also individual triggers beneath the thumbs. The center of the grip has the “blip” switch, which grounds the magneto and temporarily shuts off the engine. On this grip, the blip switch was moved from the center to the right and up slightly for ease of reach. Richthofen apparently did the same modification. This is one of only two Dr.I replicas currently flying with the original style grip and throttle system.

Getting into the cockpit is a challenge. In a throwback to the cavalry, the pilot puts their left foot into a stirrup and throws their right leg up and over the turtledeck into the cockpit. Sitting there, it is impressive how completely blind you are looking forward, with the only view being through the two mid-wing cutouts to see down and to either side.

The Engine

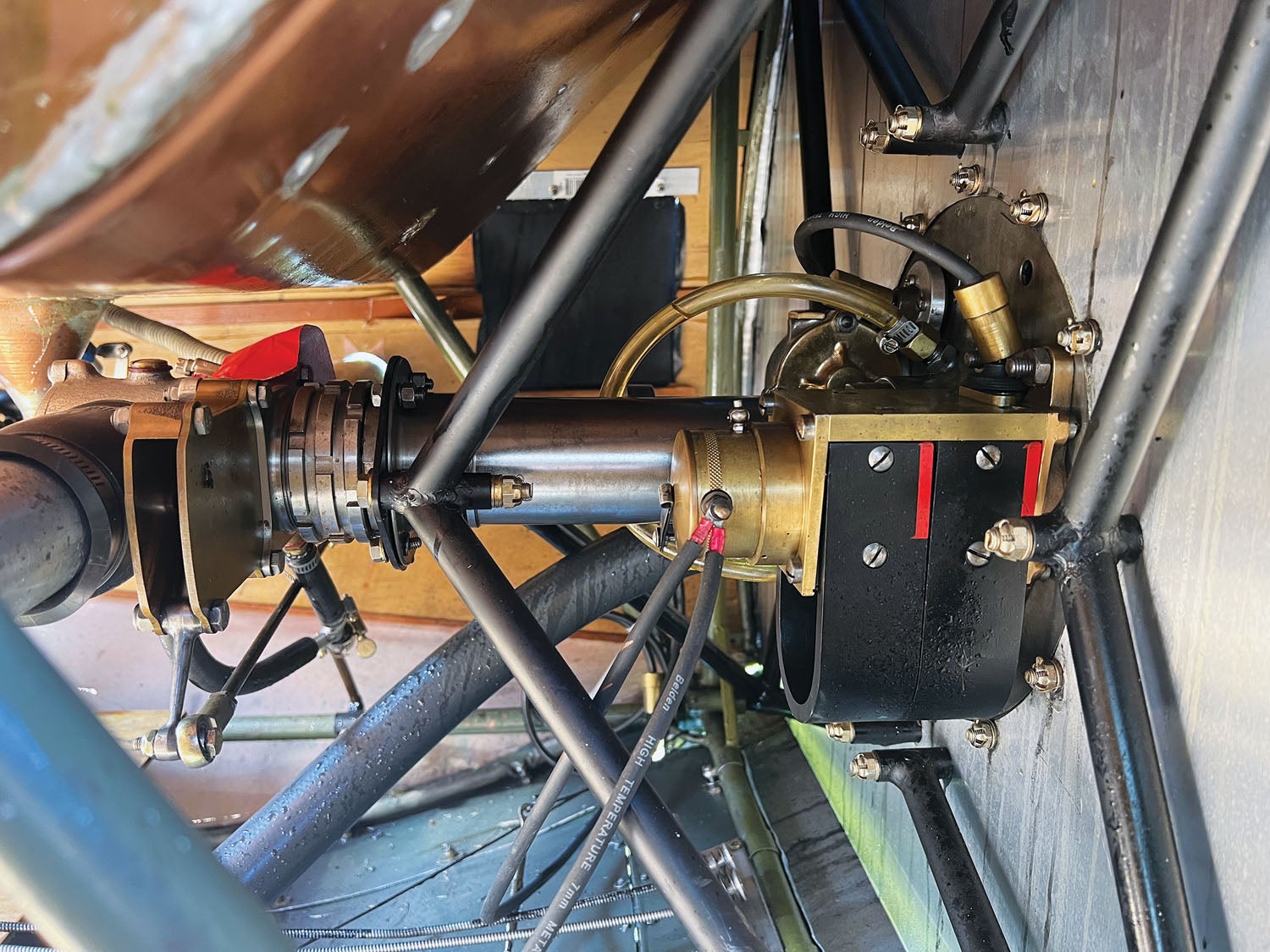

Although the aircraft was originally powered by a perfectly good Lycoming, that wasn’t authentic enough for Chris. Rotary engines are rare and extremely difficult to obtain, but through a fortuitous twist of fate he was able to find an 80-hp Le Rhône in 2019. Fitting it required redoing everything firewall forward—including a new fuel tank, cowling, fairings, not to mention the engine controls and, of course, the gun mounts.

