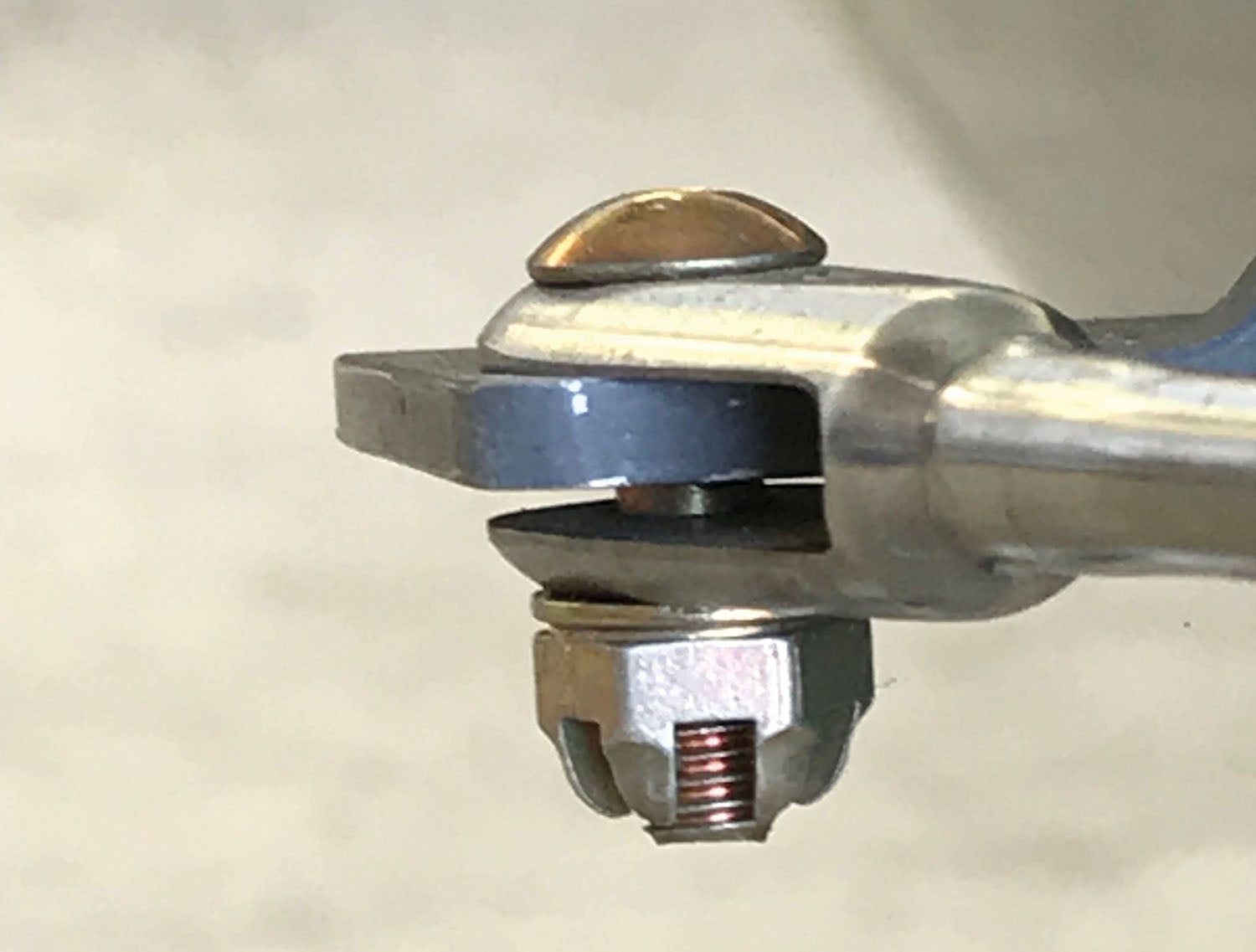

Wherever a bolt is subject to rotation, it is required to have a castellated nut and cotter key. A typical mistake I see on amateur-built aircraft is the use of a heat nut or fiber nut on the rudder control horn. The second picture shows the proper bolt/nut combination; however, the cotter key is missing.

Wherever a bolt is subject to rotation, it is required to have a castellated nut and cotter key. A typical mistake I see on amateur-built aircraft is the use of a heat nut or fiber nut on the rudder control horn. The second picture shows the proper bolt/nut combination; however, the cotter key is missing.

I haven’t gone that far in my build, but I might expect to see a washer between the fork and the horn too.

Agreed!

Agreed

Does the note about fiber nut apply to amateur-built? There’s A&Ps out there that say it doesn’t…Seems like best practice to me, but not sure what the FARs say specifically wrt amateur-built.

Again, if the nut is subject to rotation, it is required to have a castellated nut and cotter key. As for the comment that it doesn’t apply to amateur-built aircraft, it is a best practice to follow AC-43.13C as a guildeline for everything that is going to fly, whether certified or amateur-built.

Does this apply to push tube linkages as well? Plans don’t call for them. RV14.

In the case of most push-pull tubes, the end link is a rod end bearing with a center element that rotates freely. So you can safely use a self-locking nut and tighten it down to clamp the center of the rod end to the control horn or whatever. Loosening of the nut is prevented by two mechanisms, the nut preload and the self-locking feature.