Depending on your viewpoint engines are one of those death and taxes things—a basic unavoidable in the kit-aircraft world or one of the more exciting opportunities to make your airplane exactly the way you want it. Unless you’re building a glider, it’s inevitable you’ll eventually need to decide which engine to put on your new build, or perhaps use to replace an existing powerplant. Helping you make that decision is the very point of this guide.

Depending on your viewpoint engines are one of those death and taxes things—a basic unavoidable in the kit-aircraft world or one of the more exciting opportunities to make your airplane exactly the way you want it. Unless you’re building a glider, it’s inevitable you’ll eventually need to decide which engine to put on your new build, or perhaps use to replace an existing powerplant. Helping you make that decision is the very point of this guide.

Certainly engines are a major investment. A new, overhauled, or custom-built conventional four-cylinder engine is all but guaranteed to cost around $25,000. Performance modifications or showy presentations can add $10,000. Traditional six-cylinder aviation engines are more like $35,000 to $45,000. If you’re considering a Rotax then—in round numbers— 100 hp is about $19,000 carbureted and $22,000 when fuel injected; moving to the turbocharged Rotax powerplants means nearly $31,000 carbureted and $37,000 fuel injected.

It’s a big chunk of change, for sure, but powering your airplane is not the place to cut corners. Obviously, reliability is crucial to safety when talking about aircraft engines, so hopefully there’s no need to belabor that point. But it’s also important to match the engine to your airframe’s needs and provide you with the performance required to make your overall investment worthwhile. This is a critical but often overlooked point: No one wants to build a ground-hugging dog, even if the goal is gas-sipping cross-country cruising or just a Saturday-morning pancake chaser. Therefore, even though engines are a considerable investment, it’s smart to make all the investment necessary to arrive at the airplane you want.

Another reality in the aircraft engine world is that the overwhelming majority of popular kits and plansbuilt aircraft use Rotax, Continental, or, especially, Lycoming engines. That’s because they are known quantities in the aircraft maintenance and resale worlds. They’re also well known to the airframe manufacturers, which is why they’re normally the go-to choice on the factory’s ships. Sure, it’s absolutely possible to build a well-performing airplane around other engines—such as those in this guide—but that’s best a job for the seasoned builder with a solid foundation in engine fundamentals. For most builders, replicating (not necessarily duplicating) what the airframe creator has done is the fastest, lowest-stress way to a flying airplane.

Where to Buy an Engine

There are a surprising number of ways to purchase an engine. Most direct is to order the engine through your airplane’s kit manufacturer, assuming they offer that service. Kit makers such as Van’s and Zenith often make arrangements with engine manufacturers to offer the suggested engines through the kit maker. You simply check the $29,000 box on the kit maker’s website and wait for motor freight to arrive… That approach greatly simplifies sourcing such things as inlet ducts, exhaust systems, baffling and so on.

Next up in convenience is likely ordering an engine directly from an engine manufacturer. Be aware that even with Lycoming and Continental, the engine makers keep few of their engines in stock. In fact, volumes are so low they list the individual engines they have on the shelf on their websites. Obviously, the farther you get from the mainstream engine choices the greater the chance you’ll have to wait for the engine to be built. This can be a meaningful amount of time with some of the overseas makers, so if you’re considering something such as a Jabiru or Rotec radial, definitely call ahead well in advance. A year ahead is not too soon to make an inquiry. The exception is Rotax; it sells in such volume and is well-enough funded that its engines seem to be in ready supply. It’s always smart to double check, though.

Because the market for Experimental aircraft has grown to be such a significant portion of the new-airplane world, Lycoming and Continental have established their own in-house boutiques to provide non-certified, often custom engines to the Experimental market. Lycoming’s solution is a separate assembly shop in the corner of their factory offering all sorts of custom services and aftermarket parts; the resulting engines are sold under the Thunderbolt name and compete directly with the better aftermarket overhaul houses such as Aero Sport Power, Barrett Precision Engines, and Ly-Con Aircraft Engines.

Continental simply builds a line of engines under the Titan brand name; these, too, may include aftermarket parts and specialized machining steps—porting, for example. Continental—at least under the Continental name—is not in the Experimental market and offers only certified versions of its engines wearing Continental data plates. At the other extreme, Rotax is firmly in the Experimental aircraft market and therefore has no need for an in-house boutique or separately named engines. A Rotax is a Rotax.

Once past factory-new engines, the purchasing process becomes less straightforward. But if the considerations go up, so do the optional possibilities, and the price could go down—though that assumes you’re wiling to consider a used or overhauled engine. Remember that with some engines what can be thought of as a new engine is actually a combination of mainly new and a few used, rebuilt parts. No one is building new Corvair engine cases, for example, so such engines are bound to have a “seasoned” case, as the machinists like to say. This is not a reliability or safety issue, but some builders are only comfortable with a 100%, brand-new engine.

Topping the roll-your-own method is to work with an overhaul shop. Some of these are relatively large, well-known outfits such as the aforementioned Aero Sport, Barrett, and Ly-Con. They are accustomed to working nationally and internationally, so crating up their wares to Kuala Lumpur or the like is not an issue. All of these shops overhaul certified engines as their bread and butter business, but they have their own line of special parts and hot-rod knowledge even the factories likely don’t possess—ideal if you’re looking for something special, racy, or show-worthy.

Other shops are far more local, ranging all the way down to one-man-in-a-hangar operations. The quality and capabilities of such outfits runs the gamut from superb to no way; which is which falls to the buyer to determine. It’s worth noting the small operations have very limited, if any, machining capabilities and must work with specialist firms for things such as connecting-rod reconditioning, balancing, crankshaft grinding, or engine case machine work.

When dealing with an engine shop—large or small—you can either walk in the door empty handed or start with a core engine or even a partial pile of engine parts. Even if the core engine you have isn’t the engine you need for your current build, it’s trading fodder. Alternately, the larger shops keep surprisingly large inventories of core engines and parts on hand, so if you are starting from scratch, the shop can often supply a core to start from, for a price, of course. This can be a cost effective way to arrive at a fresh engine, so it’s worth exploring.

Until a couple of years ago, it was not unusual for the engine shops to buy a new engine kit from Superior, Lycoming, or other parts manufacturers. Such kits are simply the parts needed to assemble an engine, delivered to the engine shop as unassembled parts. The kit pricing used to make this a viable way for a buyer with no core engine to arrive at an essentially new, assembled engine. But wanting that business for themselves, the parts makers have raised their kit prices such that simply buying one of their experimental engines makes as much financial sense. The engine kits are still available, and if a hot-rod engine is desired from a custom shop, they still are a viable starting point.

In the VW and Corvair engine market, kit engines are still the norm. These engines are aimed at the hands-on enthusiast who’s happy to assemble his engine and keep the cash that would have been spent paying the shop to do the same. If you’re not that guy, almost all such shops will assemble the engine for you for a fee, so keep that in mind when comparing prices.

Our Guidelines

A few engines may seem to be missing from this guide. We’re not going to cover Pratt & Whitney’s latest turbofan, nor are we delving into the ultralight engines—less than 50 hp. The large-bore Continentals, such as the IO-550, aren’t here, either; Continental does not want to sell them direct to the Experimental market—so we haven’t listed them here. If you have a kit that needs one of these, chances are the kit manufacturer will help you source one.

We’ve continued our tradition of grouping engines by general design feature. Thus, the flat (horizontally opposed) four-stroke engines are flocked together, followed by the inline and vee configurations, followed by the round-motor radials and rotaries, Wankels, Diesels (Jet A), and, because they are something unto themselves, Volkswagen derivatives. We close with turbines, Corvairs, and the few two-strokes that fit our criteria.

Horizontally Opposed Four-Stroke Gasoline

AC Corporation

Andy Higgs is the personality powering AC Corporation, where performance is the word and clean-sheet designs are the order of the day. Best known for his AX50 cylinder based on Lycoming 360/540 parallel-valve architecture, Higgs has combined that cylinder with his own Lycoming-based crankcase and intake designs to arrive at some very modern-looking flat engines that will fit under common kit-aircraft cowlings. Both four- and six-cylinder engines are possible, and all are not to be confused with other “clone” type replacement Lycoming engines. Instead, these use much more optimized intake airflow paths with rather obvious visual changes in manifold design. Inside, they feature multiple AC Corporation parts such as valves, valve springs, pistons, connecting rods and even crankshafts.

A quick glance at the AX50 cylinder shows just how different these designs are. Most obviously the cooling fins are more robust, the machined surfaces typically more organic in the way they flow from surface to surface, rather than the blocky functionality offered by stock Lycoming parts. A closer look shows the AX50 cylinder is a single aluminum casting, rather than a separate head and barrel joined together, and a removable sleeve is provided for the cylinder bore. The sleeve can be field-replaced at overhaul time.

Currently AC Corporation is listing its Lycoming-based engines under the “RS” banner, that standing for Race Spec powerplants. These engines are built to order in the United Kingdom (Higgs is based in Japan, but is originally from England), then shipped to the customer.