The following year, Chris was able to work out a deal with a museum and acquired a 120-hp Le Rhône 9Jb, the same kind of engine that powered the Dr.I prototype. After an extensive restoration and rebuild, including making all new exhaust cam rollers to correct a 100-year-old manufacturing defect, it was mounted in place of the 80-hp engine at the end of 2020. The engine is an incredible piece of art, but you have to be a machinist to keep it running. While early rotaries were monosoupapes (French for single valve), later Le Rhônes have traditional intake and exhaust valves. However, there is only an intake system as the exhaust valves vent directly out of the cylinder head.

Historically, folks tend to think all rotary engines were solely controlled with a blip switch that had only two settings: off and on. While this was true originally, later engines had carburetors that allowed throttle control down to about 30% thrust, at which time the blip switch had to be utilized. The engine is incredibly sensitive to fuel flow and will fluctuate rich or lean with little provocation. Taxiing up a hill changes the fuel pressure from the gravity-fed system and will cause it to run rich. Pulling positive G’s also causes it to run rich. Conversely, negative G’s cause it to become lean. Stop and think about that for a second: Yanking and banking in combat is stressful enough without worrying that your engine is going to quit.

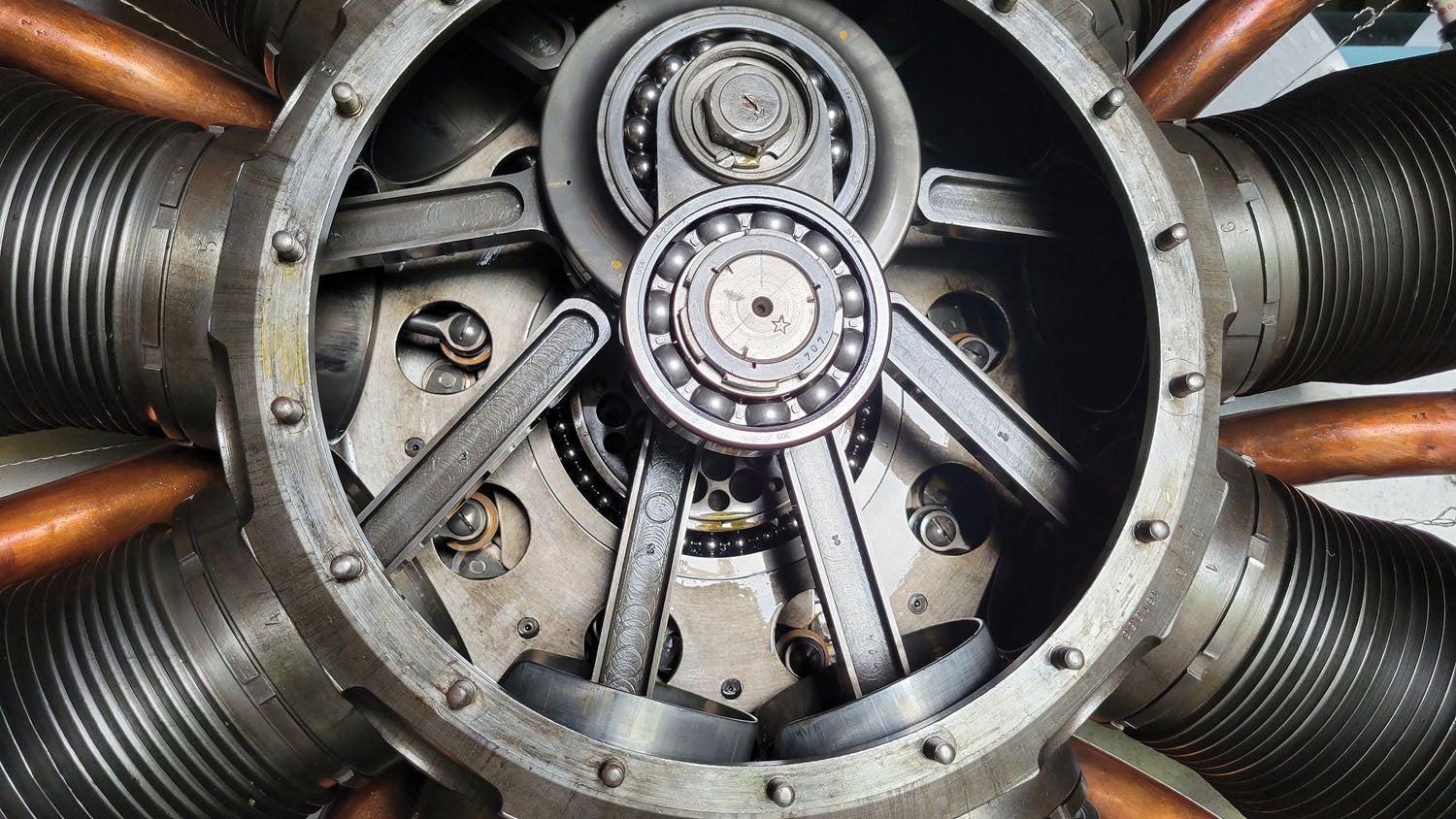

The cam runs at 9/10 the speed of the engine through a gear and bearing system, and it utilizes a thrust block rather than a master rod to allow for the connecting rods to spread out and come together as the engine rotates. Remember, with rotary engines the entire engine spins around a stationary crankshaft—all 330 pounds of it! Three races of tracks and bearings allow the connecting rods to move in harmony as the crank spins.

