Fuel filters are found on every aircraft that has an engine. They need to be changed after some period of use to ensure a reliable fuel supply. There is no universal filter that every aircraft engine uses and no one location where we can expect to find the filter mounted in the aircraft.

The fuel lines that connect to the filter may be rigid tubing or rubber hoses. While there are good reasons for using both types of fuel lines, removing and reattaching these lines is required for filter replacement. How difficult and time consuming this procedure is will often determine if the filter gets changed as often as it should!

Rigid fuel lines may utilize AN flared fittings for connection to the filter. A wrench makes removal and replacement of these filters straightforward. However, fuel filters plumbed with rubber fuel lines use various types of clamps that must be removed and reinstalled for a filter change.

A filter that has remained in place for a number of years can be a challenge to remove as the rubber hose can seize onto the filter nipples. Even after removing the clamps, those barbed fittings may not let go no matter how hard you pull. Often it is easier to cut off the hose end at the old filter because the rubber has been permanently deformed by the clamp in that area. If there is not enough additional hose slack to accommodate these trimmings, the old ends must be reused with the new filter. If the filter is located in an area of the fuselage or wing that is hard to access, filter replacement may be delayed or altogether skipped as we rationalize to leave well enough alone!

Our goal is to make replacement of filters with rubber lines fast and easy so there is never an excuse to skip this important task. Instead of hose clamps, consider using quick-connect fuel fittings. (They are also called quick-disconnect fittings). This technology has been used extensively by the automotive industry for dozens of years on millions of high-pressure fuel injected automobiles. The parts needed are inexpensive, easy to obtain and use, and most importantly, very reliable. While there are several variations of these quick-connect fittings in use, we will discuss one of the most common and easy-to-use designs. What makes it even better is that it does not require special tools!

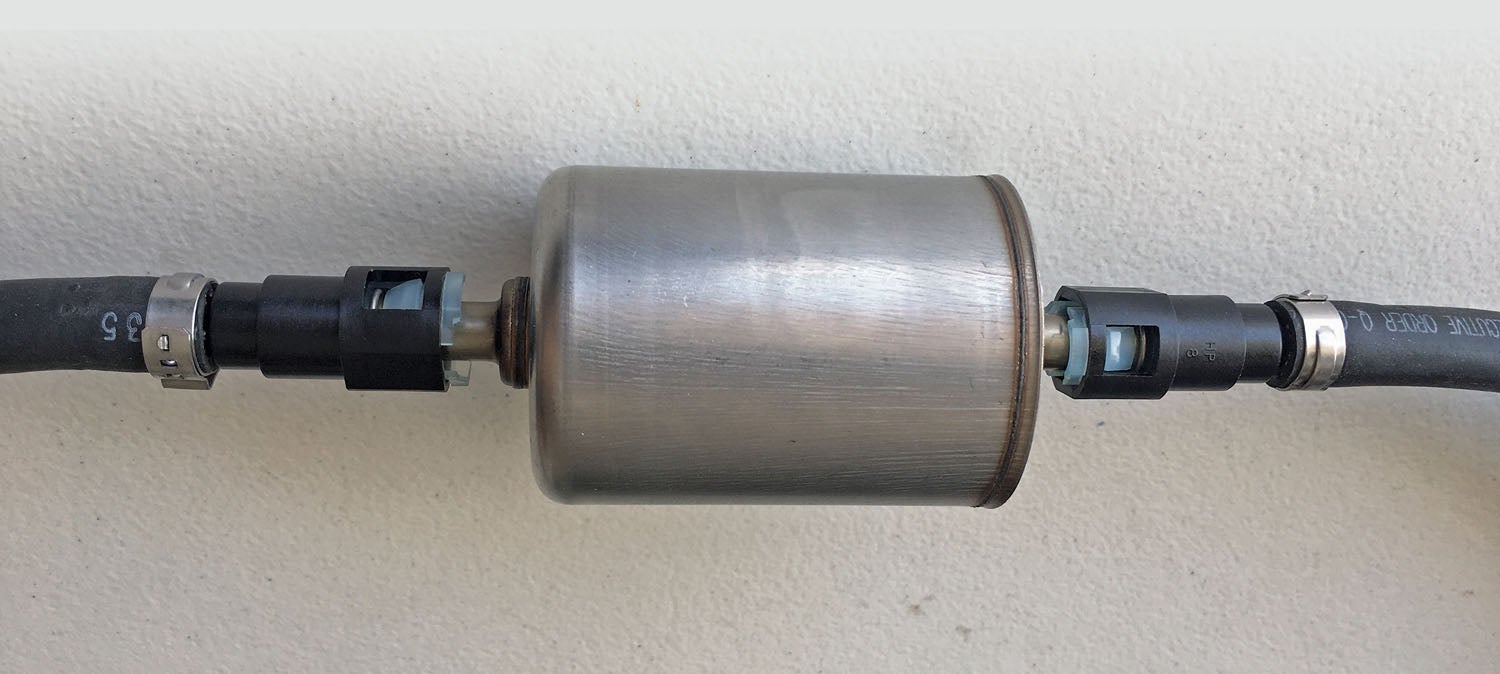

Three components make up the quick-connect fuel filter system: a quick-connect fuel filter, a quick-connect fitting and the associated clip.

Fuel filter hose stems have a ridge located 3/4 inch from the end. This is in contrast to the barbed stems we use with clamps. These filters can be purchased at local auto parts stores, online auto speed shops or Amazon.com.

Quick-connect fittings have a translucent clip on one end that mates with the ridge on the fuel filter’s hose stem. The fitting’s other end has a barbed stem that attaches to the fuel hose with a clamp of your choice.

The fitting locks into place on the fuel filter with a “click” when it is pressed onto the stem. To unlock the quick-connect fitting for removal, simply press the two tabs of the clip inward and pull the fitting off. Note that the translucent clip will remain on the filter stem after removing the fitting.

The quick-connect fitting can be reattached to the filter or removed later with little effort. When the filter is eventually due for changing, the clips on both ends can be easily removed with a screwdriver for reuse with the new filter.

When ordering quick-connect fittings, there are two dimensions you need to specify—the size of the fuel hose that connects to the barbed end of the fitting and the diameter of the filter stem. Both are typically 5/16 or 3/8 inch. For example, the manufacturer Dorman makes Part #800-080, a quick-connect fitting that matches these dimensions.

Choosing the proper fuel filter can be more challenging. Automotive fuel injected engine filters generally possess similar filtering criteria needed by aircraft engines from the standpoint of flow rate, pressure and filtering capacities. But this is a generalization, and you should understand the specific needs of your engine to find a compatible filter that is suitable. Automotive online speed shops carry universal filters with clearly documented specifications, so you can choose one that matches the needs of your aircraft engine.

There’s another version of a quick-connect hose fitting that has a barb at one end and a stem (similar to the filter stem) on the other end. This allows you to disconnect your filter and temporarily tap in with a section of hose (fitted with this fitting on one end) so you can easily drain your fuel system.

Next time you are designing a fuel system that utilizes rubber hoses, consider a quick-connect system for the fuel filter. You will be encouraging on-schedule filter changes when the time comes for periodic maintenance on your aircraft.