A new initiative is water-cooled cylinders for Lycoming engines. The idea is to replace the excess cooling fuel used during take off with water; Higgs says he’ll be at the Reno races September 2020 with a water-cooled 540 derivative.

BRP Rotax

Old hands think of Continental or Lycoming as the world’s number one light aircraft engine makers, but by a large margin it’s actually been Rotax for a long while. A division of BRP, Rotax is based in central Austria, where it is tasked with building engines for the greater BRP empire which includes all sorts of light recreational vehicles such as side-by-side utilities, boats, personal watercraft, snowmobiles, motorcycles, and light aircraft. Therefore, Rotax is a larger engine maker than it might seem at first, with first-rate production facilities and engineering.

For 2020 Rotax is continuing with its existing 912, 914 and 915 series engines which combine air-cooled cylinders with water-cooled cylinder heads. These relatively lightweight and compact engines are designed for higher rpm, therefore they all include a built-in spur gear propeller speed reduction unit (gearbox) to optimize propeller rpm. All are dry sumped and employ hydraulic valve lifters; carburetor or electronic fuel injection are offered depending on the model. Warranty periods are relatively short for Rotax engines in experimental applications—just 18 months or 200 hours—but in certified aircraft that grows to two years or 400 hours for essentially the same hardware. Also lengthening over the years has been Time Between Overhauls for the four-stroke Rotaxes; the 912 is now at 2000 hours TBO. Rotax offers several distributors and maintenance facilities in North America, with some of those, such as California Power Systems and Lockwood Aviation, offering various schools for interested homebuilders or maintenance pros. The engines are dependable and rebuildable.

Still the best selling Rotax is the carbureted 912 series, available in 80 hp carbureted form as the 912 UL or with 100 hp as the 912 ULS. The 80 hp is most popular in Europe where higher octane gasoline is difficult to find while the 100 hp variant is number one in the United States. It’s worth noting, however, that Rotax engines do best on unleaded mogas because the lead in 100LL eventually accumulates as sludge in the gearbox. Furthermore, Rotax says the 912’s market share is starting to transfer quickly to the 912 IS and turbocharged 915 IS engines, both of which feature electronic fuel injection.

Rotax offers two turbocharged engines, the carbureted 914 and its newest powerplant, the 915 IS, which is entering its second year of full production. The latter is definitely spendy at over $38,000, but offers the best power-to-weight ratio in its class, along with a meaty 141 hp up to 15,000 feet for excellent mid-altitude performance. By comparison, the 914 will save you about $7,000 in trade for carburetion and a maximum of 115 hp; the 914 has a TBO of 2000 hours compared to the 915’s 1200 hours, as well.

If the all-singing, all-dancing 915 Rotax does offer some interesting performance capabilities to anyone interested in zipping along just a bit shy of the flight levels, it’s worth remembering even the entry-level 80-hp Rotax offers aviating for notably less than half the money and in a definitely less-stressed, should-last-forever package.

Rotax releases pricing at the first and mid-year, so the prices given here are for late 2019. Like other European engines, pricing in 2019 has been stable or even slightly lower thanks to a strong dollar, but pricing will change with the euro/dollar relationship.

Continental / Titan

Last year we reported The Big C had started construction of a new headquarters and manufacturing facility in Alabama, very close to its heritage site in Mobile. We can now report all administrative and engineering staff have moved into the new building, but at our press time manufacturing was continuing in the old factory as the new machine tools were arriving and being installed. It’s proving to be a large, lengthy process, but generally speaking the new manufacturing line should be operational in late 2020.

The new plant should also be worth the wait as not only is the building new, but the manufacturing machinery inside will also jump forward a generation or more. A good example is crankshaft manufacturing. Currently it takes eight machines plus heat treating to bring a crankshaft to life; that will change to one machine in the new plant. That means seven fewer set-ups to save both costs and increase machining accuracy.

Continental continues to offer a huge selection of engines if you consider the various legacy certified gasoline Continentals, the newer certified diesel engines, plus its Titan line of experimental derivatives of Lycoming parallel-valve architecture engines (320, 340, 370 four-cylinders and a 540 six-cylinder). They now even have a certified version of the 370 parallel-valve engine, sort of like Ford building its version of a Chevy LS.

Now, before getting carried away on Continental—we should say Titan, because that is the brand they are being sold under—building Lycoming clones, Continental/Titan is quick to point out its improvements of the breed. For sumps/intake manifolds Titan’s standard offering is a magnesium version of the traditional “hot sump” casting; it saves a meaningful seven pounds over the original aluminum casting. Optional sumps are either Titan’s vertical or the Superior Air Parts cold air intake with a forward-facing throttle body inlet. There is no forward facing hot sump, or rear-facing sump of any kind.

Titan engines also boast steel insert thrust washers for the crankshaft. The original design has thrust loads taken by the parent aluminum of the case, which can gall if run hard before fully wetted during break-in or under very hard loads or extreme time in service. Titan simply machines its cases to accept the steel thrust washers first seen in Continental 470/520 engines to essentially eliminate this issue.

All Titan engines now fit roller valve lifters as standard, although if you really want flat tappets they are optional. Titans allow front or rear propeller governors as the customer specifies, too. Also stock is Continental’s nickel-carbide cylinder treatment (NiC3) for better durability and corrosion resistance. They’re happy enough with it to offer a five-year warranty against cylinder rusting on all Titan engines along with its normal two-year or TBO warranty on the rest of the engine assembly. Warranties begin when the engine is put in service, not to exceed one year after purchase.

Another help is now that the 370 engine has been certified under the Continental Prime banner, the required Operator’s plus the Maintenance and Overhaul manuals are now available; they should be a help to all Titan engine owners. And for RV builders, Titan is offering the base version of several of its engines—these are engines configured for specific RV models—at “very competitive” prices on the Titan website. This gives simple, check-the-box shopping for RV engines, albeit just in the configuration suggested by Van’s. If modifications from those standards are desired, it’s back to the regular Titan line-up.

Speaking of modifications, while Titan does not offer a “custom shop” storefront, Titan offers an extensive line of optional gear buyer’s can choose from. The aforementioned Superior cold air intake is one example, another is the newest EFII System 32 electronic engine management system, added in the fall of 2019. All Titans have electronic ignition of some sort.

As for 540s, Titan is the only source other than Lycoming for these powerful, lightweight six-cylinders. Titan has one helicopter customer taking a slow, steady supply of these, along with the occasional RV-10 builder.

D-Motor

Another engine from Belgium is the technically curious D-Motor. We say curious because it combines the very dated flathead combustion chamber layout—shades of your ’32 Highboy—with such advanced features as dual electronic engine management. Actually, the flat-head design is not quite as technologically antiquated as it might seem. With rpm limited to just 3000 revolutions, engine breathing is less demanding than in higher speed engines, so the flathead layout—where the valves are sequestered in the engine block (case)—doesn’t pose as much breathing restriction as we might first think. Let’s also note the flathead combustion chamber is hardly the last word in efficiency and certainly would never pass emissions testing as an automotive engine, but for the moderate compression ratios run in aircraft engines and without emission limits to contend with the D-Motor proves its contrarian point.

The flathead advantages are a very much more compact engine, especially in width, along with a lesser parts count, reduced weight and cost. It’s simple, in other words, and that’s rarely a bad thing in aircraft where simple typically means reliable.

More to the high-tech side, D-Motor used Nikisil coated cylinders for corrosion resistance. This is a high-nickel treatment favored by Porsche, among others. There are the dual computers, electronic fuel injection and ignition, and it’s worth noting the fuel injection is returnless, meaning there is no need to plumb a fuel line from the engine back to the fuel tank. Also convenient are the engine mounting points; they are identical to Jabiru and ULPower engines, which aids finding a workable mount.

Given its bent for simplicity, the D-Motor is understandably not a real fire-breather. The four-cylinder version is rated at 92 hp; the six-cylinder variant yields 125 hp/121 hp continuous, also at 3000 rpm for maximum power, so smaller diameter propellers are a must on these direct-drive engines. But for an LSA where reduced weight and simplicity are key, the D-Motor seems better suited.

Let’s also note that after a rocky start several years ago, D-Motor has replaced its original North American distributor. Furthermore, North America has been overshadowed by European demand for D-Motors, but recognizing the market here D-Motor is setting up an assembly facility in Canada to service the Americas. It will assemble engines using parts manufactured in Belgium. A deposit system ($1000 into an escrow account) is now in place; expect Canadian engine assembly for North America and thus engine deliveries here to commence in early- to mid-2020.

Franklin Aerospace

A mainstream certified engine during WW-II and for quite a while later, the Franklin lives on thanks to the amazing parts inventory produced—mainly for military consumption—during the engine’s heyday. Used extensively in Stinsons, the Franklin still has a following in the certified ranks, but with its type certificate now the property of a Polish company, Franklin Aerospace engines assembled in the U.S. today, mainly from new old stock, are experimental-only powerplants.