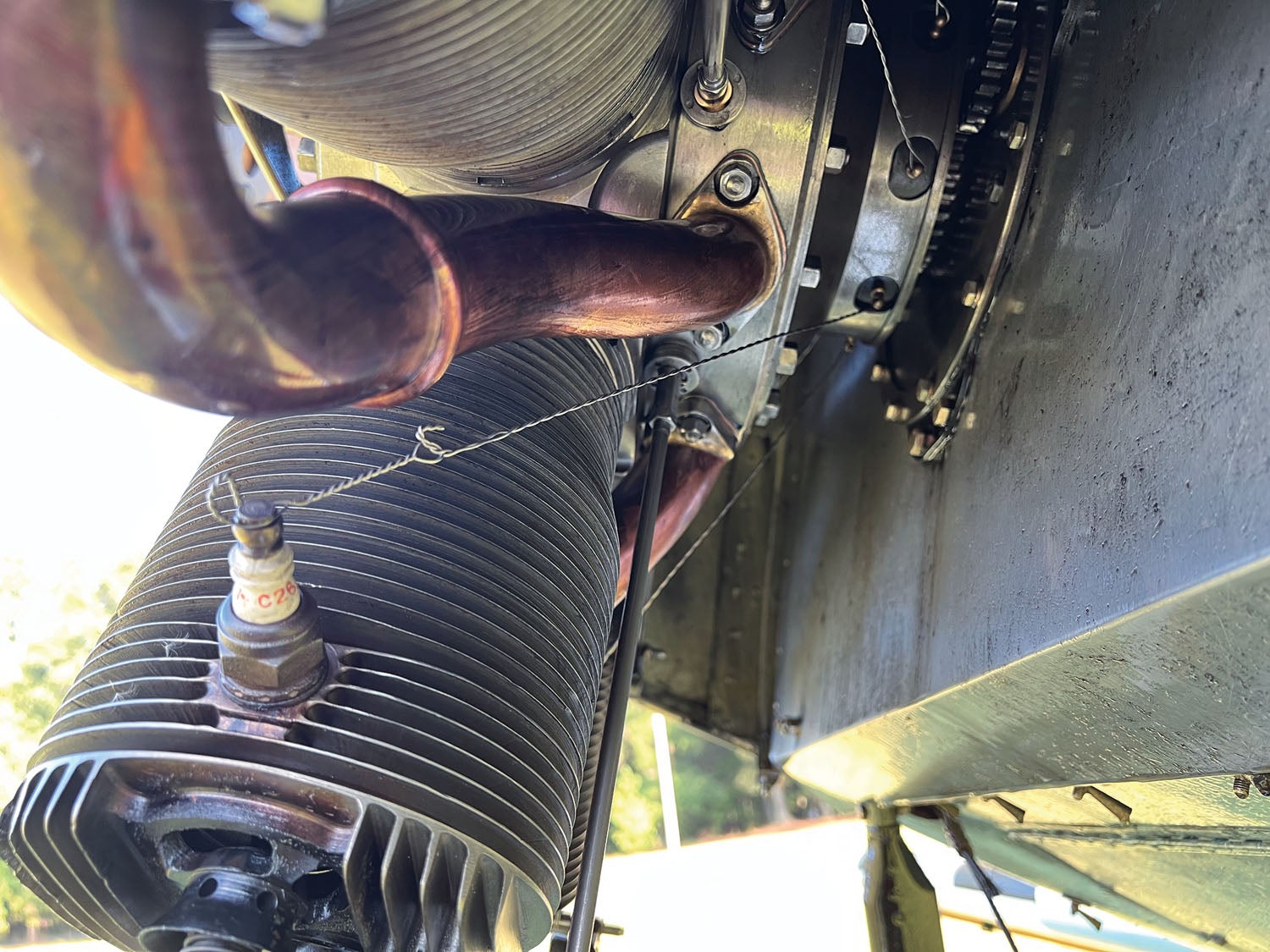

The single magneto sends its spark through a distribution ring to each cylinder. The wire between the ring and each plug is unshielded safety wire. The fuel/air mixture is drawn from the carburetor, which is mounted on the cockpit side of the firewall, into the rear of the engine case through a distributor ring to the intake manifolds (which are gorgeous copper and works of art) and then to the cylinders, which, by the way, are screwed into the crankcase. There is a single pushrod for each cylinder, and Chris sets the valve clearances generously. The compression ratio is 4.5:1, and it’s flown with 93-octane, ethanol-free auto gas. The exhaust springs are soft and as the engine is turned by hand the suction in the cylinder during what would be the power stroke allows some air to slip past, creating a distinctive “pop-pop-pop” sound.

By design, rotaries are an oil-loss system. Oil is injected into the main bearings from the oil pump every 14.3 revolutions of the engine, then through the hollow crankshaft where the fuel is introduced. The oil isn’t mixed directly with the fuel but enters through a small copper line onto the bearings, then through the cam box and out to the cylinders. The centrifugal force of the engine spinning around doesn’t allow oil to be returned to the crankcase, but rather it is flung overboard. This Dr.I holds 16 gallons of fuel (enough for 1 hour and 45 minutes of flight) and 3 gallons of oil (the originals held slightly over 2 gallons). It runs out of fuel before oil, but not by much.

So, what type of oil? Castor oil. Why? It’s not soluble in fuel, which keeps it from being washed off the internal components where fuel, air and oil all mix together. And it smells nice.