And that’s what the U.S. based Franklin Aerospace offers with its 4A-235 four-cylinder and 6A-350 six-cylinder engines. The four-banger is kept in stock for ready delivery; the six-cylinder is built—or perhaps we should say rebuilt—to order. Both boast Electroair electronic ignition and a Rotec throttle body along with lightweight starters, but modifications to customer order are also possible if you have something specific in mind.

One thing Franklin Aerospace has done is reduce the compression ratio for mogas compatibility. The originals were pretty high compression engines to begin with, so the current six cylinder is good “for about 210 hp.” There is no shortage of parts—at least most of them—according to Franklin Aerospace. Private owners have been gathering surprisingly large stashes for years, and Franklin is still buying major collections, often by the semi-truck load. Combined with machining new examples of the few non-plentiful parts the Franklin remains viable today.

Jabiru

Seemingly having found its stretch in its fourth generation, the Australian Jabiru engines make a simple-is-better appeal to LSA and smaller E/A-B aircraft. Their combination of lower cost and simplicity via air cooling, direct-drive and simple slide-carburetion have made them popular at the populist end of the light aviation market, including the Arion Lightning, which is appropriate as Arion is the Jabiru distributor for North America.

The fourth generation Jabiru relies heavily on aluminum construction of the crankcase and cylinders—silicon carbide and nickel coated—for low weight and rapid heat transfer. Jabiru in Australia has the parts mainly constructed by specialist machine shops in South Queensland, Australia, then assembles them in its own nearby facility before shipping them to Arion in

Shelbyville, Tennessee. Although sales are good and the supply chain between Australia and the U.S. is always moving, so it’s smart to plan ahead when ordering, which is done through Arion.

Two engines are offered, a four-cylinder 2200 rated at 80 hp and a six-cylinder 3300 good for 120 hp. Both are popular, the just 132-pound 2200 in the smaller Zenith and Sonex airframes; the bigger 3300 typically being seen in the Arion, larger Zenith, RANS and Van’s models. Again, simplicity, light weight and affordable cost are Jabiru goals, so both engines use a single Bing slide-type carburetor, mechanical fuel pump, and inductive ignitions built into the flywheel. There are distributors, but they have no timing component as timing is fixed. Both the alternator and ignition are integral to the engine, and both should be working as long as the engine is rotating.

Perhaps unique in general aviation, Jabirus are fitted with RAMAIR air ducts at the factory. These fit under the cowling and simplify engine installation as the air baffling is already fitted to the engine. There are no technical or price changes to the Jabiru line for 2020.

Lycoming

In the traditional big-bore, direct-drive aviation piston world, Lycoming continues it dominance of the Experimental/Amateur-Built market. Embracing the experimental airframers years ago has been a big part of why its engines—or clones thereof—are seen more often than any other in the burgeoning build-it-yourself airplane neighborhood. Also, with Continental now owned by the Chinese, Lycoming is the last large U.S.-owned aircraft engine manufacturer and thus has a leg-up in the drone/UAV market where military contracts lean toward U.S. content. Today Lycoming continues to extend its reach by offering anything from dead stock grocery-getting certified mills to extreme performance thumpers for aerobatic and racing fans.

For 2020 Lycoming reports more of the same in the engine hardware department, with no price increase, but there is an increasing range of optional gear on its hot rod engines. The latter includes a new electronic ignition system developed as a Lycoming part in partnership with SureFly. A drop-in replacement, magneto-like, electrically self-generating unit, its big potential is adjustable ignition timing for better fuel economy, along with no maintenance or overhaul requirement for the life of the engine. Experimentals can run the system now; CubCrafters is one of the first of the certifieds to offer it stock.

Before talking options on the Thunderbolt engines, we should note a balanced crankshaft and reciprocating assembly is standard, as are ported cylinders and limited number of paint colors (more colors are optional, as is chrome detailing). Airflow Performance or Avstar constant-flow, mechanical fuel injection is also standard, along with magneto ignition. Not to be overlooked, all Thunderbolt engines are broken in on one of Lycoming’s dynos for between 1.5 and 3 hours, eliminating any worries about the engine’s viability during the first flight, plus relieving the harried—and often apprehensive—pilot from following restrictive engine break-in protocols.

Typical modifications in the Thunderbolt line are increased compression to 10:1, with the caveat that 100LL fuel is then required (no mogas), along with any number of electronic ignitions. P-MAG and LightSpeed Engineering Plasma series are popular.

It’s a measure of how custom-oriented the engine market is getting to hear Lycoming say its Thunderbolt engines are best-sellers and constitute approximately 35 percent of its production. The biggest issue they’ve reported recently is keeping up with demand. All Thunderbolts are assembled in the Advanced Technology Center, a dedicated shop inside Lycoming’s Williamsport, Pennsylvania facility where two-man teams concentrate on building one engine at a time. Lycoming says they have three such build teams working and need to add more, always a good sign.

And where are all the engines going? On Van’s RVs, of course, followed by the back country airplanes according to Lycoming. The remainder of Thunderbolt and mainstream Lycoming production is spread over the entire range of experimental and general aviation, including some direct sales overseas.

As for the engines themselves, Lycoming lists its familiar, O-235, 320, 360, 390, 540 and 580 cubic inch designs in its Thunderbolt line-up. That’s pretty much the entire line of current Lycoming production save the eight-cylinder 720, which can still be had as a certified engine if you really need that much oomph. Of the engines offered, all use parallel valve cylinders except the 390 and 580, which employ angle-valve cylinder heads. That makes them more efficient and powerful, but also heavier.

Finally, to put things in perspective, Lycoming holds one major trump card in the time-tested nature of its powerplants. There are so many Lycs flying that the company estimates the Lycoming brand accrues 1 million fleet hours monthly.

MW Fly Aero Power

While in basic terms MW Fly groups its engines as either BT22 or BT25 units, when combinations of displacement, power ratings, drive type and gearbox ratio are considered, MW Fly offers no less than 12 engine combinations ranging from 100 to 155 hp. These modern, designed for aviation engines use a flat cylinder layout to better integrate into existing cowlings and mounts, but are water-cooled for tighter internal tolerances and quieter operation. The result is commendable fuel economy on mogas, immunity to shock cooling and potentially better engine life and power. They seem to offer somewhat better power or performance depending on the application due to either higher engine output or the propeller gearing.

MW Fly is dedicated to electronic FADEC controls. A plug-and-play philosophy is supported by the CAN bus electrical architecture, so integrating the engines into an EFIS or custom tailoring the engine electronic mapping is said to be relatively easy. Engine installation is also aided by the direct mounting of coolers and the accessories.

Gearbox-equipped models turn higher engine rpm—as much as 4550 rpm—for increased power and slower prop rpm to support longer propellers. There are two gearbox ratios available; some can accommodate hydraulically-controlled constant-speed propellers along with either left- or right-hand rotation.

In June of 2019 MW Fly released a mandatory service letter counseling against low-octane or old gasoline. It requires a fuel system draining and system flow check if the aircraft has not been operated in more than two months, so the issues surrounding rapidly degrading mogas would appear universal.

MW Fly is an Italian company; distribution in North America is through MW Fly Sales and Service North America Ltd in Carp, Ontario, Canada, but separate dealers are being sought for Canada, the U.S. and Mexico. A pending project is the turbocharged B25T variant. MW Fly sees it as a “green” engine for use in UAV, urban mobility platforms and general aviation. Three versions of the B25T are being considered, a 170-hp turbo-normalized, plus two 240-hp options, one turbo-supercharged and one turbo-hybrid.

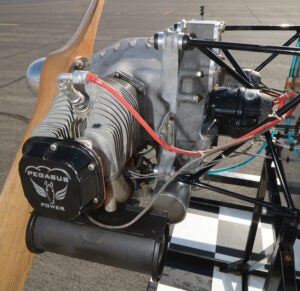

Pegasus

Patience is a virtue around new engines; witness the O-100 Pegasus DP-1, a twin-cylinder derivative of the mega-popular O-200 Continental. It’s designed to use all-new Pegasus parts where needed and existing Continental O-200 parts as possible. LSA fans have been patiently waiting for the engine for several years since the first-article DP-1 was first shown running on an engine stand, and while this should have been the year the new 58-hp engine went into production, we’re going to need a little more patience says Pegasus majordomo Pete Plumb.

Two changes have slowed the DP-1’s debut. To provide slimmer packaging, Plumb has spent the last two years redesigning the oil sump and case to accommodate the intake runners. Not only does this allow tucking the intake runners more tightly under the engine, but allows mounting the carburetor directly to the aft end of the plenum at the back of accessory case, either horizontally or vertically. To save weight Plumb favors simple slide-type carburetors. Achieving the new carburetor mounting meant extending the engine case a half inch deeper than a stock O-200. Therefore a stock Continental accessory case would still work—if a moon-shaped shim was inserted in the gap—but Plumb wanted the better solution of modifying the case to fit.