This brings us to some of the myths surrounding these aircraft: the amount of oil getting sprayed everywhere and the effect on the pilot. While the rotary certainly sprays oil everywhere, most of it is vented down and to the pilot’s left due to the timing of the exhaust valves opening and the lower cutout of the cowl. Castor oil is a laxative, and there are legends of WW-I pilots having chronic diarrhea from it. However, in talking with pilots who’ve actually flown these aircraft, the exposure—let alone ingestion of the oil—is minimal and they report no gut issues.

Where does one get castor oil? Chris ordered a 55-gallon drum from a cosmetic supply company and figures by the time this one is empty he’ll be close to having more rotary time than anyone currently flying.

The Prop

The propeller is just over 8 feet 6 inches in length. The only known surviving original Dr.I prop is in a museum in Berlin—and that is only the hub and one blade as the other blade is broken. It is not on display, but rather in the museum’s archives.

A Swedish Dr.I enthusiast was able to scan the prop to replicate the original planform and airfoil. He was kind enough to share the files, and Chris was able to have a duplicate carved by John Weatherseed in Canada. This prop, partnered with the Le Rhône engine, recreates the most historically accurate firewall forward system for the Dr.I and makes it only one of two Dreideckers in the world with this combination. The prop is big enough to create prop wash over 35% of all four lifting surfaces (three wings and the airfoil between the landing gear).

Let’s Fly!

But first, let’s do a preflight. Aside from the usual walk-around and making sure that the required fluids are accounted for, the rotary has some unusual needs beyond a standard flat four-cylinder engine. First, the oil needs to be turned on. Having an aircraft that needs to be taken apart to truck to airshows, or if the engine has to be pulled, means there must be a way to avoid inadvertently draining all of the oil out of the tank. Once the oil tank valve has been opened, oil is purged from the system by opening the bleed valve and closing it quickly—before the oil starts leaking everywhere!

Next on the checklist are the external engine parts that aren’t lubricated by the oil system in flight: The valve rocker front and rear bearings as well as the pushrod pins and valve guides of all nine cylinders get a squirt of oil with a hand can. Each cylinder is primed with a shot of fuel through each exhaust valve, with the goal of dripping fuel onto the spark plugs. As each cylinder is primed, the engine is rotated in reverse to prevent the fuel from leaking out the exhaust valves.

Start-Up

Once the engine is oiled and primed, things are ready to fire up. The carburetor is flooded so that fuel is ready to be sucked into the crankcase as the primed fuel in each cylinder ignites. The pilot opens the throttle, allowing the fuel to flow freely. Opening the fuel valve at this point allows the fuel to run into the carburetor until it hits the overflow tube, venting it overboard and onto the floorboards of the aircraft. Are your eyes wide yet? The fuel valve is then turned off, but the pilot remains ready to open it again as soon as the engine starts to fire.

With the throttle cracked about 15%, the magneto is turned on and an assistant hand props the huge propeller. About a quarter turn of a smooth but strong rotation is needed to get it to fire and start up. As soon as it starts to pop and chuff, the fuel valve is opened to keep things running. The next step is to keep the engine happy by managing the mixture. You can’t set it too rich or too lean as either end of the stoichiometric ratio will cause the engine to quit. This dance will continue throughout the flight.

Flight

Once the oil is warm, and if all looks and sounds right, the chocks are pulled. Keep in mind the only control is with the throttle and blip switch. Having only one mag means no need for a run-up, and at sea level the Dr.I is airborne almost before the throttle hits the stop, with a ground roll of perhaps 300 feet. The flight is carefully planned around the very real possibility that the engine might fail, always keeping an eye out for emergency landing sites and being aware of how far the aircraft must travel to return to home base.

When asked what it flies like, Chris says, “It flies like a Cub,” with a twinkle and a laugh. Clearly, it doesn’t, but it might be close. Per his description, the control forces are extremely light, with the ailerons being the heaviest of the axes, and even these are still quite light.

The lack of a vertical stabilizer creates an entirely flying rudder. Adding to that, the aerodynamically balanced rudder area ahead of the hinge catches the air and helps force the rudder over if it gets out of line, requiring opposite rudder to get it back in line. It’s entirely unstable, especially in the yaw axis, and the pilot is always dancing on the rudder. The plus side of this incredible yaw rate is that it allows the Dr.I its legendary dogfighting capabilities, and it can happily fly sideways if the rudder is displaced without other control inputs.

The gyroscopic forces of rotary engines are the stuff of legends—both fact and myth. While it’s clear that having 330 pounds of rotating metal out in front of the aircraft creates significant gyroscopic forces, the various reports aren’t entirely accurate. Per Chris’ firsthand accounts, the torque isn’t nearly as bad as people say, and turns to the right are effortless. Right aileron, right rudder, stick back, and it whips around on the spot.

The left turn is where things get murky. There are stories that a Camel could turn right 270° before it could turn left 90°. And if one tries a left turn in the same manner as a right turn, that probably is the case. If one does that, the nose begins to rise and there isn’t enough left rudder to bring it down before too much speed is lost. However, if the pilot sets the bank angle first, before they feed in the elevator, it will pivot almost as fast to the left as the right (about a second difference in a 180° turn). This skill set is the difference between the masters of the aircraft and their victims.

The Dr.I is quite sensitive in pitch, and at normal speeds it wants to pitch up. There is no trim to offset, so the pilot is constantly pushing the stick forward. (At around 55 mph the stick is neutral.) As the nose pitches up, it wants to yaw. As it yaws, it wants to roll, so aside from always waggling the rudder, the pilot is pushing forward and stirring the control stick to ensure it is behaving itself. Chris described this dance while laughing and says, “It’s busy to fly.” The ailerons are best described as “adverse yaw generators” and while it actually has the same roll rate as a Spitfire, the roll maneuver requires more finesse because it is a low-energy event.