The other change was from the originally intended Austempered Ductile Iron (ADI) crankshaft to a traditional forging. The ADI process has strength-to-weight and prototyping advantages, but apparently all such manufacturing capability has been outsourced from Detroit to Mexico, complicating things impossibly for the DP-1’s small production runs. Plumb has therefore reverted to the tried-and-true forging process, and was awaiting proof samples at our deadline. Once the forged crankshaft is proven via testing by Pegasus the remainder of the engine has been finalized and is production-ready; a prototype DP-1 has already completed 50 hours of trouble-free flight testing.

Furthermore, along with the costly investment in forging dies, Pegasus is ready with relatively high volume parts runs by aviation standards—100 engines—to hopefully satisfy start-up demand. Plumb also pointed out there is no price increase due to the crankshaft change.

Superior

Superior Air Parts comes to engine building from decades of building aftermarket replacement parts for popular engines, especially Lycomings. As its inventory of part numbers grew, it became logical for them to begin selling complete engine kits, and eventually assembling its parts into replacement engines. Superior is quick to point out that they’ve upgraded materials and manufacturing processes to provide better parts at competitive prices. They’ve also provided important competition to help keep costs in line across the engine marketplace.

While Superior offers some certified engines, it is its XP line of experimental engines based on Lycoming architecture that are of interest to experimental builders. Several options are available, including your choice of flat or roller tappets, or intake manifolds based on the original Lycoming model of combined oil sump/intake manifold or Superior’s cold air style intake.

The Superior cold air intake is its more popular offering, not only due to the efficiency of the cold air design, but also because it is available in traditional updraft or horizontal layouts. The horizontal cold air allows a slimmer cowling and eases packaging a ram style air inlet, while the updraft version accommodates existing standard-depth cowls. Superior offers a choice of Bendix-style mechanical fuel injection from Precision Airflow or traditional carburetion on all its engines.

Superior was offering 382 and 400 cubic inch stroker versions (longer crankshaft throw) of its engine, but after some issues Superior recalled those engines in a buy-back program and is no longer offering strokers.

Another initiative of Superior’s is the Gemini opposed-piston Jet A fuel engine. While the project was announced several years ago, it is still in development and is not for sale at this time. Superior is based in Texas and is Chinese-owned.

ULPower

Product of a consortium of Belgium companies, the ULPower line of engines has been one of the more popular “alternative” (non-Lycoming) engines on the experimental market. Its distributorships have been growing in the U.S., and there are now firewall-forward kits for the popular RV and RANS airframes from Kaolin Aviation if that’s your need. There’s up to 200 hp available, if you can handle 3300 rpm, so ULPower engines are not just for evening flight flivvers. The same six-cylinder is rated at 182 hp at 2800 rpm should you be using a long prop.

ULPower engines are an interesting combination of traditional horizontally opposed, overhead valve, air-cooled, direct-drive layout and contemporary electronic engine management. All ULPower engines—both the four- and six-cylinder units—are electronically fuel injected and sparked. A single computer is stock, but dual ECUs are optional. Dual electronic ignition is standard. Just make sure you have a steady and voluminous number of electrons as these engines demand 21 amps running and 50 amps of charging.

We also recommend spending some time with the company’s good online technical information as the fuel system is entirely reliant on electrical pumps—there is no mechanical fuel pump—so that is something to consider.

Pricing of the ULPower line is dependent on the euro to dollar exchange rate. At press time that was just 1.1:1, so the dollar is buying many euros, making the ULPower engines price competitive. Robert Helms, the main ULPower spokesman in North America says the engine remains technically unchanged for 2020; market acceptance of the brand appears to be growing.

| Manufacturer/Model | Drive Type | Horsepower/Config | Weight | Price |

|---|---|---|---|---|

| AC Corporation | ||||

| AC-379RS | direct | 230 hp 4-cyl | 248 lbs wo/ fuel system, ignition, or starter | $34,562 |

| AC-568RS | direct | 350 hp 6-cyl | 370 lbs wo/ fuel system, ignition, or starter | $53,000 |

| AC-758RS | direct | 475 hp 8-cyl | Special order | TBD |

| AC-335RS Gladiator | direct | 210 hp 4-cyl, liquid cooled | 226 lbs wo/ fuel system, ignition, or starter | $28,895 |

| AC-379RS Gladiator | direct | 240 hp 4-cyl, liquid cooled | 236 lbs wo/ fuel system, ignition, or starter | $34,562 |

| AC-568RS Centurion | direct | 360 hp 6-cyl, liquid cooled | 354 lbs wo/ fuel system, ignition, or starter | $53,000 |

| BRP Rotax | ||||

| 912 UL | geared | 80 hp @ 5800 rpm carbureted | 130 lbs w/ exhaust, internal alternator | $16,503 |

| 912 ULS | geared | 100 hp @ 5800 rpm carbureted | 137 lbs w/ exhaust, internal alternator | $19,701 |

| 912 iS | geared | 100 hp @ 5800 rpm EFI | 155 lbs w/ exhaust, internal alternator | $23,284 |

| 914 UL | geared | 115 hp @ 5800 rpm carbureted, turbo | 155 lbs w/ exhaust, internal alternator | $31,539 |

| 915 iS | geared | 135 hp @ 5800 rpm EFI, turbo, intercooled | 185 lbs bare, approx 245 installed | $38,667 |

| Continental Motors / Titan Brand | ||||

| OX-320 | direct | 160-167 hp carbureted | 240 lbs w/ mags, fuel system, starter | $26,775 |

| IOX-320 | direct | 160-167 hp injected | 240 lbs w/ mags, fuel system, starter | $28,245 |

| OX-340 | direct | 166-180 hp carbureted | 244 lbs w/ mags, fuel system, starter | $28,455 |

| IOX-340 | direct | 166-180 hp injected | 244 lbs w/ mags, fuel system, starter | $29,925 |

| OX-360 | direct | 180-185 hp carbureted | 277 lbs w/ mags, fuel system, starter | $28,350 |

| IOX-360 | direct | 180-185 hp injected | 277 lbs w/ mags, fuel system, starter | $29,820 |

| OX-370 | direct | 185-187 hp carbureted | 278 lbs w/ mags, fuel system, starter | $29,505 |

| IOX-370 | direct | 185-187 hp injected | 278 lbs w/ mags, fuel system, starter | $30,975 |

| OX-370 | direct | 195 hp carbureted, counterweighted crank | 283 lbs w/ mags, fuel system, starter | $29,925 |

| IOX-370 | direct | 195 hp injected, counterweighted crank | 283 lbs w/ mags, fuel system, starter | $30,345 |

| OX-540 | direct | 260 hp carbureted, counterweighted crank | 401 lbs w/ mags, fuel system, starter | $45,045 |

| IOX-540 | direct | 260 hp injected, counterweighted crank | 401 lbs w/ mags, fuel system, starter | $45,236 |

| D-Motor | ||||

| LF26 2690cc 4-cyl | direct | 92 hp @ 3000 rpm | 137 lbs w/ alternator, starter, dual ECU, exhaust, fluids | $17,640 |

| LF39 3993cc 6-cyl | direct | 125 hp @ 3000 rpm | 184 lbs w/ alternator, starter, dual ECU, exhaust, fluids | $30,429 |

| Franklin Aerospace | ||||

| 4A-235 4-cyl | direct | 125 hp @ 2800 | 207 lbs w/ starter, alternator, Rotec TBI, Electroair EI | $15,900 |

| 6A-350 | direct | 220 hp @ 2800 | 344 lbs w/ starter, alternator, fuel injection, ignition | $28,900 |

| HKS Co. Ltd | ||||

| 700E Twin | geared | 60 hp @ 6200 rpm (3 min) 56 hp @ 5800 continuous | 121 lbs w/ carburetors, fuel pump, dual CDI | $10,990 |

| Jabiru AU | ||||

| Generation 4 2200 (4-cyl) | direct | 85 hp @ 3300 rpm | 136 lbs w/ exhaust, carb, starter, alternator, ignition | $14,900 |

| Generation 4 3300 (6-cyl) | direct | 120 hp @ 3300 rpm | 184 lbs w/ exhaust, carb, starter, alternator, ignition | $18,900 |

| Lycoming | ||||

| O-235-EXP | direct | 118 hp @ 2800 rpm carbureted parallel valve | 250 lbs w/ mags, fuel system, starter | $26,100 S, $29,700 T |

| O-320-D1A | direct | 160 hp @ 2700 rpm carbureted parallel valve | 255 lbs w/ mags, fuel system, starter | $26,900 S, $30,500 T |

| IO-320-DIA | direct | 160 hp @ 2700 rpm injected parallel valve | 270 lbs w/ mags, fuel system, starter | $28,500 S, $32,100 T |

| O-320-D2G | direct | 160 hp @ 2700 rpm carbureted parallel valve | 250 lbs w/ mags, fuel system, starter | $26,400 S, $30,000 T |

| O-360-A1A | direct | 180 hp @ 2700 rpm carbureted parallel valve | 285 lbs w/ mags, fuel system, starter | $27,500 S, $31,100 T |

| O-360-A4M | direct | 180 hp @ 2700 rpm carbureted parallel valve | 285 lbs w/ mags, fuel system, starter | $27,400 S, $31,000 T |

| IO-360-M1B | direct | 180 hp @ 2700 rpm injected parallel valve | 290 lbs w/ mags, fuel system, starter | $28,700 S, $32,300 T |

| IO-360-A1B6 | direct | 200 hp @ 2700 rpm injected angle valve | 325 lbs w/ mags, fuel system, starter | $33,100 S, $36,700 T |

| IO-390-A3B6 | direct | 210 hp @ 2700 rpm injected angle valve | 315 lbs w/ mags, fuel system, starter | $33,800 S, $37,400 T |

| IO-390-EXP | direct | 220 hp @ 2700 rpm injected angle valve | 315 lbs w/ mags, fuel system, starter | NA, $38,000 T |

| IO-540-D4A5 | direct | 260 hp @ 2700 rpm injected parallel valve | 400 lbs w/ mags, fuel system, starter | $47,700 S, $51,300 T |

| IO-580-B1A | direct | 315 hp @ 2700 rpm injected angle valve | 440 lbs w/ mags, fuel system, starter | $65,000 S, $68,600 T |

| IO-580-B1A | direct | 320 hp @ 2700 rpm injected angle valve | 440 lbs w/ mags, fuel system, starter | NA, $69,500 T |

| MW Fly | ||||

| B22D-L-100 | direct | 100 hp @ 3300 rpm | 176 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $20,290 |

| B25D-L-115 | direct | 115 hp @ 3300 rpm | 176 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $22,750 |

| B22D-R-100 | direct | 100 hp @ 3300 rpm | 176 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $19,550 |

| B25D-R-115 | direct | 115 hp @ 3300 rpm | 176 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $22,010 |

| B22G-L-122-A | geared (1.730) | 122 hp @ 3950 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $22,620 |

| B22G-L-135-B | geared (1.958) | 135 hp @ 4550 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $23,850 |

| B25G-L-140-A | geared (1.730) | 140 hp @ 3950 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $30,000 |

| B25G-L-155-B | geared (1.958) | 155 hp @ 4550 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $32,460 |

| B22G-R-122-A | geared (1.730) | 122 hp @ 3950 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $23,240 |

| B22G-R-135-B | geared (1.958) | 135 hp @ 4550 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $24,470 |

| B25G-R-140-A | geared (1.730) | 140 hp @ 3950 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $30,620 |

| B25G-R 155-B | geared (1.958) | 155 hp @ 4550 rpm (2400 prop) | 185 lbs w/ alt, starter, FADEC ECU, oil & water tanks | $33,070 |

| Pegasus Motor Corp. | ||||

| DP-1 100ci Twin | direct | 58 hp @ 2900 rpm | 110 lbs w/ Slick mags, carb, no starter | $4,495 |

| Superior Air Parts | ||||

| XP-O-320-A1AC2 | direct | 160 hp carbureted, fixed pitch | 285 – 290 lbs w/ mags, fuel system, starter | $26,300 |

| XP-IO-320-A1AC2 | direct | 165 hp injected, fixed pitch | 285 – 290 lbs w/ mags, fuel system, starter | $27,100 |

| XP-O-360-A1AC2 | direct | 180 hp carbureted, fixed pitch | 288 – 297 lbs w/ mags, fuel system, starter | $26,300 |

| XP-IO-360-A1AC2 | direct | 185 hp injected, fixed pitch | 288 – 297 lbs w/ mags, fuel system, starter | $27,100 |

| XP-O-320-B1AC2 | direct | 160 hp carbureted, constant speed | 285 – 290 lbs w/ mags, fuel system, starter | $26,600 |

| XP-IO-320-B1AC2 | direct | 165 hp injected, constant speed | 285 – 290 lbs w/ mags, fuel system, starter | $27,400 |

| XP-O-360-B1AC2 | direct | 180 hp injected, constant speed | 288 – 297 lbs w/ mags, fuel system, starter | $26,600 |

| XP-IO-360-B1AC2 | direct | 185 hp injected, constant speed | 288 – 297 lbs w/ mags, fuel system, starter | $27,400 |

| ULPower | ||||

| UL260i 4-cyl | direct | 97 hp @ 3300 rpm / 82 hp @ 2800 rpm | 159 lbs w/ accessories, oil, and exhaust | $20,000 |

| UL260is 4-cyl | direct | 107 hp @ 3300 rpm | 159 lbs w/ accessories, oil, and exhaust | $21,000 |

| UL350i 4-cyl | direct | 118 hp @ 3300 rpm | 173 lbs w/ accessories, oil, and exhaust | $23,000 |

| UL350iS 4-cyl | direct | 130 hp @ 3300 rpm | 173 lbs w/ accessories, oil, and exhaust | $24,000 |

| UL390i 6-cyl | direct | 140 hp @ 3200 rpm / 130 hp @ 2800 rpm | 220 lbs w/ accessories, oil, and exhaust | $29,000 |

| UL390iS 6-cyl | direct | 160 hp @ 3200 rpm / 140 hp @ 2800 rpm | 220 lbs w/ accessories, oil, and exhaust | $30,000 |

| UL520i 6-cyl | direct | 180 hp @ 3200 rpm / 169 hp @ 2800 rpm | 238 lbs w/ accessories, oil, and exhaust | $31,500 |

| UL520iS 6-cyl | direct | 200 hp @ 3200 rpm / 182 hp @ 2800 rpm | 238 lbs w/ accessories, oil, and exhaust | $32,500 |

Inline and Vee Four-Stroke

AeroMomentum

It’s not everyday an engine maker says its biggest challenge is finding enough of the right employees to keep up with demand, but that’s the current challenge at the compact, privately-owned Aero-Momentum where work mainly consists of converting various non-V-8 automotive engines into aero powerplants.

For 2020, the AeroMomentum eight-strong engine line-up is unchanged, meaning a 1000cc three-cylinder, 1300 and 1500 four-cylinders and a turbocharged 2.0-liter four-cylinder. Power ranges from 75 to 260 hp via a series of standard and high-performance variants of most of these different displacements. Suzuki is the source of the 1300 and 1500 engines; the others are non-Suzuki and cannot be revealed as part of the sourcing agreement. All engines are built from all-new parts; no salvage or used engines are ever used.

What is new is the $585 Aero-Graph, an engine monitor AeroMomentum builds in-house. A plug-and-and-play unit, the Aero-Graph displays what’s going on inside the AeroMomentum FADEC computer, plus oil pressure, temperature and fuel pressure. Because it is CAN bus compatible, multiple Aero-Graphs can be daisy chained together or used with an EFIS (AeroMomentum offers one of those, too) in any combination. Aero-Graph is sold with the round display that fits into a 2-inch panel cutout, harness and the three oil and fuel sending units. It offers a series of pre-set out-of-limit alarms (programmable via cell phone if desired) and is calibrated to the supplied sensors.

A more minor change is AeroMomentum is now CNC-porting rather than hand-porting its cylinder heads.

Core to AeroMomentum’s conversions is a helical, spur-gear prop reduction gearbox. It features custom 8620 alloy gears (these aren’t quick change auto racing gears), and like many of AeroMomentum’s other parts, is designed in-house; forged, machined, heat-treat and otherwise produced by out-of-house vendors; then assembled in-house at AeroMomentum. The highest time gearbox so far logged 5500 hours in an airboat with no issues.

Adept Airmotive

Based in South Africa, Adept Airmotive has been working up a small group of auto conversion engine combinations for several years now. Aiming for the higher performance end of the conversion market, Adept is using a DOHC V-6 with a propeller gearbox and has announced 280N plus 320T and 360T versions, the 280 hp version being naturally aspirated and the 320 and 360 hp variants turbocharged. Adept has displayed at AirVenture in conjunction with Evolution aircraft, but the latest information has been difficult to come by from the company.

Auto PSRU’s

Auto PSRU’s offers a few complete automobile conversion engines, but really they are fully involved in everything firewall forward for its customers as necessary. Their main attraction is a time-tested spur gear prop reduction unit with centrifugal clutch. Available in several sizes, it works with smaller four-cylinder engines up to V-8s. As Stuart Davis of Auto PSRU’s put it, “we handle from about 150 to 550 horsepower.” Its complete engine offerings center on the Chevy LS series and Subaru engines.

For 2020, Auto PSRU’s is phasing out the VW350 gearbox for an updated version, the SD400 (the numerals indicate the unit’s horsepower capacity). The changes making the SD400 are mainly packaging items designed to accommodate the more common 11-inch Chevrolet flywheel and matching aftermarket starter motors. This eliminates the previous need for spacers and adapters; the fundamentals of the gearbox and clutch are unchanged.

An aerobatic qualified gearbox has been added, the SD550. It is the SD400 box beefed up with an external brace, much stronger prop shaft, larger bearings, different splines on the top gear drive, all to better withstand gyroscopic loads. The main market for it is the replica P-51 crowd as not too many RV-10 fan boys are aerobating their rides.