By comparison, loops are extremely tight. The Dr.I can make some of the smallest loops of any aircraft, but they also require aggressive rudder management. To add complexity, remember that the engine is likely to lose power if the mixture is too rich or too lean. Pulling positive G’s means the mixture must be leaned to avoid becoming too rich, followed by enriching it as the G’s bleed off. So that’s yet another control input. Busy to fly, indeed!

While it is absolutely magical to pilot a 100-year-old aircraft and recreate the heyday of the Great War, it is also exhausting. Legs get tired from always waggling the rudder, and there isn’t really a way to take a break. While there are stirrups for the pilot’s feet to allow a single foot to come off the rudder bar, this rest is brief at best. The control stick is constantly being pushed forward and manipulated, resulting in rapid fatigue. Flying the Dr.I for any length of time can literally be a painful affair, with hands, arms and legs cramping. Chris commented that it’s the only perfectly flying aircraft he’s ever contemplated bailing out of. Other Dr.I pilots say that Dreideckers powered by non-rotary engines perform similarly during maneuvers and are affected by the all-flying rudder, but don’t have the gyroscopic and fuel management issues.

With all of the pros and cons we’ve considered, there is something indescribable about watching and hearing a legendary WW-I aircraft fly with a vintage engine. It’s like the curtain of time has been pulled back for a moment and one is seeing the plane flying in 1917.

Landing

Sadly, all good things must come to an end and we have to return to earth. But the Dr.I isn’t exactly an easy aircraft to land. Throttling back, the mixture once again must be tweaked to keep the engine running around 800–900 rpm. Setting up on final, blipping the engine 3–5 seconds at a time sets up a nice descent rate. Every time the blip switch is released, the plane rolls to the left, requiring aileron and rudder. Flaring 6–10 feet above the ground, the Dr.I is given a last blip. As the engine temporarily shuts off, there is an instantaneous loss of lift due to the reduced airflow from the prop, and the plane settles into a three-point attitude with the stick fully back. The view to the front is completely gone and the pilot is entirely blind ahead.

As the wheels touch, the blip switch is released for a second to give a burst of air over the rudder in an attempt to maintain some degree of directional control. The only way to keep going straight is to pick something in the sky to watch—a cloud or a tall tree in the distance. If it starts to swing, release the blip switch and add power to get some directional control. There’s a reason so many Dreideckers have ground looped!

Once slowed to taxi speed, it is essential that you have a spotter or two as you’re blind to the front, except looking through the mid-wing cutouts. With no brakes you’ll need someone to grab onto a strut. Once down, the rags come out and cleaning begins because the plane has effectively been bathed in castor oil! Most of it is down the belly, between the gear legs, the left lower wing and fuselage side.

During the air-to-air photo shoot, it was amazing to watch Chris throwing the Dr.I around the sky. Our personal experience has been limited to seeing triplanes in airshows with relatively sedate circuits. We were able to get a Sopwith Camel replica to join the photo shoot, and seeing the Dreidecker swoop, pivot in space, dive and climb was absolutely thrilling beyond words. Watching it in a mock dogfight with the Sopwith Camel, it was very clear that this was one heck of a capable fighting machine in its day. It offers a glimpse into what we can only imagine was taking place in the skies of WW-I. Manfred von Richthofen’s description that it “climbs like a monkey and turns like the devil” is incredibly apt.

At the same time, seeing Chris massaging his hand after a flight makes it clear that this isn’t a simple or easy aircraft to fly and the constant adjustments are fatiguing. Chris is one of only two pilots currently flying aerobatics in a rotary-powered Dr.I. Turning it upside down requires a large degree of finesse, balancing the unique aspects of the aeronautical design limitations of 1917 with the delicate touch and constant adjustments demanded by the Le Rhône powerplant.

In October 2022 The Dawn Patrol Rendezvous, a WW-I aircraft gathering, is planned to take place in Dayton, Ohio. Stay tuned for dates as it is still in the planning phases. The hope is to have four rotary powered Dreideckers flying together as part of the celebration. The coordinators invite you to come out and take part in a rare part of aviation history.

Photos: Jonathan and Julia Apfelbaum.

Great story on the Fokker Dr1.

Love your work, keep the great stories coming

Great article, but you might like to add this to your list of rotary engine suppliers …….

Gnome Monosoupape Rotary Engine manufactured by CAMS

Production of Gnome Monosoupape 100 hp rotary engines has resumed after a lapse of nearly a century. These high quality, period authentic engines are now manufactured by Classic Aero Machining Service of Blenheim, New Zealand.