The existing 200Z gearbox is the basis of the new 300Z unit which can now handle V-6 and even small V-8 power and is oriented for vertical engine installations in helicopters. These smaller Auto PSRU’s are also good for inline six-cylinders for narrow-nosed aircraft, WW-I replicas and so on. They allow slow, 1800 rpm propeller rpm perfect for the wooden props popular on such aircraft.

Davis points out he can customize gear ratios to any need, plus easily fit his gearboxes to almost any engine with a custom adapter plate or housing. That means all the major features such as self-contained lubrication, pressurized bearing lubrication and the ability to accommodate constant-speed propellers remains with all his gearboxes.

Currently, Auto PSRU’s have off-the-shelf fitments for the Chevy LS series, popular Subaru, and Mazda 13B engines. It is typically involved in everything firewall forward as its customers work through its auto-conversion installations, including helping with engine mount weldments and other major pieces. They caution against wanting to hot rod the Chevy V-8 applications—a common customer desire—as the engines are well-engineered in stock form, lose reliability when modified and most airframes can’t use more power anyway.

Firewall Forward Aero Engines

Perhaps the first thing to get squared away is to not confuse Firewall Forward Aero Engines with The New Firewall Forward Engines. They are separate outfits; the first being the Canadian engine maker we’re covering here; the latter is a rebuild shop in Loveland, Colorado.

Firewall Forward Aero Engines has two Honda-based four-cylinders on offer, the CAM 100 and the CAM 125. These are legacy auto conversions based on the Honda Civic engine and apparently proven enough to earn a 2500-hour TBO and a five-year warranty. The CAM 100 displaces 1488cc and makes 100 hp; the CAM125 is a little larger at 1590cc and makes 125 hp. Both engines are offered with or without a 100mm wide belt-drive prop speed reduction unit; we’re listing them with its reduction drive in our chart.

Firewall Forward’s other mainstay is a husky Camdrive 500 PSRU for V-8 engines at $19,995. It packs a three-gear helical arrangement to mate with GM crate engines. These drives have been updated since their debut in the late 1990s and, while retaining the same outer physical form, have been machined internally for now-larger GM flywheels. Other features are a cast aluminum construction, two mounting pads machined on the sides plus two, optional, power take offs for a propeller governor, vacuum pump or standby alternator. Additionally, the propeller flanges are separate to more easily accommodate different propellers.

Changes for 2020 include the addition of Ray Watson, president and owner of Moose Mods, as the U.S. sales outlet. Moose Mods specializes in compete firewall-forward kits using the Camdrive 500 PSRU for the Murphy Moose, with up to 530 hp available at $45,000 plus prop and governor. Canada sales are through Archie Dobbins, operations manager of Firewall Forward Aero Engines.

Robinson V8 Power

Re-powering Seabee amphibians is where Robinson got its start converting Chevy LS engines, and having developed a successful combination, they’re sticking with it. Besides complete Seabee conversions, Robinson offers its converted LS engines in a pleasantly complete base package designed to give the LS fan a head start in fitting the popular Chevy to almost any airframe. Rated power of the conversions ranges from 300 to 425 hp.

The base kit starts with a new Chevy long block—Robinson works with a variety of LS engines, both naturally aspirated and supercharged by GM—to offer a wide range of performance. Highlights of the base package are exhaust manifolds, alternator, starter, flywheel, ignition harness, an engine control module (computer), engine wiring harness, throttle body, and a propeller gearbox. The latter is available in three lengths, two gear ratios and uses a Morse chain drive allowing variable pitch, constant-speed or reversing propellers, those being popular with seaplane pilots. The base kit is delivered assembled as far as practical, too.

Robinson uses the stock General Motors computer, but removes the unneeded code regarding oxygen sensors (which are deleted) and other emissions components. Mogas (91 octane) or 100LL are allowed; Robinson reports a 12 gph fuel burn with the 425 hp LS-3 engine at cruise power settings of 23 inches and 3300 rpm.

Optional accessories are a custom engine mount, the remainder of the exhaust system and an entire cooling system based around the Chevy Corvette radiator. Robinson asks for 30 percent down when ordering, another 30 percent a month later, another 30 percent at the second month and the final 10 percent prior to shipment. There is no refundable deposit.

Air conditioning is something of a surprise and delight feature of the Robinson conversions, which retain their automotive air conditioning hardware. Cockpit heat is also fast acting.

Viking Aircraft Engines

Specializing in Japanese auto conversions, Viking has an affordable three-engine line-up based on current, multi-valve, computer-controlled engines from Honda and Mitsubishi. Viking prides themselves in keeping a large enough inventory to claim next-day shipping of its several firewall-forward kits.

Viking’s entry-level offering is a 90- hp version of a three-cylinder Mitsubishi engine. Fitted with Viking’s own gearbox (climb or cruise gear ratios can be ordered; it can also work in pusher applications) the combination weighs but 159 pounds and posts a particularly muscular low-end torque curve when augmented with the lower of the two gear sets.

For its popular 130-hp engine, Viking starts with the Honda Fit four-cylinder power plant. Also geared with a fairly steep 2.33:1 ratio, and also with good low- and mid-range thrust, the combination weighs 220 pounds. Because the Fit engine has its exhaust manifold integral with the cylinder head, the engine is not a good candidate for turbocharging, but it does boast gasoline direct fuel injection (fuel is shot directly into the cylinders). This gives an in-cylinder cooling that allows a higher compression ratio for increased efficiency. By venting crankcase blow-by to the atmosphere instead of back into the engine, Viking escapes the valve deposit issues found in some automotive GDI applications.

Viking’s top offering is the 170-hp version of the Honda Civic engine. Naturally this gives a fat low-end torque curve, also augmented by the gearbox and Honda’s gasoline direct injection. Weight naturally rises to 260 pounds, but either 100LL or mogas can still be run.

Multiple firewall-forward kits are available from Viking to support these engines in Zenith, RANS, Van’s, Kitfox, Glastar and other airframes. Viking says they have engines in the field with over 1000 total hours and that its product development program has a 100-hp version of the three-cylinder engine in the works for release at a later date.

| Manufacturer/Model | Drive Type | Horsepower/Config | Weight | Price |

|---|---|---|---|---|

| Aero Momentum | ||||

| AM10 | geared | 85 hp @ 6000 rpm-upright | 139 lbs w/ PSRU, starter, alternator, ECU | $8,495 |

| AM13u | geared | 100 hp @ 5800 rpm-upright | 170 lbs w/ PSRU, starter, alternator, ECU | $8,995 |

| AM13h | geared | 100 hp @ 5800 rpm-low profile | 170 lbs w/ PSRU, starter, alternator, ECU | $10,995 |

| AM13hp | geared | 126 hp @ 6500 rpm-low profile | 174 lbs w/ PSRU, starter, alternator, ECU | $15,495 |

| AM15u | geared | 117 hp @ 5800 rpm-upright | 185 lbs w/ PSRU, starter, alternator, ECU | $10,495 |

| AM15h | geared | 117 hp @ 5800 rpm-low profile | 185 lbs w/ PSRU, starter, alternator, ECU | $12,495 |

| AM15hp | geared | 147 hp @ 6500 rpm-low profile | 189 lbs w/ PSRU, starter, alternator, ECU | $16,495 |

| AM20T | geared | 260 hp @ 6000 rpm-low profile | 310 lbs w/ PSRU, starter, alternator, ECU, turbo | $19,995 |

| Adept Airmotive | ||||

| 260N V-6 | geared | 260 hp @ 5500 rpm normally aspirated | 306 lbs w/ radiator, alt, EFI, starter, dry sump system | $60,000 |

| 280N V-6 | geared | 280 hp @ 5500 rpm normally aspirated | 306 lbs w/ radiator, alt, EFI, starter, dry sump system | $65,000 |

| 300N V-6 | geared | 300 hp @ 5500 rpm normally aspirated | 306 lbs w/ radiator, alt, EFI, starter, dry sump system | $75,000 |

| 320T V-6 | geared | 320 hp @ 5500 rpm turbocharged | 340 lbs w/ radiator, alt, EFI, starter, dry sump system | $85,000 |

| 360T V-6 | geared | 360 hp @ 5500 rpm turbocharged | 340 lbs w/ radiator, alt, EFI, starter, dry sump system | $95,000 |

| Auto PSRU’s | ||||

| LS-3 Chevrolet | geared | 360 hp @ 4500 (centrifugal clutch) 1.666:1 ratio | 580 lbs installed, typical, complete | $39,200 FF |

| 2.5L Subaru | geared | 150 hp @ 5000 (centrifugal clutch) 1.859:1 ratio | 355 lbs installed, typical, complete | $27,400 FF |

| 3.0L Subaru | geared | 230 hp @ 5000 (centrifugal clutch) 1.859:1 ratio | 375 lbs installed, typical, complete | $27,600 FF |

| Firewall Forward Aero Engines (CAM engines) | ||||

| CAM100 Honda | 100 mm belt | 100 hp @ 5500 rpm | 226 lbs w/ PSRU, injection, no starter or alternator | $16,790 |

| CAM125 Honda | 100 mm belt | 130 hp @ 5500 rpm | 247 lbs w/ PSRU, injection, no starter or alternator | $18,645 |

| Robinson V-8 Power | ||||

| LS-3 Chevrolet (LS-376/480) | geared | 450 hp @ 5000 rpm 1.98:1 ratio | 525 lbs installed, typical, ready to run | $39,500 base |

| Viking Aircraft Engines | ||||

| V-90 Mitsubishi | geared | 90 hp @ 5800 rpm | 160 lbs w/ exhaust, alternator | $9,995 |

| V-130 Honda Fit | geared | 130 hp @ 5400 rpm | 215 lbs w/ exhaust, alternator | $10,995 |

| V-170 Honda Civic | geared | 170 hp @ 5400 rpm | 260 lbs w/ exhaust, alternator | $16,995 |

Radial and Rotary

Classic Aero Machining

With its barking exhaust, intermittent cylinder cut-out “idle” and memorable gyroscopic personality, there’s nothing in aviation that begins to replicate the experience brought by a rotary engine. And for those seeking the ultimate authentic WW-I experience, New Zealand based Classic Aero Machining has been developing a brand new Gnome monosoupape engine for several of years. It is a faithful rendition of the Gnome used in many French, English and German aircraft just prior to and during the first war.

This year CAM has improved the induction ports and developed a fuel pump for the engine (the originals relied strictly on gravity). Purists may decry it, but CAM also has an electric starter for its rotary—it must be the first non hand-propped rotary ever—and lists output at a muscular 120 hp and 580 pound-feet of torque while whirling at just 1120 rpm.

CAM wants to emphasize these engines are viable, reliable, real-world choices for WW-I replicas and that they’re in rotary business for the long term. They certainly are the only new engine capable of delivering the true early-bird rotary experience, which might be a little more performance oriented than first imagined. CAM reports its rotary has a Sopwith Pup replica going 110 mph straight and level, plus 1000 fpm vertically. They expect several more of its engines to fly by next spring.

CAM is part of the burgeoning replica and restoration scene in New Zealand and has a well-established business replicating various warbird parts, especially P-40 items.

Warner Engine Company (Monocoupe Aeroplane Corporation)

Last year we reported on the Monocoupe organization’s effort to put the 185-hp Warner engine back in production as the experimental-only 185X. That effort has, unfortunately, failed and has been closed down. It’s unlikely, but there may be a handful of parts loose on the market with 185X numbers on them as the licensing agreement required all new parts to be identified as 185X pieces, and a very few parts were made (no complete engines were built).

The Warner type certificate holder is John Duncan who does business as The Warner Engine Company. John has some certified Warner parts for sale, but no complete engines. It’s too bad the 185-hp Warner hasn’t made it back to production as it’s a perfect fit for many experimental aircraft, especially replicas. A big-bore version of the much more common 165 Warner, these radials were good engines in their day, and according to John, given modern manufacturing capabilities should prove bulletproof reliable, with good power-to-weight ratios packaged in an attractive size for personal aircraft use.

Motorstar NA

There aren’t too many homebuilts that take all the muscle a 621 cubic inch M-14P radial can dish out, but if you want a new $50,000+ one from builder Motorstar Romania then Coy Aircraft Sales is also Motorstar NA, and they can make it happen. More practically Coy can also source a factory overhaul—now a fixed $21,500 if you have a core. That gets you the three-ring piston upgrade and Savarese ignition, along with overhauled air compressor, carburetor and oil pump, test stand run-in, all work being done in Romania. The turnaround is 60 days and shipping $3300.

As usual, when an M-14P goes in for overhaul, more often than not it goes from the base 360 hp to the 400 hp M-14PF upgrade as the price isn’t that much greater. Other sources for these robust Russian-designed radials are Jill Gemerzke’s M-14P Inc. in Kingman, Arizona, and Barrett Performance Engines in Tulsa, Oklahoma, which specializes in hot rod versions with electronic ignition and Airflow Performance fuel injection.

Rotec Aerosport

In the not-too-big, not-too-small radial category is Australian engine maker Rotec, which continues to supply the most round motors to the experimental market. The naturally slow-turning and geared Rotecs provide the sound and long-prop looks so popular with amateur builders looking for either a vintage appearance or who simply want something a little different than the ubiquitous flat-engine norm. The engines remain unchanged for 2020.

Rotec offers two engines, the seven-cylinder R2800 good for 110 hp, and its big brother R3600 which sports nine of the same cylinders for a 150-hp rating. Both are un-supercharged. The smaller engine is most often paired with a fixed-pitch 76-inch-diameter prop while the R3600, which was later to market but seems to have picked up sales steam lately, can swing 90-inch blades.

Standard Rotec induction is a simple Bing slide carburetor, but Rotec’s own—and still quite simple—TBI Mk 2 throttle-body fuel injection is optional. Its main attraction is staying on the job during aerobatics, and besides fitments for its radials, Rotec offers versions of its carburetor for everything from VW conversions to Rotax, Jabiru and even Lycomings.

Rotec sells direct, so planning ahead for engine construction and freighting from Australia will help avoid frustration.

Verner Motor

A bit under our lower power limit is the little 42-hp three-cylinder engines put out by Verner Motor, but if you have raging dreams of a Demoiselle reproduction, the pocket-sized Verner radial bears a look. Otherwise, one of Verner’s larger five, seven, or nine-cylinder radials has the compact dimensions to fit a number of fun-flying personal planes and give them the unmistakable round motor look, feel and sound. So far that’s been Hatz biplanes, older Kitfoxes and a slew of WW-I replicas, both scale and full-size, as Verner continues to make in-roads on the U.S. market.

Built in the Czech Republic by a small company that’s been in the airplane engine business since 1993, the Verner radials we’re detailing here use the same two-valve, 3.62 x 4.02-inch cylinder, but fit five, seven, or nine of them as power needs rise. (Let’s note the little 28-inch diameter three-banger shares its smaller cylinders—now aluminum with steel liners—with a five-cylinder version as well). All of the larger engines, which Verner groups under the Scarlett name, are relatively low-rpm, direct-drive designs using no supercharging but employing carburetor and optional fuel injection. Designed to run on 93-octane U.S. or 95-octane European premium mogas, the Scarlett series has a 32-inch diameter and a TBO of 1000 hours. Experience shows some lead fouling on a steady diet of 100LL fuel, but this responds favorably to lead-scavenging additives or simply by running mogas.

Power ranges from 83 hp in the Scarlett 5Si to 158 hp in the largest Scarlett, the 9S. A recent change is a rationalization of parts and engine models to improve Verner’s production efficiency. That’s eliminated the 7Si and 7H models which were fairly redundant to the remaining 7U, plus all crankcases are now magnesium. Three U.S. dealers are available, and seem to be enjoying a growing interest in these engines for various retro-themed airframes.

| Manufacturer/Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

| Classic Aero Machining Service | ||||

| Gnome Monosoupape | rotary | 120 hp @ 1125 rpm | 260 lbs with oil pump, air pump, ignition | $62,000 |

| Motorstar NA | ||||

| M14-P | geared | 360 hp @ 2900 | 515 lbs w/ air or electric start, B&C alternator | $52,000 |

| M14-PF | geared | 400 hp @ 2900 | 515 lbs w/ air or electric start, B&C alternator | 55000 ($28K-32K reman) |

| Rotec Aerosport Pty Ltd | ||||

| R-2800 | geared | 110 hp @ 3600 rpm | 224 w/ starter, alternator, carb, ignition, stub exhaust | $22,500 |

| R-3600 | geared | 150 hp @ 3600 rpm | 275 w/ starter, alternator, carb, ignition, stub exhaust | $27,500 |

| Verner Motor | ||||

| Scarlett Radial 3V, 100ci | direct | 42 hp @ 2500 rpm | 86 lbs w/ starter, alternator, carb, ignition | $7,250 |

| Scarlett Radial 5V, 166ci | direct | 60 hp @2300 rpm | 119 lbs w/ starter, alternator, carb, ignition | $9,315 |

| Scarlett Radial 5S, 207ci | direct | 83 hp @ 2200 rpm | 152 lbs w/ starter, alternator, EFI, ignition | $14,670 |

| Scarlett Radial 7U, 290ci | direct | 124 hp @ 2300 rpm | 183 lbs w/ starter, alternator, EFI, ignition | $19,262 |

| Scarlett Radial 9S, 372ci | direct | 158 hp @ 2400 rpm | 238 lbs w/ starter, alternator, EFI, ignition | $25,710 |

Rotary (Wankel)

American Rotary Engine

American Rotary Engine is the aviation sidebar to Atkins Rotary, which makes hop-up parts and adapters for Wankel engines for just about anything that moves. So, while the parent company stays busy with automotive and other outlets, American is keeping a low flame under the aviation engine part of the business.

American has some of its earlier engines flying and continues to slowly develop its Mazda 13B-based airplane engine. They have a new rotor housing cast and are now machining it, but truth is they are getting more calls on its marine Wankel applications than aviation units so progress is limited. As always, American is ready to build its Wankel to order, which uses a Power-sport PSRU gearbox.

Auto PSRU’s

While Auto PSRU’s continues to offer full support for the Mazda 13B engine as a kit, they say interest in Wankel engines has significantly fallen off across the full breadth of the alternative engine community. They don’t know why, as the Wankel remains available and still a power-to-weight champion, but they’ve seen little interest in the rotary lately. Because the Auto PSRU’s 13B kit was finalized some years ago, it’s no problem for Auto PSRU’s to continue to keep the option in its catalog; all that’s needed are customers.

| Manufacturer/Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

| American Rotary Engine | ||||

| 2 rotor 13B | geared | 180 hp @ 6000 rpm | 320 lbs wet w/ alternator, starter, ECU, EFI and EI | $20,000 |

| Auto PSRU’s | ||||

| Mazda 13B | geared | 180 hp @ 7600 (centrifugal clutch) 2.778:1 ratio | 385 lbs installed, typical, complete | $28,400 FF |

| Mazda 13B Turbo Normalized | geared | 200 hp @ 7600 (centrifugal clutch) 2.778:1 ratio | 410 lbs installed, typical, complete | $36,900 FF |

Compression Ignition (Diesel & Jet A)

Continental

in certified airframes.

Diesels or (Jet A engines) are by nature premium devices full of expensive parts, so their penetration into the amateur-built world by any manufacturer has been more promise than actuality. Several very interesting engines have been under development for some time, but they’re so complex and expensive they’re just now breaking into the defense department budget as possible drone engines. Whether we’ll ever get an affordable, well-developed Jet A burner remains a wide open question.

In the meantime, Continental has a surprising well-populated line of certified diesels as it seems to enjoy buying up diesel programs started by Thielert, Austro, and other European outfits. At least in their technical specifications, these engines are suited to larger homebuilt aircraft. But since they’re certified engines, Continental has no interest in selling them to homebuilders, though they can be purchased indirectly through non-factory outlets.

To this group we can now add Continental’s 3.0-liter CD-300, a powerful—300 hp at a quiet 2300 rpm—V-6. Its specifications read like an aircraft engine wish list with four-valves per cylinder, common rail injection, twin-turbos, water cooling, dual FADEC electronics with single lever control, gearbox, and prop governor. Already announced as going into Diamond Aircraft’s DA50 single-engine luxury cruiser, the CD-300 is EASA certified with FAA certification pending. The combination weighs 548 pounds, which can be offset by carrying less fuel because it is rated at just 9.2 gph at cruise power. If that all sounds irresistible, remember if you need to ask how much it costs you can’t afford it (pricing is not announced, but it’s not likely to be package-competitive with gasoline engines of the same power). And the current time between replacement (not overhaul) is just 1200 hours (2000 hours is the projected eventual TBR).

AC Corporation / Higgs Diesel

The same Andy Higgs we met in the horizontally-opposed section of this guide is active in the diesel world as well under the Higgs Diesel banner. Andy has been showing a series of interesting compression ignition engines on his website, without question the flashiest one being the E-1000 V-12 which carries a cool 1000 to 1600 hp rating. He also displays upright and inverted V-4s on his website.

All of these AC Corporation diesels use a two-stroke engine cycle, but Andy says he has a way of stratifying the exhaust charge inside the combustion chamber resulting in many benefits. The main idea is by more carefully controlling the charge distribution inside the cylinder Andy is able to optimize the traditional two-stroke port’s flow and scavenging characteristics, sufficiently that the intake charge is admitted straight into the cylinder without passing through the crankcase. A cascade of advantages follow, including cleaner oil, increased piston cooling, better fuel economy and so on.

Like anything in the 1000-hp class, if you’re interested in the E-1000 V-12 Condor engine you best talk directly to Andy about pricing and availability. The E330J/G Hawk V-4 seems a little further out developmentally, and is listed as 300 – 500 hp and costing $54,000 – $74,000 (the latter with turbocharging).

Finally, there is the FL1500 inverted-V-4. Designed to weigh just 148 pounds and offer between 120 and 200 hp, the little guy is touted as a Rotax replacement.

| Manufacturer/Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

| AC Corporation | ||||

| AC E-1000J/G | geared | 1600 hp liquid cooled JET A | 679 lbs w/ starter, ECU and alternators | $260,000 |

| AC E-660J/G | geared | 800 hp liquid cooled JET A | 499 lbs w/ starter, ECU and alternators | $150,000 |

| AC E-330J/G | geared | 350 hp liquid cooled JET A | 286 lbs w/ starter, ECU and alternators | $58,000 |

| AC FL-2000 | geared | 150-230 hp liquid cooled JET A | 154 lbs w/ starter, ECU and alternators | $39,000 |

| Continental Motors | ||||

| CD-135 | geared | 135 hp @ 3890 rpm | 295 lbs with accessories, dual FADEC | Kit program only |

| CD-155 | geared | 155 hp @ 3890 rpm | 295 lbs with accessories, dual FADEC | Kit program only |

| CD-230 | direct | 235 hp @ 2200 rpm | 450 lbs with accessories | Beta Program |

Volkswagen

AeroConversions

As its website says, AeroConversions is a product line of Sonex aircraft. This makes perfect sense, as Sonex has been selling aircraft kits designed for air-cooled Volkswagen power for ages, and has been offering its own converted VW engine—the AeroVee—to match for just as long.

There are two AeroVee engine kits, the 80-hp, 2.1-liter naturally aspirated engine along with a turbo version rated at 100 hp. Notice we said kits, as all AeroVees arrive at the customer’s door as disassembled engines. The idea is you don’t pay AeroConversions a lot of money to assemble your engine, but rely instead on a thorough instruction manual, other AeroConversion support and your own initiative to keep that money in your pocket.

For 2020, there are no hardware changes to the two well-developed AeroVee engines, but we can say the turbocharger water cooling system introduced last year has proven popular and is a near-universal option on the 100-hp engine. It uses a bare pint of water in a self-contained system to cool the turbocharger’s center bearing, but only after the engine has shut down and the running supply of engine oil isn’t flowing. A timer starts and stops the electrically-motivated system, making it transparent to the pilot. The system runs anywhere from 20 minutes to an hour after engine shut down and is independent of the master switch.

Great Plains Aviation Supply

Another outfit offering you-assemble engine kits is Great Plains. Again, this keeps costs low and also helps Great Plains market a surprisingly wide variety of VW engine variants. To start, Great Plains has “full” or four-cylinder VWs, or two-cylinder half-VW engines. In four-cylinder engines you can choose among driving the propeller from the flywheel end, or the pulley end of the engine, the former with an accessory isolation kit, and with or without a belt-driven propeller speed reduction unit. Kits are available as short- or long-blocks. In fact, the entire Great Plains offerings are available in just about any combination of parts and kits imaginable, and they offer a wide range of accessory items.

Hummel Engines

Certainly the Volkswagen-based engine world is a price-conscious market, but even so Hummel Engines stands out as the minimalist’s choice. By leaving off all the frills, Hummel offers assembled VW-based engines ready to fly for about the price of a good porting job at most engine shops. These are also extremely light engines.

Of course, this means you’ll get good at hand propping and won’t feel bad about flying on one magneto because there is but one magneto, no starter or alternator at the entry-level price points. But those dual-mag and starter motor luxuries are available optionally, and the price—and weight—are still low. Hummel even has a full line of two-cylinder half-VW engines if less is more your style. Hummel reports activity is brisk, with the lead time for a new engine running around eight months. Interestingly, they say the majority of its activity is in two-cylinder engines these days, so the super light market is apparently robust.

Motorav

It may look like a VW, but it’s really the VW engine completely re-engineered as an aviation engine—the Cadillac of VWs if you will. Motorav’s parent company is Rima, a very large Brazilian mining and industrial outfit that bought out VW’s Brazilian die casting plant and also has its own supply of magnesium and other metals. Starting with the Type 1 VW architecture, Motorav has addressed every aspect of the design to strengthen it for aviation as a 175 cubic inches (2868cc), air-cooled, flat-four yielding 100 hp at 2900 rpm with a 1200-hour TBO.

Notable improvements are a reinforced magnesium case, one-piece crankshaft with integral propeller flange (like Lycoming, Continental, et al.), unique cylinder heads with down-facing exhaust ports and dual spark plugs, fittings for standard aviation CHT sensors, hydraulic lifters, built-in alternator, and increased oil capacity. Electronic ignition and a single-point fuel injection systems are standard.

Motorav was listing Polymet Alloys as its U.S. distributor, but that arrangement seems to have ended as Motorav searches for another sales path in the U.S., so contact Motorav directly.

Revmaster Aviation